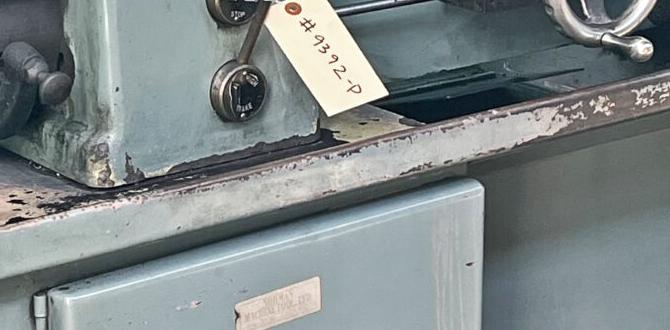

Have you ever wondered how small metal parts turn into precise tools? It all starts with a machine called a CNC metal lathe. This amazing tool shapes metal with incredible accuracy. But do you know how torque plays a part in this process?

Torque is the force that helps the lathe turn the metal. Think of it like a strong arm. The more torque a CNC metal lathe has, the easier it is to shape tough materials. This makes it a favorite among many makers and engineers.

Can you imagine how many items around you depend on this powerful machine? From bicycle parts to intricate jewelry, CNC metal lathes help create them all. Let’s dive into the world of CNC metal lathe torque and discover how it all works!

Understanding Cnc Metal Lathe Torque For Precision Machining

CNC metal lathes use torque to shape and cut metal accurately. Torque is the force that helps the lathe spin the metal piece. Did you know that proper torque settings can prevent machine damage and improve precision? Understanding torque helps you choose the right lathe for your project needs. Whether you’re a hobbyist or a professional, knowing how torque works can make all the difference in your metalworking success. Explore this fascinating world where strength meets precision!

What is CNC Metal Lathe Torque?

Definition of torque in the context of CNC metal lathes. Explanation of how torque affects machining processes.

Torque is a force that makes things turn. In CNC metal lathes, torque is very important. It helps the machine spin the metal. More torque means the lathe can cut through harder materials easily.

This affects machining in a big way. With the right torque, you get clean cuts and smooth surfaces. Without enough torque, the machine might struggle or even break. Here are some key points:

- High torque allows cutting tough metals.

- Low torque can cause damage to tools.

- Correct settings ensure quality workpieces.

How does torque influence CNC lathe performance?

Torque influences CNC lathe performance by determining how efficiently the lathe can cut materials. With high torque, machines maintain speed while cutting, leading to better results.

Calculating Torque for CNC Metal Lathes

Stepbystep guide on how to calculate torque in CNC machining. Examples of torque calculations for various materials and operations.

Understanding torque in CNC machining is simple and important. Here’s how to calculate it step by step:

- First, gather your material and specifications.

- Measure the diameter of the workpiece.

- Use the formula: Torque = Force x Radius.

- Ensure you adjust force based on the type of material.

For example, cutting aluminum needs less torque than steel. You might find a torque of 10 Nm for aluminum and 20 Nm for steel. Calculating torque helps you operate CNC lathes efficiently and safely!

How do you find torque for different materials?

To find torque for various materials:

- Identify the material type.

- Look up its cutting force requirements.

- Apply the correct torque formula.

Doing this allows you to adjust your settings for better results!

Importance of Torque in CNC Metal Lathe Performance

How torque influences cutting efficiency and tool life. The relationship between torque and precision in machining.

Torque is key for a CNC metal lathe’s success. It helps cut materials quickly and smoothly. When torque is right, tools last longer. This means less time replacing parts. Precision also improves with the right amount of torque. The machine cuts exactly as needed. Here are some important points about torque:

- Better cutting efficiency means faster work.

- Longer tool life saves money.

- Increased precision leads to better results.

How does torque affect CNC metal lathe cutting?

Torque directly affects cutting speed and tool durability. A higher torque can cut through tough materials better.

Common Problems Related to Insufficient Torque

Identification of issues caused by low torque, such as tool breakage and poor surface finish. Strategies to mitigate these problems in CNC operations.

Low torque can create some tricky problems when using a CNC metal lathe. For starters, your tools might break faster than a piñata at a birthday party! A poor surface finish can also happen, giving your metal parts that “just woke up” look. To tackle these issues, ensure your machine is properly calibrated and match the tool type to the material. Keep those RPMs in check, and remember: a well-fed lathe is a happy lathe!

| Issue | Impact | Mitigation Strategy |

|---|---|---|

| Tool Breakage | Increased costs and downtime | Use correct torque settings |

| Poor Surface Finish | Affects quality and appearance | Adjust feed rates and speeds |

Improving Torque in CNC Metal Lathe Operations

Techniques to enhance torque, including tooling and machine adjustments. Importance of choosing the right cutting tools and materials for optimal torque.

Boosting torque in CNC metal lathe operations can make your machine hum with happiness. First, focus on tool selection. The right cutting tools can dramatically improve torque. Also, check your machine settings; a simple adjustment might do wonders! Using materials designed for strength can also help you crank out better results. Remember, it’s not just about the machine—it’s about teamwork between tools, materials, and settings! Just think of it as a dance: everyone must follow the right steps.

| Technique | Description |

|---|---|

| Tool Selection | Choose strong cutting materials. |

| Machine Adjustments | Fine-tune your machine for better performance. |

| Material Quality | Use durable materials to enhance results. |

Future Trends in CNC Metal Lathe Torque Technologies

Emerging technologies that may influence torque performance in CNC lathes. Predictions on how advancements will impact CNC machining efficiency and accuracy.

Many exciting technologies are popping up that could boost the torque in CNC lathes. For example, sensors and advanced software are making machines smarter. They help operators see problems before they happen. Imagine a lathe saying, “Hey, I need some oil!” before something goes wrong! Also, new materials are popping up that are lighter yet stronger. These can lead to more efficient machining. With all these changes, machines could become faster and more accurate. Think of it as giving your lathe a turbo boost!

| Emerging Technologies | Impact on Torque Performance |

|---|---|

| Smart Sensors | Prevent wear and tear |

| Advanced Materials | Enhance machine stability |

| AI Software | Improve efficiency |

Conclusion

In summary, understanding CNC metal lathe torque is crucial for precise machining. It affects how well you can cut metal. We learned that applying the right torque improves tool performance and extends tool life. Now, you can experiment with different settings. Keep reading and exploring to master CNC machining and create amazing projects!

FAQs

What Factors Influence The Torque Output Of A Cnc Metal Lathe During Machining Operations?

The torque output of a CNC (Computer Numerical Control) metal lathe depends on several factors. First, the material you are cutting affects how much force is needed. Softer materials need less torque, while harder ones need more. The speed of the lathe also matters; slower speeds often require more torque. Lastly, the shape of the tool you use can change how efficiently the lathe works. So, choosing the right settings and tools is very important!

How Can Improper Torque Settings Affect The Machining Performance And Precision Of A Cnc Metal Lathe?

Improper torque settings on a CNC metal lathe can cause big problems. If the tools are too loose, they might shake and make bad cuts. If they’re too tight, they can break or wear out quickly. This means you won’t get the clean, exact shapes you want in your metal pieces. It’s important to set the right torque for the best results!

What Is The Relationship Between Spindle Speed And Torque In Cnc Metal Lathes?

In a CNC metal lathe, spindle speed is how fast the tool spins. Torque is the power that helps the tool cut through metal. When the speed is high, the torque is usually lower. When the speed is low, the torque can be higher. We need to find the right balance for best results while cutting metal.

How Can I Calculate The Required Torque For Different Materials When Using A Cnc Metal Lathe?

To calculate the needed torque for different materials on a CNC metal lathe, you first need to know the material’s strength. Next, look at the diameter of the tool and the cutting speed you want to use. You can use a formula or a torque chart from your machine’s manual. This will help you find the right number for each material. Always be careful and ask for help if you need it!

What Methods Can Be Employed To Optimize Torque Settings For Various Cutting Processes In Cnc Machining?

To optimize torque settings for cutting in CNC machines, you can start by adjusting the speed of the machine. Next, check the cutting tool to make sure it’s sharp. We can also test different materials to see which ones cut better. Finally, keep an eye on the machine’s temperature because too much heat can affect cutting. All these steps help you find the best way to cut.