Have you ever wondered how to keep your tools sharp? A sharp tool makes work easier and safer. One important tool in workshops is the carbide insert. These inserts help machines cut through hard materials. But what happens when they become dull? That’s where our carbide insert sharpening guide comes in!

Did you know that sharpening your carbide inserts can extend their life? Many people toss out dull inserts, thinking they’re useless. Yet, with a little effort, you can bring them back to life! Imagine saving time and money by enhancing your tools instead of replacing them.

This guide will show you step-by-step how to sharpen carbide inserts. You’ll learn tips and tricks that both beginners and experienced workers can use. Soon, you’ll see just how helpful it can be to have sharp carbide inserts at your disposal.

The Ultimate Carbide Insert Sharpening Guide: Techniques & Tips

Carbide Insert Sharpening Guide

Carbide inserts are essential for cutting tools. When they become dull, they can affect the quality of your work. Learning to sharpen them can save you money and time. The carbide insert sharpening guide teaches you how to keep your tools sharp. You discover simple techniques and tools that make the sharpening process easier. Did you know that a properly sharpened insert can last much longer? This guide helps craft a smooth and efficient cutting experience.

Understanding Carbide Inserts

Definition and applications of carbide inserts. Types of carbide inserts and their uses.

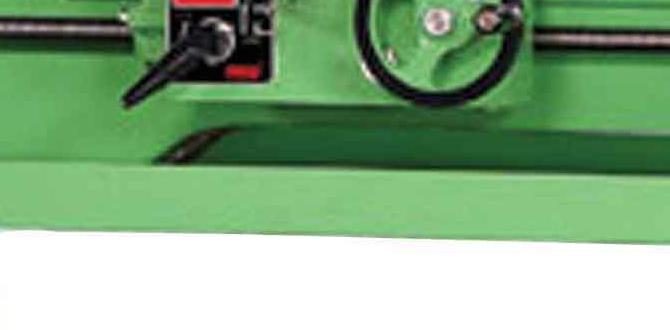

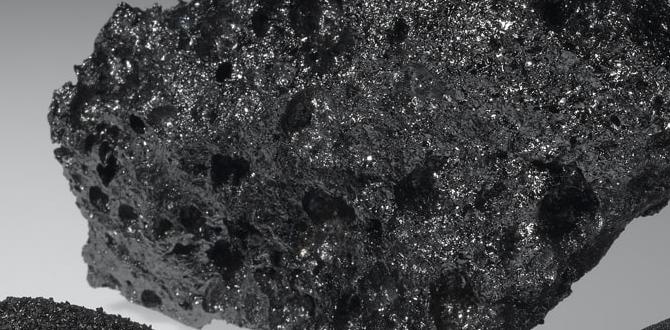

Carbide inserts are tough little tools that help machines slice through hard materials like butter. They are often used in lathes and milling machines for metalworking and woodworking. These inserts come in various shapes and sizes, depending on what you need them for. Let’s explore some types!

| Type of Insert | Application |

|---|---|

| Turning Inserts | Used for shaping and cutting metal. |

| Milling Inserts | Perfect for flat surfaces and grooves. |

| Drilling Inserts | Ideal for making holes in various materials. |

Each type of carbide insert serves a different purpose, making them versatile companions in the workshop. So, whether you’re turning up the heat on metal or drilling into wood, there’s a carbide insert just waiting for its moment to shine!

Importance of Sharpening Carbide Inserts

Benefits of sharpening versus replacing inserts. Impact on machining performance and tool life.

Sharpening carbide inserts can save time and money. Why toss them out? A sharp insert works wonders for machining. It cuts smoothly, giving better results. This means you can produce more pieces with less effort. Plus, sharpening can extend the tool’s life. Imagine getting more mileage from your tools; it’s like finding a hidden stash of candy! Check out the benefits in the table below:

| Benefits | Effects |

|---|---|

| Cost Savings | Less spending on new inserts |

| Improved Performance | Faster and smoother cuts |

| Longer Tool Life | More uses before replacements |

So, before you throw those inserts away, remember that a little sharpening can go a long way!

Tools and Equipment Needed for Sharpening

Essential tools for effective sharpening. Safety equipment and protective measures.

Sharpening inserts requires a few essential tools. You need a good sharpening stone or wheel to make those inserts shine bright like a diamond. Don’t forget safety glasses to protect your eyes; you don’t want to turn into a one-eyed pirate! A sturdy workbench helps keep everything steady. Strong gloves will help you avoid those pesky cuts. Here’s a quick list:

| Tool/Equipment | Purpose |

|---|---|

| Sharpening Stone/Wheel | To grind down the carbide inserts |

| Safety Glasses | To protect your eyes from flying debris |

| Work Bench | Stable surface for sharpening |

| Work Gloves | To avoid cuts and scrapes |

With these tools, you’ll be the superhero of sharpening. Remember, safety first, so you can keep your fingers intact for more sharpening adventures!

Step-by-Step Carbide Insert Sharpening Process

Preparing the insert for sharpening. Detailed sharpening techniques (manual and machine methods).

First, make sure to prepare the carbide insert for sharpening. Clean away any dirt and debris. This helps avoid any surprises, like that sneaky coffee stain on your shirt! Next, choose your sharpening method. You can go manual with a trusty diamond stone or kick it up a notch with a machine grinder. Both work well—just remember to keep your fingers away from the blade! Here’s a quick view of the methods:

| Sharpening Method | Pros | Cons |

|---|---|---|

| Manual (Diamond Stone) | Controlled process | Time-consuming |

| Machine Grinder | Fast and efficient | Less control |

No matter your choice, sharpening can extend your tool’s life dramatically. It’s like giving your carbide inserts a nice, refreshing spa day! So get sharpening and watch your tools shine like stars!

Measuring Insert Geometry Post-Sharpening

Importance of precise measurements. Tools for measuring insert angles and geometry.

Precise measurements after sharpening are vital. They ensure the carbide insert works well and lasts longer. Using the right tools makes this easier. Here are some useful tools for measuring angles and geometry:

- Calipers: Great for measuring thickness.

- Protractors: Perfect for checking angles.

- Micrometers: Best for very small measurements.

By using these tools correctly, you can keep your inserts in top shape.

Why are precise measurements important?

Precise measurements help maintain insert performance and reduce wear. Without them, tools may work poorly.

What tools are best for measuring?

- Calipers

- Protractors

- Micrometers

Common Mistakes to Avoid in Carbide Insert Sharpening

Frequent errors that can damage inserts. Tips to ensure consistent sharpening quality.

Sharpening carbide inserts is tricky. One common mistake is applying too much pressure. This can lead to damage. Instead, use a light touch for a smooth finish. Another error is using the wrong angle. A good tip is to keep it consistent. Also, avoid sharpening inserts too often; they wear down. Lastly, always check for chips or cracks. Regular checks keep your inserts happy and sharp—like a cat with a new toy!

| Error | Tip |

|---|---|

| Too much pressure | Light touch is best! |

| Wrong angle | Keep it consistent! |

| Sharpening too often | Only as needed! |

| Ignoring chips | Regular checks! |

Maintenance Tips for Prolonging Insert Life

Proper storage and handling of carbide inserts. Best practices for ongoing maintenance postsharpening.

To keep your carbide inserts sharp and happy, proper storage is key. Always store them in a dry place, away from moisture, because water and metal don’t mix! It’s smart to use a dedicated container so small pieces don’t go on an adventure without you. After sharpening, check for any damage. A little TLC goes a long way. Regularly clean the inserts to remove buildup. Remember, a clean insert is a happy insert! Follow these simple steps, and your inserts will thank you with a longer life.

| Storage Tips | Maintenance Tips |

|---|---|

| Keep them dry! | Clean regularly. |

| Use proper containers. | Check for damage. |

When to Replace vs. Sharpen Carbide Inserts

Indicators that sharpening is no longer viable. Costeffectiveness of replacement decisions. “`html

Knowing when to say goodbye to carbide inserts is crucial. One sign sharpening may not help is visible chips on the edge. If it looks more like a nibble than a tool, time for a switch! Also, if you find yourself sharpening frequently, it could be more cost-effective to replace them altogether. Remember, sharpening can be like trying to fix a broken pencil—sometimes it’s better to get a new one!

| Indicator | Action |

|---|---|

| Chips or cracks | Replace |

| Frequent sharpening | Consider replacement |

| Performance drop | Replace |

Ultimately, balancing costs and performance is key. Make smart choices, just like your favorite superhero would do! Remember, no one wants to battle dull tools.

“`

Conclusion

In conclusion, a carbide insert sharpening guide helps you maintain your tools for longer use. It shows you how to sharpen inserts efficiently. You save money and improve your work quality. Remember to practice sharpening regularly. For more tips and techniques, check out other resources online. With the right information, you can become a sharpening pro!

FAQs

What Are The Different Methods For Sharpening Carbide Inserts, And Which One Is Most Effective?

You can sharpen carbide inserts using a few different methods. Some people use diamond wheels, which are very strong. Others use manual tools like files or special machines. The best way depends on what you have and how sharp you need them. Many say diamond wheels are the most effective because they last a long time and work well.

How Can You Determine When A Carbide Insert Needs Sharpening Versus Replacement?

You can tell when a carbide insert needs sharpening if it feels dull or doesn’t cut well. If you see many chips or cracks, it’s time to replace it. Look at the edge carefully; if it’s worn down too much, replace it. Sharpening can help for slight dullness, but big damage means it’s better to get a new one.

What Tools And Equipment Are Necessary For Sharpening Carbide Inserts Safely And Effectively?

To sharpen carbide inserts, you need a few important tools. First, use a diamond grinding wheel because it works best for carbide. Next, have a good sharpening fixture to hold the insert steady. Safety goggles are also important to protect your eyes. Lastly, use coolant to keep everything cool while you work.

What Are The Best Practices For Maintaining The Geometry And Cutting Edge Of Carbide Inserts During The Sharpening Process?

To keep carbide inserts sharp, follow a few simple steps. First, use the right sharpening tool so you don’t damage them. Next, check the angle while sharpening to keep the edges even. Always clean the inserts after sharpening to remove dust and debris. Finally, store them safely to prevent chips or cracks.

How Does The Sharpening Angle Affect The Performance And Lifespan Of Carbide Inserts In Machining Applications?

The sharpening angle of carbide inserts helps them cut better. A sharper angle makes it easier to slice through materials, which improves performance. But if the angle is too sharp, the insert can wear out quickly. So, finding the right angle helps it last longer while still working well.