Quick Summary

For the best copper dry cutting with an extra-long carbide end mill, choose a 1/8 inch shank with a 1/4 inch cutting diameter specifically designed for non-ferrous metals. Use high feed rates and shallow depths of cut for clean results and tool longevity.

Working with copper can be tricky, especially with the delicate cuts needed for intricate projects. When you need those perfectly clean edges and have a project that demands precision, reaching for the right tool is key. But what if your project requires deep cuts or access to tight spots, and your standard end mill just won’t cut it? That’s where the extra-long carbide end mill shines. It might seem daunting, but understanding how to use this specialized tool for dry cutting copper isn’t complicated. I’m Daniel Bates from Lathe Hub, and I’m here to demystify this process for you. We’ll break down the best practices, from choosing the right mill to setting up your machine, ensuring you get fantastic results safely and efficiently. Get ready to tackle your copper projects with newfound confidence!

Understanding Extra Long Carbide End Mills for Copper

When we talk about an “extra long carbide end mill,” we’re referring to a cutting tool that has a significantly longer flute length than a standard end mill. This added length is crucial for reaching deeper into workpieces or for machining features that are recessed. For copper, which is a relatively soft and gummy non-ferrous metal, the material of the end mill is just as important. Carbide is an excellent choice because it’s much harder and more heat-resistant than High-Speed Steel (HSS). This means it can handle the demands of machining copper without quickly dulling or overheating, especially when we’re focusing on dry cutting.

The “dry cutting” aspect is particularly relevant for copper. While some metals benefit from coolant to manage heat and clear chips, copper can sometimes be machined dry effectively, especially with the right tooling and parameters. This simplifies your setup by eliminating the need for coolant systems, which can be messy and add complexity, especially for hobbyist or home workshops. The specific keyword we’re looking at is an “extra long carbide end mill 1/8 inch 1/4 shank for copper dry cutting.” This tells us we’re interested in a tool with a small overall diameter (1/8 inch for the shank, which is the part held by the collet) but likely a larger cutting diameter (though not explicitly stated, it’s common for these to have a larger cutting head for the purpose of reach). The focus remains on dry cutting copper.

Why Choose Extra Long for Copper?

Copper presents unique machining challenges. It’s soft, which means it can easily load up on the cutting edges of a dull or inappropriate tool, creating a gummy mess that ruins the surface finish and can even break the tool. It also has a tendency to gall or stick to the cutting tool. An extra-long carbide end mill, when specifically designed for copper, often has specialized flute geometries and coatings that help to:

- Improve Chip Evacuation: Longer flutes need efficient ways to get the chips away from the cutting zone. Specialized flute designs help push chips up and out.

- Reduce Friction and Heat: Copper can generate quite a bit of heat. The right carbide grade and polishing of the flutes can minimize friction.

- Reach Difficult Features: The primary benefit of the extra length is access. This is invaluable for creating features deep within a copper part.

- Maintain Sharpness: Carbide’s hardness means it stays sharp longer, leading to cleaner cuts and better surface finishes on copper.

The Importance of “Dry Cutting”

Dry cutting means you’re not using any liquid coolant, lubricant, or flood coolant system. For copper, this is often feasible and even preferred with the right end mill. When done correctly, dry cutting:

- Simplifies Setup: No need for pumps, reservoirs, or coolant filtration.

- Reduces Mess: Less cleanup and a cleaner workshop environment.

- Avoids Chip/Coolant Buildup: Coolant can sometimes mix with fine copper chips, creating a paste that can clog flutes and damage surfaces.

- Requires Specific Tooling: You need an end mill designed to handle the heat generated without coolant. This is where specialized carbide for copper excels.

The concept of dry cutting is well-supported by machining principles. For instance, the National Institute of Standards and Technology (NIST) provides guidelines and research on machining processes, including optimal cutting conditions, which, while often discussing coolant, also highlight the importance of tool material and geometry for efficient material removal and maintaining tool life in various cutting scenarios. While they may not specifically detail “extra long carbide for copper dry cutting,” their fundamental research into material properties and cutting mechanics underpins why certain tools and methods work best.

Choosing the Right Extra Long Carbide End Mill for Copper

Not all extra-long carbide end mills are created equal, and using the wrong one for copper dry cutting can lead to frustration and poor results. When you’re looking for the best tool, consider these factors:

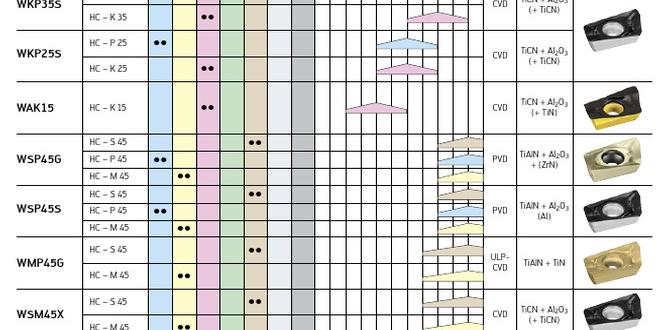

Material and Coating

For copper, you absolutely want a carbide end mill. Look for grades specifically recommended for non-ferrous metals. These often have a high percentage of cobalt, which provides toughness. The flutes should be highly polished or have a coating designed to reduce friction and prevent chip welding. A diamond-like carbon (DLC) coating is excellent for gummy materials like copper, as it’s extremely hard, has low friction, and is non-metallic, preventing any chemical reaction with the copper itself. Uncoated, polished carbide can also work well if it’s a high-quality grade designed for aluminum and copper.

Flute Count

For softer, gummier materials like copper, fewer flutes are generally better. This is because each flute needs to clear its chip. With many flutes, the space between them (gullets) gets smaller, hindering chip evacuation. For dry cutting copper, a 2-flute or 3-flute end mill is usually ideal. A 2-flute end mill offers the largest gullets for maximum chip clearance, which is essential when machining without coolant. A 3-flute can sometimes offer a slightly better surface finish but might require more careful feed rate management to avoid clog-ups.

Helix Angle

The helix angle refers to the angle of the cutting edge relative to the axis of the tool. For copper and aluminum, a higher helix angle (30-45 degrees) is often recommended. This provides a sharper cutting action and helps to lift and eject chips more effectively. A high helix angle is aggressive and efficient for chip removal.

Shank and Cutting Diameter

The keyword mentions “1/8 inch shank” and “1/4 inch cutting diameter.”

- 1/8 inch Shank: This refers to the diameter of the end mill that will be held in your collet or chuck. A smaller shank means the tool needs to fit into smaller collets.

- 1/4 inch Cutting Diameter: This is the diameter of the part of the end mill that actually does the cutting. A 1/4 inch cutting diameter is a common and versatile size for many tasks.

You’ll need to ensure your milling machine’s collet system can accommodate a 1/8 inch shank. Many systems offer a range of collet sizes. For an extra-long end mill, you’re looking for a tool where the flute length is significantly greater than the nominal 1/4 inch diameter, allowing it to reach deep.

Tool Length

The “extra long” aspect is critical. When choosing, look at the specifications for the overall length (OAL) and the flute length. Make sure the flute length is sufficient for your intended cuts. Be aware that extra-long end mills can be more prone to vibration and deflection if not used carefully, especially with thinner materials or less rigid machines. This is why rigid setups and appropriate machining parameters are so important.

Setting Up Your Milling Machine for Dry Cutting Copper

Proper setup is crucial for successful dry cutting of copper with an extra-long carbide end mill. It’s not just about having the right tool; it’s about using it correctly. Here’s a step-by-step guide:

1. Secure the Workpiece

This is non-negotiable for safety and accuracy. Ensure your copper workpiece is firmly secured to the milling machine table using clamps, a vise, or any other appropriate workholding method. Any movement can lead to ruined parts, tool breakage, or serious injury. For softer copper, consider using soft jaws in your vise to avoid marring the surface.

2. Install the End Mill Correctly

Collet Selection: Use a high-quality collet that precisely matches your 1/8 inch shank end mill. A worn or improperly sized collet can lead to runout (the end mill not spinning perfectly true), which will result in poor finish, increased vibration, and potential tool breakage. Ensure the collet is clean and free of debris.

Installation: Insert the end mill into the collet, ensuring the shank is seated firmly. Tighten the collet nut securely using the appropriate wrench. Do not overtighten, but ensure there is no possibility of the tool slipping. The drawbar mechanism (if your machine has one) should be engaged to keep the tool from pulling out under cutting forces.

3. Machine Rigidity and Vibration

Extra-long end mills are more susceptible to vibration and deflection due to their increased reach.:

- Ensure your milling machine is on a stable base.

- Minimize overhang: While you need the length, try to keep the tool engaging the material as close to the collet as possible without compromising reach.

- Check for play in your machine’s axes (X, Y, Z). Any looseness should be addressed before attempting precise cuts.

4. Setting Zero and Depth

Use your machine’s DRO (Digital Readout) or CNC probing system to accurately set your X, Y, and Z zero points. For depth control, use the Z-axis handwheel or program. Be precise when setting the depth of cut to avoid unintentionally plunging too deep, which can overload the tool.

5. Chip Evacuation Strategy

Even with a good tool, effective chip evacuation is key for dry cutting.

- Air Blast: If your machine has an air blast feature, use it to blow chips away from the cutting zone. Position the nozzle so it blows chips ahead of the tool and out of the flutes.

- Manual Air Gun: You can use a handheld air gun (with appropriate eye protection) to periodically clear chips. Be very careful to do this when the tool is not rotating at full speed or is clear of the workpiece to avoid chips being blown back into the cut or at yourself.

- Peck Drilling (for plunging): If you need to plunge the end mill into the material, use a “peck” function (if your CNC machine supports it) or manually retract the tool in small increments to clear chips.

Machining Parameters for Dry Cutting Copper

This is where many beginners struggle. Finding the “sweet spot” for cutting speed and feed rate can make the difference between pristine cuts and a melted mess. The goal is to remove material efficiently while keeping the tool and workpiece from overheating and preventing the copper from welding itself to the end mill.

Generic parameters are a starting point, but always be prepared to adjust based on your specific machine, the exact copper alloy, and the end mill. A good rule of thumb for carbide end mills machining copper is to operate like you’re machining aluminum, but with a bit more attention to chip evacuation.

Surface Speed (SFM) and Spindle Speed (RPM)

Surface speed is the speed at which the cutting edge moves through the material, measured in surface feet per minute (SFM) or surface meters per minute (SMM). The correct SFM depends heavily on the tool material, workpiece material, and coating.

For carbide machining copper, a common range for surface speed is between 200 and 500 SFM. However, for softer materials and to minimize heat, staying on the lower to mid-end of this range is often safer for beginners.

To calculate spindle speed (RPM) from SFM, use the formula:

RPM = (SFM 3.82) / Diameter (in inches)

Let’s calculate for a 1/4 inch diameter end mill:

- If we aim for 300 SFM: RPM = (300 3.82) / 0.25 = 4584 RPM

- If we aim for 400 SFM: RPM = (400 3.82) / 0.25 = 6112 RPM

Given that you are using an extra-long end mill, it’s often wise to err on the side of caution initially to minimize deflection and vibration. Start around 3000-4000 RPM and listen to the cut. For a 1/4 inch 2-flute carbide end mill, a starting point might be around 4000-5000 RPM.

Feed Rate (IPM)

The feed rate (inches per minute, IPM, or millimeters per minute, MMPM) is how fast you advance the tool into the material. This is critical for chip load – the amount of material each cutting edge removes per revolution.

For a 1/4 inch 2-flute carbide end mill in copper, a good target chip load is between 0.001″ and 0.003″ per tooth. This means:

- Chip Load = Feed Rate / (Spindle Speed Number of Flutes)

- Therefore, Feed Rate = Chip Load Spindle Speed Number of Flutes

Using our example RPM of 4500:

- Target Chip Load: 0.0015″ per tooth

- Feed Rate = 0.0015″ 4500 RPM 2 flutes = 13.5 IPM

So, a starting feed rate could be around 10-15 IPM (254-381 MMPM). Always use a calculated feed rate for CNC machines. For manual machining, aim for a consistent, smooth feed that sounds like a series of small, sharp cuts rather than a drag or a chatter.

Depth and Stepover

With extra-long end mills, it’s vital to manage the depth of cut and radial stepover to prevent tool breakage and maintain accuracy.

Axial Depth of Cut (DOC): This is how deep the end mill cuts into the material along the Z-axis in a single pass. For extra-long tools, keep this shallow. A common recommendation is 1x the tool diameter or less, but for extra-long tools, aim for 0.5x to 0.25x the diameter, or even less, especially in stiffer materials or with less rigid machines. For a 1/4 inch end mill:

- Start with an axial DOC of 0.0625″ (1/16″) to 0.125″ (1/8″).

- Do not attempt to take very deep cuts in one go. Multiple shallow passes are safer and often yield better results.

Radial Stepover: This is how much the tool moves sideways (in X or Y) in each pass when performing contouring or pocketing. For efficient material removal and good finish, a stepover of 40-50% of the tool diameter is common. For high-finish passes, you might reduce this to 10-20%.

Peck Drilling Parameters

If plunging, consider these dry cutting parameters:

- Peck Depth: Start with very shallow pecks, perhaps 0.0625″ (1/16″) or 0.125″ (1/8″).

- Retract: Ensure the peck cycle fully retracts the tool to clear chips before plunging again.

Summary of Recommended Starting Parameters (1/4″ 2-Flute Carbide End Mill for Copper, Dry Cutting)

| Parameter | Value | Notes |

|---|---|---|

| Spindle Speed (RPM) | 3000 – 5000 RPM | Adjust based on tool rigidity and sound of cut. |

| Feed Rate (IPM) | 10 – 15 IPM | Calculated based on chip load (0.001″-0.002″ per tooth). |

| Axial Depth of Cut (DOC) | 0.0625″ – 0.125″ | Keep shallow due to tool length. |

| Radial Stepover | 0.100″ – 0.125″ (40-50% of diameter) | For profiling/pocketing. |

Always use these as a starting point and be