For cutting steel with precision, an 8mm shank carbide end mill is a vital tool. Its sturdy build handles tougher materials and chip removal in steel, making it ideal for precise milling tasks in your workshop.

Ever stared at a piece of steel, wondering how to get those perfectly clean cuts and shapes you see in professional projects? It can feel a bit daunting when you’re starting out. Picking the right cutting tool makes a world of difference, and for working with steel, a specific type of end mill often comes up: the 8mm shank carbide end mill. This isn’t just any cutting tool; it’s designed to tackle the challenges steel presents. Don’t worry if it sounds technical, we’re going to break down exactly why this tool is so important and how you can use it effectively. Get ready to feel more confident about your steel milling projects!

Why an 8mm Shank Carbide End Mill is Your Go-To for Steel

When you’re milling steel, you’re dealing with a material that’s tougher and harder than wood or softer metals. This means your cutting tools need to be equally robust and capable. This is where the humble 8mm shank carbide end mill shines. Let’s dive into what makes it so special for steel machining.

The Power of Carbide

The “carbide” in carbide end mill is a big deal. Carbide, specifically tungsten carbide, is an extremely hard and wear-resistant material. Unlike high-speed steel (HSS) tools, carbide cutters can handle higher cutting speeds and temperatures without losing their sharpness. This is crucial for steel, which generates a lot of friction and heat when cut.

Benefits of Carbide for Steel Milling:

- Superior Hardness: Carbide is significantly harder than HSS, allowing it to cut through tough steels more easily.

- Heat Resistance: It can withstand the high temperatures generated during steel cutting, preventing the cutting edge from softening.

- Longevity: Carbide tools generally last much longer than HSS tools when used for appropriate materials like steel.

- Increased Productivity: The ability to cut faster means you can complete your milling jobs more quickly.

The Significance of the 8mm Shank

Now, let’s talk about the shank – the part of the end mill that fits into your milling machine’s collet or holder. An 8mm shank is a common size, particularly in many import milling machines and some European-standard setups. For beginners, having a readily available shank size like 8mm means you’re more likely to find the right collets and accessories without a hassle.

Why 8mm is a Practical Choice for Beginners:

- Availability: 8mm collets and tool holders are widely available, making it easy to equip your machine.

- Machine Compatibility: Many entry-level and hobbyist milling machines commonly use 8mm shanks.

- Balance of Strength and Size: For many common steel milling tasks on smaller machines, an 8mm shank provides sufficient rigidity without being overly large or heavy.

Understanding End Mill Types for Steel

Not all carbide end mills are created equal, especially when you’re targeting steel. The design features can significantly impact performance, chip evacuation, and tool life. For steel, you’ll often encounter these variations:

Common Carbide End Mill Designs for Steel:

- Number of Flutes: This refers to the number of cutting edges on the end mill.

- 2-Flute: Excellent for creating slots and pockets, and generally better at chip evacuation because there’s more space between the flutes. This is often preferred for steel.

- 4-Flute: Good for general-purpose milling, shoulder milling, and finishing. They remove material faster but can struggle with chip evacuation in deep cuts on gummy materials like some steels.

- Coating: Many carbide end mills for steel come with specialized coatings to further improve performance.

- TiN (Titanium Nitride): A general-purpose coating that adds a thin layer of hardness and reduces friction.

- TiAlN (Titanium Aluminum Nitride): Excellent for high-temperature applications and ideal for harder steels. It forms a protective oxide layer at high heat.

- AlTiN (Aluminum Titanium Nitride): Similar to TiAlN, offering great performance in high-temperature environments and for machining harder materials.

- Corner Radius (or Ball End Mill):

- Square End: Creates sharp internal corners.

- Corner Radius: Has a slightly rounded corner, which adds strength to the cutting edge and can help avoid chipping.

- Ball End: Has a fully rounded tip, used for 3D contouring, radiused slots, and creating fillets.

- Long Reach: Some end mills have an extended reach, allowing you to cut deeper into a workpiece or reach down into cavities. For steel, a long-reach end mill needs to be particularly rigid to prevent chatter.

Choosing Your 8mm Shank Carbide End Mill for Steel: Key Features to Look For

Now that you understand the basics, let’s get into the specifics of selecting the right 8mm shank carbide end mill for your steel projects. It’s about matching the end mill’s features to the job at hand.

Flute Count: The Chip Evacuation Champion

For steel, managing chips is paramount. Steel can produce long, stringy chips that can pack into the flutes of an end mill, leading to poor surface finish, tool breakage, or even damage to your workpiece. This is why a 2-flute end mill is often the preferred choice for steel applications.

Why 2 Flutes for Steel?

- Better Chip Clearance: With fewer flutes, there’s more space for chips to exit the cutting area. This is vital in steels, which tend to produce more cohesive chips than softer materials.

- Reduced Heat Buildup: Less material is being removed per flute rotation, which can help manage heat in tough cuts.

- Good for Slotting and Pocketing: The open flute design makes them ideal for operations where chips need to be aggressively cleared from a confined space.

While 4-flute end mills exist, they are generally better suited for finishing operations or milling materials that produce small, granular chips. If you’re doing heavy cutting or slotting in steel, stick with 2-flutes to start.

Material and Coating: The Hardness Factor

We’ve touched on carbide being great, but what about the specific grade of carbide and any coatings? For steel, especially harder steels, you’ll want to look for end mills made from high-quality tungsten carbide. Common grades are C10-C20 or the equivalent ISO K grades.

Coatings for Steel:

- TiAlN/AlTiN: These are your best friends for steel. They offer excellent thermal stability and lubricity, meaning they can handle the heat generated by cutting steel and reduce friction. They are particularly good for alloy steels and stainless steels.

- ZrN (Zirconium Nitride): Offers good performance and is often a good choice for specific materials.

- Uncoated: While less common for steel, some very specific applications might use uncoated carbide, but coated is generally preferred for performance and tool life.

When in doubt, opt for a TiAlN or AlTiN coated 2-flute carbide end mill with an 8mm shank for general steel roughing and semi-finishing. For fine finishing, a 4-flute with a similar coating might be useful, but understand its limitations in deep cuts.

Geometry: Shape Matters

The geometry of the end mill’s cutting edges and tip plays a role in its application. For steel:

- Square End Mills: These are the most common and versatile. They create 90-degree internal corners.

- Corner Radius End Mills: These have a small radius on the corners, which strengthens the cutting edge, reduces the chance of chipping, and leaves a small radius in the workpiece instead of a sharp corner. This can be beneficial for the longevity of both the tool and the part.

- Ball End Mills: Perfect for creating rounded profiles, fillets, and for 3D surfacing.

For general milling of slots, pockets, and profiles in steel, a square end mill or one with a small corner radius is usually the best starting point. If your design specifically requires rounded internal corners or 3D contours, the ball end mill is your tool.

Long Reach – Use with Caution

A “long reach” end mill has an extended flute length and shank. This can be useful for reaching deep into a workpiece or for milling parts with high aspect ratios. However, for steel, this introduces challenges:

- Reduced Rigidity: The longer the tool extends from the collet, the more prone it is to flexing and vibration (chatter).

- Increased Risk of Breakage: Chatter can lead to premature tool wear and breakage, especially in hard materials like steel.

If you need to use a long-reach end mill for steel, ensure you have a very rigid setup, use slower feed rates, and take shallower depth-of-cut passes. For many beginner steel projects, a standard length end mill will be more forgiving.

Practical Considerations for Using 8mm Shank Carbide End Mills with Steel

Once you’ve selected your tool, the next step is to use it effectively. Machining steel requires a different approach than softer materials. Safety, proper setup, and understanding cutting parameters are key.

Safety First!

Machining steel with carbide end mills presents specific safety concerns:

- Eye Protection: Always wear safety glasses or a full face shield. Steel chips can be sharp and ejected at high speeds.

- Hearing Protection: Milling can be loud.

- Secure Workpiece: Ensure your workpiece is firmly clamped and cannot move during machining.

- Tool Security: Make sure the end mill is securely seated in the collet or tool holder. A loose tool can be catastrophic.

- Clear Workspace: Keep your work area clean and free of debris to prevent trip hazards and to allow for easy chip removal.

- Coolant/Lubrication: For steel, using a cutting fluid or lubricant is highly recommended to manage heat and improve surface finish.

Always refer to your milling machine’s manual for specific safety guidelines and ensure you are familiar with its operation.

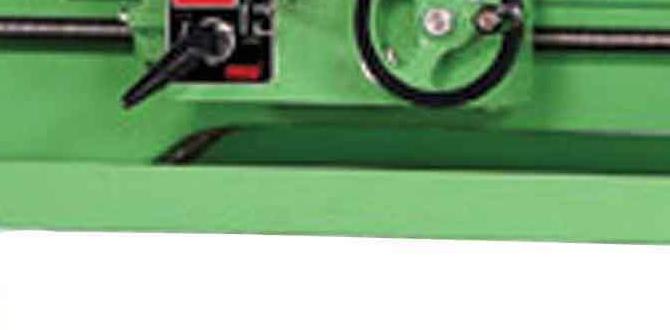

Setting Up Your Machine

The setup of your milling machine and the workpiece is critical for success:

- Secure the Workpiece: Use a vise, clamps, or other appropriate work-holding fixtures to ensure the steel part is held rigidly. Any movement will lead to inaccurate cuts and potential tool damage.

- Install the End Mill: Insert the 8mm shank end mill firmly into an 8mm collet. Tighten the collet securely in the milling machine’s spindle. Ensure there’s no runout (wobble) from the spindle.

- Set Your Zero Point: Accurately determine the starting point for your cutting operation (X, Y, and Z zero).

- Coolant Delivery: Set up your coolant system. This could be a flood coolant system, a mist coolant, or even a manual application of cutting fluid with a brush or spray.

Understanding Cutting Parameters (Speeds and Feeds)

This is often the trickiest part for beginners. Cutting speeds and feed rates determine how fast the tool rotates (spindle speed, usually in RPM) and how fast it moves through the material (feed rate, usually in mm/min or inches/min). Getting these wrong can lead to tool breakage, poor surface finish, or inefficient machining.

Factors Influencing Speeds and Feeds for Steel:

- Material Hardness: Softer steels can be cut faster than hardened steels.

- End Mill Diameter: Larger diameter end mills generally need slower RPMs.

- End Mill Type: Carbide vs. HSS, number of flutes, and coatings all play a role.

- Machine Rigidity: A more robust machine can handle higher cutting forces.

- Coolant: Using coolant allows for higher speeds and feeds.

- Depth of Cut (DOC) and Width of Cut (WOC): How deep and wide each pass is. Shallower cuts allow for faster feeds.

For an 8mm shank carbide end mill in steel, a good starting point for spindle speed might be between 200 and 800 RPM, depending on machine capability and the specific steel. Feed rates are harder to generalize, but you’re looking for a consistent chip load. A common practice is to use a chip load calculator, which takes these variables into account.

Rule of Thumb for Starting:

- Start conservatively: Always err on the side of slower speeds and lighter feeds when you’re unsure.

- Listen and observe: Pay attention to the sound of the cut and the appearance of the chips. A smooth cutting sound and well-formed chips are good signs. Chattering or screeching indicates a problem.

- Use manufacturer’s data: Many end mill manufacturers provide recommended cutting parameters for their tools and specific materials. These are excellent resources.

- Consult online resources: Websites dedicated to CNC machining and CAD/CAM often have extensive databases for speeds and feeds. For example, searching for “steel milling speeds and feeds calculator” will provide useful tools.

It takes practice to dial in the perfect settings, but starting with good references and paying attention to your machine is key.

Chip Evacuation: Keeping it Clean

As mentioned, chip evacuation is critical when milling steel. Here’s how to maximize it:

- Use 2-Flute End Mills: This is your primary defense.

- Adequate Coolant: Ensure coolant is directed effectively at the cutting zone to flush chips away.

- Program for Chip Thinning: In CNC machining, programming techniques can reduce the chip load per flute, which helps prevent chip packing.

- Pecking Cycles: For deep pockets, consider using a “peck drilling” motion where the tool retracts periodically to clear chips.

- Avoid Re-cutting Chips: Ensure your machining path doesn’t force the tool to cut through chips that haven’t cleared the pocket.

When to Use an 8mm Shank Carbide End Mill Specifically for Steel

So, when is this specific tool the absolute best choice for your steel projects? Think about these scenarios:

Ideal Applications:

- Machining Mild Steel: For common mild steel (like 1018 or mild structural steel), an 8mm carbide end mill is excellent for creating slots, pockets, and contours.

- Creating Accurate Features: If you need precise dimensions and clean edges on steel parts, this tool delivers.

- Hobbyist CNC or Manual Milling: For users with smaller milling machines that commonly accept 8mm collets, it’s a perfect fit.

- Prototyping and Small Batch Production: For making one-off parts or small runs, the efficiency and precision of carbide are invaluable.

- Adding Details to Steel Parts: For any detailed milling work on steel objects, whether functional or decorative.

Things to Consider if Steel is Particularly Hard:

If you’re working with hardened tool steels or very high-alloy steels, even a carbide end mill will have its limits. For these materials, you might need:

- Specialized end mills designed for hardened steels.

- Slower cutting speeds and even lighter depths of cut.

- More advanced cooling and lubrication strategies.

- To consider grinding or EDM (Electrical Discharge Machining) if the material is extremely hard.

Common Mistakes to Avoid

Even with the right tool, beginners can make common errors that lead to frustration or tool failure. Here are some to watch out for:

Beginner Pitfalls:

- Using the Wrong Speeds and Feeds: Too fast, and you risk burning the tool or workpiece. Too slow, and you get poor finish and potentially chatter.

- Not Enough Coolant/Lubricant: Steel generates heat. Without adequate cooling, your carbide tool can lose its hardness and wear out very quickly, even leading to catastrophic failure.

- Taking Too Deep of a Cut: For steel, and especially with an 8mm shank, start with conservative depths of cut. This is often referred to as “chip load” – the thickness of material removed by each cutting edge. Keep it appropriate for the tool and material.

- Ignoring Chip Evacuation: Letting chips pack into the flutes is one of the fastest ways to break an end mill or ruin a surface finish.

- Using a Dull or Damaged Tool: Always inspect your end mill before use. A dull tool requires more force, generates more heat, and