Have you ever wondered how to wire a metal lathe? It can seem tough, right? But don’t worry! A metal lathe wiring diagram can make it much easier. Imagine you have a shiny new lathe ready to go, but you’re stuck with wires everywhere.

Just picture this: you’ve bought your first metal lathe. You’re excited to start making cool projects. But when you see all those wires, what do you do? This is where a buying guide for metal lathe wiring diagrams comes in handy!

This guide will help you understand those tricky connections. You’ll learn how to read the diagrams clearly. Plus, you’ll find out what tools you need to wire your lathe safely. Understanding these steps will turn your metal lathe into a powerful tool for your creations.

So, are you ready to dive into the world of metal lathes? Let’s explore how you can easily wire your machine and start making amazing things today!

Buying Guide: Metal Lathe Wiring Diagram Explained

Buying Guide for Metal Lathe Wiring Diagram

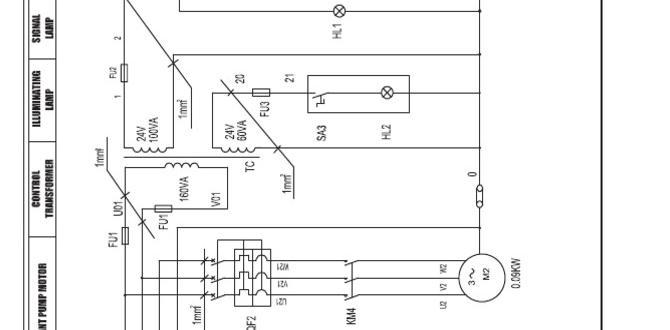

Understanding a metal lathe wiring diagram is key for safe and effective use. This buying guide helps you know what to look for in a diagram. It explains important parts like power sources, control boxes, and motor connections. Using the right diagram ensures your lathe runs smoothly. Did you know that correct wiring can enhance the life of your machine? A clear diagram can save you time and trouble, making your projects easier and more enjoyable!Importance of Wiring Diagrams

Role of wiring diagrams in metal lathe functionality. Common issues solved by clear wiring diagrams.Wiring diagrams are like treasure maps for metal lathes. They show how to connect everything properly. Without them, you might end up with a lathe that grumbles more than it works! Common issues like short circuits or weird noises can often be solved with clear diagrams. They help even the most confused tinkerer. So, avoid a wiring mess and embrace the clarity a good diagram provides!

| Common Issues | Wiring Diagram Solution |

|---|---|

| Short Circuits | Identify faulty connections |

| Machine Not Starting | Check power connections |

| Overheating | Ensure correct wiring |

Components of a Metal Lathe Wiring Diagram

Key components depicted in wiring diagrams. Explanation of electrical symbols used in diagrams.Every metal lathe wiring diagram has key parts, like switches, motors, and power sources. These pieces work together like a team – but a really nerdy team! Electrical symbols represent these parts. For example, a circle might mean a motor, and a line can show a wire. They help us understand how everything connects. Here’s a quick look at common symbols:

| Symbol | Meaning |

|---|---|

| ⚫ | Motor |

| ➡️ | Wire |

| 🔌 | Power Source |

Knowing these components makes it easier to build your lathe. It’s like assembling a LEGO set—but without the risk of stepping on tiny blocks!

Steps to Create Your Own Wiring Diagram

Tools and materials needed for crafting a diagram. Stepbystep guide to designing a wiring diagram.Creating a wiring diagram can be fun and straightforward! First, gather your tools. You’ll need a pencil, paper, ruler, and maybe some colorful markers to make it look snazzy. You can even throw in some stickers if you’re feeling fancy! Now, let’s break it down:

| Step | Description |

|---|---|

| 1 | Sketch your layout. Decide where everything goes. |

| 2 | Label parts. Make sure to name each component. |

| 3 | Draw connections. Show how everything links together. |

| 4 | Check for errors. No one likes a fussy diagram! |

And voila! You have your very own wiring diagram. Who knew making diagrams could be this cool? Get ready to impress your friends with your new skills!

Safety Considerations When Wiring a Metal Lathe

Essential safety precautions to follow. Common mistakes to avoid during wiring.Wiring a metal lathe requires caution. Safety should always come first. Here are some key precautions:

- Always unplug the lathe before working.

- Use insulated tools to prevent shocks.

- Wear safety goggles to protect your eyes.

- Keep the workspace tidy and free of clutter.

Avoid common mistakes too. Many people forget to check connections. Others may use damaged wires. These errors can lead to accidents. Always double-check your work.

What are the essential safety precautions?

The essential safety precautions include using insulated tools and unplugging devices before wiring. Wearing safety gear and keeping your workspace clean is also crucial.

What common mistakes should be avoided?

Common mistakes are not checking connections and using faulty wiring. It’s important to check everything twice to stay safe!

Tips for Troubleshooting Wiring Issues

Frequently encountered wiring problems and solutions. Tools and techniques for effective troubleshooting.Wiring issues can cause your metal lathe to stop working properly. Common problems include broken wires, loose connections, and short circuits. To fix these, follow these tips:

- Check the power source to ensure it is on.

- Look for any frayed or damaged wires.

- Make sure all connections are tight.

- Test switches and fuses for damage.

Tools like a multimeter can help you find problems. A flashlight can help you see better in tight spaces. Using these tools can make troubleshooting easier and safer.

What common wiring problems might I face?

Broken wires, loose connections, and short circuits are common wiring problems.How do I troubleshoot wiring issues effectively?

Use a multimeter to check for continuity, and inspect all connections closely.Where to Find Reliable Wiring Diagrams

Recommendations for online resources and manuals. Importance of using manufacturerspecific diagrams.Need a reliable wiring diagram? Look online! Websites like specific manufacturer pages offer goldmines of information. Manuals are often buried treasure chests of diagrams. Don’t forget to check sites like forums or DIY communities where folks share their wiring wisdom—it’s amazing what you can find! Using manufacturer-specific diagrams is crucial; they make wiring smoother than a freshly waxed floor. Check this helpful table for resources:

| Resource | Description |

|---|---|

| Manufacturer Website | Official diagrams straight from the source. |

| DIY Forums | A community treasure for tips and shared diagrams. |

| YouTube Tutorials | Watch and learn with step-by-step guides! |

Remember, a good wiring diagram is like a map. It leads you to your goal without getting lost—no one likes taking the wrong turn!

Upgrading Your Metal Lathe Wiring

Benefits of upgrading wiring systems. Best practices for implementing modern upgrades.Upgrading the wiring in your metal lathe can make a world of difference. It boosts safety and reliability. Imagine not having to worry about sudden power outages or burnt-out wires during your big project! The modern upgrades bring efficiency, giving you smoother operations. Best practices include using higher-quality wires and ensuring proper connections. Always follow the latest standards; they don’t just help you avoid sparks but also keep you from becoming a human lightning rod!

| Good Wiring Practices | Why They Matter |

|---|---|

| Use quality materials | Prevents breaks and shorts |

| Proper insulation | Increases safety |

| Follow diagrams | Makes setup easier |

Conclusion

In conclusion, a metal lathe wiring diagram is essential for setup and safety. It helps you understand connections clearly, ensuring smooth operation. You should always follow the guide closely for best results. If you’re unsure, consult an expert or look for more resources. With practice and the right tools, you can successfully wire your metal lathe.FAQs

What Are The Essential Components And Tools Needed For Wiring A Metal Lathe?To wire a metal lathe, you need some important parts and tools. First, you’ll need a power supply to give electricity. Then, you’ll need wires to connect everything together. You may also need switches to turn the lathe on and off. Finally, it helps to have a manual that shows you how to do it.

How Do I Identify The Correct Electrical Specifications For My Metal Lathe?To find the right electrical specifications for your metal lathe, first check the manual. It usually has important details like voltage and power needs. Next, look for labels on the machine itself; they often show this information too. If you’re unsure, ask someone who knows about lathes or visit a hardware store for help.

What Safety Precautions Should I Consider When Wiring A Metal Lathe?When wiring a metal lathe, always unplug it before you start. Wear rubber gloves to avoid electric shocks. Make sure the wires are in good shape and not frayed. Keep your tools dry and away from water. Finally, ask an adult for help if you’re unsure about anything.

Are There Common Wiring Diagrams Available For Different Types Of Metal Lathes?Yes, there are common wiring diagrams for different types of metal lathes. These diagrams help you connect wires correctly. You can often find them in the instruction manuals or online. If you have a specific lathe type, search for its wiring diagram. It makes understanding wiring easier!

How Can I Troubleshoot Electrical Issues In My Metal Lathe After Completing The Wiring?To troubleshoot electrical issues in your metal lathe, first check if it’s plugged in. Then, look for loose wires or connections. You can also test the power switch to make sure it works. If you still have problems, use a multimeter to check if electricity flows. If you’re unsure, ask an adult for help.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Essential Components And Tools Needed For Wiring A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To wire a metal lathe, you need some important parts and tools. First, you’ll need a power supply to give electricity. Then, you’ll need wires to connect everything together. You may also need switches to turn the lathe on and off. Finally, it helps to have a manual that shows you how to do it.”}},{“@type”: “Question”,”name”: “How Do I Identify The Correct Electrical Specifications For My Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To find the right electrical specifications for your metal lathe, first check the manual. It usually has important details like voltage and power needs. Next, look for labels on the machine itself; they often show this information too. If you’re unsure, ask someone who knows about lathes or visit a hardware store for help.”}},{“@type”: “Question”,”name”: “What Safety Precautions Should I Consider When Wiring A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When wiring a metal lathe, always unplug it before you start. Wear rubber gloves to avoid electric shocks. Make sure the wires are in good shape and not frayed. Keep your tools dry and away from water. Finally, ask an adult for help if you’re unsure about anything.”}},{“@type”: “Question”,”name”: “Are There Common Wiring Diagrams Available For Different Types Of Metal Lathes? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Yes, there are common wiring diagrams for different types of metal lathes. These diagrams help you connect wires correctly. You can often find them in the instruction manuals or online. If you have a specific lathe type, search for its wiring diagram. It makes understanding wiring easier!”}},{“@type”: “Question”,”name”: “How Can I Troubleshoot Electrical Issues In My Metal Lathe After Completing The Wiring? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To troubleshoot electrical issues in your metal lathe, first check if it’s plugged in. Then, look for loose wires or connections. You can also test the power switch to make sure it works. If you still have problems, use a multimeter to check if electricity flows. If you’re unsure, ask an adult for help.”}}]}