A 1/8 inch carbide end mill is an exceptional tool for machining titanium due to its hardness, heat resistance, and precision, making it ideal for detailed and tough materials.

Machining titanium can feel like wrestling a particularly stubborn beast. It’s incredibly strong, notoriously tough to cut, and likes to generate a lot of heat. Many beginners, and even some experienced machinists, shy away from it. But what if there was a small tool that could make a big difference, especially for intricate work? That’s where the 1/8 inch carbide end mill shines. It’s not just a tiny cutting tool; it’s a precision instrument designed to tackle the challenges of materials like Titanium Grade 5. We’ll explore why this specific tool is such a brilliant solution, what to look for when buying one, and how to use it safely and effectively. Get ready to unlock your mill’s potential for working with this amazing metal!

Why Titanium is a Machining Challenge

Titanium might be lightweight and incredibly strong, but these beneficial properties make it a real headache for machinists. It has a high tensile strength, meaning it resists deformation. It also has a low thermal conductivity, which causes heat to build up rapidly at the cutting edge. This heat can quickly dull conventional tools and lead to poor surface finishes. Furthermore, titanium has a tendency to “work harden,” becoming even tougher the more you try to cut it. These factors combined mean that choosing the right cutting tool isn’t just a preference; it’s a necessity for successful machining.

The 1/8 Inch Carbide End Mill: A Titanium’s Nemesis

So, why is a small 1/8 inch carbide end mill the “genius solution” for titanium? It boils down to a few key advantages:

- Material Hardness: Carbide, particularly tungsten carbide, is significantly harder than the tool steels used for many conventional end mills. This hardness allows it to cut through tough materials like titanium without becoming dull quickly.

- Heat Resistance: Titanium machining generates a lot of heat. Carbide can withstand much higher temperatures than high-speed steel (HSS) before losing its temper or structural integrity. This is crucial for consistent cutting and tool life in titanium.

- Precision and Detail: A 1/8 inch diameter is perfect for detailed work, intricate cuts, engraving, or creating small features. This is often where titanium is used – in applications requiring both strength and fine form, like aerospace components or medical implants.

- Chip Load Management: The smaller diameter allows for finer chip loads. This means you’re removing less material with each pass, which is gentler on the tool and the workpiece. It also helps manage the heat by not creating excessively large chips that can clog flutes.

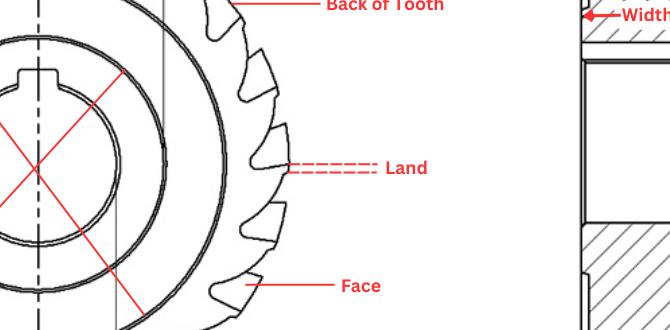

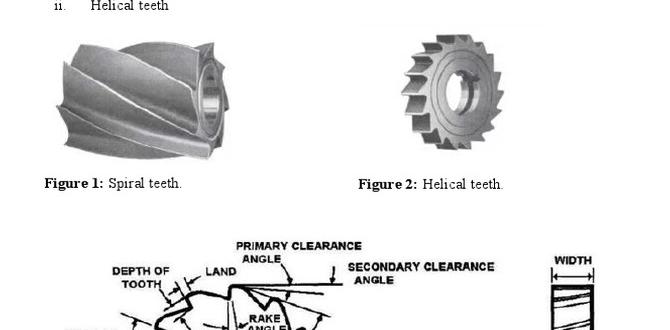

- Optimized for Toughness: Many 1/8 inch carbide end mills designed for titanium have specific flute geometries (like ball-nose or square-end with specific corner radii) and coatings that are engineered to handle the gummy nature of titanium and prevent chip welding.

Key Features to Look For in a 1/8 Inch Carbide End Mill for Titanium

Not all 1/8 inch carbide end mills are created equal, especially when it comes to titanium. Here are the critical features to consider:

Material Grade and Geometry

When machining titanium, you’ll want a solid carbide end mill. HSS tools simply won’t cut it. Look for:

- Uncoated Solid Carbide: For many titanium applications, especially at the beginner level or for general-purpose work, uncoated solid carbide is a reliable choice. It offers excellent hardness and heat resistance.

- Coated Carbide: For more demanding applications or pushing speeds and feeds, coatings like TiAlN (Titanium Aluminum Nitride) can offer additional heat resistance and lubricity, further reducing friction and preventing chip buildup. However, for beginners, an uncoated tool might be more forgiving.

- Flute Count: 2-flute or 4-flute end mills are common.

- 2-Flute: Generally preferred for roughing and pocketing in softer, gummy materials like titanium. They offer better chip evacuation due to larger flute volumes.

- 4-Flute: Can be used for finishing or in harder materials where chip load per tooth needs to be reduced, but for titanium, 2-flute is often the go-to for its chip clearing capabilities.

- Corner Radius: A slight corner radius (e.g., 0.010″ or 0.020″) can significantly improve tool life and surface finish in titanium. It distributes stress at the bottom of the cut, preventing chipping and reducing the likelihood of work hardening. A square-end mill can work, but a corner radius is often more forgiving.

Shank and Length

These details are vital for rigidity and reach.

- 10mm Shank: A 10mm shank provides a good balance of rigidity and compatibility with many milling machine collet systems. It’s a common size that offers a sturdy connection without being excessively large for a 1/8″ tool.

- Extra Long / Extended Reach: Sometimes, you might need an “extra long” or “extended reach” version. This refers to the overall length of the tool and the length of the cutting flutes. For titanium, more flute length can be beneficial for entering deeper pockets, but it also reduces rigidity. For a 1/8″ diameter, a standard length is usually sufficient for most beginner tasks, striking a balance between reach and stiffness. Prioritize rigidity for titanium – a long, thin end mill can easily deflect.

Runout and Precision

This is where quality truly matters.

- Low Runout: Runout is the deviation of the tool’s axis of rotation from its geometric axis. High runout means the tool doesn’t spin perfectly true. For titanium, low runout is critical. It ensures a consistent cut, prevents chatter, and prolongs tool life. Look for tools with a specified low runout, often measured in T.I.R. (Total Indicator Reading), ideally less than 0.0005 inches.

- High-Quality Carbide: The density and grain size of the carbide matter. Finer grain carbides are harder and more wear-resistant.

Understanding “Titanium Grade 5”

When you see “Titanium Grade 5,” it’s not just a label; it refers to a specific alloy. Grade 5, also known as Ti-6Al-4V, is the most common and versatile titanium alloy. It contains approximately 6% aluminum and 4% vanadium. This alloy offers an excellent combination of high strength, good corrosion resistance, and weldability, making it popular in aerospace, medical, and high-performance sporting goods. However, its mechanical properties also make it one of the more challenging titanium grades to machine.

Step-by-Step Guide: Machining Titanium with a 1/8 Inch Carbide End Mill

Machining titanium requires a different approach than softer metals like aluminum or mild steel. Here’s how to do it safely and effectively with your 1/8 inch carbide end mill:

Step 1: Preparation is Key

Before you even turn on the machine, proper setup is crucial.

- Secure Fixturing: Titanium can exert significant forces on the workpiece. Ensure your part is clamped extremely securely. Use appropriate workholding like a sturdy vise or custom fixtures. Avoid setups that allow any movement.

- Rigid Machine Setup: Make sure your milling machine is in good condition. A sturdy machine with minimal play in the axes is essential. Check your collets and ensure they are clean and provide a tight grip on the end mill shank.

- Coolant/Lubricant: Titanium generates intense heat. A good coolant or cutting fluid specifically designed for titanium is not optional; it’s mandatory. This reduces friction, prevents tool welding, and helps carry chips away. Flood coolant systems are ideal, but even a good quality spray or mist system can help. Look for specialized titanium cutting fluids.

Step 2: Setting Speeds and Feeds

This is where many beginners struggle. Titanium requires slower speeds and more aggressive feeds than softer metals. Overly high speeds will overheat and quickly destroy your carbide end mill.

General Starting Points for 1/8″ Carbide End Mill in Titanium Grade 5:

These are just starting points and will need to be adjusted based on your specific machine, coolant delivery, and the exact end mill. Always err on the side of caution!

| Operation | Spindle Speed (RPM) | Feed Rate (IPM) | Depth of Cut (Doc) | Width of Cut (Woc) |

|---|---|---|---|---|

| Roughing/Pocketing (2-flute) | 2000 – 4000 | 0.001″ – 0.003″ per tooth (so 4-12 IPM for 2 flutes) | 0.020″ – 0.050″ | 50% of tool diameter (approx. 0.060″) |

| Finishing (2 or 4-flute, light cut) | 3000 – 5000 | 0.0005″ – 0.0015″ per tooth (so 1-6 IPM for 4 flutes) | 0.005″ – 0.010″ | 25% of tool diameter (approx. 0.030″) |

Important Notes on Speeds and Feeds:

- Start slow and listen: Always start with conservative speeds and feeds. Listen to the machine. A harsh, chattering sound is a warning that something is wrong.

- Chip load per tooth: This value (e.g., 0.001″ per tooth) is more important than the absolute feed rate. Multiply it by the number of flutes to get your IPM.

- Depth of Cut (Doc): Use a shallow depth of cut initially. For full-depth cuts in titanium, you’ll often need a robust machine and a very conservative approach.

- Width of Cut (Woc): For pocketing, aim for a radial depth of cut of about 50% of the tool diameter. For finishing passes, keep it much lighter (25% or less).

- Machine Rigidity: A less rigid machine will require slower speeds and lighter cuts.

- Tooling Quality: Higher quality end mills with better geometry can tolerate more aggressive parameters.

For precise guidance, consult resources from reputable tooling manufacturers. For example, Sandvik Coromant and Kennametal offer extensive machining data for various materials and tools. You can often find downloadable catalogs or online tools on their websites.

Step 3: The Cutting Process

With everything set up and parameters dialed in, it’s time to cut.

- Engage Slowly: Start the spindle and then engage the feed slowly.

- Observe Chip Formation: Aim for small, uniformly shaped chips. Light, wispy chips can indicate a too-low feed rate or too shallow a depth of cut. Heavy, stringy, or galling chips mean you’re likely running too fast or not using enough coolant.

- Pecking When Necessary: For deep pockets, consider using a pecking cycle. This involves drilling down a short distance, retracting to clear chips and allow coolant flow, and then continuing.

- Avoid Dwelling: Once the cut is complete, retract the tool quickly. Don’t let the tool dwell in the cut, as this can lead to overheating.

- Maintain Coolant Flow: Ensure coolant is constantly bathing the cutting area.

Step 4: Post-Machining Checks

After the cut, take a moment to assess.

- Cool Down: Let the workpiece and tool cool down before handling or measuring.

- Inspect the Tool: Check the end mill for signs of wear, chipping, or material buildup.

- Examine the Surface Finish: Assess the quality of the machined surface. Are there any signs of tearing, burning, or chatter?

- Clean Up: Thoroughly clean the machine and workpiece to prevent swarf from causing issues in subsequent operations.

Common Pitfalls and How to Avoid Them

Machining titanium is challenging, and mistakes are common. Here’s how to navigate them:

- Overheating: The most common problem. Solution: Ensure adequate coolant, slower speeds, and appropriate feed rates. Never let the tool rub without cutting.

- Chip Welding (Galling): Titanium chips can stick to the cutting edge, effectively making the tool larger and duller, leading to poor finish and tool breakage. Solution: Proper feed rates and chip load per tooth are crucial. Chip load that is too low causes the tool to “rub” rather than cut cleanly. Good chip evacuation is key – use appropriate flute count and peck drilling cycles if needed.

- Tool Breakage: Often caused by chatter, interrupted cuts, or trying to take too aggressive a cut. Solution: Ensure rigid fixturing and machine setup. Use a slight corner radius on the end mill. Program with smooth toolpaths and avoid abrupt changes in direction.

- Work Hardening: Titanium becomes harder as it’s machined. Solution: Maintain consistent cutting action with adequate chip load and avoid allowing the tool to rub or dwell.

- Choosing the Wrong Tool: Using an HSS end mill or a carbide end mill not designed for titanium. Solution: Invest in a good quality solid carbide end mill, preferably with a geometry suited for titanium.

When Might You Need an “Extra Long” or Specific Flute Count?

While a standard 1/8 inch carbide end mill is often sufficient, there are times when specific configurations become more important:

Extra Long Reach

An extra-long end mill provides greater Z-axis reach. This is useful for:

- Machining deep pockets or slots where a standard length tool cannot reach.

- Accessing features on complex 3D parts.

Caveat: Longer tools are inherently less rigid. For titanium, the extra length increases the risk of deflection and vibration. You will need to significantly reduce your speeds and feeds, and potentially depth of cut, to maintain stability. For a 1/8″ tool, this also means a very light chip load per tooth to avoid snapping the tool. Unless absolutely necessary for reach, a standard length tool offers far greater rigidity, which is paramount for titanium.

Flute Count (2 vs. 4)

As mentioned, for titanium, the 2-flute end mill is generally preferred for most operations, especially pocketing and roughing.

- 2-Flute: Offers larger chip gullets, allowing for better chip evacuation. This is critical for sticky materials like titanium, as clearing chips helps prevent heat buildup and chip welding. They also allow for a higher chip load per tooth at a given feed rate.

- 4-Flute: While great for harder steels or finishing operations in softer metals, they can be problematic in titanium for general milling. The smaller chip gullets can lead to poor chip evacuation, and it can be harder to achieve an adequate chip load per tooth without overloading the tool in softer, gummy materials. However, a 4-flute end mill can be used for light finishing passes where a very fine surface finish is required, using very conservative parameters. Your 1/8 inch carbide end mill with 2 flutes is likely your best bet for starting out.

Benefits of Low Runout

We touched on this, but it’s worth reiterating. Low runout in your end mill, and in your collet holder, is crucial for titanium because:

- Consistent Cutting Action: The tool cuts evenly, reducing stress on the cutting edges.

- Reduced Vibration and Chatter: A tool that spins perfectly true minimizes vibration, leading to better surface finish and preventing tool damage.

- Maximized Tool Life: When every cutting edge engages the material correctly, the load is distributed evenly, and the tool lasts much longer.

- Improved Surface Finish: Less wobble means a smoother, cleaner cut surface, a vital aspect when working with materials valued for their aesthetic and functional finish.

A Note on Specific Coatings

While uncoated carbide is a strong contender for beginners, some coatings can further enhance performance in titanium:

- TiAlN (Titanium Aluminum Nitride): This dark, iridescent coating is excellent for high-temperature applications. It forms a protective oxide layer at elevated temperatures, further increasing heat resistance and reducing friction. It’s a great choice for more aggressive machining of titanium, but ensure you have robust coolant delivery, as it relies on heat for its effectiveness.

- ZrN (Zirconium Nitride): Offers good lubricity and is good for general-purpose machining, including titanium. It’s often a slightly more forgiving coating than TiAlN for those less experienced with precise coolant control.