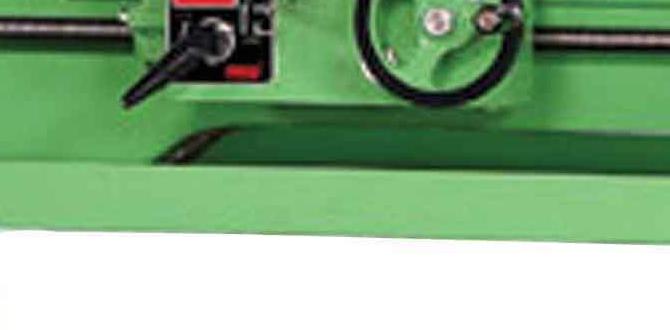

A 1/8 inch carbide end mill, especially a stub length version, can easily deflect when cutting harder materials. This guide shows you how to control that deflection for cleaner cuts and better results in your milling projects.

Have you ever noticed your cuts getting a little wobbly or rough when using a small 1/8 inch carbide end mill? It’s a common frustration for beginners, especially when trying to achieve precise details. This “deflection,” where the cutting edges bend away from the material, can ruin a project. But don’t worry! With a few simple adjustments and techniques, you can master this little tool and get those crisp, clean cuts you’re aiming for. We’ll walk through exactly how to keep your 1/8 inch carbide end mill from deflecting, turning tricky cuts into smooth successes.

Understanding End Mill Deflection: Why It Happens with a 1/8 Inch Tool

So, what exactly is deflection when we’re talking about these small end mills? Imagine pushing on a thin, flexible ruler. It bends, right? An end mill, especially a small one like our 1/8 inch carbide tool, can do the same thing when it encounters resistance from the material you’re cutting. This resistance comes from the cutting forces generated as the flutes bite into the workpiece.

A 1/8 inch end mill is particularly prone to deflection for a few key reasons:

- Small Diameter: It’s simply a smaller, less rigid tool than its larger counterparts. There’s less material to resist the bending forces.

- Longer Length-to-Diameter Ratio: If you’re using a standard length 1/8 inch end mill, a significant portion of it might be unsupported as it cuts. This overhang makes it much easier to bend.

- Material Hardness: The harder the material you’re trying to mill, the greater the cutting forces, and thus, the more the end mill will want to deflect.

- Cutting Parameters: Aggressive feeds and speeds (trying to cut too fast or too deep) will also overload the tiny cutting edges and lead to significant deflection.

For beginners, seeing this deflection pop up can be discouraging. It leads to:

- Rough surface finishes.

- Inaccurate dimensions.

- Potential for tool breakage.

- Increased stress and frustration.

The goal is to minimize this unwanted bending. This control comes from understanding how the tool interacts with your machine and material, and applying smart strategies. We’ll explore how a stub length end mill can be a game-changer, but it’s not the only solution. Let’s dive into how we can take charge of our 1/8 inch carbide end mill.

Choosing the Right 1/8 Inch Carbide End Mill for Minimal Deflection

Not all 1/8 inch end mills are created equal when it comes to fighting deflection. The right choice can make a huge difference even before you start cutting. For our purpose of minimizing deflection, a few features stand out.

The Stub Length Advantage

When you hear “stub length,” think “short and stout.” These end mills have a shorter flute length and a shorter overall length compared to standard end mills. Why is this important for controlling deflection?

- Increased Rigidity: A shorter tool is inherently stiffer. There’s less leverage for the cutting forces to act upon, leading to much less bending.

- Better Tool Support: The shorter length means more of the tool is supported by the tool holder or collet, providing a more stable connection to your milling machine.

For 1/8 inch end mills, this stub length design is particularly beneficial. It’s like swapping a long, thin pencil for a shorter, thicker crayon – the crayon is much harder to bend! When searching for these, look for descriptions like “stub length” or “short flute” in the product specifications.

Carbide vs. High-Speed Steel (HSS)

We’re focusing on carbide end mills for a reason. Carbide is a much harder and more rigid material than HSS. This inherent stiffness means carbide end mills resist deflection better than their HSS counterparts of the same size. For small diameter tools where rigidity is critical, carbide is the clear winner.

Flute Count Matters

The number of flutes (the helical cutting edges) on an end mill also influences how it cuts and how it might deflect.

- 2-Flute End Mills: Generally better for slotting and chip evacuation in softer materials. They have more “room” for chips to escape.

- 3-Flute End Mills: Offer a good balance of rigidity and chip clearance, often performing well in a wider range of materials for general milling.

- 4-Flute End Mills: Provide the most rigidity due to their construction, but can struggle with chip evacuation in deep cuts or softer, “gummy” materials.

For a 1/8 inch end mill and minimizing deflection, a 3 or 4-flute stub length carbide end mill is often an excellent choice. The added flute count contributes to overall stiffness. As you push into tougher materials or require very precise finishes, a 4-flute might offer that extra bit of rigidity.

Coating Considerations

While not directly preventing deflection, specialized coatings can improve cutting performance, which indirectly helps. Coatings like TiN (Titanium Nitride) or AlTiN (Aluminum Titanium Nitride) can reduce friction, increase hardness, and improve heat resistance. This can mean smoother cutting and less material buildup, allowing the tool to cut more freely, which can ease the forces that cause deflection.

Proven Deflection Control Techniques for Your 1/8 Inch Carbide End Mill

Now that you know how to pick the right tool, let’s talk about the techniques you can use while milling to keep that 1/8 inch end mill on track.

1. Optimize Your Cutting Parameters

This is arguably the most crucial step for any beginner. Pushing the tool too hard is a sure way to invite deflection.

Feed Rate (How Fast You Move the Tool)

The feed rate is how fast the center of the end mill moves through the material. For a 1/8 inch end mill, you generally want to use a conservative feed rate. Too fast, and the cutting edges won’t have time to properly engage and will be forced against the material, causing deflection. Too slow, and you risk rubbing, which generates heat and can also lead to poor finishes or tool wear.

Spindle Speed (RPMs)

Spindle speed determines how fast the end mill rotates. For carbide, you often want higher spindle speeds compared to HSS. However, with a small tool like 1/8 inch, you need to balance this. Too high a speed with too aggressive a feed can lead to chatter and deflection. Always consult manufacturer recommendations or online calculators for starting points.

Depth of Cut (DOC) and Width of Cut (WOC)

This is where you can really control deflection. Instead of trying to remove a lot of material in one go, take shallower cuts.

- Depth of Cut (DOC): How deep the end mill cuts into the material per pass. For a 1/8 inch end mill, especially in harder metals, taking a DOC that is much less than the diameter (e.g., 0.030″ or less in aluminum/brass) is often recommended. Avoid trying to cut deeper than the tool’s diameter, and ideally, keep it significantly less.

- Width of Cut (WOC): How wide the milling path is relative to the end mill’s diameter. When slotting, an “ioing cut” (where the WOC is less than or equal to the diameter) can induce more deflection. For critical slots, consider a multi-pass approach using a slightly smaller DOC and WOC to maintain rigidity.

Key takeaway: Take lighter, shallower passes. It takes more passes, but you’ll get a much better result and save your tool from unnecessary stress.

A good starting point for many common materials can be found on resources like the Metalforming Calculator, though always use these as guides and be prepared to adjust based on your machine and setup.

2. Master “Climb Milling” vs. “Conventional Milling”

The way the tool engages the material makes a big difference. Understanding climb milling and conventional milling is key to smoother operation and reduced deflection.

- Conventional Milling: The cutter rotates against the direction of feed. This tends to “lift” the material away from the cutting edge, creating upward forces that can contribute to deflection. It’s often more forgiving for beginners as it’s less prone to “grabbing.”

- Climb Milling: The cutter rotates in the same direction as the feed. This “pulls” the material into the cutting edge. It creates downward forces that can help hold the workpiece down and reduce upward deflection. Climb milling generally produces a better surface finish and puts less stress on the tool if done correctly.

For minimizing deflection: Whenever possible and safe for your machine, opt for climb milling. On most manual milling machines, you’ll need to ensure your backlash settings are adjusted correctly or use a machine designed for climb milling. CNC machines are generally well-suited for climb milling.

Safety Note: Climb milling can cause the tool to “grab” the workpiece if there’s too much play (backlash) in the machine’s lead screws or if the feed rate is too high relative to the spindle speed. Always start slowly and with lighter passes when trying climb milling.

3. Maintain a Clean and Rigit Setup

Your machine and workholding are just as important as the end mill itself.

- Rigid Workholding: Ensure your workpiece is held down extremely securely. Any movement or vibration in the workpiece will exacerbate deflection. Use clamps, vises, or fixtures that provide a solid, unmoving base. Avoid relying on double-sided tape for anything other than the lightest of cuts in soft materials.

- Proper Tool Holder: Use a high-quality collet or tool holder. A bit holder or a cheap collet can introduce runout (the tool wobbling slightly in the spindle). This runout is essentially adding to the forces that cause deflection. A good ER collet system is highly recommended for small end mills.

- Zero Backlash: On manual machines, make sure your table and saddle gibs are properly adjusted, and that you’ve accounted for any backlash in the lead screws. Excessive backlash means the tool can “dig in” or be pushed out of its path more easily.

- Cleanliness: Keep your machine ways, collets, and tool holders clean and free of chips and debris. This ensures smooth operation and proper seating of components.

4. Consider “Spring Passes”

A spring pass is a finishing pass taken at a very light depth of cut, often with a slightly increased feed rate, after the main cutting operations. The goal is to “clean up” any slight inaccuracies left by the bulk of the material removal. For a 1/8 inch end mill producing precise features, a spring pass can smooth out any remaining deflection marks. Even taking a final pass at a very shallow depth of cut (e.g., 0.002″ – 0.005″) can significantly improve the surface finish and dimensional accuracy.

5. Use the Right Coolant or Lubricant

For materials like aluminum or steel, using a cutting fluid or lubricant is highly recommended. It reduces friction, cools the cutting edge, and helps clear chips. This smoother cutting action can lessen the forces that cause deflection.

- For Aluminum/Brass: A light mineral oil, WD-40, or specialized aluminum cutting fluid works well.

- For Steel: Use a more robust cutting fluid designed for steel.

- For Plastics/Wood: Generally, no coolant is needed, but always check material-specific recommendations.

Ensure your coolant is applied effectively to the cutting zone. For small hobby machines, a spray mist system or even a brush-on lubricant can be effective.

Practical Applications: What Can You Do With a Controlled 1/8 Inch End Mill?

Mastering deflection control with a 1/8 inch carbide end mill opens up a world of detailed milling possibilities. Here are some examples of what you can achieve:

Engraving and Texturing

Creating custom text, logos, or intricate patterns on parts becomes much more achievable. The small diameter is perfect for fine detail.

Making Small Parts and Components

Machining small brackets, gears, jigs, or custom enclosures for electronics with tight tolerances. Think about custom camera mounts or specific automotive repair parts.

Detailing Wood Projects

While primarily for metal, the techniques learned here also apply to some finer woodworking details or creating precise inlays with a CNC. For woodworking, ensuring the feed rate is appropriate for the wood and the machine is key.

Trimming and Finishing

You can use it for precise trimming of excess material or for creating chamfers and fillets in tight areas where a larger tool wouldn’t fit.

Prototyping

Quickly creating small prototypes for fit checks or functional tests. This is where the ability to reliably mill small, detailed parts saves significant time and money.

When to Use a 1/8 Inch End Mill (and When to Consider Stepping Up)

The 1/8 inch carbide end mill is a specialized tool. It excels at fine detail and small-scale work, but it has its limitations.

When to Use It:

- Detailed engraving or texturing.

- Milling small pockets or features with tight radii.

- Working on small parts or models.

- When the desired feature size is close to or smaller than 1/8 inch.

- Making very shallow clearance cuts or chamfers.

When to Consider a Larger End Mill:

- Material Removal: If you need to remove a lot of material quickly, a larger end mill with a higher material removal rate (MRR) is much more efficient and less prone to deflection.

- Wider Pockets or Slots: For slots wider than 1/8 inch or pockets that don’t require small internal radii, use a correspondingly larger end mill.

- Reduced Cycle Times: Larger tools generally allow for more aggressive cutting parameters, leading to shorter machining times.

- Tool Life: Trying to push a 1/8 inch tool to do the work of a 1/4 inch or larger tool will drastically reduce its lifespan and increase the risk of breakage.

Understanding these trade-offs helps you select the right tool for the job. Don’t try to force a small tool to do heavy-duty work; that’s a recipe for deflection and disappointment.

Maintaining Your 1/8 Inch Carbide End Mill

Proper care ensures your tool performs well and lasts longer, keeping deflection to a minimum.

- Keep it Clean: After each use, clean the end mill thoroughly to remove any chips, coolant residue, or material buildup. A stiff brush and some solvent usually do the trick.

- Store Properly: Store your end mills in a protective case or rack. This prevents the delicate cutting edges from being damaged by bumping into other tools.

- Inspect for Damage: Before each use, visually inspect the flutes for any chips, nicks, or signs of wear. A damaged end mill will not cut cleanly and is more likely to deflect or break.

- Avoid Regrinding (for small carbide): While larger carbide tools can sometimes be reground, it’s often not cost-effective or practical for small 1/8 inch end mills, especially for hobbyists. Once they become dull or chipped, replacement is usually the best option.

Table: Comparing End Mill Features for Deflection Control

Here’s a quick comparison to help you choose the right 1/8 inch end mill:

| Feature | Impact on Deflection Control | Ideal For |

|---|---|---|

| Stub Length | Significantly higher rigidity, less overhang, less bending. | Minimizing deflection in all materials. |

| Standard Length | More prone to deflection due to longer unsupported length. | Shallow cuts or situations where rigidity is less critical. |

| Carbide Material | Inherently harder and more rigid than HSS. | Recommended for most milling, especially harder materials. |

| 3-Flute Design | Good balance of rigidity and chip clearance; can be more rigid than 2-flute. | General milling, good compromise. |

| 4-Flute Design | Offers the most rigidity due to flute count; best for finishing or harder materials where chip evacuation is manageable. | Maximizing rigidity, finishing passes, harder metals. |

| 2-Flute Design

|