Have you ever wondered how complex parts are made so precisely? It often boils down to a CNC milling tool library. This set of tools is key in the world of computer-controlled cutting. CNC, which stands for Computer Numerical Control, makes it possible to create expert designs with ease.

Imagine a world where machines build amazing shapes from metal and wood. Sounds like magic, right? Well, it’s a mix of technology and imagination! A CNC milling tool library allows engineers and hobbyists to choose the right tools for their projects quickly. Each tool has a specific use, just like different brushes for painting.

In this article, we will explore the importance of a CNC milling tool library. We’ll dive into how it helps create everything from tiny gadgets to large machinery. Get ready to discover the fun side of CNC milling!

The Complete Guide To Cnc Milling Tool Library Management

CNC Milling Tool Library

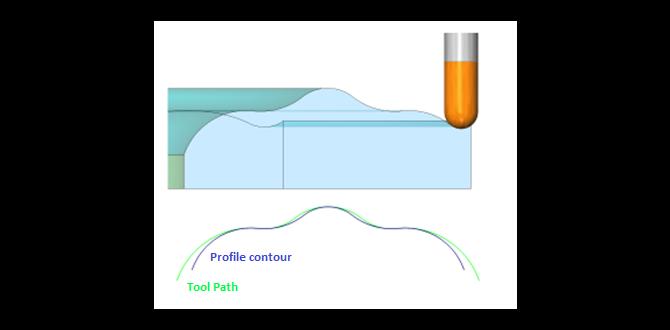

Have you ever wondered how CNC machines know which tools to use? A CNC milling tool library is essential for that! It stores information about different milling tools, like size and shape. Users can easily access this data when programming a CNC machine. This library saves time and helps avoid mistakes during milling. Understanding this tool library can make your CNC projects smoother. It’s like having a toolbox that you can quickly check before starting a project!What is a CNC Milling Tool Library?

Definition and purpose of a CNC milling tool library. Importance in the context of CNC machining processes.A CNC milling tool library is a collection of tools used in CNC machines. It helps machinists quickly find the right tools for their work. This library organizes different tools, making it easy to choose the best one for each job.

- Definition: A space for storing and sharing milling tools.

- Purpose: Saves time and improves accuracy in machining.

- Importance: Key for smooth CNC processes and better results.

Having a tool library means less confusion and wasted time. It also leads to higher efficiency and better quality work. This helps companies save money and resources.

Why is a CNC milling tool library important?

A CNC milling tool library boosts productivity and ensures consistent results. It allows for quick tool changes and better planning. In fact, efficient tool management can increase production speeds by up to 30%.

Benefits of Using a CNC Milling Tool Library

Streamlining workflow and reducing setup time. Enhancing consistency and accuracy in machining operations.A cnc milling tool library can really help anyone who loves making stuff with machines. It saves time by making the setup super easy. Think of it like having your favorite toys organized in one box. You pick what you need faster! This tool library also makes sure that every cut you make is precise. So, there’s no need to worry about your projects ending up as wobbly as a three-legged table. With consistency, your work looks professional every time.

| Benefit | Description |

|---|---|

| Streamlined Workflow | Quick access to tools saves setup time. |

| Enhanced Accuracy | Avoids mistakes for precise machining. |

How to Create a CNC Milling Tool Library

Stepbystep guide to building a customized tool library. Considerations for selecting tool parameters and specifications.Creating a customized tool library for CNC milling is simple. First, gather the necessary tools. Then, follow these steps:

- Define the tool types you need.

- Select materials and sizes for your tools.

- Input specific parameters—like speed and feed rates.

- Check specifications for accuracy.

- Save and organize your library.

Consider these points:

- Choose tools based on your project’s requirements.

- Think about the materials you’ll be cutting.

- Evaluate the tools for durability and efficiency.

With careful planning, you can build an effective CNC milling tool library.

What is a CNC milling tool library?

A CNC milling tool library is a collection of tools and their specific settings used in CNC machines. It helps to ensure better accuracy and efficiency in milling tasks.

Best Practices for Maintaining an Effective Tool Library

Importance of regular updates and audits for accuracy. Tips for organizing and categorizing tools for quick access.Keeping a cnc milling tool library organized is key to smooth operations. Regular updates help maintain accuracy. It ensures every tool is available and in good condition. Audits make sure everything matches the records. To help you stay organized, use these tips:

- Group tools by type and size.

- Label all containers clearly.

- Store tools in dedicated spaces.

- Regularly check tool conditions.

This way, you can find the right tool quickly and easily.

Why is it important to keep the tool library updated?

Regular updates keep tools accurate and ready for use. This avoids delays and helps with project timelines.

Common Challenges in CNC Milling Tool Management and Solutions

Issues such as tool wear and inventory management. Strategies to overcome these challenges effectively.Managing tools in CNC milling can feel like herding cats. One big issue is tool wear, where tools get dull and need replacing. This can slow down your work. Another headache is inventory management; finding the right tool among many can be like searching for a needle in a haystack. To tackle these problems, keep a well-organized tool library and schedule regular maintenance checks. A simple inventory table below can help! Keep it neat, and your tools will thank you!

| Tool Name | Last Checked | Status |

|---|---|---|

| End Mill | 01/12/2023 | Dull |

| Drill Bit | 01/10/2023 | Sharp |

| Face Mill | 01/15/2023 | Needs Replacement |

Future Trends in CNC Milling Tool Libraries

Innovations in software and automation for tool management. Predictions on how AI and machine learning may influence tool library systems.The future of tool management is bright! Innovations in software are making it easier to keep track of milling tools. Imagine apps that remind you when a tool needs sharpening—like a personal trainer for your tools! Automation is also stepping up, making everything more efficient. AI and machine learning will change the game further. Picture machines predicting what tools will be needed next, saving time and money. It’s like having a crystal ball for manufacturing!

| Trend | Description |

|---|---|

| Advanced Software | Tools that keep track of your gear and suggest improvements! |

| Automation | Machines doing the boring stuff, so humans can be more creative! |

| AI Predictions | Systems anticipating what tools you need, making life easier! |

Conclusion

In conclusion, a CNC milling tool library is essential for efficient machining. It helps you choose the right tools easily, saving time and improving accuracy. With this library, you can organize your tools better and enhance your projects. We encourage you to explore tool libraries further or add one to your workspace. Happy milling!FAQs

Sure! Here Are Five Questions Related To The Topic Of Cnc Milling Tool Libraries:Sure! A CNC milling tool library is like a special box where we keep all the tools we use for cutting stuff. It helps us pick the right tool for each job. We can easily find and organize our tools, so we work faster. This way, we don’t lose any tools or mix them up. Using the library makes our work better and more fun!

Sure! Please provide the question you’d like me to answer.

What Is A Cnc Milling Tool Library And How Is It Utilized In Machining Processes?A CNC milling tool library is like a toolbox for machines. It helps you find different cutting tools we need for machining, which is shaping materials like metal or wood. Each tool has a specific job, and we choose the right one from the library before we start working. This makes our work easier and more precise. Using this library helps us save time and do a better job!

How Can Users Customize Or Create Their Own Tool Libraries In Popular Cnc Programming Software?You can customize tool libraries in CNC programming software by adding or changing tools. First, open the tool library section in the software. Then, you can choose tools you want to use or create new ones. You simply fill in the details, like size and type, for each tool. Finally, save your library so you can use it later!

What Are The Advantages Of Using A Standardized Tool Library In Cnc Milling Operations?Using a standardized tool library in CNC milling makes things easier for you. You can find the right tools faster, which saves time. It helps you work safely because everyone uses the same tools. This also means your work will be more accurate, and you can make better products. Overall, it makes your job simpler and more efficient!

How Do Tool Library Settings Impact Machining Parameters Such As Feed Rate And Spindle Speed?Tool library settings help you choose the right tools for your machines. When you pick a tool, it can change how fast you move the machine and how fast it spins. For example, some tools need slower speeds to cut well. So, by using the right settings, we keep our work safe and make it better!

What Are Some Best Practices For Maintaining And Updating A Cnc Milling Tool Library To Ensure Optimal Performance?To keep your CNC milling tools working their best, check your tool library regularly. You should update it whenever you get new tools or change old ones. Always clean your tools after using them and store them properly. Make a note of any tools that wear out quickly, so you know when to replace them. This way, your tools will last longer, and your work will be better!