A 1/8 inch carbide end mill is the go-to tool specifically designed for clean, precise cuts in fiberglass. Its small diameter and durable carbide construction make it ideal for detailed work and machining this challenging material without excessive fraying or damage.

Working with fiberglass can be a bit tricky. It’s a fantastic material for building and crafting, but it can also be rough on tools. You might find that standard bits or tools just don’t do a clean job, leaving fuzzy edges or even damaging your project. This is a common frustration for many makers, woodworkers, and DIY enthusiasts when they start working with fiberglass composites. But don’t worry! There’s a specific tool that makes cutting fiberglass much smoother and more precise. This article will guide you through why a 1/8 inch carbide end mill is your best buddy for fiberglass projects, showing you exactly how to use it effectively and safely. Let’s get your projects looking sharp!

Why a 1/8 Inch Carbide End Mill is Your Fiberglass Best Friend

When you’re dealing with fiberglass, you’re working with a composite material that’s a mix of plastic resin and glass fibers. This combination makes it strong and durable, but also abrasive and prone to splintering if you don’t use the right approach. This is where the “unsung hero” of your tool collection comes in: the 1/8 inch carbide end mill.

Understanding the Material: Fiberglass Challenges

Before we dive into the tool, let’s quickly touch on what makes fiberglass tough to machine:

Abrasiveness: The glass fibers are hard and wear down softer tool materials quickly.

Fraying and Delamination: Cutting too aggressively or with the wrong tool can cause the glass fibers to separate from the resin, leading to a rough, feathered edge. This is called delamination.

Dust Generation: Fiberglass cutting produces fine dust, which can be irritating to breathe and can quickly clog up tools and machinery. Proper dust collection and personal protective equipment (PPE) are crucial.

The Magic of Carbide

Now, why carbide?

Hardness and Durability: Carbide (often tungsten carbide) is an extremely hard material. This means it can withstand the abrasive nature of fiberglass without dulling too quickly. It’s significantly harder than high-speed steel (HSS), which is common for many other types of cutting tools.

Heat Resistance: Machining can generate heat. Carbide holds its hardness at higher temperatures than HSS, allowing for faster cutting speeds and longer tool life in demanding applications like fiberglass.

The Importance of a 1/8 Inch Diameter

The 1/8 inch size isn’t just a random specification. It’s chosen for several key reasons when working with fiberglass:

Precision and Detail: A smaller diameter allows for intricate cuts, fine details, and tight corners. This is essential for hobby projects, model making, or when precise fitment is required. You can achieve cleaner lines and sharper contours compared to larger bits that might be too coarse for delicate work.

Reduced Load: A smaller diameter tool generally removes less material at any given time. This means less stress on the tool and the material, reducing the risk of chipping, delamination, and excessive force on your milling machine or CNC setup.

Maneuverability: In CNC milling, smaller end mills can navigate complex toolpaths and sharp internal radii more effectively.

Carbide End Mill for Fiberglass: The Perfect Match

Combining a 1/8 inch diameter with carbide creates a specialized tool perfectly suited for fiberglass. It offers the precision for detailed work and the toughness to handle the material’s abrasive nature. This combination minimizes tool wear, produces cleaner cuts, and ultimately leads to better-finished parts with less post-processing.

For specific applications, you might encounter terms like “1/8 inch carbide end mill 1/2 shank long reach for fiberglass mql friendly.” Let’s break that down:

1/2 Shank: This refers to the diameter of the part of the end mill that goes into the collet or tool holder. A 1/2 inch shank is common for larger machines but also available for smaller ones to provide rigidity.

Long Reach: This means the cutting flutes extend further out from the shank, allowing you to machine deeper cavities or reach areas that are harder to access.

MQL Friendly: MQL stands for Minimum Quantity Lubrication. This is a system that uses a very fine mist of coolant (lubricant) and air directed at the cutting zone. It helps to cool the tool, lubricate the cut, and evacuate chips and dust, which is especially beneficial when machining composites like fiberglass.

When searching for the right tool, keep these descriptions in mind to ensure you get an end mill that meets the demands of your fiberglass projects.

Choosing the Right 1/8 Inch Carbide End Mill

Not all 1/8 inch carbide end mills are created equal. For fiberglass, a few key features will make a significant difference in performance and longevity.

Types of End Mills and Their Suitability for Fiberglass

When looking at carbide end mills, you’ll see different flute counts and geometries. For fiberglass, a good general-purpose choice is often a 2-flute or 3-flute end mill.

2-Flute End Mills:

Pros: Excellent chip clearance, which is very important when machining fibrous materials like fiberglass that can create long, stringy chips. They tend to run cooler and are great for plunging and slotting.

Cons: Can chatter more than 3-flute mills on less rigid setups due to fewer teeth engaging the material.

3-Flute End Mills:

Pros: Offer a good balance between chip clearance and surface finish. They generally provide a smoother finish than 2-flute mills and can handle higher feed rates for finishing operations.

Cons: Chip evacuation can be slightly more challenging than with 2-flute mills, potentially leading to chip recutting if not managed well.

For fiberglass, where chip evacuation and preventing heat buildup are paramount, 2-flute end mills are often preferred for their superior chip clearing capabilities. However, a well-set-up machine using a balanced cutting strategy might benefit from a 3-flute for finishing. Always consider the specific operation.

Key Features to Look For:

Coating: While solid carbide is good, a coating can further enhance performance.

Zirconium Nitride (ZrN): Offers excellent hardness and lubricity, reducing friction and heat buildup. It’s a good general-purpose coating for abrasive materials.

Titanium Aluminum Nitride (TiAlN): Provides excellent thermal stability and hardness, making it suitable for higher-temperature machining. This can be beneficial for fiberglass, as friction generates heat.

Geometry:

Sharp Edges: High-quality end mills have very sharp cutting edges. This minimizes the force required to cut, reducing the chance of splintering fiberglass.

Up-cut vs. Down-cut Spirals: This refers to the direction the flutes spiral relative to the cutting direction.

Up-cut: Flutes spiral upwards away from the workpiece. This lifts chips out of the cut and is generally good for clearing material. It can sometimes cause a slight lifting or chipping of the material surface, which might be a concern on the top surface of fiberglass.

Down-cut: Flutes spiral downwards towards the workpiece. This pushes chips down and helps to create a cleaner finish on the top surface by compressing the material slightly. However, it can pack chips into the cut, leading to heat and potential clogging if not managed.

Combination (Up/Down): Some end mills have a combination spiral, offering benefits of both.

For fiberglass, a common recommendation is to use a down-cut end mill for the final finishing pass on the “top” surface to ensure a clean edge. For clearing material or on the underside, an up-cut can be effective.

Material Quality: Ensure the carbide is of high quality. Reputable manufacturers will specify the grade of tungsten carbide used.

Where to Buy:

You can find 1/8 inch carbide end mills from a variety of sources:

Specialty CNC and Machining Supply Stores: Websites like McMaster-Carr, MSC Industrial Supply, and many smaller online CNC retailers carry a wide selection.

Amazon and eBay: While you can find options here, be diligent about checking seller reputation and product descriptions.

Tool Manufacturers: Buying directly from well-known tool brands (e.g., Lakeshore Carbide, Melin Tool, YG-1) often guarantees quality.

Essential Accessories and Considerations

Beyond the end mill itself, a few other items are crucial for successful fiberglass machining:

1. Collet and Collet Chuck: A good quality collet, typically a ER collet system, is essential for holding a 1/8 inch shank securely and accurately. A worn or loose collet can lead to runout (wobble), poor cut quality, and tool breakage.

2. Dust Collection System: As mentioned, fiberglass dust is an irritant and can be a fire hazard. A robust dust collection system, ideally with a HEPA filter, is a must. For CNC machines, ensure your dust shoe integrates well with the spindle.

3. Coolant/Lubricant (MQL Recommended): Even with specialized tools, reducing friction and heat is vital. A Minimum Quantity Lubrication (MQL) system is highly recommended for fiberglass machining. It sprays a fine mist of coolant and air directly at the cutting edge.

Why MQL is great for Fiberglass: It significantly reduces heat, flushes away chips and dust, improves tool life, and creates a smoother finish. Look for MQL fluids specifically designed for composite machining or general-purpose synthetic coolants.

4. Personal Protective Equipment (PPE): This is non-negotiable.

Safety Glasses/Face Shield: To protect your eyes from flying debris and dust.

Respirator: A high-quality respirator, rated for fine particulates (like N95 or higher), is essential to protect your lungs from fiberglass dust.

Gloves: To prevent skin irritation from fiberglass dust.

Ear Protection: If your machinery is noisy.

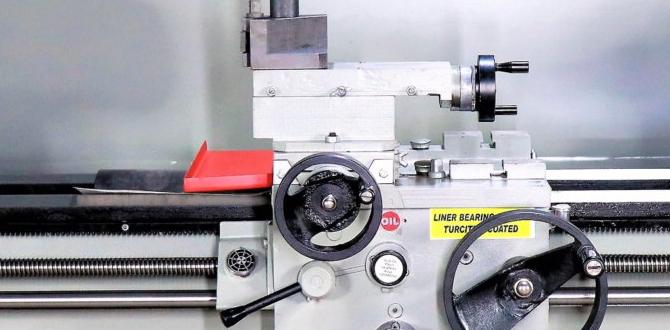

Setting Up Your Machine for Fiberglass Machining

Proper machine setup is as important as the tool itself. Here’s how to get your mill ready.

CNC Machining: Feeds and Speeds (The Basics)

Finding the perfect “feeds and speeds” can be a journey, but for a 1/8 inch carbide end mill in fiberglass, here are some starting points. These are guidelines, and you’ll often need to adjust based on your specific machine, the exact fiberglass composite, and the end mill.

General Guidelines for 1/8 Inch Carbide End Mill in Fiberglass:

| Parameter | Guideline Value | Notes |

| :—————– | :————————————– | :——————————————————————————————————————————————- |

| Spindle Speed | 15,000 – 24,000 RPM | Higher RPMs are often preferred for composites to achieve a shearing action rather than grinding. |

| Feed Rate | 15 – 30 Inches Per Minute (IPM) | Start on the lower end and increase as needed. Adjust based on chip formation and sound. |

| Depth of Cut | 0.010 – 0.030 inches (0.25 – 0.76 mm) | Use shallow passes to avoid overwhelming the tool and the material. Especially important for the first few passes. |

| Stepover | 20% – 50% of tool diameter | For profiling and pocketing. A smaller stepover gives a smoother finish. For roughing, you might go higher. |

| Plunge Rate | 5 – 15 IPM | Slower plunge rates are generally safer to avoid digging in. |

| Coolant/Lubrication | MQL Recommended | Essential for heat management and chip evacuation. Without MQL, consider a light mist of cutting fluid or even air blast at a minimum. |

Important Considerations for Feeds and Speeds:

“Chip Load”: This is the amount of material each cutting edge removes per revolution. A common target for carbide in composites is around 0.0010 – 0.0020 inches per tooth (IPT). You can calculate feed rate using this: Feed Rate (IPM) = Spindle Speed (RPM) Number of Flutes Chip Load (IPT).

Test on Scrap First: Always do test cuts on a scrap piece of fiberglass to dial in your settings before cutting your final part. Listen to the sound of the cut – a smooth, consistent hum is good; screaming or chattering indicates a problem.

Material Variation: Different fiberglass types (e.g., woven roving, chopped strand mat, carbon fiber composites) will behave differently.

Machine Rigidity: A less rigid machine will require slower speeds and lighter cuts.

Manual Machining: A Steady Hand

If you’re using a milling machine manually, the principles are similar but involve your skill and feel rather than programmed speeds.

1. Secure the Workpiece: Use clamps, a vise, or jigs to hold the fiberglass firmly. Ensure there’s no possibility of it shifting during the cut. Bridging or supporting thin materials is key.

2. Tool Holder and Collet: As with CNC, a properly seated end mill in a quality collet is critical.

3. Controlled Feed Rate: Use your machine’s handles to feed the end mill into the material at a consistent, controlled pace. Avoid jerky movements. Imagine you’re “peeling” the material away rather than “gouging” it out.

4. Flood Coolant or Mist: If your manual milling machine has a coolant system, use it. Otherwise, a spray bottle with a water-based cutting fluid can help. For very light work, even a bit of water can help.

5. Shallow Passes: Take light cuts. You’ll be making multiple passes to achieve the desired depth.

6. Chip Evacuation: Regularly clear chips and dust from the cutting area using a brush or compressed air (wear your PPE!).

Step-by-Step: How to Machine Fiberglass with a 1/8 Inch Carbide End Mill

Let’s walk through the process of using your 1/8 inch carbide end mill to cut fiberglass. This guide assumes you’re either using a CNC mill or a manual mill.

Preparation is Key

1. Design Your Part: Create your design in CAD software (for CNC) or have your measurements ready. Ensure your design accounts for the 1/8 inch tool diameter, especially for internal corners, which will have a 1/8 inch radius. If you need tighter radii, you might need specialized ball-end mills or a different machining strategy.

2. Secure the Fiberglass: Mount your fiberglass material firmly to the machine bed or vise. Use sacrificial material (like MDF or a thin composite sheet) underneath if you’re cutting all the way through to protect your machine bed.

3. Install the End Mill: Insert the 1/8 inch carbide end mill into your collet and tighten it securely in the spindle. Ensure it’s seated properly to minimize runout.

4. Set Up MQL or Coolant: If you have an MQL system, position the nozzle to deliver mist directly to the cutting zone. If using manual methods, have your lubricant ready.

5. Power Up Dust Collection: Turn on your dust collection system. This is crucial for safety and a cleaner workspace.

6. Personal Protective Equipment (PPE): PUT ON YOUR PPE NOW. Safety glasses, respirator, gloves – the works.

Machining Process

1. Establish Work Zero: For CNC, set your X, Y, and Z zero points accurately on your workpiece. For manual machining, this is where you’ll begin your cuts.

2. Program or Plan Your Toolpath:

Profiling (Cutting out a shape): For the outer boundary, use a “climb cut” on the outside for a cleaner finish and to reduce stress on the tool if your machine is rigid enough. For internal profiles (pockets), use “conventional milling” or “climb milling” depending on your machine and preference if not already defined by software.

Pocketing: Design your toolpath to efficiently clear the pocket, considering chip evacuation.

3. Initial “Dry Run” (Optional but Recommended for CNC): Run your program with the spindle off but the machine moving through its path. This helps identify any potential collisions or path errors without damaging tools or material.

4. First Cutting Pass:

Engage the Material: For CNC, the program will handle this. For manual milling, carefully bring the spinning end mill into contact with the material.

Use Recommended Settings: Start with the lower end of the suggested feed rate and depth of cut. For a 1/8 inch end mill in fiberglass, think “light and fast” (meaning high spindle RPM, moderate feed rate, and shallow depth of cut).

Listen and Observe: Pay attention to the sound and the chips being produced. Smooth operation and fine, powdery chips are often good indicators. If you hear chatter or see excessive dust without chips, your settings might be too aggressive, or your tool might be dull.

5. Subsequent Passes:

Increase Depth Gradually: Once you’re confident with the initial pass, increase the depth of cut incrementally for each subsequent pass until you reach your desired depth. Maintain your spindle speed and feed rate.

* Finishing Passes: For the final top surface of a profiled part, consider a dedicated finishing pass with a slightly adjusted stepover (e.g., 50% or less) and potentially a down-cut end mill if you’re using one for the final pass. This will leave a smoother, cleaner edge without lifting fibers