Quick Summary:

For a clean, precise cut in acrylic, a 3/16 inch carbide end mill with an 8mm shank is your go-to tool for dry cutting. This specific size and material combination minimizes melting and chipping, delivering professional results for your projects.

Working with acrylic can sometimes feel like a puzzle. You want smooth, clean edges, but often end up with melted plastic or frustrating chips. It’s a common issue, especially when you’re just starting out in the workshop. But don’t worry! With the right tools and a few simple techniques, cutting acrylic can become a breeze. Today, we’re focusing on a fantastic little tool: the 3/16 inch carbide end mill with an 8mm shank.

This combination might seem specific, but it’s incredibly effective for dry cutting acrylic. We’ll break down exactly why it works so well and walk you through how to use it for that perfect finish every time. Get ready to tackle your acrylic projects with newfound confidence!

Why a 3/16 Inch Carbide End Mill (8mm Shank) is Perfect for Acrylic Dry Cutting

Before we dive into the ‘how-to,’ let’s understand why this particular tool is a superstar for cutting acrylic. It’s all about the material and the size.

Carbide: The Hard Worker

Carbide, or tungsten carbide, is a super-hard material. It’s much harder than High-Speed Steel (HSS). This hardness is key for cutting plastics like acrylic. Why? Because acrylic can get soft and gummy when it heats up. A sharp, hard carbide tool slices through it cleanly without dragging or melting, which is what often leads to those messy edges.

- Hardness: Carbide is incredibly durable and stays sharp longer than HSS.

- Heat Resistance: While acrylic can create heat, carbide tooling can handle it better, contributing to a cleaner cut.

- Precision: The sharpness and rigidity of carbide allow for very precise cuts, crucial for intricate designs.

The 3/16 Inch Diameter: Just Right

Why 3/16 of an inch? This diameter offers a great balance for many DIY and hobbyist projects. It’s small enough to handle detailed work, like engraving or cutting small parts, but large enough to remove material efficiently. It also helps manage the heat generated during the cut. Smaller bits can sometimes struggle with heat dissipation, but 3/16 inch is often a sweet spot.

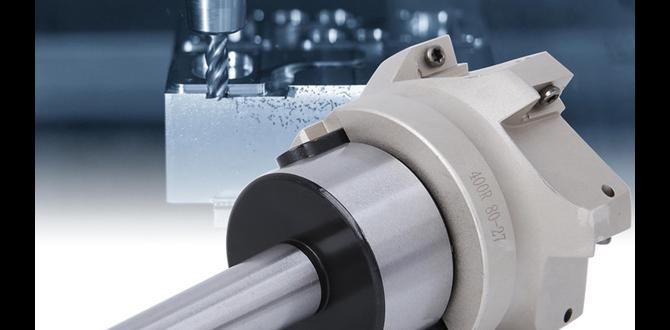

The 8mm Shank: Stability and Compatibility

The 8mm shank is a common size, especially in European and some Asian-made machines, but also found on many import CNC routers and mills catering to a global market. A slightly larger shank diameter like 8mm (which is about 0.315 inches) compared to a 1/4 inch (0.25 inch) shank offers more rigidity. This increased rigidity helps reduce vibration and chatter, leading to a smoother cut and less chance of breaking the delicate carbide bit. It also means it will fit securely in many common collets and tool holders.

When selecting your tool, look for specific “acrylic” or “plastic” end mills. These often have a higher flute count (more cutting edges) and a polished flute to help eject chips and prevent material from sticking.

Essential Tools and Setup for Acrylic Dry Cutting

Before you power up your machine, ensure you have everything you need. A little preparation goes a long way in ensuring a safe and successful cut.

Your Cutting Tool: The Carbide End Mill

As we’ve established, a 3/16 inch (approx. 4.76mm) 2-flute up-cut or straight-flute carbide end mill is ideal. For acrylic, an up-cut spiral flute is often preferred as it pulls chips up and out of the cut, helping to clear the flute and reduce heat buildup. A polished or bright finish on the flutes is a bonus, as it aids in chip evacuation and prevents plastic from sticking.

Why 2 flutes? For plastics like acrylic, fewer flutes generally provide better chip clearance, which is critical to prevent melting. While 4-flute bits are great for metals and finishing, 2-flute bits excel at clearing chips in softer materials.

Your Machine: CNC Router or Mill

This guide focuses on using a CNC router or milling machine, as these offer the precision and control needed for clean acrylic cuts. Whether you’re using a desktop CNC or a larger desktop mill, the principles remain the same.

Work Holding: Secure Your Material!

This is paramount for safety and cut quality. Never try to cut acrylic without it being firmly secured.:

- Clamps: Use specialized non-marring clamps or hold-downs that won’t damage the acrylic surface. Place them strategically so the end mill doesn’t accidentally hit them.

- Double-Sided Tape: For smaller pieces or when clamps might interfere, strong double-sided tape designed for machining can work, but it’s less secure than mechanical methods.

- Vacuum Table: If your CNC has one, this is an excellent method for holding sheet acrylic.

Always ensure your material is flat and stable. Warped acrylic can lead to inconsistent depths of cut and potential tool breakage.

Dust Collection: It’s Not Just About Dust

Even though we’re “dry cutting,” you’ll still generate acrylic chips and dust. A good dust collection system connected to your router spindle is highly recommended. It not only keeps your workspace clean but also helps remove fine particles that could otherwise recirculate heat back into the cutting zone.

For acrylic, you’re primarily managing chips rather than fine dust, but the principle of clearing the cutting area applies. Some hobbyists use a shop vac with a brush attachment around the bit to sweep chips away.

Safety Gear: Non-Negotiable

Always wear your safety glasses. Flying chips, even small ones, can be dangerous. If you’re concerned about noise or fine dust, hearing protection and a respirator are also good ideas. Wear snug-fitting clothing and tie back long hair.

Step-by-Step Guide to Cutting Acrylic with a 3/16 Inch Carbide End Mill

Now, let’s get cutting! Follow these steps for a smooth, clean experience.

Step 1: Prepare Your Design and CAM Software

First, you’ll need a digital design. This could be a vector file (like from Adobe Illustrator or Inkscape) or a CAD model.

Next, import your design into your CAM (Computer-Aided Manufacturing) software. This is where you’ll tell your CNC machine how to cut the part. Key settings for acrylic include:

- End Mill Selection: Choose your 3/16 inch, 2-flute carbide end mill from the software’s tool library.

- Cutting Strategy: For outlining shapes, a “Pocket” or “Contour/Profile” operation is typical. For cutting through a sheet, you’ll use “Contour.”

- Stepover: This is the distance your tool moves sideways with each pass. For acrylic, a smaller stepover (e.g., 30-50% of the tool diameter) can lead to a smoother finish, especially on vertical walls.

- Stepdown: This is how deep the tool cuts in each pass. For acrylic, it’s better to use multiple shallow passes rather than one deep cut. This reduces stress on the tool and the material. A good starting point is 0.125 inches (3.175mm) or less, aiming for about half the tool diameter or even less for very thin materials.

Step 2: Machine Setup and Calibration

Before you can cut, your machine needs to be ready.

- Secure the Material: As mentioned before, firmly clamp or secure your acrylic sheet to your machine’s bed. Double-check that it’s stable and won’t shift.

- Install the End Mill: Insert the 3/16 inch end mill into your machine’s collet and tighten it securely. Ensure the collet is clean and free of debris.

- Set the Zero Point (Work Origin): This tells the machine where to start cutting. Typically, you’ll set this on your material’s surface (Z-axis) and at a specific corner or center point (X and Y axes). Use a touch probe or a conventional zeroing method.

- Check Machine Rigidity: Ensure all belts are tight and there’s no excessive play in your machine’s axes.

Step 3: Configure Your Speeds and Feeds

Getting the speeds and feeds right is crucial for clean acrylic cutting. These numbers are crucial – too fast or too slow can lead to melting, chipping, or tool breakage. The key is efficient chip formation and evacuation with minimal heat buildup.

Here’s a table with starting point recommendations. Always remember: these are starting points. You might need to adjust based on your specific machine, the brand of your end mill, and the exact type of acrylic.

| Parameter | Recommended Value for 3/16″ Carbide End Mill on Acrylic |

|---|---|

| Spindle Speed (RPM) | 18,000 – 24,000 RPM |

| Feed Rate (IPM – Inches Per Minute) | 20 – 40 IPM (300 – 600 mm/min) |

| Plunge Rate (IPM) | 10 – 20 IPM (150 – 300 mm/min) – Slower than feed rate |

| Depth of Cut (DOC – Per Pass) | 0.060 – 0.125 inches (1.5 – 3.2 mm) |

| Stepover (Width of Cut) | 30% – 50% of tool diameter (0.057 – 0.094 inches or 1.4 – 2.4 mm) |

Understanding Speeds and Feeds:

- Spindle Speed (RPM): How fast the end mill spins. Higher RPMs can help with melting if chip load is managed.

- Feed Rate (IPM): How fast the machine moves the tool through the material. A balance is needed; too slow rubs and melts, too fast can break the bit or cause poor finish.

- Plunge Rate: How fast the tool moves vertically into the material. It should be slower than the feed rate to avoid shocking the bit.

- Depth of Cut (DOC): How deep each pass is. Shallow passes generate smaller chips that are easier to clear.

- Stepover: How much the tool moves sideways when cutting profiles. A smaller stepover results in a smoother wall finish.

Where to find reliable data: Many end mill manufacturers provide recommended speeds and feeds charts for their tooling. Websites like Sandvik Coromant provide valuable resources for calculating machining parameters, though they often focus on metals. For plastics, using their general principles for light, non-ferrous cutting and then adjusting for the material’s properties is a good approach.

Step 4: Perform a Dry Run (Air Cut)

Before cutting into your expensive acrylic, always perform a “dry run” or “air cut.” This means running the G-code program with the spindle turned off, just above the surface of your material. This allows you to:

- Check if the tool reaches the correct depth.

- Verify that tool paths are correct and there are no collisions.

- Ensure your work holding is sufficient and the material isn’t moving.

- Confirm your machine is moving in the expected directions.

You can also raise the material slightly off the bed or use a piece of scrap wood as a sacrificial surface to listen for any signs of distress, like excessive rubbing or vibration.

Step 5: Run the Cutting Program

Once you’re confident after the dry run:

- Turn on the Spindle: Let it reach its target RPM before engaging the cutting feed.

- Start the Feed: Initiate the cutting program.

- Observe: Watch and listen carefully as the machine cuts. You should see clean chips being produced, not melted goo. If you hear squealing, see excessive melting, or notice the tool struggling, stop the machine immediately and reassess your speeds and feeds.

- Chip Evacuation: Ensure your dust collector is effectively removing chips from the cut. If chips are piling up and re-cutting, it’s a recipe for melting.

Step 6: Clean Up

After the cut is complete, remove your finished part. Acrylic edges might have a thin film of plastic or small burrs. You can often clean these up with:

- A deburring tool: For a quick edge clean-up.

- Fine-grit sandpaper (e.g., 400-600 grit): To smooth edges.

- A file: For more aggressive shaping if needed.

- Flame polishing: A more advanced technique, but a quick pass with a propane torch can create a wonderfully smooth, flame-polished edge on acrylic. Be cautious and practice on scrap first!

If you notice melted edges despite your best efforts, it’s usually an indication that your feed rate was too slow, your spindle speed was too high for the feed rate, or your chip evacuation was poor. Adjust accordingly for the next job.

Advanced Tips and Considerations for Acrylic

While the basics cover most scenarios, here are a few extra tips to elevate your acrylic cutting game.

Choosing the Right Acrylic Type

There are different types of acrylic, and they can behave differently when cut.

- Cast Acrylic: Generally preferred for CNC cutting because it’s less prone to internal stresses and tends to chip less. It also offers superior optical clarity.

- Extruded Acrylic: Cheaper and easier to work with for some applications (like bending), but it can be more prone to chipping and stress cracking when machined.

For dry cutting on a CNC, cast acrylic is usually the better choice for a cleaner finish.

Using a Polished or Mirror Finish End Mill

Many specialized end mills for plastics feature a polished flute. This smooth surface helps chips slide off more easily, reducing friction and the chance of material sticking and melting on the cutting edges. If you’re cutting a lot of acrylic, investing in a few of these can make a significant difference.

Variable Helix / Variable Pitch End Mills

Some end mills have a variable helix angle or pitch between the flutes. These are designed to break up harmonic vibrations during cutting, leading to a smoother cut and reduced chatter. While standard 2-flute bits are good, a variable helix version can be even better for plastics.

Coolant or Lubrication: When to Use It

Although this guide is about “dry cutting” because it’s often preferred for chip management and avoiding a mess, sometimes a coolant or lubricant can help. For acrylic, specific plastic-cutting lubricants or even just a light mist of soapy water can reduce friction. However, using liquid coolants can create a sticky mess with acrylic chips, so it needs careful consideration and a robust setup to manage the slurry produced.

Important Note: Never use petroleum-based lubricants like WD-40 directly on acrylic, as they can cause it to craze (crack) over time.

Dealing with Static Electricity

Acrylic is notorious for building up static electricity, which can cause fine dust to cling to surfaces and make chip evacuation more difficult. Using an anti-static spray on your material before cutting or employing an industrial static eliminator at the cutting point can help. Good dust collection also helps mitigate this by removing those charged particles quickly.

Edge Quality: The “Dressing” of Your Cut

Even with perfect cutting parameters, the edge quality can vary. If you need a glass-like finish, consider mechanical polishing after cutting. For many functional parts, a clean cut with minimal burrs is sufficient. If you have a dial indicator and a very stable machine, you might be able to get away with a single pass at a very shallow depth (e.g., 0.010″ or 0.25mm) to “clean up” the edge after the main cutting passes, effectively acting as a finishing pass.

The Importance of Material Thickness and Tool Length

A 3/16 inch end mill with an 8mm shank might come in various lengths (flute length and overall length). For cutting acrylic, you generally want a tool that is stiff enough for the job. Avoid excessively long end mills unless your design requires them. A longer tool is more prone to