Carbide end mills last longer when you use them correctly. Proper speeds, feeds, and care are key to getting the most cuts from each tool, saving you time and money in the workshop.

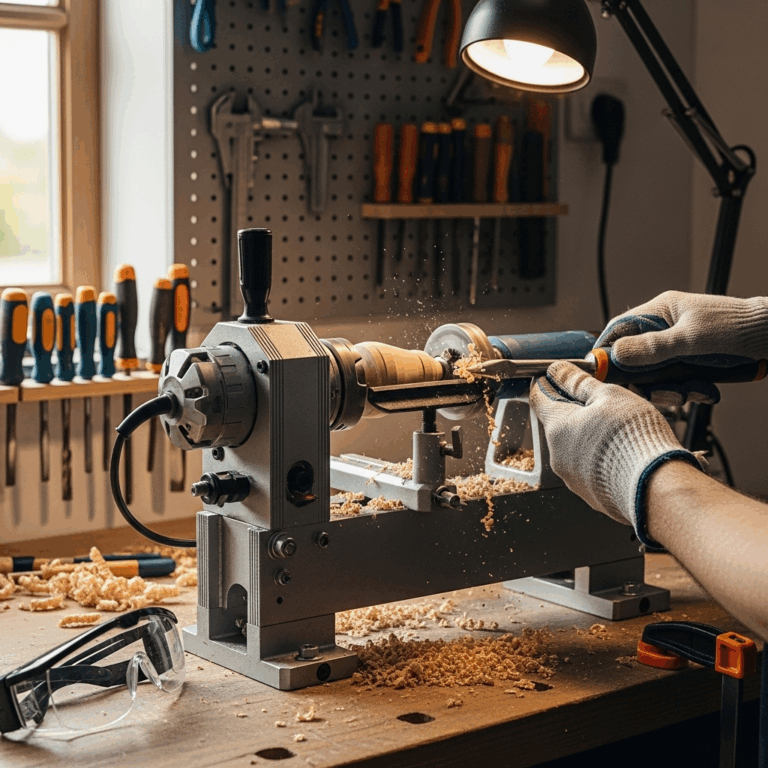

Ever notice your end mill seeming to wear out faster than you expected? You’re not alone. For beginners delving into metal and wood shaping with machines like metal lathes and milling tools, getting the most out of your cutting bits is a big deal. A crucial tool in this process is the carbide end mill. It might seem tricky at first, but understanding how to make your carbide end mills last longer is surprisingly straightforward. We’ll walk through the simple steps, from picking the right tool to caring for it. Get ready to cut cleaner, longer, and with more confidence!

What is a Carbide End Mill and Why Does It Matter?

A carbide end mill is a type of milling cutter, essential for shaping materials on a milling machine. Unlike high-speed steel (HSS) tools you might see for wood lathes or simpler metalwork, carbide is much harder and more brittle. This hardness is its superpower, allowing it to cut tougher materials and at higher speeds. When we talk about “long tool life,” it means getting many, many cuts out of that end mill before it becomes dull or breaks. For anyone using milling tools, especially those starting out, this is incredibly important. It saves money, reduces frustration, and leads to better results.

Think of it this way: a sharp, well-maintained end mill cuts smoothly and accurately. A dull one struggles, heats up, can chatter, and might even break. For beginners, this can be a real setback. Learning to keep your carbide end mills in top shape means your projects will turn out better, and you’ll spend less time and money replacing worn-out tools. We’ll cover everything from selecting the right carbide end mill for your job to the best practices for keeping it sharp and effective.

Understanding Carbide: The Secret to Durability

Carbide, specifically tungsten carbide, is a composite material known for its extreme hardness and wear resistance. This makes it ideal for cutting tools that face tough materials like hardened steel, aluminum, plastics, and even composites like FR4 (often used in circuit boards). While it�s harder than steel, it�s also more brittle, meaning it can chip or snap if mishandled. This is a critical distinction from more flexible materials.

The manufacturing process for carbide involves mixing tungsten carbide powder with a binder, usually cobalt, and then sintering it at high temperatures. The resulting material is incredibly dense and hard. This is why a carbide end mill, even a small one like a 1/8 inch with a 1/2 inch shank, can tackle jobs that would quickly wear down a lesser tool. For applications requiring precision and durability, like the specific needs of machining FR4, the right carbide end mill is indispensable.

Choosing the Right Carbide End Mill for Your Project

Not all carbide end mills are created equal. For beginners, selecting the correct one can seem daunting, but focusing on a few key features will help. We’re focusing on making your tools last, so starting with the right tool is step one!

Types of Carbide End Mills

- Number of Flutes: This refers to the cutting edges on the end mill.

- 2-Flute: Good for softer materials like plastics and aluminum. They offer good chip clearance, which is important for preventing material from sticking to the cutter.

- 3-Flute: A good all-around choice for a variety of materials, including some steels. Offers a good balance of strength and chip clearance.

- 4-Flute: Best for harder materials like steels and cast iron. They provide more cutting edges for a smoother finish but have less chip clearance.

- Coating: Some end mills have special coatings to improve performance and tool life.

- Uncoated: Suitable for general-purpose machining, especially in softer metals like aluminum.

- TiN (Titanium Nitride): A common gold-colored coating that adds hardness and reduces friction, extending tool life in steels and cast iron.

- TiCN (Titanium Carbonitride): Darker gray/blue. Harder than TiN, good for abrasive materials and harder steels.

- AlTiN (Aluminum Titanium Nitride): Black/purple coating. Excellent for machining high-temperature alloys and steels, offering great heat resistance.

- End Shape:

- Square End: The most common type, used for slotting, profiling, and general milling.

- Ball Nose End: Has a rounded tip, ideal for 3D contouring and creating curved surfaces.

- Corner Radius (Bull Nose): A square end with a rounded corner, combining the strength of a square end with improved corner strength and reduced stress concentration.

- Material & Specifications: For tasks involving FR4, you’ll often find specialized end mills. An “extra long” shank (like a 1/2 inch shank for a smaller diameter cutter) can be useful for reaching into deeper pockets or clearing workpiece fixturing. The “1/8 inch” likely refers to the cutting diameter.

Keywords in Context: “Carbide End Mill 1/8 Inch 1/2 Shank Extra Long for FR4 Long Tool Life”

This specific phrase tells us a lot. We’re looking for a carbide end mill that has these features:

- Carbide: The material type for durability.

- 1/8 inch: The actual cutting diameter of the tool. This is a small size, suitable for fine detail work or specific slot widths.

- 1/2 Shank: The diameter of the part that goes into the collet or tool holder. A 1/2 inch shank on a 1/8 inch cutter means it’s a relatively long and thin tool, offering extra reach.

- Extra Long: Suggests the tool’s overall length is greater than standard, providing more reach or clearance.

- for FR4: The intended material. FR4 requires specific cutting parameters and tool geometries to avoid chipping and delamination.

- Long Tool Life: The desired outcome.

When purchasing, always look at the manufacturer’s specifications. They will tell you the flute count, coating, material suitability, and recommended cutting parameters.

Key Factors for Achieving Long Tool Life

Making any tool last, especially a carbide end mill, comes down to treating it right. It’s like a good chef taking care of their knives – it makes a world of difference. Here are the core principles:

1. Proper Speeds and Feeds

This is often the most overlooked aspect for beginners. Setting the right rotational speed (RPM) and the rate at which the tool moves through the material (feed rate) is crucial.

Speeds (RPM): Carbide generally likes to spin faster than HSS. However, running too fast can overheat and damage the cutting edge. Running too slow can lead to rubbing and dulling.

Feeds (IPM or mm/min): This is how fast the material is being removed. Too slow, and you risk rubbing and poor chip formation. Too fast, and you risk overloading the tool, chipping, or breaking it. For small end mills like a 1/8 inch, feed rates need to be very controlled.

Manufacturers often provide recommended surface feet per minute (SFM) for their tools. You can convert this to RPM using this formula:

RPM = (SFM 3.28) / Diameter (inches)

For feed rate, look for recommended chip loads (the thickness of material removed by each tooth). Chip load and RPM together determine your feed rate in inches per minute (IPM).

2. Chip Evacuation

This means getting the chips of material cleared away from the cutting area. If chips build up, they can get recut, causing overheating, dulling, and a poor finish. For end mills, especially those with fewer flutes (like 2-flute), you need to ensure the flutes can clear the chips.

Plunge Cuts: When plunging straight down into material, make sure the end mill can clear chips effectively. Peeling out chips in stages can help.

Through Spindle Coolant (if available): On some machines, coolant can be directed through the spindle and out the center of the tool, helping to flush chips away. For FR4, this is less common than for metal machining.

Air Blast/Coolant Misting: Using compressed air or a coolant mist can help blow chips out of the flute and off the workpiece.

3. Coolant and Lubrication

Even if you’re not machining hard steel, some form of lubrication or cooling is beneficial.

For Aluminum and Plastics: A light oil or a specialized plastic cutting fluid can prevent the material from melting and sticking to the end mill. This is vital for keeping cuts clean.

For FR4: Dust is the primary concern, but a light mist of coolant or even a blast of air can help keep the area clear and cool. Overheating FR4 can cause it to melt and gum up the tool.

Avoid Dry Machining: Unless specifically recommended for your material and tool, avoid running carbide dry. It generates heat, which is the enemy of tool life and sharpness.

4. Proper Tool Holding

A secure grip on the end mill is non-negotiable.

Collets: Use the correct size collet that matches the shank diameter of your end mill. An undersized collet can’t grip properly, leading to runout (wobble) and premature wear. Oversized can damage the shank.

Set Screws: If using a tool holder with set screws, ensure they are tightened appropriately and don’t damage the carbide shank.

Runout: Excessive runout means the end mill isn’t spinning perfectly on the machine’s axis. This leads to uneven cutting, increased vibration, and shorter tool life.

5. Avoiding Shock Loads

Carbide is brittle. This means sudden impacts can cause chipping or breakage.

Leadscrews or Backlash: On older or less precise machines, backlash in the leadscrews can cause sudden engagement, leading to shock. Ensure your machine is well-maintained.

Entry and Exit: Gentle entry and exit into the material are important. Avoid slamming the tool into a shoulder or rapidly withdrawing it.

Practical Steps for Longer Carbide End Mill Life

Now, let’s get into the actionable steps. We’ll assume you have a milling machine (or a rotary tool setup that can act like one) and are trying to achieve that “long tool life” for your “carbide end mill 1/8 inch 1/2 shank extra long for FR4.”

Step 1: Review Your Material and Tool Specs

Before you even think about turning the machine on, double-check:

- Material: You’re working with FR4. This is a fiberglass-reinforced epoxy laminate. It’s abrasive and can be prone to delamination if cut incorrectly.

- Tool: You have a 1/8 inch diameter, 1/2 inch shank, extra-long flute carbide end mill. Given it’s for FR4, it’s likely a specialized PCB milling bit, possibly with a high flute count (e.g., 2 or 4 flutes) and a sharp, precise geometry. Many such bits are uncoated.

- Machine: What kind of milling machine are you using? A full CNC, a manual mill, or a specialized PCB router? This affects feed rate control.

Step 2: Calculate or Find Recommended Speeds and Feeds

This is critical. For FR4, you’ll want to:

- Use a Speeds and Feeds Calculator: Many online resources can help. Search for “speeds and feeds calculator for FR4” or “PCB milling speeds and feeds.” You’ll need to input the end mill diameter (0.125″), the material (FR4), the material’s approximate hardness (which can be tricky for composites, but general guidance exists), and the tool’s material (carbide).

- Manufacturer’s Recommendations: If the end mill came with a data sheet or packaging, check for any recommended parameters.

- General Guidelines for FR4 (Example – Always Verify!):

- RPM: For a 1/8 inch carbide end mill in FR4, speeds can range widely, but often fall between 15,000 – 30,000 RPM. Lower RPM might be better for manual control, higher for automated CNC.

- Chip Load: For tiny bits like this, chip load is very small, often in the range of 0.001″ to 0.003″ per tooth.

Let’s do a quick example calculation for RPM assuming a desired SFM. Carbide can operate at high SFM, but for FR4 and small tools, let’s aim conservatively. If we find a recommendation for 200 SFM:

RPM = (200 SFM 3.28) / 0.125 inches = 5248 RPM.

This is quite low. Often, higher RPMs are used for PCB routing to get the chip load fine enough. Conversely, if a calculator suggests 20,000 RPM, you may need to ensure your machine can achieve this stable speed and that the feed rate can be controlled precisely. Start on the lower end of recommended RPMs and gradually increase if needed.

Feed Rate (IPM) Calculation:

Feed Rate (IPM) = RPM Number of Flutes Chip Load per Tooth

Using our 5248 RPM example, and assuming a 2-flute end mill with a 0.002″ chip load:

Feed Rate = 5248 2 0.002 = 20.99 IPM (approx. 21 IPM)

If using 20,000 RPM and 0.0015″ chip load:

Feed Rate = 20000 2 * 0.0015 = 60 IPM

These numbers highlight the importance of precise control. For machines without sophisticated CNC control, faster feed rates might be impossible or lead to broken tools. Many hobbyists using machines like the Shapeoko or other CNC routers will operate in the 200-400 IPM range at high RPMs. Adjust based on your machine’s capabilities and your comfort level.

Step 3: Set Up Your Workpiece and Tool Securely

Fixturing FR4:

- Double-Sided Tape: For thin FR4, strong double-sided adheive tape is often sufficient.

- Clamps: For thicker boards, edge clamps can be used, but ensure they don’t interfere with the tool path.

- Vacuum Table: If your machine has one, it’s ideal for holding FR4 flat and secure.

Tool Holder:

- Ensure your collet is clean, the correct size (1/2 inch), and properly seated in your spindle.

- Insert the end mill shank fully into the collet. Don’t have it sticking out excessively unless the “extra long” design necessitates it for clearance.

- Tighten the collet securely.

Step 4: Implement Machining Strategy

Cooling/Lubrication: For FR4, a fine mist coolant or an air blast is usually preferred over flooding. This helps control dust and prevent melting. The goal is to keep the cutting edge cool and clear chips.

Cutting Depth: Never try to cut the full depth of your FR4 in one pass. This is a recipe for broken bits and damaged material.

- Depth of Cut (DOC): For a 1/8 inch end mill in FR4, a common DOC is between 0.050″ and 0.100″ (or 1.25mm to 2.5mm). For very thin FR4, it might be even less. Always err on the side of caution.

- Stepover: This is how much the tool moves sideways on each pass for pocketing or contouring. A stepover of 30-50% of the tool diameter is typical. For fine detail, you might go much smaller.

Ramping or Plunging: When starting a cut or plunging into the material, use a “ramp” move rather than a straight plunge if your CAM software allows. A ramp cut