If you love working with metal, you might have heard of compact metal lathes. These handy machines can turn a simple block of metal into something amazing. But did you know that the right accessories can take your projects to a whole new level?

Imagine you’re in your workshop, excited about building something special. You’ve got your metal lathe set up, but wait! What if you had the perfect tool to make your work easier? Compact metal lathe accessories can help you create with more precision and speed.

Think about how frustrating it is when you don’t have what you need. You might waste time searching for tools or even feel stuck. With the right accessories, you can solve these problems quickly. They can help you create pieces that are not only great to look at but also function well.

Did you know that adding just a few accessories can boost your creativity? You could customize your lathe to fit your projects better. This not only saves time but also makes working more fun. Explore with us how these compact metal lathe accessories can bring your ideas to life!

Essential Compact Metal Lathe Accessories For Optimal Precision

Compact Metal Lathe Accessories

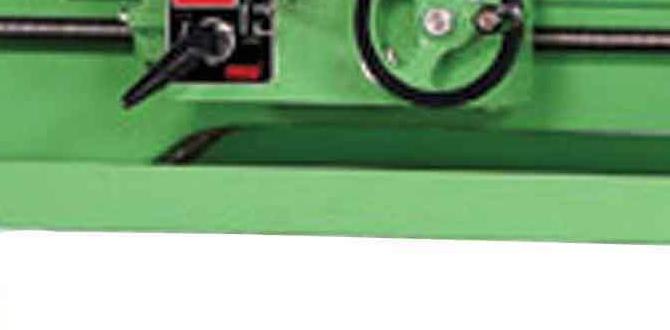

Compact metal lathe accessories can transform your machining experience. They enhance precision and ease of use. Imagine creating intricate designs with just a few simple attachments. Tools like chucks, cutting tools, and tool holders make a significant difference. Did you know that some accessories can help you work faster and save money? Upgrading your lathe with the right accessories can lead to amazing projects. Think of all the possibilities! Discover how these small tools can make a big impact on your craft.Understanding Compact Metal Lathes

Definition and advantages of compact metal lathes. Key features that differentiate them from larger models.Compact metal lathes are small machines that shape metal into various forms. They have many advantages. First, they save space and fit easily into small workshops. Second, they are often easier to use, making them great for beginners.

Key features include:

- Size: Compact models are shorter and lighter than larger lathes.

- Simplicity: They often have fewer complex parts, making them simpler to operate.

- Affordability: Compact lathes usually cost less, making them a smart choice for hobbyists.

What are the benefits of using a compact metal lathe?

The benefits include space-saving design, user-friendly operation, and cost-effectiveness. This makes them perfect for small shops and hobbyists looking to create projects easily.

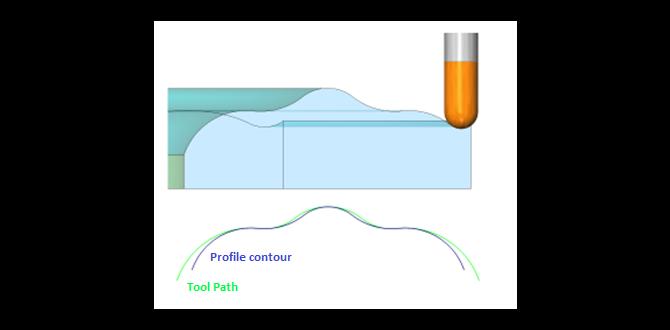

Tooling Options for Precision Machining

Types of cutting tools suitable for compact lathes. Importance of tool material and geometry on machining performance.Choosing the right cutting tools can make a world of difference for your compact lathe. Various options like high-speed steel and carbide inserts can improve your machining accuracy. The material and shape of these tools matter a lot. A sharper edge cuts better, while the right angle can save you time and frustration. As they say, “A dull tool is like a fish out of water!” Here’s a quick look:

| Tool Type | Material | Best For |

|---|---|---|

| Turning Tools | High-Speed Steel | General use |

| Face Mills | Carbide Inserts | High precision |

| Parting Tools | Cobalt | Deep cuts |

In the end, remember: the right tools are like having a superhero sidekick. They make every task easier and a lot more fun!

Workholding Solutions

Various workholding devices for compact lathes. How to choose the right chuck options for different projects.Workholding devices help keep your projects steady while you work. For compact lathes, several options exist. Chucks are popular tools here. They hold your materials tight. Choosing the right chuck depends on what you’re making.

- Scrolling Chucks: Great for round shapes.

- Four-Jaw Chucks: Best for uneven pieces.

- Collet Chucks: Perfect for small, precise tasks.

Always match your chuck to your project. This choice can really improve your results!

What are workholding solutions?

Workholding solutions are tools that help secure materials while you work on them. They allow you to focus on your project without worrying about movement.

Measuring and Setup Tools

Essential measuring tools for accurate setup. Importance of calibration and measurement for precision work.Every successful project starts by measuring twice and cutting once. Key measuring tools like calipers and micrometers help make sure your pieces fit perfectly. Without calibration, even the tiniest mistake can turn a masterpiece into a paperweight. These tools ensure precision in your work, letting you impress friends with your lathe wizardry. Each tool, like the trusty ruler, is a hero in its quest for accuracy. Remember, precision is no joke—unless you measure it wrong!

| Measuring Tool | Purpose |

|---|---|

| Calipers | Measure width, depth, and internal/external dimensions |

| Micrometers | Provide precise measurements of small objects |

| Ruler | For quick length measurements |

Upgrades to Enhance Lathe Performance

List of upgrades commonly used with compact lathes. Potential improvements in productivity and efficiency.Improving your lathe can make a big difference. Adding the right accessories helps speed up work and boosts quality. Here are some useful upgrades for compact lathes:

- Precision chucks

- Adjustable tool posts

- Quick change tool holders

- Cooling systems

- Digital readouts

These upgrades can lead to better results and more efficient work. They help save time and effort, letting you focus on creativity. Why not explore these options and see what works best for you?

What are common upgrades for compact lathes?

Common upgrades include precision chucks, adjustable tool posts, and digital readouts. These tools help improve performance and make projects easier.

Maintenance Tools for Longevity

Recommended tools and supplies for lathe maintenance. Tips on maintaining accessories for longer lifespan.To keep your compact metal lathe accessories in great shape, you’ll need the right maintenance tools. Essentials include lubricants, cleaning brushes, and wrenches. These help you tighten loose parts and keep the lathe running smoothly. Regular cleaning prevents dust from turning your lathe into a miniature sandcastle. Got a bit of rust? Use some oil and elbow grease!

Tip: Keep a checklist for maintenance, so you don’t forget anything. Trust us, your lathe will thank you by sticking around longer!

| Tool | Purpose |

|---|---|

| Lubricants | Reduce friction and wear |

| Cleaning Brushes | Remove dust and debris |

| Wrenches | Tighten loose parts |

Where to Source Quality Accessories

Recommendations for reputable suppliers and retailers. Online vs. local sources: Pros and cons of each.Finding good accessories for your metal lathe can be as tricky as finding Waldo in a crowded picture. Luckily, there are several reliable places to look. Online retailers like Amazon often stock a wide range of accessories with handy customer reviews. Local shops, on the other hand, let you see the products in person. Buying locally means you can ask questions and sometimes get discounts—who doesn’t love a bargain?

| Source Type | Pros | Cons |

|---|---|---|

| Online Retailers | Wide selection, reviews | Shipping time, can’t touch |

| Local Shops | Instant purchase, ask questions | Limited stock, higher prices |

Remember, whether you shop online or at a local store, know what you’re looking for. Happy hunting for those compact metal lathe accessories!

Customer Reviews and Experiences

Insights from users on various accessories. Discussion on bestperforming products and their features.Users share their experiences with various compact metal lathe accessories. Many highlight the importance of choosing the right tools. Some favorites include:

- Tool holders: Users enjoy how quick changes can boost their efficiency.

- Chucks: People love their strong grip, making tasks safer.

- Cutting tools: Reviews mention durability, saving time and money.

Overall, high-quality accessories often lead to better performance. When investing in these tools, experts suggest focusing on features that enhance usability and safety.

What should I look for in compact metal lathe accessories?

Look for durability, ease of use, and compatibility with your lathe. These features help you work efficiently and safely.

Conclusion

In conclusion, compact metal lathe accessories enhance your machining projects. You can improve your lathe’s precision and versatility with the right tools. Remember to choose accessories that fit your needs. Explore different options to find what works best for you. Happy machining, and don’t hesitate to learn more to master your skills!FAQs

What Are The Essential Accessories For Enhancing The Functionality Of A Compact Metal Lathe?To make your compact metal lathe work better, you need some key accessories. First, a good set of cutting tools helps you shape metal easily. Next, a chuck holds the metal firmly in place while you work. A steady rest supports the metal for smoother cuts, and a tailstock adds extra strength. Finally, a digital readout shows accurate measurements, making your projects more precise.

How Do Different Types Of Tool Holders Impact The Performance Of A Compact Metal Lathe?Different tool holders can change how well a compact metal lathe works. Some holders grip tools tightly, making cuts cleaner. Others might loosen and cause messy edges. Choosing the right holder helps you make better shapes and cuts on your projects. This means you can create things more easily and with better quality.

What Safety Accessories Should Be Considered When Operating A Compact Metal Lathe?When using a compact metal lathe, you should wear safety glasses to protect your eyes. Hearing protection is important too, as lathes can be noisy. A dust mask can keep you from breathing in harmful dust. Also, use a sturdy apron or gloves to protect your body. Make sure to keep your hair tied back and wear closed shoes for safety.

How Can Additional Workholding Devices Improve Precision And Efficiency In Compact Metal Lathe Operations?Using extra workholding devices can help us hold the metal pieces better. This keeps them steady while we work, so we make fewer mistakes. When things don’t move around, we can cut and shape metal more accurately. This also saves time because we don’t have to redo our work. Overall, we finish jobs quicker and better!

What Are The Benefits Of Using Digital Readouts And Dro Systems With Compact Metal Lathes?Using digital readouts (DRO) on compact metal lathes helps you see exact measurements. This makes it easier to cut pieces that fit perfectly. You won’t make as many mistakes, which saves time and material. Plus, it’s faster than looking at a tape measure or ruler. Overall, it makes your work cleaner and more accurate!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Essential Accessories For Enhancing The Functionality Of A Compact Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To make your compact metal lathe work better, you need some key accessories. First, a good set of cutting tools helps you shape metal easily. Next, a chuck holds the metal firmly in place while you work. A steady rest supports the metal for smoother cuts, and a tailstock adds extra strength. Finally, a digital readout shows accurate measurements, making your projects more precise.”}},{“@type”: “Question”,”name”: “How Do Different Types Of Tool Holders Impact The Performance Of A Compact Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Different tool holders can change how well a compact metal lathe works. Some holders grip tools tightly, making cuts cleaner. Others might loosen and cause messy edges. Choosing the right holder helps you make better shapes and cuts on your projects. This means you can create things more easily and with better quality.”}},{“@type”: “Question”,”name”: “What Safety Accessories Should Be Considered When Operating A Compact Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When using a compact metal lathe, you should wear safety glasses to protect your eyes. Hearing protection is important too, as lathes can be noisy. A dust mask can keep you from breathing in harmful dust. Also, use a sturdy apron or gloves to protect your body. Make sure to keep your hair tied back and wear closed shoes for safety.”}},{“@type”: “Question”,”name”: “How Can Additional Workholding Devices Improve Precision And Efficiency In Compact Metal Lathe Operations? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Using extra workholding devices can help us hold the metal pieces better. This keeps them steady while we work, so we make fewer mistakes. When things don’t move around, we can cut and shape metal more accurately. This also saves time because we don’t have to redo our work. Overall, we finish jobs quicker and better!”}},{“@type”: “Question”,”name”: “What Are The Benefits Of Using Digital Readouts And Dro Systems With Compact Metal Lathes? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Using digital readouts (DRO) on compact metal lathes helps you see exact measurements. This makes it easier to cut pieces that fit perfectly. You won’t make as many mistakes, which saves time and material. Plus, it’s faster than looking at a tape measure or ruler. Overall, it makes your work cleaner and more accurate!”}}]}