Quick Summary

For machining titanium, a 3/16-inch carbide end mill, especially one with an 8mm shank designed for high Metal Removal Rates (MRR) and suitable for Grade 5 titanium, is an excellent choice. Look for specific carbide grades and geometries optimized for tough materials to ensure efficient and clean cuts.

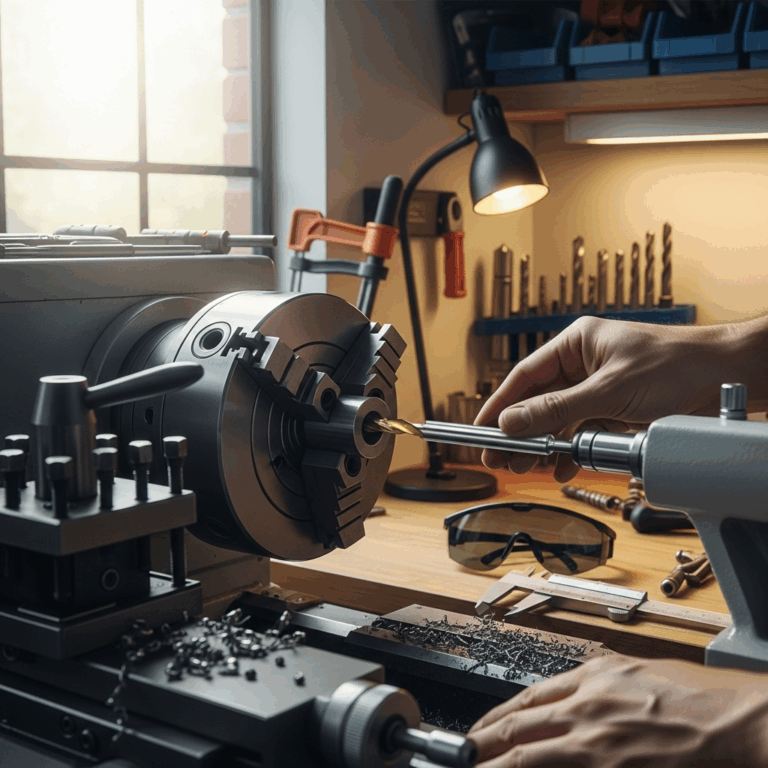

Hey there, fellow makers and machinists! Daniel Bates here from Lathe Hub. Ever stared at a piece of tough titanium and wondered what tool to use? It’s a common puzzle, especially when you’re starting out. Titanium can be tricky, but with the right tools, you can tackle it with confidence. Today, we’re diving into a specific hero for this job: the 3/16-inch carbide end mill. We’ll break down why it’s often the go-to, how to pick the best one, and what you need to know to get those clean cuts. Stick around, and we’ll make machining titanium less intimidating, one step at a time!

Why a 3/16-Inch Carbide End Mill is Your Titanium Buddy

Titanium is a super strong and lightweight metal, which makes it fantastic for aerospace, medical implants, and high-performance gear. But its toughness can be a real headache for your tools. It’s prone to work hardening, meaning it gets even tougher the more you cut it, and it doesn’t conduct heat well, leading to tool wear and poor surface finish if you’re not careful. This is where the right end mill comes in.

An end mill’s job is to cut material away, creating shapes and slots. When you’re dealing with a material as demanding as titanium, you need a tool that’s not only strong but also designed to handle heat and abrasion. That’s why carbide is king, and a 3/16-inch size is often perfect for many common machining tasks.

The Magic of Carbide

Carbide, specifically Tungsten Carbide, is incredibly hard and can withstand higher temperatures than traditional High-Speed Steel (HSS). When machining titanium, tools get hot! Carbide’s hardness and heat resistance allow it to maintain its cutting edge and shape, even under stressful conditions. This means:

- Longer Tool Life: Your carbide end mill will last much longer than an HSS one when cutting titanium.

- Higher Cutting Speeds: Because it handles heat better, you can often run carbide mills faster, leading to quicker machining times.

- Better Surface Finish: A sharp, strong carbide tool provides a cleaner cut, reducing chatter and improving the look and feel of your workpiece.

Why 3/16-Inch and 8mm Shanks?

The 3/16-inch diameter is a versatile size. It’s small enough for detailed work and creating precise slots, but robust enough for making good progress. It’s a common size for many milling operations, so you’ll find a good selection available. Many of these are paired with an 8mm shank. While inches are common in the US, metric sizes like the 8mm shank are prevalent globally, especially in Europe. An 8mm shank provides ample grip in standard milling machine collets and holders, ensuring secure tool holding for aggressive cuts. For reference, 3/16 of an inch is approximately 4.76mm, so an 8mm shank offers a significant advantage in rigidity and clamping force compared to a tool with a shank close to its diameter.

For those working with specific grades like Grade 5 titanium (Ti-6Al-4V), which is the most common alloy, the geometry and coating of the end mill become crucial. Tools specifically designed for aerospace alloys will have features that minimize friction and chip welding. We’ll talk more about these features next.

Choosing Your 3/16-Inch Carbide End Mill for Titanium

Not all carbide end mills are created equal, especially when titanium is on the menu. Here’s what to look for to make sure you get the right tool for the job:

1. End Mill Geometry

The shape of the end mill’s cutting edges and flutes is called its geometry. For titanium, you want geometry that helps manage heat and evacuate chips effectively.

- Number of Flutes: For titanium, 2 or 4 flutes are generally recommended.

- 2-Flute: Excellent for slotting and produces a larger chip load per tooth, which can help clear chips more efficiently. This is often preferred for aggressive material removal.

- 4-Flute: Offers a smoother finish and better rigidity. They are good for profiling and finishing passes where chip evacuation might be less of a bottleneck.

- Helix Angle: A higher helix angle (like 30-45 degrees) helps to lift chips away from the cutting zone more efficiently. This is crucial for preventing chip recutting and reducing heat build-up.

- Corner Radius: A small corner radius can add strength to the cutting edge, making it less prone to chipping. For heavy roughing, a square end (no radius) is common, but for better tool life and finish, a slight radius is often beneficial.

- Center Cutting: Make sure your end mill is center-cutting. This means it has cutting edges on the very tip, allowing you to plunge or drill into the material. This is essential for many machining operations.

2. Carbide Grade and Coating

The ”grade” of carbide refers to its composition and microstructure, which affects its hardness, toughness, and wear resistance. For machining tough alloys like titanium, you’ll want a premium carbide grade.

- Carbide Grade: Look for fine-grain or micro-grain carbide. These grades offer a good balance of hardness (for wear resistance) and toughness (to resist chipping). Manufacturers often specify their grades for specific applications; look for those rated for high-temp alloys or stainless steels.

- Coatings: Coatings add an extra layer of protection. For titanium, consider:

- TiAlN (Titanium Aluminum Nitride): This is a very common and effective coating for machining titanium. It forms a protective aluminum oxide layer at high temperatures, significantly improving heat resistance and reducing friction.

- AlTiN (Aluminum Titanium Nitride): Similar to TiAlN, it provides excellent performance at high temperatures and is great for abrasive materials.

- ZrN (Zirconium Nitride): Offers good lubricity and helps prevent chip welding, which is common with titanium.

- Uncoated: While less common for titanium, some specialized uncoated carbide grades can perform well if used with excellent coolant and optimized parameters. However, coated tools generally offer better performance and tool life for titanium.

3. “High MRR” and “For Titanium Grade 5” Designations

When you see “High MRR” (Metal Removal Rate) on a tool, it means the end mill is designed to cut a lot of material quickly. This is achieved through optimized flute geometry, sharp cutting edges, and robust construction. For titanium, this is key to being productive.

The mention of “Titanium Grade 5” (Ti-6Al-4V) is a strong indicator that the tool manufacturer has specifically engineered the end mill for the challenges of this particular alloy. Tools marketed this way usually incorporate the best practices in geometry, carbide grade, and coating for success.

4. Shank Diameter & Length

As mentioned, an 8mm shank is common for a 3/16-inch end mill. Ensure your machine’s collet or tool holder can securely grip the 8mm shank. For depth of cut, consider the overall length. Shorter, stubbier end mills are more rigid and less prone to vibration or deflection, which is beneficial for roughing. Longer end mills allow you to reach deeper into a workpiece or machine features further from your machine’s Z-axis.

Key Considerations for Machining Titanium

Using the right tool is only half the battle. How you use it is just as important, especially with titanium. Here are some critical points for successful machining:

1. Cutting Parameters (Speeds and Feeds)

This is probably the most critical factor. Titanium requires slower surface speeds and higher feed rates compared to softer metals like aluminum. The goal is to get a good, thick chip that carries heat away. If your chip is too thin and powdery, you’re likely rubbing and generating excessive heat, which will dull your tool quickly.

A good starting point for a 3/16-inch carbide end mill in Grade 5 Titanium might look something like this (always consult manufacturer recommendations and use these as guidelines):

| Operation | Surface Speed (SFM) | Feed per Tooth (IPT) | Axial Depth of Cut (DOC) | Radial Depth of Cut (DOC) | Coolant |

|---|---|---|---|---|---|

| Roughing (2 Flute) | 150-250 | 0.002 – 0.004 | 0.06 – 0.125 inches | 50-75% of Diameter (0.09 – 0.14 inches) | Flood or Mist Recommended |

| Finishing (4 Flute) | 200-300 | 0.001 – 0.002 | 0.01 – 0.03 inches | 10-25% of Diameter (0.02 – 0.05 inches) | Flood or Mist Recommended |

Note: SFM = Surface Feet per Minute. IPT = Inches per Tooth. These are general guidelines; always adjust based on your machine’s rigidity, coolant delivery, and tool manufacturer’s recommendations. For example, a very rigid setup might allow for higher SFM and larger chip loads.

Adjusting these parameters is key:

- If the tool is chattering or vibrating: Reduce feed rate, adjust depth of cut, or improve workholding rigidity.

- If the tool is getting too hot or showing signs of burning: Reduce surface speed, increase feed rate (to get a bigger chip), or improve coolant flow. Ensure your coolant is not contaminated or evaporating too quickly.

- If tool life is poor: Double-check speeds and feeds. Often, a slight adjustment in SFM or IPT can make a massive difference.

2. Coolant and Chip Evacuation

Titanium generates a lot of heat. Effective cooling is not optional; it’s essential. Flood coolant is highly recommended. A high-pressure coolant system that directs coolant directly into the flutes (through-spindle coolant, if available) is even better. This:

- Cools the cutting edge, preventing premature wear and thermal shock.

- Lubricates the cut, reducing friction.

- Helps to blast chips away from the cutting zone, preventing recutting and buildup.

If flood coolant isn’t an option, mist coolant can help, but it’s generally less effective for titanium. Make sure your chip evacuation strategy is working. If chips are building up in the flutes, they can jam, causing tool breakage or poor surface finish.

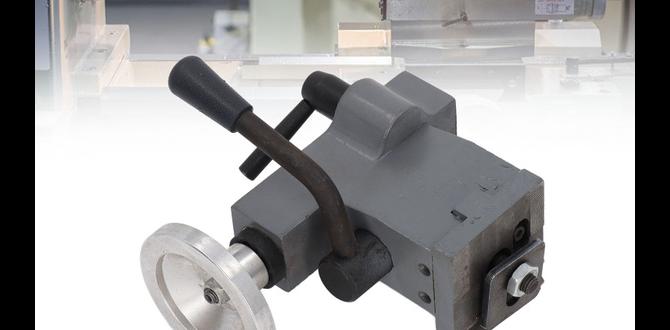

3. Rigidity and Workholding

Machining something as tough as titanium requires a very rigid setup. This means:

- Machine Rigidity: A sturdy milling machine with minimal play in the ways and spindle is crucial.

- Tool Holder Rigidity: Use a high-quality collet chuck or a hydraulic/milling chuck for the best tool holding. Avoid set-screw type tool holders for aggressive titanium cuts.

- Workholding: Secure your workpiece extremely well. Any movement or vibration in the workpiece will lead to poor results and potentially tool failure. Use strong vises, clamps, or fixtures designed for heavy-duty machining.

A less rigid setup will lead to chatter (vibration), poor surface finish, and reduced tool life. It’s a domino effect – a weak link anywhere can ruin the whole process.

4. Tool Path Strategies

For titanium, avoiding shallow depths of cut and high engagement angles is often beneficial. When doing any kind of contouring or profiling, consider

You can learn more about cutting strategies and best practices for aerospace materials from resources like the

NASA Machining of Titanium document. This paper provides in-depth information on the challenges and solutions for working with titanium alloys, which is invaluable for anyone serious about this material.

Step-by-Step: Using Your 3/16-Inch End Mill on Titanium

Let’s walk through a typical scenario. Imagine you need to cut a slot in a piece of Grade 5 Titanium plate using your 3/16-inch carbide end mill with an 8mm shank.

Preparation is Key:

- Select Your Tool: Choose a 3/16-inch (approx. 4.76mm) carbide end mill, preferably 2-flute for slotting, with a TiAlN or AlTiN coating and a suitable helix angle (30-45 degrees). Ensure it has an 8mm shank if that’s what your setup uses.

- Mount the End Mill: Securely insert the 8mm shank into your collet or tool holder. Ensure it’s clean and seated properly for maximum rigidity and to avoid runout.

- Secure the Workpiece: Clamp your Grade 5 Titanium plate firmly in your milling machine vise or fixture. Use soft jaws if necessary to prevent marring the surface, but ensure you have a very strong grip.

- Apply Coolant: Set up your flood coolant system and ensure it’s aimed directly at the cutting zone.

- Program or Manually Set Toolpath: Program your CNC or set up your manual machine for a slotting operation. You’ll need to define the start point, depth, and width of the slot. For a slot that matches the end mill diameter (3/16″), a simple plunge and climb milling motion will work.

Machining Process:

- Set Z-Zero: Carefully touch off on the top surface of your workpiece to establish your Z-zero point.

- Set X/Y Zero: Establish your X and Y zero point where your slot should begin.

- Initiate the Cut:

- Plunge: If plunging directly into the material, do so slowly using the recommended plunge feed rate. Many experts recommend not plunging directly into the center of titanium with an end mill, but rather using a helical interpolation or a pre-drilled hole. However, if you must plunge, use a very shallow plunge, and then transition to a side milling motion. A more advanced technique for slotting is “helical interpolation” where the tool rotates and moves in a circular path to create the slot, minimizing plunging stress.

- Side Milling: Once at the desired depth (or if starting from the edge of the part), begin your side milling operation. Use climb milling (where the cutter rotation direction matches the feed direction against the workpiece) for a cleaner cut and to reduce forces on the cutting edge.

- Monitor and Listen: Continuously monitor the cutting process. Listen for any unusual sounds like chatter or high-pitched squealing, which can indicate problems. Watch the chip formation – you want to see consistent, well-formed chips being ejected, not fine dust or molten metal.

- Achieve Depth: Continue the cut until you reach your final desired depth. For very deep slots, consider stepping down in multiple passes to manage heat and cutting forces.

- Finish the Operation: Once the slot is cut, retract the tool cleanly. Ensure the coolant is running until the tool is clear of the material.

Post-Machining:

- Clean and Inspect: Clean the workpiece and the tool. Inspect the tool for signs of excessive wear, chipping, or coating degradation. Inspect the surface finish of the slot.

- Deburr: Carefully deburr any sharp edges created by the milling process.

This systematic approach, from tool selection to execution, will help you achieve successful machining results with your 3/16-inch carbide end mill on titanium.

When to Use Which Type of End Mill (Table Comparison)

To help you make an informed choice, here’s a quick look at how different end mill types perform with titanium.

| End Mill Feature (3/16″ Diameter) |

Best for Titanium | Not Ideal for Titanium | Why? |

|---|---|---|---|

| Material | Carbide (Tungsten Carbide) | High-Speed Steel (HSS) | Car

|