A 1/8 inch carbide end mill is an excellent choice for precise and efficient aluminum cutting, especially on smaller parts or when deep pockets are needed. It offers good heat resistance and sharpness for clean finishes when used correctly.

Carbide End Mill 1/8 Inch: Proven Aluminum Cutting Power

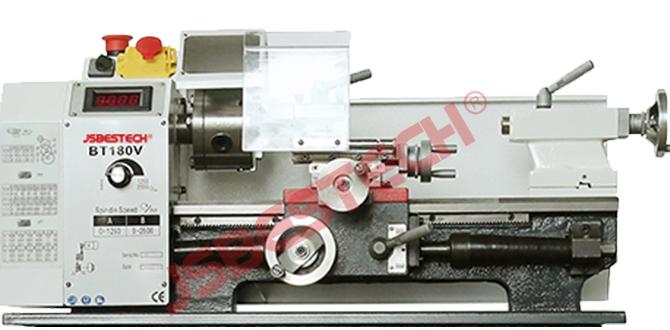

Hey everyone, Daniel Bates here from Lathe Hub! Ever found yourself staring at an aluminum project, wondering what tiny tool can tackle it with precision? The good news is, you don’t need a massive milling machine or a huge end mill to get fantastic results on aluminum. A 1/8 inch carbide end mill is a secret weapon for hobbyists and machinists alike. It’s perfect for those intricate cuts, small details, and tight spaces. Let’s dive into how this small but mighty tool can deliver some serious aluminum-cutting power for your projects.

The Mighty 1/8 Inch Carbide End Mill: Your Aluminum Ally

When you’re working with aluminum, especially on smaller projects or with limited machine capabilities, the 1/8 inch carbide end mill proves to be an invaluable tool. Its small diameter allows for intricate detailing and access to tight corners that larger tools simply can’t reach. Carbide, known for its hardness and heat resistance, makes it ideal for cutting softer metals like aluminum, maintaining its sharp edge longer and producing cleaner cuts.

For a project like creating small brackets, intricate designs, or even just cleaning up small features, this size is often perfect. You might see them specified with a 10mm shank, which means the shank (the part that goes into the collet or holder) is 10mm in diameter, while the cutting head is only 1/8 inch (about 3.175mm). This can be important for ensuring a secure fit in your milling machine’s collet system. When looking for the best performance with aluminum, you might also see terms like “high MRR” (Material Removal Rate), which means the tool is designed to efficiently hog out material, and “6061” which refers to a common and versatile grade of aluminum alloy often used in hobbyist and industrial applications.

Why Choose Carbide for Aluminum?

The choice of material for your cutting tool is crucial, and carbide stands out for aluminum machining for several key reasons:

- Hardness: Carbide is significantly harder than high-speed steel (HSS). This means it can withstand the forces involved in cutting aluminum without deforming or wearing down as quickly.

- Heat Resistance: Machining generates heat. Carbide can handle higher temperatures than HSS, which is important because aluminum can have a tendency to stick to the cutting tool if it gets too hot. Better heat resistance means a longer tool life.

- Edge Retention: Due to its hardness, carbide tools maintain a sharp cutting edge for much longer. This translates to more consistent cutting performance and cleaner finishes on your aluminum parts.

- Reduced Chipping: High-quality carbide end mills are less prone to chipping than some other tool materials, making them more reliable for precise work.

Understanding the “1/8 Inch” and “10mm Shank” Specification

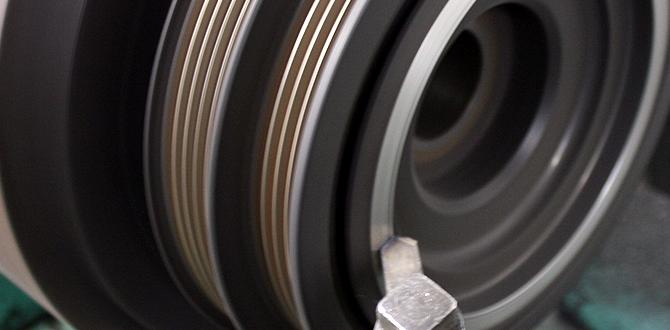

When you’re shopping for an end mill, you’ll see a lot of numbers and specifications. For our focus, “1/8 Inch” refers to the diameter of the cutting portion of the end mill. This is the part that actually removes material from your workpiece.

The “10mm shank” means the part of the end mill that grips into your milling machine’s collet or tool holder has a diameter of 10 millimeters. It’s vital that the shank size matches the collet you have available in your milling machine. A 1/8 inch end mill (which is approximately 3.175mm) will fit securely in a 10mm collet, but you need to ensure your machine’s collet system can accommodate this specific shank size. Most common milling machines will have collets that cover a range of sizes, so a 10mm shank is generally not an issue.

“Extra Long” for Deeper Reach

The term “extra long” in end mill descriptions refers to the overall length of the tool or, more importantly, the length of the cutting flutes (the spiraled grooves that cut the material). An extra-long 1/8 inch end mill will have a longer reach, allowing you to:

- Cut deeper pockets in your aluminum parts.

- Machine components with taller features.

- Access hard-to-reach areas within a workpiece.

However, longer tools can be more prone to vibration and deflection, especially at higher speeds or with aggressive cuts. For aluminum, with a capable milling machine and proper technique, an extra-long end mill can be a fantastic asset.

High MRR and 6061 Aluminum

High MRR (Material Removal Rate): This specification often indicates that the end mill is designed with a geometry (like fewer, wider flutes, or specific edge geometry) optimized for quickly removing a large volume of material. For aluminum, tools with geometries that help with chip evacuation (like polished flutes) often contribute to a higher MRR.

6061 Aluminum: This is one of the most popular aluminum alloys for machining. It’s known for its good strength, weldability, and excellent corrosion resistance. It machines well, but can sometimes be “gummy” or prone to sticking to cutting tools if not machined with the right parameters and tooling. A sharp carbide end mill designed for aluminum is perfect for this common and versatile alloy.

Essential Setup for Your 1/8 Inch Carbide End Mill

Before you even think about plunging that end mill into your aluminum, a proper setup is crucial. This ensures safety, precision, and the best possible finish.

Choosing the Right Collet and Holder

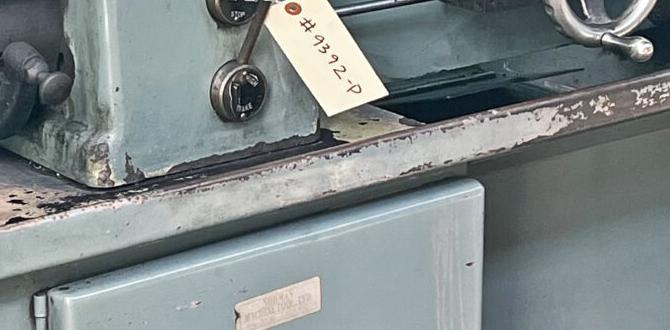

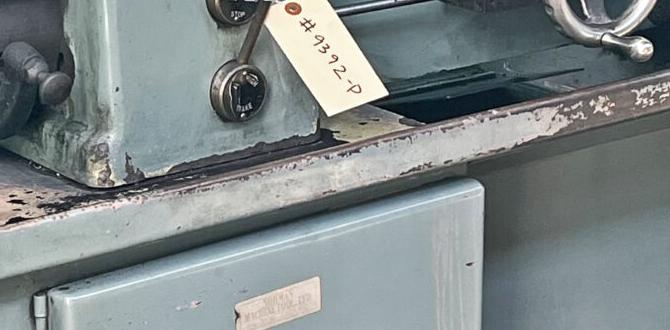

The collet is what holds your end mill securely in the milling machine spindle. For our 1/8 inch end mill with a 10mm shank, you’ll need a collet that can grip a 10mm shank. Ensure your collet is clean and free of debris. A well-fitting collet is vital for runout (wobble) prevention, which is critical for tool life and finish.

For smaller end mills, minimizing runout is key. This often means using a high-quality ER collet system. If your machine has an R8 spindle, you’ll use an R8 to ER collet chuck adapter, and then the appropriate ER collet.

Secure Workholding: The Foundation of Precision

This is non-negotiable. Your aluminum workpiece MUST be clamped down securely to your milling machine’s table. For a 1/8 inch end mill, you might be working on smaller parts, but even small parts can become projectiles if they come loose.

- Vise: A good quality milling vise is the most common and reliable method. Ensure the vise jaws are clean and have good grip.

- Clamps: For irregularly shaped parts or when a vise isn’t suitable, use clamp kits. These typically include T-nuts, studs, clamps, and washers. Always ensure clamps are positioned to provide solid support and don’t interfere with the cutting path.

- Fixturing: For repetitive parts, consider a custom fixture. This provides the most secure and repeatable method.

Never rely on just one point of contact or assume a part will stay put. Watch out for “workpiece lift” where the end mill can catch an edge and pull the part upwards if not clamped properly.

Setting the Z-Axis Zero

Accurately setting your Z-axis zero is how the machine knows where “zero depth” is. This is often done using a tool presetter, an edge finder, or by carefully jogging the spindle down to touch the top surface of your workpiece.

For softer materials like aluminum, a manual Z-axis setter or even a piece of paper can work. You jog the spindle down until the paper just starts to drag or tear. Then, set your Z-axis to zero. Some CNC machines have probes for this, but for smaller machines, manual methods are common.

Machining Aluminum with Your 1/8 Inch End Mill: The How-To

Now for the exciting part – cutting! Aluminum can be a dream to machine or a sticky nightmare, depending on your approach. Here’s how to get it right with your 1/8 inch carbide end mill.

Recommended Speeds and Feeds for Aluminum

Speeds and feeds are the two most critical parameters for successful machining. Get them wrong, and you’ll break tools, ruin finishes, or get that dreaded aluminum buildup on your end mill.

- Spindle Speed (RPM): For a 1/8 inch carbide end mill in aluminum, a common starting point is between 10,000 and 25,000 RPM. Higher speeds are generally better for aluminum, as they help whisk away chips quickly and reduce heat buildup.

- Feed Rate (IPM or mm/min): This is how fast the tool moves into the material. For a 1/8 inch carbide end mill, a good starting range is between 10 and 30 IPM (inches per minute), or roughly 250 to 750 mm/min. Lighter cuts generally benefit from higher feed rates to avoid rubbing and instead engage the cutting edge.

Important Note: These are starting points! The exact speeds and feeds will depend on factors like the specific alloy of aluminum, the depth of cut, the width of cut, the rigidity of your machine, and the specific geometry of your end mill. Always consult the end mill manufacturer’s recommendations if available. For example, the Metcut Company provides valuable resources on machining speeds and feeds for various materials.

Depth and Width of Cut Recommendations

When machining aluminum, especially with a small end mill, it’s generally best to use lighter cuts to prevent tool breakage and ensure a good finish. This is often referred to as “climb milling” versus “conventional milling.” For aluminum, climb milling is usually preferred.

- Axial Depth of Cut (DOC): How deep the end mill cuts along its length. For a 1/8 inch end mill in aluminum, start with an axial DOC of 0.010″ to 0.050″ (0.25mm to 1.27mm). You can often go deeper once you see how the machine is handling it.

- Radial Depth of Cut (WOC): How much of the end mill’s diameter is engaged in the cut (width of cut). Aim for a WOC of 0.010″ to 0.040″ (0.25mm to 1mm) if you’re slotting (cutting a full-width groove). If you are profiling around an edge, you can often take a wider cut. Lighter radial cuts are crucial when slotting to avoid excessive force.</li

Coolant and Lubrication: Keeping Aluminum Happy

Aluminum has a tendency to stick to cutting tools. Lubrication, and sometimes coolant, is key to preventing this. For small-scale hobbyist work, a spray mist of cutting fluid or even a light oil can make a huge difference.

- Cutting Fluid: Specifically designed for machining, these provide lubrication and cooling. A mist system is ideal for small mills.

- Lubricants: For manual milling or very light cuts, a dab of high-quality cutting wax or aluminum-specific cutting fluid applied to the tool or workpiece can help.

- Air Blast: A stream of compressed air can help clear chips and cool the cutting zone.

Avoid using water-based coolants without rust inhibitors on aluminum, as it can cause corrosion.

Common Cutting Strategies with a 1/8 Inch End Mill

- Slotting: Cutting a groove that is the full diameter of the end mill. Requires careful chip evacuation and often lighter radial cuts.

- Pocketing: Removing material from an area to create a recessed shape. This can involve multiple passes, spiraling in or plunging down to rough out the pocket before finishing.

- Profiling/Contouring: Cutting around the outside or inside profile of a shape. This is where a smaller end mill shines for intricate shapes.

- Drilling (with caution): Some end mills can be used to plunge straight down to create a hole, especially with specialized “plunge end mills.” However, standard end mills are not ideal for true drilling and can be damaged if plunged too aggressively without proper chip breaking.

Step-by-Step Example: Cutting a Small Pocket

Let’s say you want to cut a 0.5 inch by 0.5 inch pocket that is 0.1 inches deep in a piece of 6061 aluminum.

- Secure Workpiece: Clamp your aluminum block firmly in the milling vise.

- Install End Mill: Insert your 1/8 inch, 10mm shank carbide end mill into the collet, ensuring it’s seated properly. Tighten the collet.

- Set Z-Axis Zero: Jog the spindle down to the top surface of the aluminum and set your Z-axis to zero.

- Set X/Y Zero: Using an edge finder or by jogging, find the corner of where you want your pocket and set your X and Y zeros.

- Program or Manually Control:

- If using CNC, program your toolpath. You might choose a spiral-in approach from the center of the pocket, moving radially outwards, or a plunging move followed by a conventional path.

- If manual milling, you’ll carefully jog the machine. For a small pocket, you might plunge the tool straight down (at a slow feed rate, or at an angle if possible) to a depth of 0.1 inches. Then, move the X or Y axis to rough out the pocket shape, making multiple passes.

- Apply Lubrication: Use a mist coolant or apply cutting fluid as you machine.

- Cut at Recommended Speeds/Feeds: Start with conservative speeds and feeds (e.g., 15,000 RPM, 15 IPM, 0.040″ axial DOC, 0.020″ radial DOC when spiraling).

- Make Finishing Pass: Once the bulk of the material is removed, make a final pass with a very light depth of cut (e.g., 0.002″ – 0.005″) to achieve a nice surface finish.

- Clean Up: Carefully remove the workpiece and clean the pocket.

Troubleshooting Common Issues

Even with the right tools, problems can arise. Here’s how to tackle them:

- Aluminum Buildup (Galling): If aluminum starts sticking to your end mill, it’s a sign of too much heat or not enough lubrication. Slow down your feed rate slightly, increase spindle speed if possible, ensure adequate coolant/lubrication, and clean the tool. A tool specifically designed for aluminum with polished flutes can help immensely.

- Tool Breakage: This is usually due to taking too aggressive of a cut (too deep or too wide), feeding too slowly (rubbing instead of cutting), dull tooling, improper tool seating, or a weak work holding. Always err on the side of lighter cuts, especially with small end mills.

- Poor Surface Finish: Can be caused by dull tooling, excessive runout, incorrect speeds/feeds (often too slow of a feed for the spindle speed), or vibration. A finishing pass with a very light depth of cut usually cleans up a subpar finish.

Maintaining Your Carbide End Mill

Even carbide isn’t indestructible. Proper care ensures longevity and performance.

- Cleaning: After each use, clean the end mill thoroughly. Use a brass brush and a solvent to remove any aluminum residue and cutting fluid.

- Inspection: Periodically check the cutting edges for wear, chipping, or signs of excessive heat. A worn or damaged tool will compromise your cuts and lead to future problems.

- Storage: Store end mills in a protective case or holder to prevent accidental damage to the cutting edges.

When to Consider Other End Mill Types for Aluminum

While carbide is fantastic, sometimes other types of end mills have their place, or are even preferred for specific tasks or machines:

| End Mill Type | Pros for Aluminum | Cons for Aluminum | When to Use |

|---|---|---|---|

| High-Speed Steel (HSS) Single Flute |

Good chip evacuation (single flute), less prone to chipping on impact than typical multi-flute carbide, good for hand-held routers. | Wears out much faster than carbide, cannot handle high speeds and heat, dulls quickly. | Very large, soft aluminum workpieces where rigidity is low and chip evacuation is paramount, hand routers, specific low-speed applications. |

| Carbide Multiple Flutes (2, 3, 4) |

Excellent edge retention, good heat

|