Quick Summary:

Experiencing frustrating chatter when milling brass with a 3/16 inch carbide end mill? This guide decodes why it happens and offers proven solutions, focusing on proper tool selection, speeds, feeds, and setup techniques to achieve smooth, chatter-free brass cuts every time.

Hello fellow makers! Daniel Bates here from Lathe Hub. If you’ve ever tried to machine brass with an end mill, you’ve probably run into a common annoyance: chatter. That’s the vibration that leaves ugly ridges on your workpiece, making your nice brass parts look rough. It’s frustrating, especially when you’re aiming for those beautiful, shiny finishes brass is known for. But don’t worry! Chatter isn’t some unsolvable mystery. With a few key adjustments and the right approach, you can banish it from your workshop.

This guide is all about fixing that brass chatter using a 3/16 inch carbide end mill—a popular size for many projects. We’ll break down exactly why chatter happens and, more importantly, how to stop it. We’ll walk through everything step-by-step, from choosing the right tool to setting up your machine correctly. By the end of this article, you’ll have the knowledge and confidence to tackle brass with your end mill and get those smooth, professional results you’re looking for. Let’s get started and make some beautiful brass parts!

Why Does Brass Chatter? The Nitty-Gritty (Made Simple!)

Chatter, that annoying vibration you hear and see when milling, happens when the cutting tool (your end mill) isn’t taking a consistent bite of the material. Imagine trying to push a wobbly wheel; it doesn’t move smoothly. The same thing happens with your end mill. Several things can cause this wobble, especially with a soft metal like brass.

Brass is a relatively soft and “gummy” material. This means it can be prone to sticking to the cutting edge and deforming rather than cleanly shearing off. When the tool engages the brass, it might push into it, then pull away slightly, then push in again. This inconsistent engagement is the root cause of chatter. It’s a dynamic process involving the tool, the machine, the workpiece, and the cutting forces.

- Tool Deflection: The end mill bends slightly under cutting pressure, then snaps back.

- Machine Rigidity: Loose components in the machine (like spindle bearings or ways) vibrate more easily.

- Workpiece Holding: If your brass part isn’t held down tightly, it can move and vibrate.

- Cutting Speed & Feed: Going too fast or too slow, or taking too large a bite, can disrupt the cutting action.

- Tool Geometry: The shape and number of flutes on your end mill play a big role too.

Understanding these factors is the first step to solving the problem. We’re going to focus on how to control these elements, especially when using a 3/16 inch carbide end mill on brass.

Choosing the Right 3/16 Inch Carbide End Mill for Brass

Not all 3/16 inch end mills are created equal, especially when it comes to milling brass. For this soft, somewhat gummy metal, we want an end mill that cuts cleanly and efficiently. Carbide is a great choice because it stays sharp and rigid, but the specific design matters.

Key Features to Look For:

- Number of Flutes: For brass, fewer flutes are often better. A 2-flute end mill is typically the go-to. Why? Each flute has more space to clear chips, reducing the chance of recutting chips or the material packing up. More flutes (like 3 or 4) mean less chip clearance, which can be a recipe for chatter in softer metals.

- Helix Angle: A high helix angle (often 45 degrees or more) is ideal for brass. This steep angle helps the tool “screw” through the material, creating a cleaner shearing action and pulling chips up and out of the cut more effectively. This reduces the tendency for brass to build up on the cutting edge.

- Coating: While not strictly necessary for brass, a good quality uncoated or AlTiN (Aluminum Titanium Nitride) coated end mill can perform well. Uncoated carbide is common and effective. Avoid bright, shiny coatings like TiN (Titanium Nitride) as they’re often designed for harder materials or higher speeds.

- End Mill Type: For general milling of brass, a standard end mill with a flat end is usually sufficient. You might see “single-lip” or “carbide drill mill” tools, which are designed for drilling and some light milling—these can sometimes work well in brass for specific tasks due to their aggressive cutting action but a dedicated 2-flute high helix end mill is often superior for profiling and pocketing.

- Shank: A 3/16 inch shank is what we’re focusing on. Ensure it provides enough rigidity for the forces involved. For demanding cuts, consider an end mill with a Weldon shank (flat ground) for better clamping in your tool holder if your collet or holder supports it.

A good starting point for milling brass is a 2-flute, high helix, uncoated carbide end mill with a 3/16-inch diameter. Reputable manufacturers like Maritool, Grainger, or the cutting tool section of MSC Industrial Supply offer excellent options. Always check the manufacturer’s recommendations if available.

Dialing in Speeds and Feeds: The Heart of Chatter Prevention

This is where most beginners struggle, but getting speeds and feeds right is CRUCIAL for a chatter-free brass cut. It’s not just about picking numbers; it’s about understanding the relationship between how fast the tool spins (spindle speed), how fast it moves into the material (feed rate), and how deep it cuts (depth of cut).

Understanding the Basics:

- Spindle Speed (RPM): This is how fast the tool rotates. Measured in revolutions per minute.

- Feed Rate (IPM or mm/min): This is how fast the tool moves through the material. Measured in inches per minute (IPM) or millimeters per minute (mm/min).

- Depth of Cut (DOC): How deep the end mill cuts into the material on each pass.

- Width of Cut (WOC): How much of the end mill’s diameter is engaged in the material sideways. For brass, we often want to use a slightly lower WOC than the tool diameter, especially in finishing passes, to reduce side load.

- Chip Load: This is the thickness of the chip that each cutting edge (tooth) removes. Too thick a chip can overload the tool and cause chatter; too thin can lead to rubbing and poor finish. It’s a critical parameter often calculated directly from RPM, feed rate, and number of flutes.

Recommended Starting Points for 3/16 Inch Carbide End Mill in Brass:

These are starting points. You’ll likely need to fine-tune them based on your specific machine, the exact brass alloy, and your setup. Always err on the side of lighter cuts and slower feeds initially.

Let’s look at some common brass alloys. While “brass” is a broad term, common types for machining include:

- Free-Machining Brass (e.g., C36000): This is the easiest to machine.

- Naval Brass (e.g., C46400): A bit tougher, but still manageable.

- Red Brass / Cartridge Brass (e.g., C26000): Can be a bit “gummier.”

For a 3/16 inch (0.1875″) 2-flute carbide end mill in Free-Machining Brass (like C36000):

- Surface Speed (SFM): Aim for around 250-400 SFM (Surface Feet per Minute).

- Calculate RPM: The formula is: RPM = (SFM 12) / (pi Diameter)

- For 3/16″ (0.1875″): RPM = (300 12) / (3.14159 0.1875) ≈ 609 RPM. Let’s round to 600 RPM as a starting point.

- Chip Load: A good starting chip load for brass with a 2-flute carbide end mill is around 0.001″ to 0.003″ per tooth. Let’s use 0.002″ per tooth.

- Calculate Feed Rate: Feed Rate (IPM) = RPM Number of Flutes Chip Load

- Feed Rate = 600 RPM 2 Flutes 0.002″ / Flute = 2.4 IPM. This seems very slow. Let’s re-evaluate based on a slightly higher SFM or Chip Load.

- Let’s try 350 SFM for the calculation: RPM = (350 12) / (3.14159 0.1875) ≈ 716 RPM. Let’s use 700 RPM.

- With a 0.0025″ chip load: Feed Rate = 700 RPM 2 Flutes 0.0025″ / Flute = 3.5 IPM. Still quite slow but safer for beginners.

- Let’s try a more aggressive chip load of 0.004″ per tooth at 700 RPM: Feed Rate = 700 RPM 2 Flutes 0.004″ / Flute = 5.6 IPM. This is getting more reasonable.

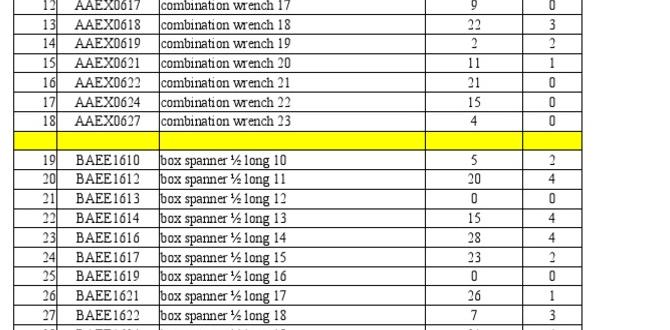

Table 1: Sample Speeds & Feeds for 3/16″ 2-Flute Carbide End Mill in Brass (C36000)

| Parameter | Value | Notes |

|---|---|---|

| Spindle Speed (RPM) | 600 – 1000 | Start lower, increase if cuts are clean. |

| Feed Rate (IPM) | 3 – 8 | Depends heavily on RPM and chip load. Listen to the machine. |

| Depth of Cut (Axial – DOC) | 0.060″ – 0.125″ | About 1/3 to 2/3 of the tool diameter. |

| Width of Cut (Radial – WOC) | 30% – 70% of Diameter (0.056″ – 0.131″) for roughing. 50% or less for finishing. | Using full ¼” WOC is asking for trouble with chatter. Use less than half the diameter. |

| Chip Load per Tooth | 0.001″ – 0.004″ | Critical for smooth cutting. |

Important Considerations:**

- Machine Rigidity: A less rigid machine (like a small hobby mill) will require slower speeds, lighter depths of cut, and potentially lower feed rates.

- Coolant/Lubrication: While brass doesn’t always require coolant, a light mist of cutting fluid or even WD-40 can help lubricate the cut, keep the tool cool, and improve chip evacuation, reducing chatter.

- Tool Sharpness: A dull end mill will absolutely cause chatter. If your tool is used, inspect it for wear.

- Listen and Observe: The sound of your cut is a HUGE indicator. A smooth, consistent hum is good. A high-pitched squeal or a rhythmic banging is chatter. Also, watch the chips – they should be consistent and not too fine (indicating rubbing) or too large and clunky.

For more technical details on calculating speeds and feeds that can be applied to various materials and tools, you can refer to resources like the Federality Speeds and Feeds Calculator which offers a solid understanding of the underlying principles.

Setting Up for Success: Eliminating Vibration Sources

Even with the perfect end mill and speeds/feeds, a shaky setup will lead to chatter. Think of it as trying to paint a masterpiece on a vibrating table – impossible! We need to make sure everything is as solid and stable as possible.

Workpiece Fixturing is Key:

This is paramount. Your brass part needs to be held down with absolute certainty.

- Clamps: Use sturdy clamps that firmly press the brass against a solid surface. Avoid overtightening so much that you deform the workpiece, but ensure it cannot move.

- Vise: A good quality milling vise with hardened jaws is excellent. Make sure the jaws are clean and the vise is clamped securely to the machine table.

- Tooling Plate/Fixtures: For more advanced setups, dedicated tooling plates with T-nuts or custom fixtures offer superior rigidity.

- Support: For longer or thinner parts, use supports (like parallels or riser blocks) underneath to prevent deflection or vibration.

Tool Holder and Spindle Integrity:

The connection between your spindle and your end mill is critical.

- Collet Chuck: A good quality collet chuck (like a ER collet holder) provides excellent runout and clamping force. Ensure the collet is clean and the correct size for your 3/16 inch shank end mill.

- Runout: Excessive runout (the amount the tool wobbles in the spindle) is a major chatter culprit. Make sure your spindle bearings are good and your collet holder is in good condition.

- Shank Seating: Ensure the end mill shank is fully seated in the collet. For Weldon shanks, ensure the set screw is snug but not overtightened.

Machine Condition:

- Cleanliness: Ensure your machine ways are clean and properly lubricated.

- Gibs: Adjust the gibs on your mill’s table and saddle to remove excess play without making movement stiff.

- Cutting Taboo: Avoid “climb milling” when starting out with brass, especially with larger diameters or less rigid machines. Conventional milling usually offers better control and reduced chatter risk for beginners.

Workpiece Material Handling:

Sometimes the brass itself can be the problem. If you’re using cast brass or a less homogenous alloy, it might behave differently. Ensure your starting material is consistent.

Techniques to Reduce Brass Chatter

Beyond tool selection and setup, there are specific milling techniques that significantly help in preventing chatter.

1. Step-Down Strategy (Depth of Cut):

Don’t try to take too much material off at once. The depth of cut (how deep you plunge the end mill into the material axially) and the width of cut (how much of the tool diameter engages radially) are crucial.

- Axial Depth of Cut (DOC): For a 3/16″ end mill, try starting with a DOC of around 0.060″ to 0.100. You can often increase this if the cut is clean, but it’s better to take multiple lighter passes than one heavy pass that chatters.

- Radial Width of Cut (WOC): This is often more critical than axial DOC. For brass, using a WOC that’s a significant percentage of the tool diameter (e.g., 70-100%) can lead to chatter due to the forces involved. Try using a WOC of 30-50% of the tool diameter. This reduces the side load on the tool.

2. Lead Angle/Toolpath Strategy:

How the tool enters and exits the material matters.

- Contour Milling (Pocketing/Profiling): When milling a perimeter or a pocket, the tool engages the material at different angles.

- Conventional Milling: The tool rotates against the direction of feed. This generally provides more control for beginners and can be less prone to chatter on sticky materials like brass.

- Climb Milling: The tool rotates with the direction of feed. This can result in a better finish and faster cutting but puts more stress on the tool and can cause chatter if not set up perfectly. For