Carbide end mills, especially those with a 1/8 inch 1/4 shank in standard length, are a fantastic solution to minimize deflection when machining tough Tool Steel D2. Choosing the right carbide end mill geometry, quality, and machining techniques will dramatically improve your results and reduce frustrating part distortion.

Ever tried to machine hardened Tool Steel D2 and found your cuts wandering? It’s a common frustration, especially when you’re just starting out with metalworking. This tough material can really push your tools and your patience. When your end mill starts to flex, or “deflect,” it leads to inaccurate cuts, rough surfaces, and even broken tools. The good news is, there’s a proven way to tackle this: using the right carbide end mill. In this guide, we’ll explore why tool steel D2 is so tricky and how a properly selected carbide end mill can be your secret weapon to achieve clean, precise cuts. Let’s get your milling projects back on track!

Understanding Tool Steel D2 and the Deflection Challenge

Tool Steel D2 is like the workhorse of hardened steels. It’s known for its exceptional hardness, excellent wear resistance, and good toughness. This makes it a popular choice for tools such as dies, punches, knives, and cutting tools. Think of anything that needs to hold a sharp edge or withstand constant abrasion – D2 is often in the mix.

However, all those great qualities come with a catch: D2 is notoriously difficult to machine, especially in its hardened state. It’s significantly harder than mild steels or aluminum, which means it demands more from your cutting tools and your milling machine setup. When you introduce a cutting force, D2 resists it strongly. This resistance is what causes deflection. Imagine trying to push a stiff spring – it bends, and then it tries to spring back. Your end mill does the same thing under pressure.

Why does deflection matter so much?

- Inaccurate Dimensions: When the tool deflects away from the desired path, your part ends up being the wrong size or shape. For precision parts, this means scrap.

- Poor Surface Finish: Deflection can cause chatter, leading to rough, uneven surfaces that are unpleasant to look at and often require extra finishing steps.

- Increased Tool Wear: The forces involved in fighting deflection can overload the cutting edges of your end mill, causing them to wear out faster or even chip.

- Tool Breakage: In severe cases, the stress on a deflected end mill can be too much, leading to a sudden and often spectacular breakage. This is not only costly but also dangerous.

For beginners, these issues can be incredibly discouraging. You’re trying to make something precise, and the material itself seems to be fighting you. The key to overcoming this is understanding that the cutting edge isn’t just removing material; it’s battling the material’s inherent resistance. The solution often lies in choosing a tool that’s designed to minimize this battle and the resulting flex.

Why Carbide End Mills are Your Best Bet for D2

When it comes to machining tough materials like D2, not all end mills are created equal. High-Speed Steel (HSS) is a common material for end mills, but for hardened steels, it often falls short. This is where carbide end mills shine.

The Advantages of Carbide

Carbide, specifically Tungsten Carbide, is a ceramic material known for its extreme hardness and rigidity. This translates into several key advantages for milling hardened steels:

- Superior Hardness: Carbide is significantly harder than HSS. This means it can cut through harder materials like D2 without easily dulling or deforming.

- Higher Rigidity: Carbide is less prone to flexing (deflecting) than HSS. This rigidity is crucial when trying to maintain accurate tool paths in tough materials, directly combating the D2 deflection problem.

- Higher Cutting Speeds and Feeds: Because carbide is harder and can withstand higher temperatures, you can often run your milling machine at faster speeds and deeper depths of cut compared to HSS. This can lead to faster machining times.

- Better Heat Resistance: Hardened steels generate a lot of heat during machining. Carbide holds its hardness at higher temperatures than HSS, allowing it to maintain its cutting ability.

While carbide tools are generally more expensive upfront than HSS, their longevity and superior performance on tough materials often make them more cost-effective in the long run, especially when you factor in reduced downtime, fewer broken tools, and improved part quality.

Selecting the Right Carbide End Mill: Key Features

Not all carbide end mills are identical. For tackling Tool Steel D2 and minimizing deflection, specific features are paramount. Think of it like picking the right tool for a delicate job – you need precision and strength.

Material and Coating

Carbide Grade: Look for micro-grain carbide. This is a denser, more uniform structure that offers the best balance of hardness and toughness for machining hardened steels. Lower-quality carbide might chip more easily.

Coatings: Coatings are thin, hard layers applied to the surface of the end mill to improve performance. For D2, consider:

- TiN (Titanium Nitride): A general-purpose coating that’s good for a wide range of materials, offering increased hardness and lubricity for better chip evacuation.

- TiAlN (Titanium Aluminum Nitride): Excellent for high-temperature applications and hardened steels like D2. It forms a protective oxide layer at high heat, further enhancing tool life and preventing built-up edge. This is often the go-to for D2.

- AlCrN (Aluminum Chromium Nitride): Similar to TiAlN, offering superior performance at very high temperatures and for demanding materials.

A TiAlN or AlCrN coating will significantly help your end mill survive the heat and abrasion generated when cutting D2.

Geometry Matters: Flutes and Helix Angle

The design of the cutting edges, or “flutes,” and their angle, or “helix,” significantly impact how an end mill cuts and how much it deflects.

-

- Number of Flutes:

- 2-Flute: These offer more chip clearance, which is beneficial for deep cuts and materials that produce long, stringy chips like some softer metals. However, for harder materials where rigidity is key, they might be more prone to vibration.

- 3-Flute: A good compromise for harder materials. They provide better rigidity than 2-flute and better chip evacuation than 4-flute. They are excellent for general-purpose slotting and profiling in steels.

- 4-Flute: These offer maximum rigidity and surface finish. They are often preferred for finishing passes and for materials that produce smaller, granular chips, which is common with hardened steels. The extra flute adds stiffness to the tool.

- Number of Flutes:

For D2, a 3-flute or 4-flute end mill is generally recommended for its superior rigidity.

-

- Helix Angle:

- High Helix (30-45 degrees): These end mills cut more aggressively and have better chip evacuation. They tend to produce a smoother cut and can reduce chatter. However, a very high helix can sometimes lead to more axial thrust, pushing the tool into the material axially.

- Standard Helix (30 degrees): A good all-around choice, balancing cutting action with rigidity.

- Low Helix (0-20 degrees) or Straight Flutes: Offer maximum rigidity but can be prone to chatter and have poorer chip evacuation. Usually not ideal for this application.

- Helix Angle:

A standard to slightly high helix angle (around 30-35 degrees) often provides a good balance for D2, allowing for efficient cutting while maintaining tool rigidity.

- Corner Radius: A corner radius (a small rounded edge on the tip of the end mill) adds significant strength to the cutting edge, making it less susceptible to chipping. For D2, incorporating a small corner radius is highly recommended. It helps to blunt any tendency for the edge to fracture under the high cutting forces.

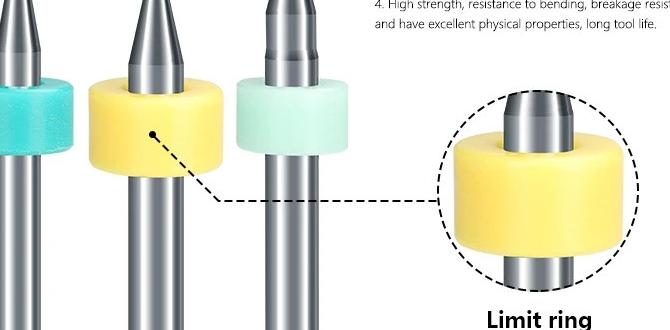

Shank and Length: The Impact on Rigidity

When deflection is your main enemy, the physical dimensions of the end mill play a huge role in its stiffness.

-

- Shank Diameter: This is straightforward: a larger diameter shank provides more stiffness. Commonly, you’ll see end mills with 1/4 inch or 1/2 inch shanks. For D2, if your machine’s collet chuck or tool holder can accommodate it, a larger shank is always better for rigidity. However, if you need to machine small features or work in tight spaces, you might be limited to smaller diameters.

- Tool Length: This is critical. An end mill sticking out a long way from its holder (a long “stick-out”) is inherently less rigid and much more prone to deflection. For D2, always aim for the shortest possible tool engagement length. If you need to cut a deep slot, consider using a shorter end mill and taking multiple passes at increasing depths rather than one deep pass with a long tool.

- Standard Length: These are the most common.

- Short Length (or Stub): Designed with a shorter flute length and often a longer shank. The shorter flute length protruding from the holder significantly increases rigidity.

- Extended Length: These have longer flute lengths for reaching deeper into parts. While useful for access, they are the most prone to deflection and should be used cautiously, if at all, on D2 with standard settings.

For D2, always choose a “standard” or, even better, a “short” or “stub” length end mill whenever geometry permits. Minimize your tool stick-out in the holder to gain maximum rigidity.

The Keyword Specifics: Carbide End Mill 1/8 Inch 1/4 Shank Standard Length for Tool Steel D2

Let’s break down the keyword “carbide end mill 1/8 inch 1/4 shank standard length for tool steel d2 minimize deflection” and see how it relates to our discussion:

- Carbide End Mill: We’ve covered why carbide is essential.

- 1/8 Inch: This refers to the diameter of the cutting flutes. A 1/8 inch end mill is quite small. For tough materials like D2, smaller diameter tools can sometimes be more challenging to keep rigid due to their smaller shank diameter. However, they are necessary for fine detail work. If you need a 1/8 inch diameter, prioritize a high-quality carbide with a good coating and minimize stick-out ruthlessly.

- 1/4 Shank: This is the diameter of the portion that goes into your collet or tool holder. A 1/4 inch shank is a common size. While a 1/2 inch or larger shank would offer more rigidity, a 1/4 inch shank, when paired with the right end mill features and machining practices, can still be effective for moderate cuts on D2.

- Standard Length: As discussed, this is the general length of the end mill. While “standard” is okay, remember that a “short” or “stub” length end mill would be even better for rigidity. If you must use a standard length, be extra diligent about keeping the tool rigidly supported in the collet.

- Tool Steel D2: The material we are targeting, known for its hardness and tendency to cause deflection.

- Minimize Deflection: The primary goal, achieved by selecting the right tool and machining parameters.

So, a “carbide end mill 1/8 inch 1/4 shank standard length for tool steel d2 minimize deflection” is a very specific request that highlights the need for a rigid tool with features optimized for cutting hardened materials, while acknowledging the limitations of smaller diameters and standard lengths that require careful application.

Recommended Carbide End Mill Specifications for D2

To make things clearer, here’s a table summarizing ideal specifications:

| Feature | Recommendation for D2 | Reasoning |

|---|---|---|

| Material | Micro-grain Tungsten Carbide | Highest hardness and wear resistance. |

| Coating | TiAlN or AlCrN recommended; TiN acceptable | Superior high-temperature performance and lubricity for hardened steels. |

| Diameter | As required by the feature; smaller diameters are more prone to deflection. | Determines the detail you can achieve. Use the largest diameter that fits the feature. |

| Shank Diameter | As large as your machine can accept (e.g., 1/2″ or larger preferred) | Maximizes rigidity. A 1/4″ shank is common but less rigid than larger sizes. |

| Length (Flute Length) | “Short” or “Stub” length preferred; “Standard” acceptable. Avoid “Extended”. | Minimizes tool stick-out for maximum rigidity. |

| Number of Flutes | 3 or 4 flutes | Greater rigidity and stability for tougher materials. |

| Helix Angle | 30-35 degrees (Standard to High) | Good balance of cutting action, chip evacuation, and rigidity. |

| Corner Radius | Small radius (e.g., 0.010″ – 0.030″ for 1/4″ dia, scaled for 1/8″) | Strengthens the cutting edge, prevents chipping. |

| End Type | Square or Ball nose with radius | Square for full slotting/profiling; Ball nose for complex contours. |

When shopping, look for end mills specifically marketed for “hard milling,” “die steels,” or “Tool Steel.” Reputable manufacturers will often detail the recommended applications for their tools.

Safe and Effective Machining Strategies for D2

Even with the perfect tool, how you use it is just as important. Safe and effective machining on D2 requires a methodical approach. Think of it as a dance between the tool, the material, and your machine.

Machine Rigidity and Setup

This is non-negotiable. Your milling machine, vise, workpiece, and the tool holder all need to be as rigid as possible.

- Machine Condition: Ensure your milling machine’s ways are well-lubricated and gibs are properly adjusted. A sloppy machine amplifies deflection.

- Vise/Workholding: Use a robust vise. Position it as close to the machine’s table ways as possible. Ensure the vise jaws are clean and the workpiece is seated firmly. Consider using a vise specifically designed for heavy-duty milling.

- Workpiece Clamping: Clamping force must be sufficient to prevent any movement during cutting. Use clamps or a vise that keeps the workpiece rigidly held. If possible, clamp on a non-critical surface or use parallels to raise the workpiece for better clamping leverage.

- Tool Holder Rigidity: Use a high-quality tool holder, like a shrink fit holder or a well-balanced ER collet chuck. Avoid flimsy set-screw holders if possible. Ensure the collet is the correct size and clean.

- Minimize Stick-Out: This is the single biggest factor you can control with your existing tools. Insert the end mill as far into the collet as possible without compromising cutting access. The less it sticks out, the stiffer it is. For a 1/4″ shank, aim to have at least 3/4 of the shank length engaged in a good ER collet.

Cutting Parameters: Speeds, Feeds, and Depth of Cut

These numbers are a starting point. Always consult manufacturer recommendations and be prepared to adjust based on your observations.

Speeds and Feeds for Hardened D2 (General Guidelines for Carbide):

Machining hardened D2 typically requires significantly slower surface speeds than softer materials. For a general-purpose carbide end mill (e.g., 1/4″ diameter, TiAlN coated, 3-4 flute), consider these starting points:

- Surface Speed (SFM): 100-200 SFM is a common range.

- Spindle Speed (RPM): Calculate based on your tool diameter.

RPM = (SFM 3.82) / Diameter (inches)

For a 1/4″ end mill at 150 SFM: RPM = (150 3.82) / 0.25 = 2292 RPM. Let’s round to 2300 RPM. - Feed Rate (IPT): Chip load is critical. For a 1/4″ 4-flute end mill, aim for a chip load of 0.001″ – 0.002″ per