Carbide end mills are essential for machining hardened steel because their superior hardness and heat resistance allow them to cut through tough materials that would quickly dull or break conventional tool bits. Mastering their use unlocks precise and efficient machining of hardened steel parts.

Have you ever tried to machine hardened steel and ended up with a dull, smoking tool bit and a workpiece that’s barely scratched? It’s a common frustration for many hobbyists and aspiring machinists. Working with hardened steel can feel like trying to cut metal with a butter knife using the wrong tools. But don’t let that stop you! There’s a specialized tool that makes machining this tough material not just possible, but surprisingly efficient: the carbide end mill.

Think of it this way: regular high-speed steel (HSS) tools are great for softer metals, but hardened steel is on a whole other level of toughness. You need something that can stand up to the heat and wear generated. That’s where carbide comes in. In this guide, we’ll explore exactly why a carbide end mill is your best friend when it comes to tackling hardened steel, covering what makes them special, how to choose the right one, and the essential techniques for using them safely and effectively. Get ready to conquer that hardened steel!

Why Carbide End Mills Rule for Hardened Steel

Hardened steel is, well, hard. It’s been treated to become significantly tougher and more resistant to deformation. This makes it ideal for tools, wear parts, and other applications where strength is paramount. But for a machinist, that toughness presents a challenge. Traditional high-speed steel (HSS) cutting tools, while versatile, simply can’t handle the abrasive wear and high temperatures generated when trying to cut hardened steel. They will dull quickly, leading to poor surface finish, increased heat, and potential damage to your workpiece and machine.

The Magic of Carbide

Carbide, specifically tungsten carbide, is a ceramic material renowned for its extreme hardness and high melting point. When formed into an end mill, these properties translate directly into superior cutting performance on tough materials like hardened steel.

Here’s a breakdown of why carbide shines:

Unmatched Hardness: Tungsten carbide is one of the hardest carbides used in machining. This means it can maintain its sharp cutting edge even when encountering the extreme hardness of treated steel.

High Heat Resistance: Machining generates friction, and friction generates heat. Carbide can withstand much higher temperatures than HSS without softening or losing its temper. This is critical for extended cutting operations.

Rigidity: Carbide is a brittle material, but it’s also very rigid. This rigidity helps prevent the tool from deforming or vibrating excessively, leading to more accurate cuts and better surface finishes.

Wear Resistance: The inherent hardness of carbide translates to excellent resistance to abrasive wear. This means a carbide end mill will last significantly longer when cutting hardened steel compared to an HSS tool.

For these reasons, using a carbide end mill, especially one designed with specific geometries for hardened steel (like those with higher helix angles or specific coatings), is not just recommended—it’s practically a necessity for efficient and successful machining of materials like HRC60 steel.

Choosing the Right Carbide End Mill for Hardened Steel

Not all carbide end mills are created equal, especially when you’re targeting hardened steel. Several factors come into play to ensure you have the right tool for the job.

Material Hardness Matters (HRC Ratings)

Hardened steel is typically measured on the Rockwell C scale (HRC). Common grades might range from HRC 50 to HRC 60 or even higher.

HRC 50-55: This range is often considered “medium” hardened steel. Many general-purpose carbide end mills can handle this, but specialized ones will still offer better longevity and efficiency.

HRC 55-60: This is where things get serious. You absolutely need a carbide end mill specifically designed for hardened steel. Look for tools marketed for this range.

Above HRC 60: Machining steel this hard is advanced territory. You’ll need specialized end mills, often with very specific geometries, coatings, and advanced machining strategies.

End Mill Geometry and Features

The design of the end mill itself plays a huge role. For hardened steel, you’ll want to look for:

Higher Helix Angles: A steeper helix angle (30-45 degrees is common) provides better chip evacuation and can reduce cutting forces, which is beneficial for harder materials.

More Flutes: While 2-flute end mills are good for slotting and plunging in softer materials, 4-flute or even 5-6 flute end mills are often preferred for hardened steel in general milling. More flutes mean more cutting edges engaging the material, leading to a smoother finish and better MRR (Material Removal Rate) when used with appropriate parameters.

Corner Radii/Chamfers: A small corner radius helps to strengthen the cutting edge and prevent chipping. Some end mills for hardened steel have a slight chamfer on the cutting edge instead of a sharp corner for added durability.

Center Cutting vs. Non-Center Cutting: For plunging operations (drilling a hole), you’ll need a center-cutting end mill. For general milling, either can work, but center-cutting is more versatile.

Coatings: Specialized coatings can significantly improve performance.

TiAlN (Titanium Aluminum Nitride): Excellent for high-temperature applications and works well on hardened steels and exotic alloys. It forms a protective aluminum oxide layer at high temperatures.

AlTiN (Aluminum Titanium Nitride): Similar to TiAlN but can offer even higher temperature resistance.

ZrN (Zirconium Nitride): Can provide good lubricity and wear resistance, useful for certain hardened steels.

Length and Shank Diameter

Common shank diameters include 1/8 inch, 1/4 inch, 3/8 inch, 1/2 inch, and metric sizes like 6mm, 8mm, 10mm, 12mm.

1/8 inch shank: Often found on very small end mills, useful for intricate detail work. They are less rigid than larger shanks.

10mm shank: A common metric size, offering a balance of rigidity and tool size.

Extra Long: For hardened steel, you generally want to avoid “extra long” or “extended reach” end mills unless absolutely necessary. The longer the tool, the more it can deflect, leading to inaccuracy and chatter, especially in hard materials. Shorter, more rigid tools are preferred for machining hardened steel.

Example Product Configuration

When looking for a carbide end mill for hardened steel, you might see specifications like:

“Carbide End Mill, 1/4 inch diameter, 4 Flutes, TiAlN Coated, 1/4 inch Shank, General Purpose”

For hardened steel, you’d refine this to something like:

“Carbide End Mill, 1/4 inch diameter, 4 Flutes, TiAlN Coated, 1/4 inch Shank, for Hardened Steel up to HRC 60”

Or, considering your keyword:

“Carbide End Mill, 1/8 inch diameter, 4 Flutes, TiAlN Coated, 6mm Shank, for Hardened Steel up to HRC 60, High MRR”

This refined selection prioritizes the material, hardness, coating, and flute count suitable for the tough job.

Setting Up Your Machine for Success

Before you even think about touching that hardened steel with your new carbide end mill, proper machine setup and workpiece preparation are crucial. This isn’t just about safety; it’s about ensuring accuracy and tool longevity.

Workholding is Key

Hardened steel can be unforgiving if it moves during machining. Secure your workpiece with robust workholding solutions.

Vises: A sturdy machinist vise is essential. Ensure the vise jaws are clean and provide good surface contact. For extra security, consider using parallels or a vise stop.

Clamps: If your workpiece is irregular, custom fixtures or strap clamps might be necessary. Make sure clamps do not interfere with the cutting tool’s path.

Cleanliness: Any debris or oil between the workpiece and your fixture can lead to movement and inaccuracies. Thoroughly clean all surfaces.

Machine Rigidity and Precision

Your milling machine needs to be in good shape.

Backlash: Minimize any backlash in your machine’s lead screws or ball screws. Excessive backlash can cause chatter and poor surface finish.

Spindle Bearings: Ensure your spindle bearings are in good condition and properly preloaded. A sloppy spindle can ruin a precision cut.

Tool Holder: Use a high-quality tool holder, such as a collet chuck or an ER collet system. These provide superior runout accuracy and gripping force compared to a basic end mill holder, which is vital when working with carbide. A clean tool holder and a clean shank on the end mill are non-negotiable for good runout.

Coolant or Lubrication

Machining hardened steel generates significant heat. While some carbide end mills are designed for dry machining, using a coolant or lubricant is highly recommended for several reasons:

Heat Dissipation: It cools the cutting edge, preventing premature wear and reducing the risk of thermal shock to both the tool and the workpiece.

Lubrication: It reduces friction between the cutting edge and the workpiece, leading to a smoother cut and better surface finish.

Chip Evacuation: It helps to flush chips away from the cutting zone, preventing chip recutting and potential tool breakage.

For hardened steel, high-pressure coolant systems or specialized cutting fluids designed for high-temperature applications are best. Flood coolant is common, but a mist coolant system can also be effective.

Safe and Effective Machining Techniques

Now that you’re set up, let’s talk about how to actually cut the hardened steel. This is where understanding cutting parameters and techniques becomes vital.

Understanding Cutting Parameters (Speeds and Feeds)

This is perhaps the most critical aspect of machining hardened steel with carbide end mills. Carbide requires different parameters than HSS.

Surface Speed (SFM or m/min): This is the speed at which the cutting edge moves across the workpiece. For carbide end mills in hardened steel, surface speeds are typically lower than for HSS in softer materials, but the higher rigidity of carbide allows for higher Metal Removal Rates (MRR).

Rounds Per Tooth (RPT) or Feed Per Tooth (FPT): This is the amount of material each cutting edge removes on each revolution. For hardened steel, you typically want a higher FPT to ensure the carbide edge is taking a substantial chip, preventing rubbing and glazing.

Spindle Speed (RPM): This is calculated based on your surface speed and the diameter of your end mill. RPM = (Surface Speed 3.82) / Diameter (for SFM and inches). Or RPM = (Surface Speed 1000) / (π Diameter) (for m/min and mm).

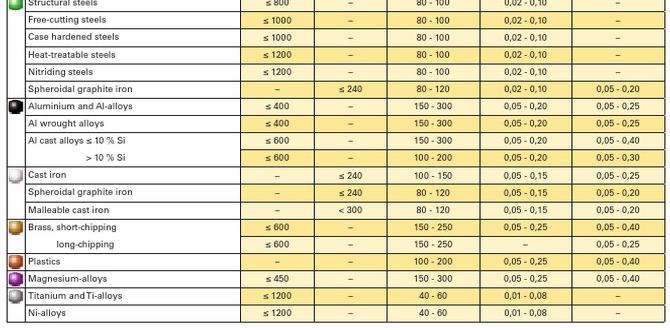

General Starting Points for Carbide End Mills in Hardened Steel (HRC 55-60)

These are very general starting points and will vary based on the specific end mill, machine rigidity, coolant, and desired MRR. Always consult the end mill manufacturer’s recommendations if available.

| Parameter | Typical Range (Inches) | Typical Range (Metric) | Notes |

| :——————— | :——————— | :——————— | :————————————————————————————————– |

| Surface Speed (SFM) | 100 – 250 | 30 – 75 | Lower end for less rigid setups, higher end for rigid machines. |

| Feed Per Tooth (FPT)| 0.001″ – 0.003″ | 0.025mm – 0.075mm | Start on the lower end and increase if sounds/vibration allow. Higher FPT is key for MRR. |

| Axial Depth of Cut | 0.010″ – 0.050″ | 0.25mm – 1.25mm | Less is often more. Smaller depths reduce cutting forces. |

| Radial Depth of Cut | 20% – 50% of diameter | 20% – 50% of diameter | For slotting, use 50% or less. For profiling, higher can be used if rigidity allows. |

| Spindle Speed (RPM) | Varies greatly | Varies greatly | Calculated from SFM and diameter. |

Important Note on MRR: The keyword mentioned “High MRR” (Material Removal Rate). To achieve high MRR with hardened steel and carbide, you generally need a rigid setup, good coolant, a well-designed end mill (e.g., 4+ flutes, appropriate helix), and you’ll push the feed rate (FPT) and axial depth of cut as much as the machine and tool allow without chatter or tool failure. It’s about finding the sweet spot where you remove material quickly and efficiently but also safely.

Machining Strategies

How you approach the cutting operation matters. You can’t just plunge in and expect the best results.

Plunging: If you need to create a hole, use a center-cutting end mill. Plunge straight down rather than using helical interpolation if your machine is not very rigid or if you’re not experienced. Start with a slow plunge rate.

Slotting: When milling a full slot, a 2-flute or 4-flute end mill can work. Be mindful of chip packing. Using a slightly lower radial depth of cut and ensuring excellent chip evacuation is key. Walking the dog (using a series of small radial movements to create a wider slot) can sometimes be more effective than a single full-width pass.

Profiling (Contouring): When milling around the outside or inside of a shape, use climb milling whenever possible.

Climb Milling: The tool rotation direction is the same as the feed direction. This results in a thinner chip at the start and a thicker chip at the end of engagement. It’s generally preferred for its ability to reduce cutting forces and improve surface finish. However, it puts more stress on the cutting edge at the start of engagement, so a strong edge (like a small radius or chamfer) is helpful for hardened steel.

Conventional Milling: The tool rotation direction is opposite to the feed direction. This results in a thicker chip at the start and a thinner chip at the end. It can be more prone to chatter and can create larger cutting forces.

Always start with conservative parameters and gradually increase them as you gain confidence and observe the machining process. Listen to the sound of the cut and watch for any signs of chatter, excessive vibration, or tool wear.

Tool Life and Monitoring

Carbide end mills are durable, but they aren’t invincible.

Tool Wear: Look for chipping on the cutting edge, excessive flank wear (the flat surface on the side of the cutting edge), or a visible sheen indicating heat buildup.

Chatter Marks: If you see repeating patterns on the surface, it’s a sign of vibration, which is detrimental to tool life and accuracy.

Monitoring: Periodically stop the spindle (after the tool has retracted from the workpiece) and inspect the cutting edge. Keep a log of your cutting parameters and the resulting tool life. This data is invaluable for future jobs.

When to Consider Specialized Carbide End Mills

While a good general-purpose carbide end mill for hardened steel will get many jobs done, some applications demand more specialized tools.

For Extreme Hardness or Specific Alloys

If you’re consistently working with materials above HRC 60, or with exotic alloys that have unique machining characteristics, you might need:

Nano-grain Carbide: This finer grain structure provides enhanced toughness and edge stability.

Advanced Coatings: Coatings like DLC (Diamond-Like Carbon) can be even more effective for certain highly abrasive or adhesive materials, though they are often more expensive.

Tool Geometry for Specific Materials: Some end mills are designed with specific flute counts, helix angles, and relief angles optimized for materials like tool steels, stainless steels, or titanium.

Your end mill supplier is an excellent resource for recommendations on these specialized tools. They can often provide detailed machining data based on your specific material and application. For instance, companies that offer milling tools often have extensive catalogs specifying optimal RPMs and feed rates for hundreds of different materials.

The Role of Coatings in Enhanced Performance

Many carbide end mills designed for hardened steel come with coatings. As mentioned before, TiAlN and AlTiN are popular choices due to their excellent performance at high temperatures. These coatings create a harder, more heat-resistant surface on the carbide, which directly translates to:

Extended Tool Life: The coating acts as a barrier against wear and heat.

Higher Cutting Speeds/Feeds: Because the tool can withstand more heat and wear, you can often push the machine parameters harder, leading to better productivity and higher MRR.

Improved Surface Finish: A sharper, more durable cutting edge leaves a cleaner surface.

While uncoated carbide is sometimes used, especially in situations where a very specific surface finish is required and lubrication is excellent, coated carbide generally offers a significant advantage for machining hardened steels.

Carbide End Mills vs. Other Tooling for Hardened Steel

It’s worth briefly contrasting carbide with other common tooling options to reinforce why it’s the go-to choice for hardened steel.

High-Speed Steel (HSS): Great for softer metals (Aluminum, mild steel, brass, plastics). It’s tougher (less brittle) than carbide but significantly softer and has a lower heat resistance. Trying to machine hardened steel with HSS will result in rapid tool failure.

Cobalt (HSS-E): An improved version of HSS with added cobalt for increased hardness and heat resistance. It can