Understanding Cnc Metal Lathe Chuck: Key Features And Uses

A CNC metal lathe chuck is crucial for holding your workpiece steady while machining. Did you know that a good chuck can improve precision? These chucks come in various types, like three-jaw and four-jaw, to suit different tasks. They help maintain the right grip, ensuring your metal projects turn out perfectly. Imagine making a custom part for a robot or a car; a reliable chuck makes a big difference. Understanding your options helps you choose the best fit for your needs!

What is a CNC Metal Lathe Chuck?

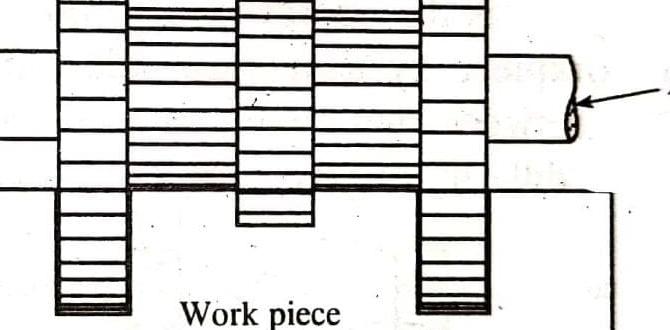

Definition and function of a CNC metal lathe chuck. Components and types of CNC metal lathe chucks.

A CNC metal lathe chuck holds metals in place while they spin. Think of it as a loyal sidekick for machines! It has different parts, like jaws, to grip the material tightly. There are various types of chucks too, including three-jaw and four-jaw options. Three-jaw chucks are the popular choice, like pizza at a party, while four-jaw chucks are more versatile, like that friend who can dance and sing!

| Type of Chuck | Description |

|---|---|

| Three-Jaw Chuck | Grips with three jaws for quick loading. |

| Four-Jaw Chuck | Offers more control and flexibility. |

With a CNC metal lathe chuck, machining becomes a breeze. It ensures the metal stays put, enabling precise cuts. Remember, a good chuck does wonders, but don’t let it handle your pizza!

Types of CNC Metal Lathe Chucks

Threejaw chucks: advantages and applications. Fourjaw chucks: benefits and use cases. Collet chucks: features and appropriate usage. Specialpurpose chucks: when to use them.

There are several types of CNC metal lathe chucks, each with unique benefits. Three-jaw chucks are popular for holding round pieces. They grip evenly, making them great for tasks like drilling. Four-jaw chucks can hold square or irregular shapes. They offer more flexibility, allowing fine adjustments. Collet chucks are perfect for small parts. They provide tight holds and are ideal for precision work. Lastly, special-purpose chucks serve specific tasks when needed, like in specialized machining processes.

What are the types of CNC metal lathe chucks?

Three-jaw, four-jaw, collet, and special-purpose chucks are the main types.

Key Benefits

- Three-jaw chucks: Fast setup and great for round pieces.

- Four-jaw chucks: Versatile for odd shapes and precise adjustments.

- Collet chucks: Strong grip suitable for very small parts.

- Special-purpose chucks: Designed for unique tasks or materials.

How to Choose the Right CNC Metal Lathe Chuck

Factors to consider: size, capacity, and compatibility. Material types and their impact on performance. Common applications and selecting for specific tasks.

Picking the right CNC metal lathe chuck is like choosing the perfect ice cream flavor. You want to consider a few key factors to avoid a ‘brain freeze’ moment! First, think about the size and capacity. Make sure it fits your machine. Next, check the material types. Some are more durable than others, which can affect performance. Lastly, know your tasks. Different chucks work better for specific jobs, so choose wisely!

| Factor | Importance |

|---|---|

| Size | Fits your lathe |

| Capacity | Handles your workload |

| Material | Affects durability |

| Application | Specific job needs |

Installation and Setup of CNC Metal Lathe Chucks

Stepbystep guide to installing a CNC metal lathe chuck. Adjustments and calibrations for optimal performance.

Installing a CNC metal lathe chuck can seem tough. Follow these steps to make it easy. First, gather your tools like wrenches and a level. Then, turn off the machine and clean the surface. Place the chuck carefully and secure it tightly. Next, adjust it using shims if needed. Always check that it spins smoothly. For best results, calibrate the chuck by testing various speeds. Regular checks ensure your machine works safely and efficiently.

How do you adjust a CNC metal lathe chuck?

You can adjust a CNC metal lathe chuck by following these steps: Use a dial indicator to find any wobble. If wobbling occurs, loosen the screws and adjust the chuck. Then, re-tighten the screws and check again. Repeat until there is no wobble.

- Gather tools (wrenches, level)

- Turn off the machine

- Clean the surface

- Place and secure the chuck

- Adjust with shims if necessary

- Check for smooth spinning

- Calibrate for optimal performance

Maintenance Tips for CNC Metal Lathe Chucks

Routine maintenance practices to extend lifespan. Troubleshooting common issues and solutions. Signs indicating the need for replacement or repair.

Keeping your CNC metal lathe chuck in tip-top shape is a must! Regular cleaning is key, usually using compressed air and a soft cloth. Check for any *loose screws* or parts that seem off. When something isn’t working, look for signs like vibrations or uneven cuts. This means it might need fixing. If you see cracks or major wear, it’s definitely time for *replacement*. Remember, a well-maintained lathe chuck is like a well-fed cat—much more fun and less trouble!

| Maintenance Tips | Signs of Trouble | Action Needed |

|---|---|---|

| Clean often | Unusual noises | Check alignment |

| Inspect parts | Vibrations | Tighten screws |

| Lubricate regularly | Ineffective clamping | Consider replacement |

Safety Considerations when Using CNC Metal Lathe Chucks

Essential safety protocols and best practices. Importance of proper protective equipment.

Using a CNC metal lathe chuck safely is very important. Follow these simple safety rules:

- Always wear proper protective equipment like goggles and gloves.

- Make sure your workspace is clean and free of clutter.

- Check the machine settings before starting.

- Nobody should be nearby while the machine is running.

- Know how to turn off the machine quickly in case of an emergency.

Being safe keeps you and others out of harm’s way. Remember, a little caution goes a long way!

What is the importance of protective equipment?

Using protective equipment is crucial. It helps prevent injuries. Always wear gear to protect your eyes and hands. Safety first!

Innovations in CNC Metal Lathe Chuck Technology

Recent advancements in materials and design. Future trends and their implications for manufacturing.

Recent changes in cnc metal lathe chuck technology are transforming how we make things. New materials are stronger and lighter, leading to better designs. For example, carbon-fiber chucks are becoming popular. They hold parts firmly while weighing less than a sandwich! These advancements promise faster production times and lower costs, making everyone happy. Future trends will likely focus on smart technology. Imagine your chuck sending you a text when it needs maintenance. Time to toast that innovation, right?

| Advancement | Benefit |

|---|---|

| Carbon-fiber Materials | Stronger & Lighter |

| Smart Chucks | Efficiency & Alerts |

| Better Designs | Faster Production |

Conclusion

In summary, a CNC metal lathe chuck is essential for precise machining. It holds metal pieces securely while you work. Choosing the right chuck improves your projects. We encourage you to explore different chucks to find the best fit for your needs. Keep learning about CNC tools to enhance your skills and create amazing things!

FAQs

What Are The Different Types Of Chucks Used In Cnc Metal Lathes, And What Are Their Specific Applications?

CNC metal lathes use different types of chucks to hold metal pieces. A three-jaw chuck holds circular items and is great for making parts like shafts. A four-jaw chuck can hold square or uneven shapes. We also have collet chucks, which squeeze tight to hold smaller parts for precise work. Each chuck helps us make different shapes accurately.

How Do You Properly Install And Align A Chuck On A Cnc Lathe To Ensure Precision Machining?

To install a chuck on a CNC lathe, first, make sure the machine is turned off. Next, clean the surface where the chuck will sit. Place the chuck gently onto the machine’s spindle. Then, tighten it securely using a wrench. To align it, check that the chuck’s teeth are centered and adjust if needed. Lastly, do a quick test run to make sure everything spins evenly.

What Maintenance Practices Should Be Followed To Ensure The Longevity And Accuracy Of A Cnc Lathe Chuck?

To make your CNC lathe chuck last longer, you should clean it regularly. Always check for dirt or chips and remove them. You must also keep the chuck well-lubricated. This helps it move smoothly. Finally, be sure to check for any damage and fix it right away.

How Does The Choice Of Chuck Jaw Style (E.G., Hard Jaws Vs. Soft Jaws) Impact The Machining Process And Workpiece Stability?

Choosing the right chuck jaw style matters a lot. Hard jaws grip tightly but can hurt softer materials. Soft jaws can be made to fit any shape, which keeps the workpiece stable. If we use soft jaws, we can hold different shapes better without damaging them. This helps us make better and safer parts when we machine.

What Safety Considerations Should Operators Be Aware Of When Working With Chucks On Cnc Metal Lathes?

When using chucks on CNC (Computer Numerical Control) metal lathes, we need to be careful. Always wear safety glasses to protect your eyes. Keep your hands and clothes away from the moving parts. Make sure the chuck is tight so the metal doesn’t fly off. Never reach inside while the lathe is running. Safety is very important!