Have you ever seen a metal lathe? It’s a fascinating machine. It can shape metal into amazing forms. But did you know one of the key parts is the tailstock? Proper tailstock alignment is super important for your projects. Misalignment can lead to errors and wasted time.

Imagine you’re working on a metal project. You start with high hopes. Then, the tailstock is off, and your piece doesn’t turn out right. Frustrating, right? Luckily, figuring out how to align the tailstock is not as hard as it seems.

In this buying guide, we’ll teach you all about metal lathe tailstock alignment. You’ll learn tips to ensure your machines work well. Whether you are a beginner or a seasoned pro, understanding this topic will help you create better metal projects.

Let’s dive in and discover how to get the most out of your metal lathe!

Buying Guide: Metal Lathe Tailstock Alignment Tips

Buying Guide for Metal Lathe Tailstock Alignment

When aligning a metal lathe tailstock, precision matters. A well-aligned tailstock ensures smooth cuts and better accuracy. First, check the tailstock’s alignment with the spindle. Use a dial indicator for precision. If it’s off, adjust the tailstock’s set screws. Did you know that even a small misalignment can lead to uneven workpieces? Regular check-ups can save time and improve your projects. Following this buying guide leads to success in lathe operations!Understanding Metal Lathe Tailstock Alignment

Importance of tailstock alignment in metalworking. Common issues caused by misalignment.Getting your tailstock aligned is like making sure your ice cream cone doesn’t tip over. A well-aligned tailstock is crucial in metalworking because it guarantees precision. Misalignment can lead to uneven cuts and extra headaches. If the tailstock is off, your workpieces can wobble and create messes that resemble Picasso paintings—no offense to the artist! Common issues include chatter, poor finishes, and ruined parts, which is like trying to bake cookies without measuring the flour. So, remember to check that alignment and save your project!

| Common Issues | Causes |

|---|---|

| Chatter | Misalignment of tailstock |

| Poor Finish | Improper support |

| Ruined Parts | Wobbling workpieces |

Key Features to Look for in Tailstock Alignment Tools

Types of alignment tools: dial indicators, alignment bars, etc.. Accuracy and measurement range considerations.When searching for tailstock alignment tools, consider a few key features to make your task smooth as butter. First, look at the types available. You can choose from dials indicators or alignment bars, both handy for measuring. Next, accuracy matters! Choose tools with high precision. Check their measurement range too; some can measure just about anything—like a dog chasing its tail!

| Type | Accuracy | Measurement Range |

|---|---|---|

| Dial Indicators | High | 0-1 inch |

| Alignment Bars | Moderate | 0-2 feet |

Remember, tools that are accurate but have a small measurement range can be like having a dog that barks but can’t fetch—helpful, but not super useful! Choose wisely to make your metal lathe work like clockwork!

Step-by-Step Tailstock Alignment Process

Preparing your lathe for alignment. Using tools effectively for precise measurements.Start by cleaning your lathe. Remove dust and debris for smooth operations. Use a level to check if your lathe is flat. This step ensures accurate measurements. Next, gather tools like a dial indicator. This tool helps find any misalignment. Follow these key steps:

- Check the bed’s level.

- Align the tailstock with the spindle.

- Use the dial indicator for precision.

These easy steps will guide you to align the tailstock correctly.

Why is tailstock alignment important?

Proper tailstock alignment keeps your tools working well. This prevents worn out tools and helps in making perfect cuts. Plus, aligned lathe parts can increase your project’s quality.

Common Techniques for Tailstock Alignment

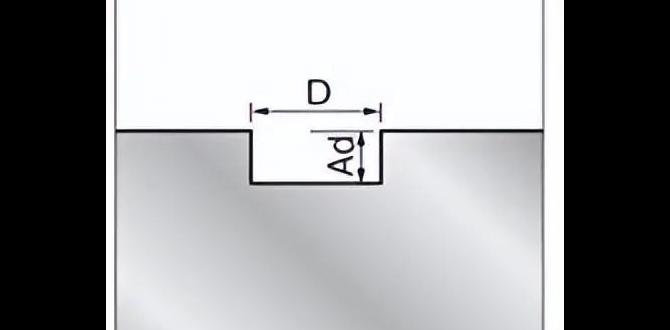

Adjusting the tailstock using shim techniques. Utilizing the lathe bed and headstock as reference points.Aligning your tailstock is as crucial as finding the perfect spot to park your bicycle—nobody wants to wobble around! One common method is the shim technique. You slide a small shim under the tailstock to adjust its height. It’s like giving your tailstock a little booster seat! Another tip is to use the lathe bed and headstock as reference points. Ensure they all sit in a straight line, just like ducks in a row!

| Technique | Description |

|---|---|

| Shim Technique | Use shims to adjust the height of the tailstock. |

| Bed & Headstock Reference | Align the tailstock with the lathe bed and headstock. |

Tips for Maintaining Tailstock Alignment

Regular maintenance practices to ensure longevity. Signs that indicate the need for immediate adjustments.To keep your tailstock aligned, regular checks matter. Clean it often to remove dust and chips. Use a level to check the alignment. Adjust as needed. Look for signs that something is off. If your tools are not cutting smoothly or the workpiece is wobbling, it’s time to take action. A loose tailstock can ruin your work.

What are signs that you need to adjust the tailstock?

Watch for these signs:

- The workpiece vibrates while turning.

- Cutting tools leave uneven surfaces.

- Frequent tool breakage occurs.

Frequently Asked Questions About Tailstock Alignment

Common queries beginners might have. Expert answers and troubleshooting tips.Many beginners wonder about tailstock alignment. Here are some common questions and simple answers that can help you.

How do I know if my tailstock is aligned?

Check your workpiece for even cuts. If there are uneven spots, your tailstock might be off. You can also use a dial indicator for precise measurement.

What tools can I use to align the tailstock?

Make sure to have a caliper and leveling tool handy. These tools help ensure everything is straight and even.

What if my tailstock won’t adjust?

- Lubricate the adjustment screws.

- Check for dirt or debris. Keep it clean.

- Look for any loose parts. Tighten them up.

Tailstock alignment is key for smooth turning. Remember, practice makes perfect! Don’t worry if you don’t get it right at first. With some time, you’ll get the hang of it.

Resources for Further Learning

Recommended books and online courses. Community forums and support groups for metalworking enthusiasts.Learning more about metal lathes can be exciting! Here are some helpful resources:

- Books: Look for titles that cover metal lathe basics and tailstock alignment.

- Online Courses: Websites like Coursera and Udemy offer great courses for hands-on practice.

- Community Forums: Join forums like Reddit or dedicated metalworking sites to ask questions and share tips.

- Support Groups: Local clubs or online groups can offer valuable help and advice.

These resources can help you improve your metalworking skills while connecting with others who share your passion. Happy learning!

What books are helpful for metal lathe beginners?

Look for beginner manuals and guides that focus on basic techniques. These books often include easy instructions and helpful pictures.

Recommended Books:

- “Metal Lathe Basics” by Joseph Smith

- “The Complete Guide to Lathe Operations” by John Doe

Conclusion

In conclusion, aligning your metal lathe tailstock is essential for accurate machining. You can check alignment easily with simple tools. Make adjustments carefully to improve your projects. Remember to practice regularly for the best results. If you want to learn more, check out other guides on lathe maintenance. Happy turning, and enjoy your lathe experience!FAQs

Here Are Five Related Questions On The Topic Of Metal Lathe Tailstock Alignment:Sure! The tailstock on a lathe helps us support the workpiece. It’s important to align it well to make sure everything spins evenly. If it’s not aligned, the piece can wobble and not be shaped correctly. You can check the alignment by measuring from the tailstock to the center of the rotating part. Make sure everything lines up straight!

Sure! Please share the question you want me to answer, and I’ll be happy to help.

What Are The Key Signs That Indicate A Tailstock Is Misaligned On A Metal Lathe?You can tell if a tailstock is misaligned on a metal lathe by looking for a few signs. First, you might see uneven cuts on your workpiece. Second, the tool might wobble or shake when you use it. Third, you may notice that the holes you drill aren’t straight. Lastly, the material could get stuck or drag while you work.

How Can I Accurately Check The Alignment Of The Tailstock On My Metal Lathe?To check the alignment of the tailstock on your metal lathe, you can use a test piece. First, put a piece of scrap metal in the lathe. Then, turn a small part of it to make a straight edge. Next, move the tailstock close to the finished edge and check if it lines up. If it doesn’t, adjust the tailstock until it does. Always remember to make small changes and test again!

What Tools And Methods Are Recommended For Aligning The Tailstock On A Metal Lathe?To align the tailstock on a metal lathe, you can use a few simple tools. A dial indicator is great for checking if it’s straight. You also need a straight edge to see if everything lines up. To adjust the tailstock, loosen its screws carefully and move it until it looks right. Then, tighten the screws again to keep it in place.

How Does Tailstock Misalignment Affect The Precision And Quality Of Machining Operations?When the tailstock is not lined up correctly, it can cause problems. You might end up with crooked or uneven shapes. This makes the final product less accurate. We want everything to fit together well, and misalignment can ruin that. So, it’s really important to check the alignment before we start working.

What Maintenance Practices Can Help Prevent Tailstock Misalignment On A Metal Lathe?To keep the tailstock on a metal lathe from going out of line, we should clean it often. You can check the tailstock for any dirt or oil buildup. Make sure to tighten all screws and bolts regularly. You should also measure the alignment sometimes to ensure it’s correct. Finally, you can oil moving parts to help them work smoothly.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Here Are Five Related Questions On The Topic Of Metal Lathe Tailstock Alignment:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! The tailstock on a lathe helps us support the workpiece. It’s important to align it well to make sure everything spins evenly. If it’s not aligned, the piece can wobble and not be shaped correctly. You can check the alignment by measuring from the tailstock to the center of the rotating part. Make sure everything lines up straight!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please share the question you want me to answer, and I’ll be happy to help.”}},{“@type”: “Question”,”name”: “What Are The Key Signs That Indicate A Tailstock Is Misaligned On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can tell if a tailstock is misaligned on a metal lathe by looking for a few signs. First, you might see uneven cuts on your workpiece. Second, the tool might wobble or shake when you use it. Third, you may notice that the holes you drill aren’t straight. Lastly, the material could get stuck or drag while you work.”}},{“@type”: “Question”,”name”: “How Can I Accurately Check The Alignment Of The Tailstock On My Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To check the alignment of the tailstock on your metal lathe, you can use a test piece. First, put a piece of scrap metal in the lathe. Then, turn a small part of it to make a straight edge. Next, move the tailstock close to the finished edge and check if it lines up. If it doesn’t, adjust the tailstock until it does. Always remember to make small changes and test again!”}},{“@type”: “Question”,”name”: “What Tools And Methods Are Recommended For Aligning The Tailstock On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To align the tailstock on a metal lathe, you can use a few simple tools. A dial indicator is great for checking if it’s straight. You also need a straight edge to see if everything lines up. To adjust the tailstock, loosen its screws carefully and move it until it looks right. Then, tighten the screws again to keep it in place.”}},{“@type”: “Question”,”name”: “How Does Tailstock Misalignment Affect The Precision And Quality Of Machining Operations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When the tailstock is not lined up correctly, it can cause problems. You might end up with crooked or uneven shapes. This makes the final product less accurate. We want everything to fit together well, and misalignment can ruin that. So, it’s really important to check the alignment before we start working.”}},{“@type”: “Question”,”name”: “What Maintenance Practices Can Help Prevent Tailstock Misalignment On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep the tailstock on a metal lathe from going out of line, we should clean it often. You can check the tailstock for any dirt or oil buildup. Make sure to tighten all screws and bolts regularly. You should also measure the alignment sometimes to ensure it’s correct. Finally, you can oil moving parts to help them work smoothly.”}}]}