Quick Summary

A 1/8 inch extra-long carbide end mill with a 1/2 inch shank is ideal for cast iron. Its design minimizes deflection, ensuring precise cuts and excellent surface finish for intricate machining tasks. Choose this tool for reliable performance in demanding cast iron applications.

Mastering the 1/8 Inch Extra-Long Carbide End Mill for Cast Iron: A Beginner’s Guide to Minimizing Deflection

Working with cast iron can be a rewarding experience for any machinist or hobbyist, offering durability and a satisfying machining feel. However, it can also present unique challenges, especially when dealing with smaller, detailed work or when trying to achieve extremely fine finishes. One common frustration is tool chatter or deflection, where your cutting tool bends or vibrates, leading to inaccurate dimensions and a rough surface. This is especially true when using smaller diameter tools. Fortunately, specific tool choices can make a world of difference. This guide is your starting point to understanding how a particular end mill – the 1/8 inch extra-long carbide end mill with a 1/2 inch shank – can be your secret weapon for tackling cast iron with confidence and precision, minimizing those pesky deflections right from the start.

We’ll walk through why this specific tool is so well-suited for cast iron, how to set it up for success, and what settings to use. Our goal is to demystify the process, ensuring you can achieve smooth, accurate cuts without the headache of unpredictable tool behavior. Get ready to elevate your machining game and build confidence with your metalworking projects!

Why Choose a 1/8 Inch Extra-Long Carbide End Mill for Cast Iron?

Cast iron is a fantastic material, known for its strength and wear resistance. However, it’s also brittle and can be abrasive, which means your cutting tools have to be tough and sharp to handle it. When you’re working on projects that require intricate details or delicate cuts, the size of your tool becomes critical. A small diameter end mill, like a 1/8 inch one, is perfect for carving out fine slots, pockets, or detailed contours. But here’s the catch: smaller tools have less rigidity. Without the right design, they’re more prone to bending or vibrating – what we call “deflection” or “chatter.”

This deflection is a machinist’s nemesis. It leads to inaccurate dimensions, rough surfaces, and can even break your fragile tool. That’s where the specific design of an extra-long 1/8 inch carbide end mill with a 1/2 inch shank comes into play, especially for cast iron. Let’s break down why this combination is so effective:

The Benefits of Carbide

Carbide, or more precisely tungsten carbide, is an incredibly hard and dense material. It’s significantly harder than High-Speed Steel (HSS), which is another common tool material. This hardness is a game-changer for machining tougher materials like cast iron because:

- Superior Hardness and Wear Resistance: Carbide tools can withstand higher temperatures generated during cutting and resist wear much better than HSS. This means they stay sharp for longer, providing consistent performance and reducing the need for frequent tool changes.

- Higher Cutting Speeds: Because carbide can handle more heat, you can often run your machines at faster spindle speeds and feed rates when using carbide tools. This translates to quicker machining times.

- Better Surface Finish: A sharp, rigid carbide tool cuts cleanly, typically resulting in a smoother and more precise surface finish on your workpiece.

The Extra-Long Shank Advantage

The “extra-long” aspect of the shank is crucial for reaching into deeper features or cavities within your cast iron part. However, it also introduces a potential for increased deflection because the tool is further away from its support. This might seem counterintuitive, but the combination with other features often negates this downside.

The 1/2 Inch Shank: Stability and Rigidity

The 1/2 inch shank is a significant factor in minimizing deflection, especially for a 1/8 inch cutting diameter. Here’s why:

- Increased Stiffness: A larger diameter shank provides much more torsional stiffness and bending resistance than a smaller shank (e.g., 1/4 inch or 3/8 inch). When cutting forces are applied to the small 1/8 inch cutting edge, the 1/2 inch shank acts as a much sturdier lever arm, resisting the tendency to bend away from the cut.

- Better Grip in Collet/Holder: A larger shank diameter provides a more substantial connection with your machine’s collet or tool holder. This secure grip ensures that the tool is held firmly, reducing any movement or runout that could contribute to inaccuracies.

- Reduced Vibration: The increased mass and stiffness of the thicker shank can help dampen vibrations that might otherwise be transmitted through a thinner shank, leading to a smoother cut.

The 1/8 Inch Cutting Diameter: Precision for Detail

The 1/8 inch cutting diameter is your enabler for fine detail work. This is the part of the tool that actually does the cutting. For tasks requiring high intricacy in cast iron, such as engraving, cutting small features, or machining tight radii, this small diameter is essential. The challenge is balancing this fine cutting ability with the need for rigidity, which the other features of the tool help achieve.

Tailored for Cast Iron

Many end mills designed for cast iron have specific flute geometries (the spiral grooves on the tool). These are often optimized for chip evacuation in this material, helping to prevent chips from clogging the flutes and causing overheating or poor surface finish. They might be designed with fewer flutes (e.g., 2 or 3) compared to those for softer metals, which can improve chip clearance and reduce the risk of the tool digging in.

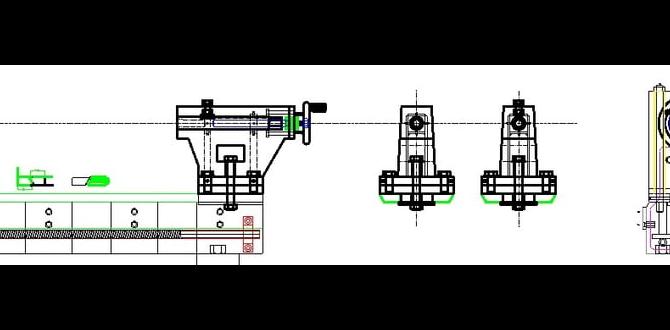

Understanding End Mill Terminology

Before we dive into setup and usage, let’s quickly clarify some terms you’ll encounter. Knowing these will not only help you understand this guide but also when reading tool specifications or talking to suppliers.

| Term | Definition | Relevance |

|---|---|---|

| Cutting Diameter | The actual diameter of the cutting edge. | Determines the width of the slot or feature you can create. (e.g., 1/8 inch) |

| Shank Diameter | The diameter of the part of the end mill that is held by the tool holder or collet. | Impacts rigidity and grip. (e.g., 1/2 inch) |

| Overall Length (OAL) | The total length of the end mill from the tip to the end of the shank. | Determines reach; extra long versions offer more reach. |

| Effective Cutting Length | The length of the cutting flutes on the end mill. | Indicates how deep a cut can be made with a single pass, or how much material can be engaged axially. |

| Flutes | The spiraled grooves along the body of the end mill that carry away chips. | Number and geometry of flutes affect chip clearance, cutting action, and suitability for different materials. |

| Coating | A thin layer applied to the end mill surface to improve performance. | Different coatings enhance hardness, reduce friction, and improve heat resistance for materials like cast iron. |

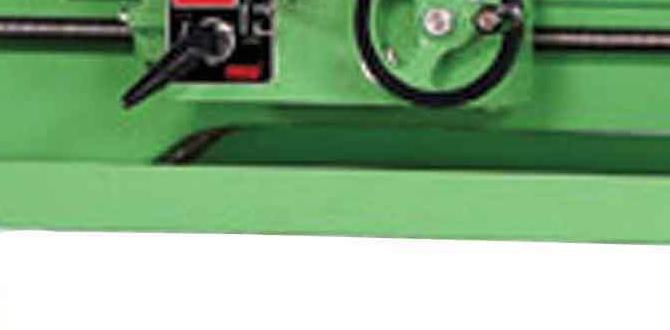

Setting Up Your Machine for Success

Achieving predictable results with your 1/8 inch extra-long carbide end mill in cast iron starts with proper machine setup. This isn’t just about putting the tool in the spindle; it involves ensuring everything is aligned and secure.

1. Ensuring Spindle Rigidity and Runout

Your machine’s spindle is the heart of its precision. If it’s worn or not properly maintained, even the best tool will struggle.

- Spindle Bearings: Listen for any unusual noises (grinding, whining) when the spindle is running. These could indicate worn bearings that lead to increased vibration and runout.

- Runout: This is the amount of wobble or deviation from a perfect rotation. You can check spindle runout using a dial indicator. Ideally, you want very low runout (typically less than 0.0005 inches, or 0.012 mm). Excessive runout will cause uneven cutting and premature tool wear.

2. Selecting the Right Tool Holder and Collet

The way you hold the end mill is just as important as the tool itself. For a 1/2 inch shank, you’ll need a corresponding 1/2 inch collet and a good quality collet chuck or holder.

- Collet Quality: Use high-precision collets. Cheaper or worn collets can introduce runout and won’t grip the shank as securely. For a 1/2 inch shank, ensure the collet can accommodate it snugly.

- Collet Chuck: A well-balanced, precision collet chuck (e.g., ER collet chucks are very common and effective) will ensure the tool is held concentrically with the spindle axis. Look for quality brands known for their accuracy.

- Cleanliness: Always ensure the collet, collet chuck, and the end mill shank are clean and free from chips, coolant residue, or oil. Contamination can prevent a secure grip and introduce runout.

3. Securely Mounting the End Mill

Once you have the correct collet and chuck, mounting the end mill requires care:

- Insert the End Mill: Slide the 1/2 inch shank of the end mill into the collet. Ensure it’s seated fully.

- Tighten the Collet: Tighten the collet nut securely. For ER collets, this usually involves a collet wrench. Make sure you apply enough torque to prevent slippage during cutting, but don’t overtighten, which could damage the collet or nut.

- Verify Depth: The extra-long shank will extend quite far. Ensure that the deepest part of the cutting flute is exposed, but that enough of the shank is engaged in the collet for a rigid hold. Avoid having too much of the slender cutting section unsupported if possible, unless your machining operation specifically requires it.

4. Workpiece Clamping

A securely clamped workpiece is non-negotiable. Any movement of the cast iron part during machining will lead to lost accuracy and can be dangerous.

- Solid Clamping: Use sturdy vices, clamps, or fixtures. Ensure that the clamping force is applied in a way that doesn’t obstruct the cutting path of the end mill.

- Support: For larger or irregularly shaped parts, use supports or shims to ensure the workpiece is stable and doesn’t rock or flex under the cutting pressure.

- Foundation: Make sure your workpiece is mounted on a flat and stable surface (like the bed of your lathe or milling machine table).

Recommended Machining Parameters for Cast Iron

Finding the sweet spot for cutting speeds and feeds is crucial for good results and tool longevity, especially with cast iron. These are starting points, and you’ll need to fine-tune them based on your specific machine, the exact alloy of cast iron, and the setup’s rigidity.

Surface Speed (SFM) and Spindle Speed (RPM)

Surface speed is the linear speed of the cutting edge as it moves around the workpiece. It’s usually given in surface feet per minute (SFM) or meters per minute (m/min).

- Carbide End Mills: For carbide end mills in cast iron, a good starting range for surface speed is typically 200-400 SFM (60-120 m/min).

- Calculating RPM: Your machine’s spindle speed (RPM) is calculated using the surface speed and the tool’s cutting diameter. The formula is:

RPM = (SFM × 12) / (π × Cutting Diameter in inches)

Using a 1/8 inch (0.125 inch) diameter end mill and a conservative starting SFM of 200:

RPM = (200 × 12) / (3.14159 × 0.125) ≈ 6111 RPM

If your machine can’t reach that high, you’ll need to adjust your feed rate accordingly or use a slower SFM. Always error on the side of caution with these smaller tools.

- Machine Limitations: Be mindful of your machine’s maximum RPM. If your maximum RPM is lower than the calculated value, you’ll need to use that lower RPM and accept that the surface speed will be less, meaning you might need to adjust feed rates.

Feed Rate (IPM)

Feed rate is how fast the tool advances into or along the workpiece. It’s typically measured in inches per minute (IPM) or millimeters per minute (mm/min).

- Chip Load: A key concept here is “chip load,” which is the thickness of the chip formed by each cutting edge of the end mill. For a 1/8 inch carbide end mill in cast iron, a starting chip load might be between 0.001 to 0.003 inches per tooth.

- Calculating Feed Rate: The feed rate is calculated based on the chip load, the number of flutes on the end mill, and the spindle RPM.

Feed Rate (IPM) = Chip Load (inches/tooth) × Number of Flutes × RPM

Let’s assume a 2-flute end mill and a chip load of 0.002 inches/tooth, at our calculated 6111 RPM:

Feed Rate = 0.002 × 2 × 6111 ≈ 24.4 IPM

You’ll likely want to use a feed rate that is a bit slower at the start, perhaps 15-20 IPM, and listen to the cut. If the cut sounds smooth and the chips look healthy, you can gradually increase it.

- Starting Conservative: For beginners, always start with the lowest recommended feed rate and gradually increase it as you gain confidence and assess the cutting action.

Depth of Cut (DOC) and Width of Cut (WOC)

These parameters determine how much material the end mill engages with on each pass.

Depth of Cut (DOC)

This is the axial depth the end mill cuts into the material.

- Axial Engagement: With an extra-long end mill and a 1/8 inch diameter especially, you’ll want to be conservative with the DOC to minimize deflection of the flutes. For roughing, aim for no more than 0.5 times the cutting diameter (0.06 inches or 1.5 mm). For finishing passes, it should be much shallower, often 0.01 to 0.02 inches (0.25 to 0.5 mm).

- Avoid Full Slotting if Possible: Machining a full slot where the end mill’s diameter is equal to the slot width (100% radial depth) puts a lot of stress on the tool. The 1/2 inch shank helps, but it’s still a significant engagement. If you need to create a slot wider than 1/8 inch, consider taking multiple shallow passes or using a “plunge” or “interpolate” motion where the tool moves sideways into the cut.

Width of Cut (WOC)

This is the radial depth the end mill engages the material, essentially how wide a step it takes when milling across a surface.

- For Slotting: If you are cutting a slot that is exactly 1/8 inch wide, your WOC is 100% of the cutting diameter.

- For Pocketing/Contouring: When milling pockets or contours, a common strategy is “step-over.” For cast iron, especially with a small end mill, a step-over of 20-40% of the cutting diameter (0.025 to 0.05 inches) is a good starting point. This distributes the cutting load and prevents the tool from being overwhelmed. Subsequent passes will gradually widen the pocket.

Tool Coatings

Many carbide end mills for cast iron come with specialized coatings. Common ones include:

- TiN (Titanium Nitride): A general-purpose coating that adds hardness and lubricity, extending tool life.

- TiCN (Titanium Carbonitride): Harder than TiN, offering better wear resistance, especially good for abrasive materials like cast iron.

- AlTiN (Aluminum Titanium Nitride): Resists high temperatures very well, making it excellent for harder materials and higher heat generation. It’s a popular choice for cast iron.

If your end mill has a coating, it’