Have you ever faced problems with your wood lathe? You’re not alone. Many woodworkers encounter common wood lathe problems. These issues can be frustrating, especially when you’re in the middle of a project. What if you could easily fix them? Imagine being able to enjoy your hobby without constant interruptions!

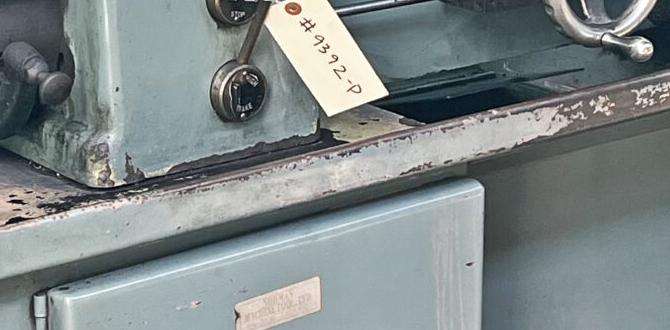

Wood lathes allow you to create amazing projects. But they can sometimes act up. For instance, is your lathe making strange noises? Or maybe it vibrates more than it should? These problems can be tricky. Fortunately, there are simple solutions to common wood lathe problems.

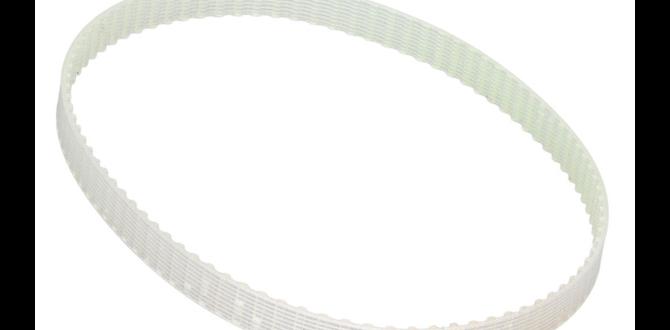

Did you know that a loose belt is a frequent cause of issues? It’s true! Understanding these problems helps you become a better woodworker. Let’s explore the challenges woodworkers face. Together, we’ll find easy fixes for your wood lathe troubles.

Common Wood Lathe Problems Solved: Tips For Smooth Turning

Common Wood Lathe Problems Solved

Woodworking brings joy, but what happens when your lathe misbehaves? Understanding common wood lathe problems can save you time and frustration. Issues like vibration, uneven cuts, and tool chatter are frequent. These may arise due to loose components or poor alignment. Simple solutions, such as checking tension and making adjustments, can enhance your crafting experience. Did you know that many lathe problems can be solved with just a wrench? Get ready to turn those frustrations into fun!Common Issues Experienced by Wood Lathe Users

List of frequent problems encountered. Symptoms and signs of each issue.Using a wood lathe can be fun, but it can also bring some challenges. It’s like a roller coaster ride; thrilling but with a few unexpected bumps! Here are some common problems you might face:

| Problem | Symptoms |

|---|---|

| Vibration | Unwanted shaking or wobbling. |

| Stalling | Machine stops unexpectedly. |

| Poor finish | Rough surface or uneven cuts. |

| Tool marks | Visible scratches or lines on the wood. |

Keep an eye out for these signs. They can save you from turning your project into a lopsided masterpiece! Don’t shy away from troubleshooting; it’s all part of the woodturning adventure!

Troubleshooting Vibration and Noise Issues

Identifying causes of vibration and noise. Solutions for balancing and alignment.Vibration and noise can feel like a bad dance party happening at your workbench. Their annoying presence usually points to a few main culprits. First, check if your wood lathe is unbalanced. A wobbly lathe can make your life difficult. Second, misalignment can cause unwanted sounds. Take a moment to align your lathe properly. Here’s a quick table for easy reference:

| Cause | Solution |

|---|---|

| Unbalanced Lathe | Adjust the feet or add weights |

| Misalignment | Realign the tool rest and headstock |

With some adjustments, you can turn that chaotic noise into sweet woodworking harmony. So, shake your tools, not your lathe!

Dealing with Tool Chatter

Explanation of tool chatter phenomenon. Techniques to reduce or eliminate chatter.Tool chatter is a pesky problem that happens when the tool vibrates while cutting wood. This can lead to rough surfaces and mistakes. To reduce chatter, try these techniques:

- Adjust the speed and feed rate.

- Check and tighten the tool holder.

- Use sharp tools for a smoother cut.

- Support the wood properly to prevent movement.

By following these tips, you can control chatter and create better wood pieces!

What causes tool chatter?

Tool chatter is caused by vibrations between the tool and the workpiece, often due to setting too high a speed or insufficient support.

How can I fix chatter?

Fixing chatter involves adjusting speed, ensuring tools are sharp, and securely supporting your material.

Fixing Lathe Speed Control Problems

Common causes of speed inconsistencies. Steps to troubleshoot and resolve speed control issues.Speed control issues on a lathe can be frustrating. Common problems may stem from a worn belt, power supply issues, or faulty controls. To troubleshoot these issues, follow these steps:

- Check the power source to ensure it is working.

- Inspect the drive belt for wear or damage.

- Examine speed control knobs or switches for faults.

- Test the motor for overheating or noise.

By addressing these areas, you can often solve speed inconsistencies and keep your lathe running smoothly.

What causes lathe speed problems?

Common causes include:

- Worn belts may slip and cause speed changes.

- Electrical issues can disrupt power delivery.

- Faulty controls can give incorrect speed readings.

Be sure to check these factors to fix your lathe quickly!

Addressing Electrical and Motor Failures

Identifying electrical issues in wood lathes. Safety measures and troubleshooting motor problems.Electrical issues can make your wood lathe act like a stubborn mule. First, check the power cord for damage. A frayed wire can cause sparks—and not the romantic kind! If your lathe won’t start, inspect the switch and look for blown fuses. Remember safety first: always unplug before poking around! If the motor sounds rough, it might need some oil or a good clean. Here’s a quick table to guide you:

| Issue | Solution |

|---|---|

| Lathe won’t start | Check power cord and switch |

| Strange noises | Oil motor and clean parts |

| Overheating | Give it a break! |

Taking these steps can turn your wood lathe back into a workhorse instead of a lounge chair! Happy turning!

Preventing and Fixing Excessive Dust and Debris

Importance of dust collection systems. Solutions for effective dust management.Dust and debris can be a big problem when using a wood lathe. It’s important to have a good dust collection system. A clean workspace makes it safer and more pleasant to work. Effective dust management goes beyond a vacuum. Here are some tips:

- Use a dust hood around the lathe.

- Connect a powerful shop vacuum.

- Position fans for better air flow.

By taking these steps, you keep your space tidy and protect your health.

How can I manage dust from a wood lathe?

To manage dust, use a good collection system with a vacuum and dust hood.

Wood Lathe Maintenance Best Practices

Routine maintenance tips to prevent issues. Importance of keeping tools and equipment clean.Regular upkeep makes your wood lathe run smoothly. Simple tasks like cleaning and oiling prevent big problems later. Pay attention to your tools and equipment. A clean workspace leads to better projects. Think of your lathe like a pet — it needs care to stay happy!

- Check belts and gears for wear.

- Wipe down surfaces after each use.

- Lubricate moving parts regularly.

- Keep sharp tools for safer cuts.

Why is cleaning tools important?

Clean tools prevent rust and damage. They also help you work better and create neat pieces. Taking care of your lathe means it works well for you.

Resources for Further Learning and Support

Recommended books and online resources. Community forums and expert assistance options.Learning more about wood lathes can make your projects better. Here are some great resources:

- Books: Look for titles that explain lathe techniques and tips. Some popular ones are “The Lathe Book” and “Woodturning for Beginners.”

- Online Resources: Websites like YouTube offer video guides. Also, check out blogs dedicated to woodworking.

- Community Forums: Websites like Reddit and woodworking forums have helpful members. You can ask questions and share your work.

- Expert Assistance: Local workshops often have classes to improve your skills.

Conclusion

In summary, common wood lathe problems can be solved with careful attention and troubleshooting. You should check for tight belts, ensure proper tool sharpness, and maintain the lathe regularly. By doing this, you can improve your projects and enjoy smoother woodturning. If you’re eager to learn more, consider reading guides or watching videos on wood lathe care!FAQs

What Are The Most Common Alignment Issues That Can Occur With A Wood Lathe, And How Can They Be Resolved?Wood lathes can have a few common problems. First, the tailstock may not line up with the spindle. To fix this, you can adjust the tailstock until it lines up correctly. Also, the bed can be uneven. You should check and level it to make sure it’s flat. Lastly, your tool rest may be too high or low. Adjust it to be level with your workpiece so it cuts smoothly.

How Can I Troubleshoot And Fix Vibration Problems In My Wood Lathe While Turning?If your wood lathe is vibrating, start by checking if it’s on a flat and steady surface. You can tighten all the screws and bolts to make sure everything is secure. Look at the wood piece you are turning; if it’s not properly balanced, that can cause problems. Lastly, if the lathe is old, it might need some oil to help it run smoother. If you try these steps, you should notice less vibration while you work!

What Steps Should I Take To Address Inconsistent Speed Or Power Loss In A Wood Lathe?First, check the power source to make sure it’s working well. Next, look for loose wires or connections. You can also clean the lathe to remove dust and dirt. Lastly, read the manual to see if it needs any special care or adjustments. If it still doesn’t work right, ask an adult for help.

How Can I Prevent And Fix Chipping Or Tearing Of Wood During The Lathe Turning Process?To prevent chipping or tearing while using a lathe, you should use sharp tools. Sharp tools cut better and make cleaner edges. Keep the wood steady and secure so it doesn’t move. If you notice any tears, you can sand them down gently after you finish turning. Always go slow and be careful with each cut!

What Maintenance Practices Can Help Avoid Common Wood Lathe Issues And Ensure Optimal Performance?To keep your wood lathe working well, you should clean it regularly. This means wiping off dust and wood shavings. You also need to check the belts and change them if they look worn out. Lubricate the moving parts so they don’t get stuck. Finally, make sure to tighten any loose screws or bolts.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Most Common Alignment Issues That Can Occur With A Wood Lathe, And How Can They Be Resolved? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Wood lathes can have a few common problems. First, the tailstock may not line up with the spindle. To fix this, you can adjust the tailstock until it lines up correctly. Also, the bed can be uneven. You should check and level it to make sure it’s flat. Lastly, your tool rest may be too high or low. Adjust it to be level with your workpiece so it cuts smoothly.”}},{“@type”: “Question”,”name”: “How Can I Troubleshoot And Fix Vibration Problems In My Wood Lathe While Turning? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If your wood lathe is vibrating, start by checking if it’s on a flat and steady surface. You can tighten all the screws and bolts to make sure everything is secure. Look at the wood piece you are turning; if it’s not properly balanced, that can cause problems. Lastly, if the lathe is old, it might need some oil to help it run smoother. If you try these steps, you should notice less vibration while you work!”}},{“@type”: “Question”,”name”: “What Steps Should I Take To Address Inconsistent Speed Or Power Loss In A Wood Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “First, check the power source to make sure it’s working well. Next, look for loose wires or connections. You can also clean the lathe to remove dust and dirt. Lastly, read the manual to see if it needs any special care or adjustments. If it still doesn’t work right, ask an adult for help.”}},{“@type”: “Question”,”name”: “How Can I Prevent And Fix Chipping Or Tearing Of Wood During The Lathe Turning Process? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To prevent chipping or tearing while using a lathe, you should use sharp tools. Sharp tools cut better and make cleaner edges. Keep the wood steady and secure so it doesn’t move. If you notice any tears, you can sand them down gently after you finish turning. Always go slow and be careful with each cut!”}},{“@type”: “Question”,”name”: “What Maintenance Practices Can Help Avoid Common Wood Lathe Issues And Ensure Optimal Performance? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep your wood lathe working well, you should clean it regularly. This means wiping off dust and wood shavings. You also need to check the belts and change them if they look worn out. Lubricate the moving parts so they don’t get stuck. Finally, make sure to tighten any loose screws or bolts.”}}]}