Quick Summary: Use a specialized HRC60 carbide end mill designed for hardened steel. Proper speeds, feeds, and rigid setup are key to eliminating chatter and achieving smooth cuts. This guide explains how to select and use the right end mill to conquer chatter in tough materials.

Hey everyone, Daniel Bates from Lathe Hub here! Ever been in the middle of a milling job, especially with some tough hardened steel, and suddenly you hear that awful chattering sound? It’s like nails on a chalkboard for a machinist! That’s not just annoying; it means your tool and workpiece are vibrating badly, leading to poor surface finish, tool wear, and even broken tools. It’s a common headache when working with materials hardened to HRC60. But don’t worry, there’s a secret weapon: the right carbide end mill.

Today, we’re going to dive deep into how a specific type of carbide end mill can be your best friend in tackling this chatter problem. We’ll explore what makes these tools special, how to pick the right one, and the crucial steps you need to take to get those chatter-free, beautiful finishes on your hardened steel projects. Get ready to transform your frustration into perfectly milled parts!

Understanding Chatter: The Machinists’ Nemesis

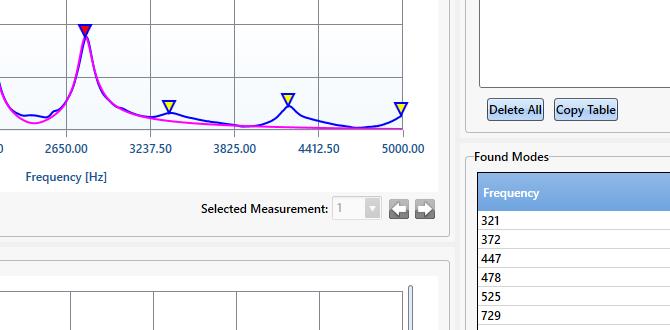

Chatter, that high-pitched squeal and vibration you hear during milling, is a vibration problem. It happens when the cutting forces from the mill aren’t consistent. As the tool engages and disengages from the material, it causes small, rapid disturbances. These disturbances can resonate with the machine’s structure, the workpiece, or the tool itself, amplifying the vibration. Think of it like pushing a swing: if you push at just the right moment, the swing goes higher. Chatter is the machining equivalent of that uncontrolled swing.

This vibration isn’t just an aesthetic issue. It leads to:

- Poor Surface Finish: Your parts will look rough and wavy, not smooth and precise.

- Reduced Tool Life: The constant banging and stress can chip or break your cutting edges quickly.

- Increased Machine Wear: The vibrations are stressful for your milling machine’s spindle and other components.

- Inaccurate Dimensions: The uneven cutting can lead to parts that aren’t within your specified tolerances.

When you’re working with materials like hardened steel, which are designed to resist wear and deformation, these materials are inherently tougher to machine. Standard tools might struggle, and the risk of chatter increases significantly. That’s where specialized tooling comes in.

The Solution: HRC60 Carbide End Mills

So, what exactly makes a carbide end mill a “chatter buster” for materials hardened to HRC60? It’s a combination of the material itself (carbide) and specific design features tailored for tough jobs.

Why Carbide?

Carbide, or tungsten carbide, is a composite material that is exceptionally hard and wear-resistant. It’s significantly harder than High-Speed Steel (HSS) and can withstand higher cutting temperatures. This makes it ideal for cutting hard materials like tool steel and hardened alloys. However, carbide can also be brittle, so its design is critical.

Features of a Chatter-Busting HRC60 End Mill:

Not all carbide end mills are created equal, especially when you need to cut materials hardened to HRC60. Look for these key features:

- High Hardness Rating: Specifically designed for materials in the HRC55-HRC60 range. This means the carbide alloy and its heat treatment are optimized for this hardness.

- Variable Helix Angle: Traditional end mills often have a uniform helix angle (e.g., 30 degrees). Chatter-busting mills frequently use a variable helix angle, meaning the angle of the flutes changes slightly along their length. This unconventional design disrupts the harmonic vibrations that cause chatter. It’s like making the cutting path less predictable for the vibration to lock onto.

- Uneven Flute Spacing: Similar to the variable helix, end mills designed to reduce chatter often have flutes that are not evenly spaced around the circumference. For example, instead of every 90 degrees, they might be at 80, 100, 85, and 95 degrees. This irregular spacing again breaks up the rhythmic impact that causes vibration.

- Specialized Coatings: While not always present, advanced coatings like TiCN (Titanium Carbon Nitride) or AlTiN (Aluminum Titanium Nitride) can further enhance wear resistance, reduce friction, and improve performance at high temperatures, all contributing to a smoother cut.

- End Mill Geometry: Look for end mills with a stronger core, optimized flute forms, and sharp cutting edges. These contribute to rigidity and efficiency.

When people search for a “carbide end mill 1/8 inch 6mm shank standard length for hardened steel hrc60 reduce chatter,” they are looking for a tool that encapsulates all these features in a common size for smaller CNC machines and hobbyist setups.

Choosing the Right HRC60 Carbide End Mill

Selecting the correct end mill is crucial. For your “carbide end mill 1/8 inch 6mm shank standard length for hardened steel hrc60 reduce chatter,” here’s what you should consider:

Key Specifications to Look For:

- Material Hardness: Confirm it’s rated for HRC60 or higher.

- Number of Flutes: For hardened steels and chatter reduction, 2-flute or 4-flute end mills are common. Less flutes generally allow for better chip evacuation, which is important in harder materials. However, more flutes can provide a smoother finish. For chatter control, the design features (variable helix/spacing) often outweigh the number of flutes.

- Cutting Diameter: In your case, this is likely 1/8 inch (3.175mm).

- Shank Diameter: Also likely 1/8 inch (3.175mm) or 6mm (0.236 inches). A 6mm shank for a 1/8 inch cutter provides a bit more rigidity.

- Length: “Standard length” is relative, but it usually means within typical project needs. Avoid excessively long end mills when possible, as they are more prone to deflection and vibration.

- Coating: A good coating like TiCN or AlTiN can offer benefits.

- Geometry: Look for descriptions mentioning “anti-chatter,” “variable helix,” or “unbalanced flute spacing.”

Example Tool Profile:

A good example of a tool meeting these needs might be described as: “3.175mm (1/8″) Diameter, 6mm Shank, 50mm Overall Length, 2-Flute, Solid Carbide End Mill, HRC60+, Variable Helix, Unbalanced Flute Spacing, TiCN Coated, for Hardened Steel & Chatter Reduction.”

Where to Find Them:

Reputable industrial tooling suppliers are your best bet. Websites specializing in CNC tooling, carbide tooling, or mill-duty cutters will carry these specialized end mills. Look for brands known for quality tooling.

Setting Up for Success: The Foundation of Chatter-Free Machining

Having the right tool is only half the battle. The setup of your machine and workpiece is just as critical for eliminating chatter.

1. Machine Rigidity is Paramount

A sturdy machine is less likely to vibrate.

- No Play in the Spindle: Ensure your spindle bearings are in good condition and have no looseness.

- Solid Workholding: This is a BIG one. Your workpiece needs to be clamped down securely. Any movement or flex will invite chatter. Use a robust vise, clamps, or fixtures that are appropriate for the forces involved. Avoid flimsy setups.

- Machine Condition: Ensure your machine’s ways (the surfaces that guide movement) are clean, lubricated, and without excessive wear.

2. Workpiece Clamping Techniques

The way you hold your part can make or break your cut:

- Use the Right Vise: A steel machine vise, properly aligned with the machine’s axes, is ideal. Avoid aluminum hobby vises for hard machining.

- Jaw Pads: Use hardened steel vise jaws or soft jaws (if you need to protect a delicate surface, though less common for HRC60 steel). Ensure the jaws are clean and that the workpiece is seated firmly against the fixed jaw.

- Support: For larger or thinner parts, use parallels, vises, or other supports to prevent flexing.

- Torque: Tighten your vise securely, but don’t overtighten to the point of damaging your machine or workpiece.

3. Tool Holder Rigidity

Just like the workpiece, the tool needs to be held supremely rigidly.

- Collet Chucks: These offer the best runout and gripping force for end mills. A precision collet chuck is far superior to a standard drill chuck for milling.

- Side-Lock Holders: If using a side-lock holder, ensure the set screw is tightened firmly against the flat on the end mill shank (if present).

- Runout: Check for runout (wobble) in your tool holder and spindle. Even a tiny bit of runout can exacerbate chatter.

The Art of Speeds and Feeds: Fine-Tuning for Chatter-Free Cuts

This is where we move from the static setup to the dynamic cutting process. Finding the right balance of speed and feed rate is crucial for efficient machining and chatter prevention.

Understanding Surface Speed (SFM) and Chip Load

Surface Speed (SFM – Surface Feet per Minute) or Surface Speed (m/min): This is the speed at which the cutting edge of the tool moves relative to the workpiece material. Carbide tools can typically run at higher SFM than HSS.

Feed Rate (IPM – Inches per Minute) or Feed Rate (mm/min): This is how fast the tool advances into the material. It’s often related to the Chip Load.

Chip Load (CL): This is the thickness of the material removed by each cutting edge of the end mill per revolution. It’s perhaps the most important parameter for controlling chatter and achieving good finish. Chip load is typically measured in inches per tooth (IPT) or millimeters per tooth (mm/tooth).

Calculating Rough Speeds and Feeds

For a “carbide end mill 1/8 inch 6mm shank standard length for hardened steel hrc60 reduce chatter,” you’ll need to consult manufacturer datasheets or general carbide machining charts. However, here are some starting points for HRC60 steel and a 1/8″ end mill:

General Starting Points for HRC60 Steel (1/8″ Carbide End Mill)

| Parameter | Typical Value for HRC60 Steel | Notes |

|---|---|---|

| Surface Speed (SFM) | 150 – 300 SFM (45 – 90 m/min) | Lower end for heavy cuts or less rigid setups, higher for lighter cuts/rigid setups. |

| Chip Load per Tooth (IPT) | 0.0005 – 0.0015 IPT (0.013 – 0.038 mm/tooth) | CRITICAL for chatter. Start low, increase slowly. |

| Spindle Speed (RPM) | Calculated based on SFM and Diameter | |

| Feed Rate (IPM) | Calculated based on RPM, Flutes, and Chip Load | |

| Depth of Cut (DOC) | 0.010″ – 0.040″ (0.25 – 1.0 mm) | Depends on tool diameter and rigidity. Shallow DOCs are often better for chatter. |

| Width of Cut (WOC) | 25% – 50% of diameter (0.03″ – 0.06″ for 1/8″) | Full slotting (100%) is much harder on tools and prone to chatter. Try to avoid if possible, or use specialized tools. |

Calculations:

Let’s calculate Spindle Speed (RPM) and Feed Rate (IPM):

- Spindle Speed (RPM) = (SFM 3.82) / Diameter (inches)

Using a lower SFM of 150 SFM for a 1/8″ (0.125″) end mill:

RPM = (150

3.82) / 0.125 = 5730 / 0.125 = 4584 RPMUsing a higher SFM of 300 SFM:

RPM = (300 3.82) / 0.125 = 1146 / 0.125 = 9168 RPM

So, a good starting range for RPM might be 4000 – 9000 RPM, depending on your machine.

- Feed Rate (IPM) = RPM Number of Flutes Chip Load (IPT)

Let’s use 4500 RPM (lower end), 2 flutes, and a conservative chip load of 0.0008 IPT:

Feed Rate = 4500 2 0.0008 = 7.2 IPM

Let’s use 8000 RPM (higher end), 2 flutes, and chip load of 0.0012 IPT:

Feed Rate = 8000 2 * 0.0012 = 19.2 IPM

So, a starting Feed Rate range could be from 7 to 20 IPM.

Tips for Fine-Tuning to Eliminate Chatter:

- Start Conservative: Always begin with the lower end of the recommended speed range and the minimum chip load.

- Listen and Observe: This is where machining intuition comes in. If you hear chatter, the first thing to adjust is usually the feed rate.

- Increase Feed Rate: If the cut is too light or you’re not getting chatter, try increasing the feed rate. A slightly higher chip load often helps to “take a more substantial bite,” which can stabilize the cut and reduce chatter. Increasing the feed rate is often more effective at stopping chatter than changing RPM.

- Slightly Adjust RPM: If increasing feed rate doesn’t help, a small adjustment to RPM can sometimes shift the natural frequency of the system just enough to break the chatter cycle. Try increasing or decreasing RPM by small increments (e.g., 5-10%).

- Reduce Depth/Width of Cut: If you’re slotting or taking deep cuts, try reducing the depth of cut (DOC) or especially the width of cut (WOC). Slotting (cutting a full-width groove) is notoriously prone to chatter. Consider using a “trochoidal” milling strategy or taking multiple shallow passes.

- Down-Milling vs. Up-Milling: For slotting and reduced chatter, down-milling (where the cutter rotates in the same direction as the feed) can sometimes be more predictable. However, up-milling can sometimes give a better finish. Experiment to see what works best for your specific material and setup.

- Check Tool Runout: Re-seat the end mill and ensure your collet and holder are clean.

Remember, these are starting points. Every machine, every workpiece material, and every end mill is slightly different. The goal is to find the sweet spot where the chip load is substantial enough for smooth cutting but not so large that it overloads the tool or machine.

Machining Strategies for Chatter Reduction

Beyond tool choice and basic speeds/feeds, specific machining strategies can prevent chatter, especially in challenging materials.

1. High-Feed Milling / Plunging

This strategy involves using very high feed rates and relatively shallow depths of cut. The idea is to create a very small chip load per tooth, but to have many teeth engaging the material rapidly. This can sometimes stabilize the cutting process. However, it requires a very rigid machine and setup.

2. Trochoidal Milling (High-Speed Machining – HSM)

This is particularly useful for slotting or pocketing. Instead of moving in straight lines, the tool follows a curved path (like a spiral or a series of overlapping circles). This ensures the tool is always engaged with a consistent