A stub length carbide end mill is a fantastic, robust choice for working with tough Tool Steel A2, offering excellent stability and precision for achieving that coveted mirror finish with the right approach.

Working with Tool Steel A2 can feel a bit daunting, especially when you’re starting out. Its hardness is great for making durable parts, but it can really give standard cutting tools a tough time—or even break them! Many beginners find themselves frustrated by chatter, poor surface finish, or unexpected tool breakage. It’s a common hurdle, but with the right tools and techniques, it’s completely surmountable. This guide is going to walk you through exactly why a “genius stub” carbide end mill is your best friend for tackling A2 steel, and how to use it effectively. We’ll demystify the process, making it achievable and even enjoyable, leading you to that smooth, mirror-like finish you’re after, without the headaches.

Why Tool Steel A2 Demands Special Attention

Tool Steel A2 is a popular air-hardening tool steel known for its excellent toughness, wear resistance, and good machinability relative to other tool steels. However, “good machinability” for A2 still means it’s significantly harder and more abrasive than mild steels or aluminum. This hardness is precisely why it’s chosen for dies, punches, molds, and cutting tools—it holds an edge and resists deformation.

When you try to machine A2 with inadequate tooling or incorrect settings, you’ll quickly encounter problems like:

Premature Tool Wear: Softer steels or standard high-speed steel (HSS) end mills can dull rapidly, losing their cutting edge.

Chatter and Vibration: The force required to cut through A2 can cause vibrations, leading to a poor surface finish, inaccurate dimensions, and even tool breakage.

Heat Buildup: Abrasive materials generate more heat. Excessive heat can lead to tool failure or alter the temper of the workpiece.

Poor Surface Finish: Achieving a smooth, shiny finish can be incredibly difficult if the tool isn’t suited for the material or if cutting parameters are off.

Introducing the Stub Length Carbide End Mill: The A2 Hero

This is where the humble yet mighty stub length carbide end mill shines. Let’s break down why it’s such a perfect match for Tool Steel A2.

What is a Stub Length End Mill?

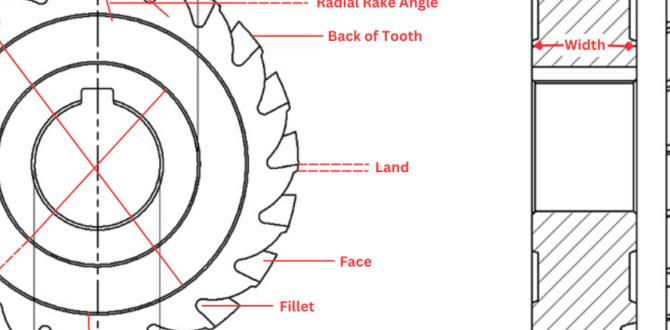

A stub length end mill is a type of end mill that has a shorter flute length and overall length compared to standard end mills or long reach end mills.

Why Carbide?

Carbide (specifically tungsten carbide) is a composite material that is exceptionally hard and wear-resistant. This makes it ideal for cutting harder materials.

Why Stub Length for A2?

The shorter flute length and overall rigid design of stub length end mills offer several critical advantages when machining tough materials like A2 steel:

Increased Rigidity: Less tool overhang means less deflection under cutting forces. This is crucial for maintaining accuracy and preventing chatter.

Reduced Vibration: The shorter, sturdier tool is less prone to vibrating, which directly translates to a better surface finish and longer tool life.

Higher Metal Removal Rates (with proper setup): While it might seem counterintuitive, the rigidity allows for more aggressive cutting parameters (feed and speed) when controlled properly, potentially leading to faster machining times.

Durability: Their robust construction makes them less susceptible to breakage, especially during demanding operations.

The “Genius Stub” Combination for A2

When you combine a carbide stub length end mill, particularly one designed with a specific geometry for steels and with appropriate coatings, you get a tool that’s engineered to conquer Tool Steel A2. For achieving that elusive mirror finish, you’ll often look for end mills with:

More flutes (e.g., 3, 4, or even 5 flutes vs. 2) for smoother cutting and better chip evacuation in harder materials.

Polished flutes to reduce friction and improve chip flow.

Specific geometries designed for steel, such as sharp corner radii and optimized helix angles.

SEO Focus Keywords:

`carbide end mill 1/8 inch shank stub length for tool steel a2`

`mirror finish tool steel A2 milling`

`best end mill for A2 steel beginner`

`stub length carbide end mill cutting parameters A2`

`small carbide end mill steel machining`

Choosing the Right 1/8-inch Shank Stub Length Carbide End Mill

When you’re starting out and targeting Tool Steel A2, making the right initial selection is key. For a 1/8-inch shank, you’re likely working on smaller projects or fine details, often on a benchtop CNC or a small manual mill.

Key Features to Look For:

Material: Solid Tungsten Carbide. This is non-negotiable for Tool Steel A2.

Geometry:

Number of Flutes: For A2, 3 or 4 flutes are a good balance. More flutes can provide a smoother finish but might require more power and better chip evacuation. 2-flute mills are often used for slotting.

Helix Angle: A standard helix angle (around 30 degrees) is a good all-rounder. Higher helix angles (like 45 degrees) can provide a smoother cut and better chip evacuation but might be less rigid on very small diameters.

Coatings: For A2, coatings like TiCN (Titanium Carbonitride) or AlTiN (Aluminum Titanium Nitride) can significantly improve performance by increasing hardness, reducing friction, and extending tool life. TiCN is often favoured for its added lubricity and wear resistance.

Corner Radius: A small corner radius (e.g., 0.010″ to 0.030″ for a 1/8″ end mill) helps to strengthen the corner of the tool, making it less prone to chipping, and can help control chip formation for a better finish.

Length: Stub length is critical. For a 1/8″ shank, a flute length of 1/4″ to 3/8″ and an overall length of 1.5″ to 2″ would be considered stubby and rigid. Always ensure your cutting depth doesn’t exceed your flute length and ideally keep the depth of cut much less than the flute length to maintain rigidity.

Brand Reputation: While not always a guarantee, reputable manufacturers often have better quality control and better-engineered designs.

Example Tool Specifications:

While specific part numbers vary by manufacturer, you might be looking for something described as:

“Solid Carbide End Mill, 1/8″ Diameter, 4 Flutes, 1/4″ Flute Length, 1.5″ Overall Length, TiCN Coated, Stub Length, for Steel.”

Always check the manufacturer’s specifications for suitability with hardened steels.

Understanding Cutting Parameters for A2 Steel

This is perhaps the trickiest part for beginners. Machining Tool Steel A2 requires slower speeds and feeds than softer metals. The goal is to allow the carbide to cut cleanly without chewing up the edge or generating excessive heat.

Here’s a general guideline table, but always remember these are starting points. Your specific machine rigidity, coolant usage, and exact end mill geometry can influence optimal settings. It’s always best to consult the end mill manufacturer’s recommendations if available.

General Cutting Parameters for 1/8″ Carbide Stub End Mill in Tool Steel A2

| Operation | Tool Diameter | Spindle Speed (RPM) | Feed Rate (IPM) | Depth of Cut (Axial) | Depth of Cut (Radial) | Notes |

| :————— | :———— | :—————— | :————– | :——————- | :——————– | :————————————————————————————————————————————————————– |

| Roughing | 1/8″ | 1500 – 2500 | 2 – 5 | 0.010″ – 0.020″ | 0.020″ – 0.050″ | Focus on chip evacuation. Use coolant. Moderate engagement. |

| Finishing | 1/8″ | 2000 – 3000 | 5 – 10 | 0.002″ – 0.005″ | 0.005″ – 0.010″ | Light cuts are key. Higher spindle speed, moderate feed. Aim for a smooth surface. Coolant is essential. |

| Slotting | 1/8″ | 1200 – 2000 | 1 – 3 | 0.010″ – 0.015″ | 0.125″ (full width) | Use 2-flute end mill if possible. Take multiple passes if slot is deep. Coolant is vital to clear chips and heat. |

| Contouring | 1/8″ | 2500 – 3500 | 5 – 10 | 0.002″ – 0.005″ | 0.020″ – 0.050″ | Moderate stepover. Maintain consistent feed rate. Focus on maintaining a thin chip load for a good finish. |

Important Considerations for Cutting Parameters:

Chip Load: This is the thickness of the material removed by each cutting edge. For A2 steel and small end mills, a starting chip load might be around 0.001″ to 0.002″ per tooth. You can calculate RPM and Feed Rate using this:

Feed Rate (IPM) = RPM × Number of Flutes × Chip Load per Tooth

Example: 2000 RPM × 4 Flutes × 0.0015″ Chip Load = 12 IPM

Surface Speed: Manufacturers often specify recommended surface speeds (SFM or SMM) for their end mills. You can convert this to RPM for your specific tool diameter:

RPM = (Surface Speed × 12) / (Tool Diameter in Inches)

For carbide in hardened steel, SFM might range from 50 to 150 SFM.

Coolant/Lubrication: Absolutely essential for A2. Flood coolant, a mist coolant, or even a high-quality cutting fluid applied directly to the cutting zone makes a massive difference in tool life, surface finish, and chip evacuation. For mirror finishes, a good quality synthetic coolant that leaves minimal residue is preferred.

Machine Rigidity: A sturdy machine will tolerate slightly more aggressive parameters. Flimsy machines will amplify vibrations, leading to chatter.

Air Cutting: Always perform a dry run with the spindle off to ensure your tool paths are correct and the tool doesn’t crash into anything.

Step-by-Step: Milling Tool Steel A2 with Your Carbide Stub End Mill

Let’s walk through a typical milling operation to get that mirror finish. For this example, let’s assume we’re finishing a pre-machined surface on A2.

Tools and Setup You’ll Need:

1. CNC Mill or Rigid Manual Mill: Essential for stability.

2. Carbide Stub Length End Mill (1/8″ shank): As discussed, with TiCN coating and 3-4 flutes.

3. Rigid Workholding: A good vise with hardened jaws, or custom fixturing. Ensure the workpiece is firmly clamped and won’t move.

4. Coolant System: Flood, mist, or a high-quality cutting fluid.

5. Workpiece: Tool Steel A2, preferably annealed if you’re doing extensive roughing. For finishing, it could be hardened.

6. Measurement Tools: Calipers, depth gauge, dial indicator for setup verification.

7. Safety Gear: Safety glasses are paramount! Gloves and apron are also recommended.

Step-by-Step Process:

-

Secure the Workpiece

Clamp your A2 steel securely in the milling machine vise. Ensure the surface you’re going to mill is accessible and presented correctly. A slight overhang on the vise jaws for support is good, but don’t let it be flimsy.

-

Install the End Mill

Insert the 1/8″ shank carbide stub end mill into a clean, high-quality collet. Ensure it’s seated firmly for maximum rigidity. An ER collet system is ideal for small diameter tools.

-

Set Up Your Machine Parameters

Based on the tables and notes above, carefully set your spindle speed and feed rate. Double-check your tool length offsets and work offsets. For finishing, we’ll aim for lighter chip loads and higher speeds than roughing.

Example Finishing Parameters:

- Spindle Speed: 2800 RPM

- Feed Rate: 8 IPM

- Chip Load per Tooth: ~0.001″ (8 IPM / 4 Flutes / 2800 RPM = ~0.0007″ – slightly conservative for a start)

- Depth of Cut (Axial): 0.003″

- Depth of Cut (Radial): 0.025″ (20% of tool diameter)

-

Apply Coolant

Turn on your coolant system. Ensure a good stream is directed right at the cutting zone. This will lubricate the cut, cool the tool and workpiece, and help wash away chips.

-

Begin the Finish Pass

Initiate the milling operation. Watch and listen to the machine. You should hear a consistent, smooth cutting sound. If you hear chattering, buzzing, or struggling, stop the machine immediately and review your parameters.

Avoid plunging directly into virgin material with a finishing pass if possible. If you need to start a new contour, ramp into the material or use a shallow entry angle if your CAM software supports it. For manual machines, a shallow helix or circular interpolation is best.

-

Observe Chip Formation

Good chip formation is a sign of successful machining. The chips should be small, consistent, and easily evacuated by the coolant. If they’re large, stringy, or gummy, your feed rate might be too low, or your chip load is too high for the speed. If they’re dusty and not forming chips, your speed might be too high relative to your feed.

-

Complete the Operation

Allow the machine to complete its programmed path. For a mirror finish, multiple light finishing passes (with potentially slightly different stepovers or spindle speeds) can sometimes yield better results than one aggressive pass.

-

Inspect and Clean

Once machining is complete, carefully inspect the surface. It should be smooth and reflective. Clean the workpiece thoroughly to remove any coolant residue and metal chips. The finish should be consistent across the entire milled area.

Troubleshooting Common Issues

Even with the right tools, occasional issues can arise. Here’s how to tackle them:

Chatter/Vibration:

Cause: Tool deflection, spindle imbalance, worn machine components, incorrect speeds/feeds, too deep of a cut.

Fixes: Reduce depth of cut (axial and radial), increase rigidity (if possible), verify tool is sharp and properly seated, try slightly different speeds (avoiding resonant frequencies), use coolant. For stub lengths, this is less common but still possible.

Poor Surface Finish (Scalloping, Roughness):

Cause: Tool wear, inadequate coolant, incorrect chip load, tool deflection, workpiece chatter.

Fixes: Ensure you’re using a sharp, high-quality end mill. Increase spindle speed slightly while maintaining a proper chip load. Use more effective coolant. Reduce depth of cut. Check for workpiece movement. For an exceptionally smooth finish, dedicated finishing passes with a very light depth of cut (0.001″ – 0.002″) are often required.

Tool Breakage:

Cause: Too aggressive feeds/speeds, plunging into material incorrectly, insufficient coolant, tool runout, workpiece hardness variation.

Fixes: Reduce depth of cut dramatically, slow down feed rates, ensure adequate coolant flow, check tool for damage before use, verify tool is runout-free in the collet. Never plunge a carbide end mill unless it’s specifically designed for it and you’re using very light depths.

Heat Buildup / Melting Chips:

Cause: Insufficient coolant, feed rate too high for the speed, dull tool, insufficient chip evacuation.

Fixes: Increase coolant flow and ensure it’s reaching the cutting edge. Reduce feed rate. Check and replace the tool if dull. Ensure chip valleys are clear.

Achieving That Mirror Finish

A true mirror finish isn’t just about the tool; it’s about the process. Here’s how to push your carbide stub end mill to its limit for that polished look:

1. Dedicated Finishing Pass: After your main milling operation, perform at least one, preferably two, very light finishing passes.

2. Light Depth of Cut: Aim for axial depths of 0.001″ to 0.003″. Radial depth of cut can be more generous (20-30% of diameter).

3.