Have you ever wanted to create something amazing with metal? Imagine having the power to shape metal into your ideas. That’s where a metal lathe comes into play.

But wait! Not all metal lathes are the same. If you’re interested in thread cutting, you need the right tool for the job.

Buying a metal lathe for thread cutting can be tricky. What features should you look for? How do you know the best quality for your money?

Don’t worry! This buying guide will help you make smart choices. You’ll learn about key features, benefits, and more. By the end, you’ll feel ready to choose the perfect metal lathe.

Did you know that one of the first lathes was created over 2,000 years ago? These machines have helped inventors, engineers, and hobbyists create wonders throughout history.

So, are you excited to discover how you can start your journey with metal lathes? Let’s dive in!

Buying Guide: Metal Lathe Thread Cutting Essentials

Buying Guide for Metal Lathe Thread Cutting

Are you ready to dive into metal turning? Selecting the right metal lathe for thread cutting can feel overwhelming. Look for a model that suits your project needs. Consider size, weight, and ease of use. Would you prefer a machine with digital controls or manual options? Remember, quality matters! You’ll enjoy smoother cutting and precision with the right choice. Fun fact: A well-chosen lathe can transform your metalwork from good to great!Understanding Metal Lathes

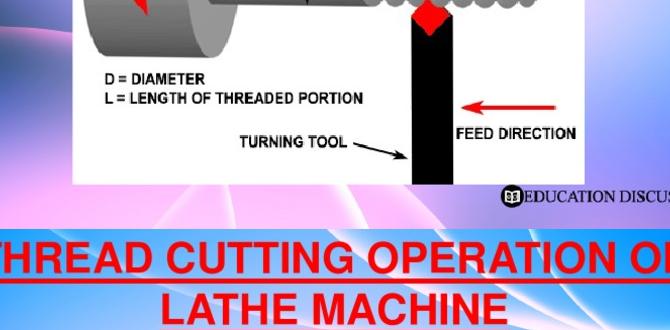

Definition and function of metal lathes. Differences between types of metal lathes.Metal lathes are special machines that shape metal into different items. Picture a giant pencil sharpener, but for metal! They spin the metal and use tools to cut, carve, and create fantastic shapes. There are different types of lathes, like the engine lathe, perfect for sharpening your crafting skills, and the turret lathe, which is great for making many identical parts. Here’s a quick look at their differences:

| Type of Lathe | Function |

|---|---|

| Engine Lathe | Multi-purpose crafting hero. |

| Turret Lathe | Fast and efficient for mass production. |

| CNC Lathe | Computer-controlled wizard for complex designs. |

Key Features to Consider

Motor power and its impact on threading capabilities. Swing over bed and length of bed: determining your capacity.Choosing the right metal lathe can feel like picking a favorite ice cream flavor—so many choices! First, think about motor power. More power means better threading capabilities. If the motor is weak, you might end up with threads like a lopsided sweater. Next, consider the swing over bed and the length of the bed. These measurements decide how big your projects can be. Imagine trying to fit a giraffe in a mini car; it won’t work! Check out the table below for quick tips:

| Feature | Why It Matters |

|---|---|

| Motor Power | More power equals better threading! |

| Swing Over Bed | Determines size of workpieces. |

| Length of Bed | Affects your capacity to create! |

Essential Accessories for Thread Cutting

Types of cutting tools and their roles in threading. Importance of lathe chucks and tailstocks.Cutting tools are vital for threading. They help shape the metal into threads. Types of cutting tools include:

- Threading taps: Perfect for making internal threads.

- Cutting blades: Best for external threads.

Lathe chucks hold the metal securely. Tailstocks support the work, ensuring precision. Good equipment makes threading smoother and more accurate. Proper tools lead to better projects!

What tools help with thread cutting?

Cutting tools, lathe chucks, and tailstocks are key for effective thread cutting.

What are the types of cutting tools used in threading?

- Threading taps

- Cutting blades

Safety Considerations When Working with Metal Lathes

Common hazards and safety gear required. Best practices for safe operation during thread cutting.Metal lathes can be fun but also dangerous. Always wear safety gear like goggles and gloves. These protect you from flying metal chips. Be careful of sharp tools and moving parts. Follow these best practices:

- Keep your work area tidy.

- Don’t wear loose clothing; it can get caught in the machine.

- Always check your tools before starting.

Stay alert and focused while working. Remember, safety comes first!

What protective gear is essential when using a metal lathe?

Wear safety goggles to guard your eyes and gloves to protect your hands. Also, use ear protection to shield from loud noises.

Common Mistakes to Avoid in Thread Cutting

Frequent errors beginners make and how to prevent them. Importance of precision and measuring tools in threading.Beginners in thread cutting often make simple mistakes. One common error is not measuring correctly. This can lead to uneven threads. Always use the right tools for precise measurements. Another mistake is rushing through the process. Take your time to ensure accuracy. Practicing patience will help you create better results. Lastly, avoid skipping steps in the setup. Each step matters for a safe and effective threading experience. Remember, precision is key in achieving success!

What are common thread cutting mistakes?

Common mistakes include incorrect measurements, rushing the process, and skipping setup steps.Tips to avoid mistakes:

- Always double-check measurements.

- Focus on each step of the setup.

- Practice threading slowly.

Budgeting for Your Metal Lathe Purchase

Price ranges for different types of metal lathes. Cost vs. quality: understanding what to prioritize.Buying a metal lathe can feel like a rollercoaster ride. Prices range widely depending on the machine’s features. A basic lathe may cost around $300, while a professional one can soar to over $5,000. Remember, it’s not just about the cost, but also the quality. Sometimes spending more means getting better tools that last longer. Here’s a quick breakdown of what to expect:

| Type of Lathe | Price Range | Quality Rating |

|---|---|---|

| Entry-Level | $300 – $600 | ⭐️⭐️ |

| Mid-Range | $600 – $2,000 | ⭐️⭐️⭐️⭐️ |

| High-End | $2,000 – $5,000+ | ⭐️⭐️⭐️⭐️⭐️ |

Focus on features that matter for your projects. A more expensive lathe may seem scary, but it can save you from headaches later on. After all, it’s cheaper than therapy when your project goes wrong!

Maintenance Tips for Longevity and Performance

Regular maintenance tasks to keep your metal lathe in top shape. Troubleshooting common threading issues and their solutions.Taking care of your metal lathe is key for it to work well and last long. Regular tasks help keep it in great shape. Here are some useful tips:

- Clean the machine after each use. Dust and chips can cause problems.

- Check the oil levels. Proper lubrication keeps parts moving smoothly.

- Inspect belts and gears for wear. Replace them if they show damage.

- Calibrate the machine regularly. This ensures accurate threading.

If you run into threading issues, here’s how to solve them:

- If threads are uneven, check your tool height.

- If the metal is chipping, adjust the feed rate.

- For vibrations, tighten loose parts.

By following these tips, your lathe will perform wonderfully!

How to fix common threading problems?

First, check tool height for uneven threads. For chipping, adjust the feed rate. Lastly, tighten any loose parts to minimize vibrations.

Conclusion

In conclusion, a metal lathe for thread cutting can be a great tool for your projects. We’ve learned how to choose the right size, understand features, and consider your budget. Before you buy, think about your needs and the projects you want to create. Explore more resources online to deepen your knowledge and make the best choice for your needs!FAQs

Sure! Here Are Five Related Questions For A Buying Guide On Metal Lathe Thread Cutting:Sure! When buying a metal lathe for thread cutting, think about how big or small you need it. Check if it can cut different sizes of threads. Find out what materials you will use, like metal or plastic. Make sure it’s easy to use and has safety features. Always read reviews to see what others think!

Sure! Just ask your question, and I’ll be happy to help you with a simple answer.

What Are The Key Features To Look For In A Metal Lathe Specifically For Thread Cutting?When choosing a metal lathe for cutting threads, look for a few important features. First, ensure it has a good gearbox. This helps you change speeds easily. Next, check the threading tool holder; it should be easy to adjust. Also, make sure it has a clear display for measurements. Finally, find a lathe with sturdy parts to keep everything steady while you work.

How Do Different Types Of Thread Cutting Tools Impact The Performance And Versatility Of A Metal Lathe?Different thread cutting tools help a metal lathe work better in different ways. Some tools can make fine threads, while others can cut thicker ones. This means you can create more kinds of pieces with your machine. When you change tools, you can also change what you create, making your work more exciting and varied. So, more types of tools mean more fun and useful projects!

What Is The Importance Of Feed Rates And Spindle Speeds When Selecting A Metal Lathe For Thread Cutting?Feed rates and spindle speeds are really important for using a metal lathe to cut threads. The feed rate tells the machine how fast to move the tool. A good speed helps make clean and smooth threads. If we use the wrong speeds, the threads can be messed up. So, choosing the right settings helps us make nice, strong threads every time!

Are There Specific Brands Or Models That Are Highly Recommended For Thread Cutting Applications In Metal Lathes?Yes, some brands are great for thread cutting on metal lathes. You can look at brands like Grizzly, Jet, and Smithy. They make strong and reliable machines. Many people recommend these because they work very well. Always check reviews to find the best fit for you!

What Safety Precautions Should Be Taken When Operating A Metal Lathe For Thread Cutting To Prevent Accidents And Ensure Quality Work?When using a metal lathe for thread cutting, always wear safety goggles to protect your eyes. Make sure your hair and clothes are tucked away so they don’t get caught. Keep your hands away from the spinning parts at all times. Double-check that tools are secure before starting. Finally, always follow your teacher’s or supervisor’s instructions for safe operation.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions For A Buying Guide On Metal Lathe Thread Cutting:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! When buying a metal lathe for thread cutting, think about how big or small you need it. Check if it can cut different sizes of threads. Find out what materials you will use, like metal or plastic. Make sure it’s easy to use and has safety features. Always read reviews to see what others think!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Just ask your question, and I’ll be happy to help you with a simple answer.”}},{“@type”: “Question”,”name”: “What Are The Key Features To Look For In A Metal Lathe Specifically For Thread Cutting?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When choosing a metal lathe for cutting threads, look for a few important features. First, ensure it has a good gearbox. This helps you change speeds easily. Next, check the threading tool holder; it should be easy to adjust. Also, make sure it has a clear display for measurements. Finally, find a lathe with sturdy parts to keep everything steady while you work.”}},{“@type”: “Question”,”name”: “How Do Different Types Of Thread Cutting Tools Impact The Performance And Versatility Of A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Different thread cutting tools help a metal lathe work better in different ways. Some tools can make fine threads, while others can cut thicker ones. This means you can create more kinds of pieces with your machine. When you change tools, you can also change what you create, making your work more exciting and varied. So, more types of tools mean more fun and useful projects!”}},{“@type”: “Question”,”name”: “What Is The Importance Of Feed Rates And Spindle Speeds When Selecting A Metal Lathe For Thread Cutting?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Feed rates and spindle speeds are really important for using a metal lathe to cut threads. The feed rate tells the machine how fast to move the tool. A good speed helps make clean and smooth threads. If we use the wrong speeds, the threads can be messed up. So, choosing the right settings helps us make nice, strong threads every time!”}},{“@type”: “Question”,”name”: “Are There Specific Brands Or Models That Are Highly Recommended For Thread Cutting Applications In Metal Lathes?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Yes, some brands are great for thread cutting on metal lathes. You can look at brands like Grizzly, Jet, and Smithy. They make strong and reliable machines. Many people recommend these because they work very well. Always check reviews to find the best fit for you!”}},{“@type”: “Question”,”name”: “What Safety Precautions Should Be Taken When Operating A Metal Lathe For Thread Cutting To Prevent Accidents And Ensure Quality Work?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When using a metal lathe for thread cutting, always wear safety goggles to protect your eyes. Make sure your hair and clothes are tucked away so they don’t get caught. Keep your hands away from the spinning parts at all times. Double-check that tools are secure before starting. Finally, always follow your teacher’s or supervisor’s instructions for safe operation.”}}]}