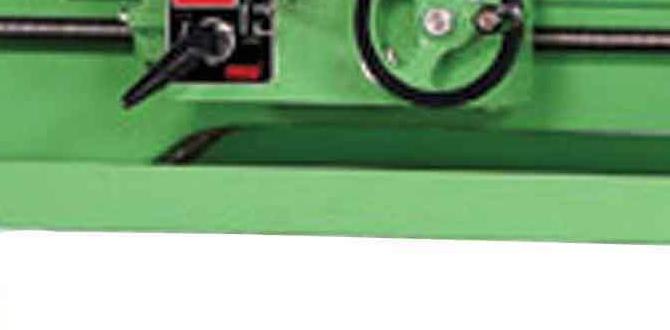

Have you ever wondered how small metal parts are made? It’s actually pretty fascinating! One important tool in this process is the cnc metal lathe handwheel. This handy device helps machinists shape metal with precision.

Imagine turning a simple block of metal into a beautiful, smooth cylinder. That’s what a cnc metal lathe can do. The handwheel makes controlling the lathe easier, allowing for careful adjustments.

Did you know that many of the machines we use today started with similar tools? From cars to small toys, everything benefits from CNC machining. When you understand how a cnc metal lathe handwheel works, you unlock a world of creativity.

Curious about how this tool can improve your projects? Let’s dive deeper into the fascinating world of CNC lathes and see how they turn ideas into reality!

Cnc Metal Lathe Handwheel: Essential Tools For Precision Machining

The CNC metal lathe handwheel is a crucial tool for precise machining. It enables users to manually adjust the lathe settings easily. Imagine being able to control the speed and direction of metal pieces smoothly. This handwheel lets operators fine-tune their work without intricate setups. Not only does it enhance accuracy, but it also speeds up the workflow. Knowing how to use it effectively can lead to impressive projects and improved skills in metalworking.

Understanding CNC Metal Lathes

Definition and functionality of CNC metal lathes. Importance of precision and control in machining.

A CNC metal lathe is a machine that shapes metal into different forms. It uses computer control for accuracy. This technology helps make precise cuts and designs. Precision is key in machining. It ensures parts fit together perfectly. Control over the machining process leads to consistent quality. Machines that work well can save time and materials. Imagine a sculptor carving a statue. Each detail matters, just as it does in machining.

What is the function of CNC metal lathes?

CNC metal lathes allow for accurate and repeatable machining, creating parts with exact dimensions and shapes.

Key benefits of using CNC metal lathes:

- High precision and accuracy

- Reduced waste of materials

- Faster production times

- Enhanced safety and control

The Role of the Handwheel in CNC Lathes

Functions of the handwheel in manual operations. How the handwheel enhances user control and machining accuracy.

The handwheel is an important part of a CNC lathe. It helps you move the machine in manual operations. This makes it easier to control how much you want to cut. With the handwheel, users can adjust their movements carefully. It improves user control and allows for better machining accuracy. This means you get a cleaner and more precise cut every time. Using the handwheel gives you a feeling of control over the entire process.

What are the functions of the handwheel in CNC lathes?

The handwheel has several key functions:

- Manual Control: You can move the tool closer or farther from the workpiece.

- Fine Adjustments: It allows for small changes to improve cuts.

- Feedback: You feel how the machine responds to your movements.

Choosing the Right Handwheel for Your CNC Lathe

Factors to consider: size, material, and compatibility. Pros and cons of different handwheel types.

Choosing the right handwheel can make a big difference in your CNC lathe work. Consider these key factors:

- Size: The wheel should fit comfortably in your hand.

- Material: Choose a strong material like metal for durability.

- Compatibility: Ensure it matches your CNC machine type.

Different handwheel types have their pros and cons:

- Plastic: Lightweight but less durable.

- Metal: Heavy and sturdy, but may cause fatigue.

The right choice will improve control and comfort. Are you ready to spin!?

What is the best material for a CNC lathe handwheel?

The best material is usually metal due to its strength and long life. Plastic can be lighter but may wear out quickly.

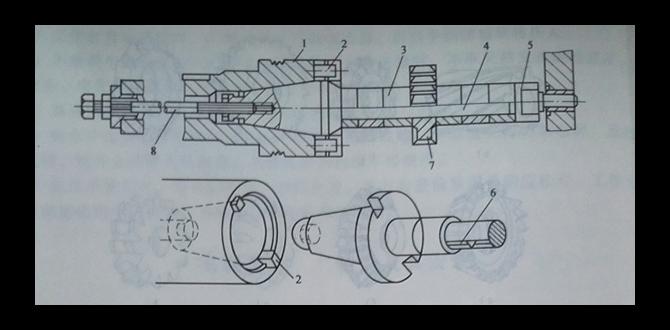

Installation and Maintenance of CNC Metal Lathe Handwheels

Stepbystep installation guide for beginners. Maintenance tips to prolong the lifespan of handwheels.

Installing a CNC metal lathe handwheel can be simple. Start with these steps:

- Gather your tools: screwdriver and wrench.

- Remove the old handwheel if needed.

- Align the new handwheel on the shaft.

- Secure it tightly with the screws.

- Test the handwheel to ensure it turns smoothly.

To keep the handwheel working well, follow these tips:

- Clean it regularly to remove dust and debris.

- Check for loose screws and tighten if necessary.

- Lubricate the moving parts every few months.

- Store it in a dry place to prevent rust.

These steps help your handwheel last longer and work better.

How do I replace the handwheel on my CNC lathe?

To replace the handwheel, turn off the machine, remove the old handwheel, and follow the installation steps above. It’s important to secure the new handwheel properly to avoid issues later.

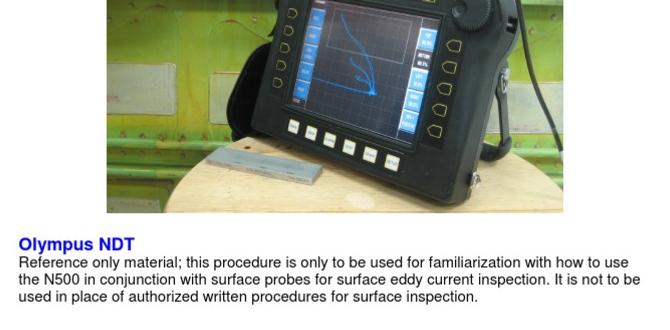

Common Issues and Troubleshooting

Identifying common problems with handwheels. Solutions and preventative measures for handwheel malfunctions.

Handwheels on CNC metal lathes can face some common hiccups. One issue is the handwheel becoming stiff to turn. This can happen due to dirt or lack of lubrication. A quick solution? Clean it well and add some grease. Sometimes, the handwheel might feel loose. Tightening the screws usually fixes that. To prevent these problems, keep the area clean and check for wear and tear regularly. Remember, a happy handwheel makes a happy machinist!

| Problem | Solution |

|---|---|

| Stiff Movement | Clean and lubricate |

| Loose Handwheel | Tighten screws |

| Wear and Tear | Regular checks |

Enhancing Performance with Upgraded Handwheel Options

Benefits of upgrading to advanced handwheel features. Comparison of aftermarket handwheels versus standard options.

Upgrading to advanced handwheels can make a big difference. They often offer better grip and control. This helps in making precise cuts. Aftermarket handwheels provide improved durability compared to standard ones. They can reduce wear and tear. Here’s a quick look at the benefits:

- Comfort: Easier to grip and turn.

- Durability: Resistant to damage.

- Precision: Improved accuracy during operation.

Many users find these upgrades make their work easier and more enjoyable. Why settle for less?

Why should I upgrade my handwheel?

Upgrading your handwheel improves overall performance. It makes your CNC machine function better. This leads to better projects and more satisfaction

What are the options between aftermarket and standard handwheels?

Aftermarket handwheels often provide better quality and more features compared to standard options. They are specifically designed to enhance user experience.

User Experiences and Testimonials

Reallife experiences from machinists using handwheels. Impact of handwheel quality on machining outcomes.

Machinists have plenty of stories about using handwheels. Many share how a smooth, quality handwheel makes working on a CNC metal lathe a breeze, almost like butter on warm toast! Poorly made handwheels can lead to sloppy cuts and frustrating results, much like trying to slice bread with a pickaxe. Here’s what some users say:

| User | Experience |

|---|---|

| John | “Upgrading my handwheel changed my life! Now my cuts are precise!” |

| Lisa | “My old handwheel wobbled like a jelly—total mess!” |

The difference is clear! A good handwheel boosts confidence and results. So, if you’re tired of wonky cuts, maybe it’s time for a handwheel upgrade!

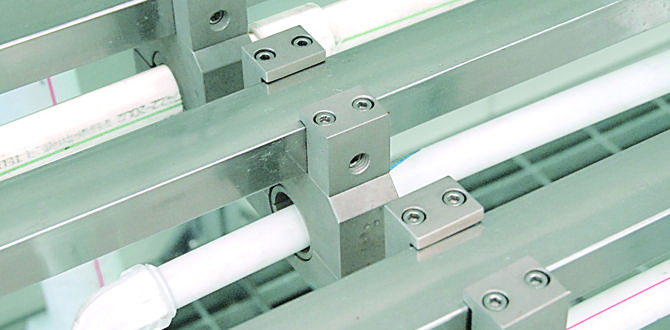

Future Trends in CNC Handwheel Technology

Innovations and advancements expected in handwheel designs. The role of technology in improving the user experience.

Exciting changes are coming for handwheel technology. Imagine controls that feel like magic! Innovations will make handwheels smoother and easier to use. With smart features, users can adjust settings with a twist while sipping coffee. A good handwheel will be the star of the show, making machining fun. Designers are adding cool styles and comfortable grips. It’s like upgrading from a bike to a rocket ship!

| Future Features | Benefits |

|---|---|

| Smart Sensors | Instant feedback on your work! |

| Ergonomic Design | Say goodbye to sore hands! |

| Customizable Settings | Personalize your experience! |

These changes will help users feel like superheroes. The future of handwheels looks bright, and it promises more fun in the workshop!

Conclusion

In summary, the CNC metal lathe handwheel is an essential tool for precise machining. It helps you control movement accurately. Using it improves your skills and results. If you’re interested, consider trying it out in a project or read more about its features. Remember, practice makes you better at using this handy tool!

FAQs

What Is The Primary Function Of The Handwheel On A Cnc Metal Lathe?

The handwheel on a CNC metal lathe helps you move the cutting tool. You can use it to change where the tool goes. Turning the handwheel makes the process smoother. It lets us make precise cuts on the metal. This way, we can create the shapes we want easily.

How Do You Properly Calibrate The Handwheel For Accurate Movement And Positioning?

To calibrate the handwheel, first make sure it’s clean and free of dirt. Next, you should check if it moves smoothly. Turn the wheel and notice where it stops. If it doesn’t match the right spot, adjust the settings gently until it does. Test it again to make sure it’s accurate!

What Are The Common Materials Used In Manufacturing Handwheels For Cnc Lathes?

CNC lathes use handwheels made from materials like aluminum, plastic, and steel. Aluminum is lightweight and strong. Plastic is easy to shape and lighter. Steel is very tough and lasts a long time. These materials help the handwheels work well and feel good to use.

How Can Operators Maintain And Care For The Handwheel To Ensure Longevity And Performance?

To keep the handwheel working well, you should clean it regularly. Use a soft cloth to wipe off dirt and dust. You can also check for any loose parts and tighten them if needed. Make sure to keep it dry and store it in a safe place. This helps the handwheel last longer and work better.

What Safety Precautions Should Be Taken When Using The Handwheel On A Cnc Lathe During Operation?

When using the handwheel on a CNC lathe, always keep your hands clear of moving parts. Make sure to wear safety goggles to protect your eyes. Before you start, check that everything is secure and properly set up. Don’t wear loose clothing or jewelry that can get caught. Always pay attention to what you are doing and follow the machine’s instructions closely.