Imagine walking into a workshop filled with the hum of machines and the smell of metal. You see a skilled worker shaping a metal piece with precision. What makes this possible? The answer lies in cnc metal lathe tools.

These tools are superheroes of the machining world. They turn blocks of metal into beautiful shapes. Have you ever wondered how metal parts for cars or planes are made? CNC metal lathe tools play a big role in that process.

Here’s a fun fact: CNC stands for Computer Numerical Control. That means computers help control the movements of the machine. This leads to accurate and complex designs. It’s like magic, but it’s really advanced technology!

In this article, we will explore how CNC metal lathe tools work. We will also dive into why they are so important in modern manufacturing. Get ready to discover the fascinating world behind these powerful tools!

Essential Cnc Metal Lathe Tools For Precision Machining

CNC metal lathe tools make precision machining simple and efficient. They allow users to carve, shape, and finish metal with ease. Ever wonder how manufacturers create those perfect parts? CNC lathes automate the process, saving time and reducing human error. Fun fact: these machines can replicate complex designs quickly. Understanding the different types of CNC lathe tools helps users choose the right one for their projects, whether for hobby work or large-scale production.

Understanding CNC Metal Lathes

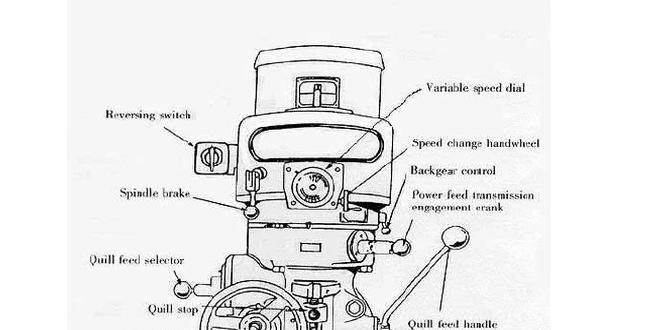

Definition and purpose of CNC metal lathes. Differences between CNC and manual lathes.

CNC metal lathes are clever machines that shape metal using computer commands. Think of them as magic pens that carve out precision pieces. Their main purpose is to create parts that are uniform and accurate. Unlike manual lathes, where humans control every turn, CNC lathes do the heavy lifting with just a few clicks. This means they work faster and can make things like intricate gears or fancy parts without breaking a sweat.

| Feature | Manual Lathes | CNC Lathes |

|---|---|---|

| Control | Human-operated | Computer-controlled |

| Speed | Slower | Faster |

| Precision | Depends on skill | Highly precise |

| Complexity | Simple shapes | Complex designs |

Key Features of CNC Metal Lathes

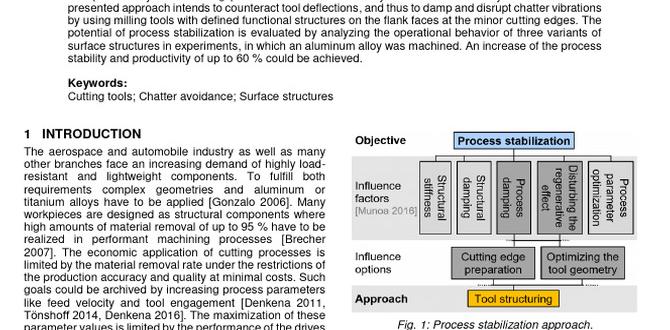

Essential features for efficiency and precision. Importance of software integration in CNC metal lathes.

CNC metal lathes have key features that make them effective for work. First, they provide high precision. This means they can cut metal very accurately. Second, they use advanced software integration. This software helps control the machine and allows for easy programming. With tight control over movements, they create detailed designs and parts quickly. Efficient tools ensure less waste and better results. Together, these features make CNC lathes excellent for modern manufacturing.

What makes software important in CNC metal lathes?

The software helps machines run smoothly. It allows for quick changes to designs. With good software, workers save time and reduce mistakes. Automation boosts productivity and ensures quality.

Key Features of CNC Metal Lathes:

- High precision for accurate cuts

- Efficient programming through software

- Less material waste

- Quick production times

Applications of CNC Metal Lathe Tools

Industries that utilize CNC metal lathes. Common applications and projects suitable for CNC lathes.

CNC metal lathes are like magical machines that help many industries. From car making to making fancy metal parts for planes, these tools create shapes with precision. They can handle wood too, but metals seem to be their true love! Common projects include making gears, bolts, and even artwork. Did you know? The aerospace industry spends over $2 billion on metal fabrication each year! Check out the table below for more on where you see these machines in action:

| Industry | Common Applications |

|---|---|

| Aerospace | Engine parts, frame components |

| Automotive | Axles, gears, custom parts |

| Manufacturing | Machinery components, tools |

| Medical | Surgical instruments, implants |

Benefits of Using CNC Metal Lathe Tools

Advantages over traditional machining methods. Impact on production speed and accuracy.

CNC metal lathe tools change the game! They beat traditional machines like a champion. These tools make parts faster and more precisely. In fact, they can increase production speed by up to 50%. Imagine getting your work done quicker while being spot-on accurate! This precision means fewer mistakes and less waste, saving both time and money. Who wouldn’t want to work smarter, not harder? So, say goodbye to guesswork and hello to the future!

| Feature | CNC Metal Lathe Tools | Traditional Machining Methods |

|---|---|---|

| Speed | Fast | Slow |

| Accuracy | High | Medium |

| Waste | Less | More |

Factors to Consider When Choosing CNC Metal Lathe Tools

Critical specifications to evaluate. Budget considerations and costeffectiveness.

Choosing the right CNC metal lathe tools can feel like picking the best superhero. You need to know their powers! Start with critical specifications. Look for features like spindle speed and tool size. These details shape your projects. Next, let’s talk money. Don’t spend your whole allowance! Check out budget considerations and ask yourself if the tool brings value. Remember, the best tools save time and money in the long run. Here’s a handy table to help:

| Factor | What to Evaluate |

|---|---|

| Specifications | Spindle Speed, Tool Size, Material Compatibility |

| Budget | Cost, Long-term Savings, Quality |

Picking the right CNC metal lathe tools is smart and a bit fun! Think of it as a treasure hunt where the prize is the perfect tool for your next project.

Maintenance Tips for CNC Metal Lathes

Routine maintenance practices for longevity. Troubleshooting common issues with CNC lathes.

To keep your CNC metal lathe tools running well, do regular maintenance. This includes cleaning, checking for wear, and ensuring lubrication. Without proper care, parts can wear out quickly. Here are some tips for longevity:

- Clean the machine regularly.

- Check and replace worn parts.

- Lubricate moving parts often.

If you face issues, troubleshoot like this:

- Look for loose connections.

- Check for abnormal sounds during use.

- Inspect for oil leaks.

Quick fixes can save time and money. So, remember to stay on top of maintenance!

What are common issues with CNC lathes?

Common issues include loose belts, poor alignment, and software errors. Each can disrupt production. Regular checks can help catch these problems early.

The Future of CNC Metal Lathe Technology

Emerging trends in CNC machining. Potential advancements in metal lathe technology.

The world of CNC metal lathe technology is changing fast. New ideas make machines work better and faster. Robots and smart software help with this. Some exciting trends include:

- Automation: Machines can do more tasks with less help.

- 3D Printing: This mixes new ways of making parts.

- Energy Efficiency: Machines use less power, saving money.

As technology grows, we can expect incredible advancements. Imagine lathes that learn and adapt. They might even predict problems before they happen. This means better products and happier customers.

How will CNC metal lathes improve?

New tools and smarter technology will make them faster and more accurate. This will change how we make things every day.

Conclusion

CNC metal lathe tools are essential for shaping metal with precision. They automate processes, making tasks easier and faster. You can create complex designs with these machines. Explore different tools and learn about their uses. Practicing on a CNC lathe will improve your skills. Keep reading and experimenting to master metalworking with CNC technology!

FAQs

What Are The Different Types Of Cutting Tools Used In Cnc Metal Lathes, And How Do They Vary In Application?

CNC metal lathes use different cutting tools to shape metal. Some common types are turning tools, boring bars, and threading tools. Turning tools help you carve the metal into different shapes. Boring bars make holes bigger, and threading tools create screws and threads. Each tool has a special job to help us make different metal parts.

How Do You Choose The Appropriate Tool Material For Cnc Metal Lathe Machining Processes?

To choose the right tool material for CNC metal lathe machining, you need to think about what you are cutting. Different metals need different tools. For soft metals, we can use high-speed steel (HSS) tools. For harder metals, carbide tools work better because they stay sharp longer. It’s important to pick a tool that matches the kind of metal you are using!

What Are The Key Factors To Consider When Setting Up A Cnc Metal Lathe For Optimal Tool Performance?

When setting up a CNC metal lathe, you need to think about a few important things. First, make sure the tool is sharp and clean. Next, adjust the speed to suit the type of metal you are using. You also need to set the right feed rate, which is how fast the tool moves through the metal. Lastly, check that everything is firmly in place to avoid any wobbles. This way, the tool will work better and last longer!

How Does Tool Geometry Affect The Machining Efficiency And Quality Of Workpieces On A Cnc Lathe?

Tool geometry on a CNC lathe affects how well the machine works and how good the finished piece looks. If the tool is shaped right, it can cut faster and more smoothly. This means we can make our workpieces quicker and with fewer mistakes. A good shape also helps the tool last longer, saving us time and money. So, having the right tool shape is really important for good work!

What Maintenance Practices Are Essential For Ensuring The Longevity And Precision Of Cnc Metal Lathe Tools?

To keep your CNC metal lathe tools working well, clean them often to remove dirt and metal shavings. Check and tighten small parts regularly to stop wear and tear. Oil the moving parts so they move smoothly and don’t get stuck. Finally, store your tools in a dry place to prevent rust. This will help your tools last longer and work better!