Have you ever thought about how machines help us create things? Compact metal lathes are amazing tools that can shape metal into many forms. But did you know that alignment is key to making the most of these machines? A simple misalignment can lead to mistakes in your project. Imagine spending hours on a piece, only to find it doesn’t fit right!

Aligning a compact metal lathe might sound tricky, but it can be fun and rewarding. Picture setting up your lathe perfectly and watching it work like magic. With the right steps, you can make sure your cutting is precise. Learning about this process might just turn you into a master craftsman.

In this article, we will explore compact metal lathe alignment. You’ll discover tips and tricks that can help you avoid common pitfalls. Who knows? You might even find a new hobby or a passion for metalworking!

Compact Metal Lathe Alignment: Ensuring Precision In Machining

Compact Metal Lathe Alignment

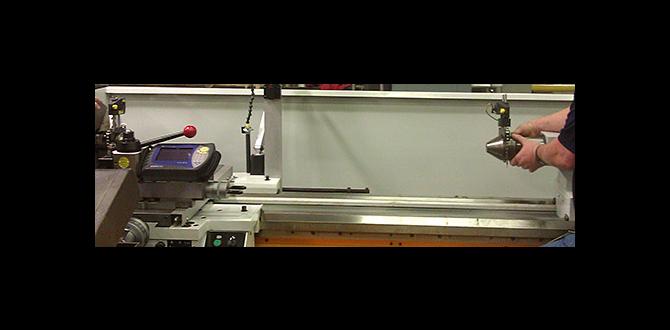

Aligning a compact metal lathe is crucial for precision work. Proper alignment helps create accurate parts and reduces wear on the machine. Did you know that even a tiny misalignment can lead to big problems? Regular checks and adjustments can make all the difference. Start by ensuring the bed is level. Then align the tailstock with the spindle. This simple maintenance keeps your lathe running smoothly and extends its life. Precision matters; let’s make it a priority!Understanding Compact Metal Lathes

Definition and purpose of compact metal lathes. Advantages of using compact metal lathes in various applications.Compact metal lathes are small machines that shape metal into various items. They spin metal pieces while cutting tools remove material. This helps create precise parts for different projects. These lathes are useful because:

- They save space.

- They are easy to use.

- They offer great precision.

- They work well for many tasks, like making tools or hobby projects.

In short, compact metal lathes make metalworking simple and fun!

What are the advantages of compact metal lathes?

Using compact metal lathes has many advantages. They take up less space and are easier to operate. This makes them great for small shops or home use. You can create detailed parts quickly.

The Importance of Proper Alignment

Impact of misalignment on machining accuracy. Longterm effects of poor alignment on lathe performance.Aligning your lathe correctly is crucial for good work. If your lathe is off, it can mess up your precision. Picture trying to draw a straight line with a bent pencil! Misalignment leads to mistakes in cutting and finishing. Over time, poor alignment can wear out your machine and cause bigger issues, like extra vibrations and even breakdowns. Trust me, keeping it straight is the best way to keep things running smoothly.

| Effects of Misalignment | Long-term Impact |

|---|---|

| Uneven Cutting | Machine Wear |

| Inaccurate Measurements | Increased Vibration |

| Wasted Material | Frequent Repairs |

Tools Required for Alignment

Essential tools for aligning a compact metal lathe. Recommended gauges and measuring devices.To align a compact metal lathe properly, you need some important tools. These help ensure everything is in the right place. Here are the main tools you’ll need:

- Level: This checks if your lathe stands straight.

- Dial Indicator: This measures tiny changes in height.

- Taper Gauge: This helps check the alignment of the spindle.

- Straightedge: This is used to see how flat the surface is.

- Alignment Bars: These help in precise measurement and placement.

Using these tools can make a big difference in your lathe’s performance.

What is the best tool for aligning a lathe?

The best tool for aligning a lathe is often a dial indicator. It helps measure slight misalignments very accurately, making it essential for great results.

Step-by-Step Alignment Process

Preparing the lathe for alignment. Detailed steps for aligning the headstock and tailstock. Tips for checking alignment accuracy during the process.Get your lathe ready by first cleaning it up! Dust and dirt can make alignment a struggle. Next, check that the headstock and tailstock are level. Use a digital level or a simple bubble level for this—no rocket science here! Here’s a funny tip: if you find your level is off, don’t worry! It’s not a “bad karma” day; it’s just your lathe needing a little TLC.

To align the headstock and tailstock:

| Step | Action |

|---|---|

| 1 | Loosen the tailstock clamp. |

| 2 | Move the tailstock until it lines up with the headstock. |

| 3 | Tighten the clamp gently. |

Finally, double-check your alignment. A simple test is to run a piece of scrap metal through the lathe. If it cuts evenly, you’re golden! If it wobbles, you might need to make a few adjustments. Remember, a well-aligned lathe makes a happy worker!

Common Alignment Issues and Solutions

Identifying signs of misalignment. Troubleshooting common problems and effective solutions.Misalignment can cause problems in your metal lathe. Look for signs like uneven cuts or weird noises. These hints show something is off. Misalignment can make your work messy. Here are some common issues and solutions:

- Vibration – Check if parts are tightly secured.

- Uneven cuts – Use shims to level the machine.

- Difficulty with settings – Recalibrate carefully.

Taking quick actions can save time and effort. Fixing alignment issues can improve your lathe’s performance. This leads to better projects and happier builds.

What are signs of misalignment?

Some signs include uneven cuts and strange noises. A misaligned lathe can make work more difficult.

Common solutions for misalignment:

- Secure all parts tightly.

- Use shims for leveling.

- Recalibrate the machine.

Maintenance Tips for Sustaining Alignment

Routine checks and adjustments. Best practices for maintaining lathe alignment over time.To keep your lathe working well, you need to check it regularly. This means looking closely at its parts. Small adjustments can help it run smoothly. Here are some tips to follow:

- Check the level often.

- Clean the lathe to remove dust and chips.

- Lubricate moving parts as needed.

- Tighten bolts and screws to avoid wobbling.

- Inspect belts and pulleys for wear.

By following these steps, you can make sure your compact metal lathe stays aligned over time. A properly aligned lathe works better and lasts longer!

How often should I check my lathe alignment?

You should check your lathe alignment at least once a week if you use it often. Regular checks keep it running smooth and prevent major problems.

Upgrading Your Compact Metal Lathe for Better Alignment

Modifications and enhancements that aid alignment. Choosing the right accessories for optimal performance.Upgrading your compact metal lathe can greatly improve its alignment and performance. Here are some easy modifications to consider:

- Install precision leveling feet for better stability.

- Use a quality tailstock alignment tool to ensure straight cuts.

- Upgrade to a digital readout for accurate measurements.

Choosing the right accessories is also important. Look for tools made for your specific lathe model. They enhance performance and make your work easier. A well-aligned lathe can improve the quality of your projects.

What are the benefits of upgrading your lathe?

Upgrading your lathe can lead to better accuracy, smoother operation, and longer tool life. This means you can create better projects and spend less time fixing mistakes.

Conclusion

In conclusion, aligning your compact metal lathe is essential for accurate work. Proper alignment helps avoid mistakes and improves your projects. Remember to check your lathe regularly and adjust as needed. If you’re curious, explore more about lathe maintenance and techniques to enhance your skills. With practice, you’ll become a pro in no time!FAQs

Sure! Here Are Five Questions Related To Compact Metal Lathe Alignment:Sure! Here are some simple answers about compact metal lathe alignment. 1. **What is a compact metal lathe?** A compact metal lathe is a machine that cuts metal into different shapes. It spins metal while tools shape it. 2. **Why is alignment important for a lathe?** Alignment makes sure everything is straight. This helps you make better and smoother cuts on the metal. 3. **How do you check if the lathe is aligned?** You can use a ruler or a special tool. Place it against the lathe and check for any gaps. 4. **What happens if the lathe is not aligned?** If it’s not aligned, the cuts can be crooked. This makes your project look bad and can waste materials. 5. **Can I fix the alignment myself?** Yes, you can! With some tools and patience, you can adjust the lathe to make it straight again.

Sure, I can help with that! Please let me know the question you want me to answer.

What Are The Key Steps Involved In Aligning A Compact Metal Lathe To Ensure Accurate Machining?To align a compact metal lathe, start by checking the bed. Use a level to see if it’s straight. Next, adjust the tailstock so it lines up with the spindle. After that, check the cutting tool to make sure it’s at the right height. Finally, test the lathe with a small piece of metal to see if it cuts evenly.

How Can Misalignment In A Compact Metal Lathe Affect The Quality Of The Finished Workpiece?When the parts of a compact metal lathe are not lined up correctly, it can cause problems. The cutting tool might not touch the metal evenly. This can make the shape not smooth or wonky. You might end up with a rough or uneven workpiece instead of a nice one. Good alignment is important to make sure everything looks and works well.

What Tools And Equipment Are Typically Required To Check And Adjust The Alignment Of A Compact Metal Lathe?To check and adjust the alignment of a compact metal lathe, you need a few simple tools. First, you use a level to see if it’s straight. A dial indicator helps measure tiny movements accurately. You might also use a straightedge, which is a flat ruler to check for straightness. Lastly, a wrench helps you tighten or loosen screws to make adjustments.

How Often Should The Alignment Of A Compact Metal Lathe Be Checked And Re-Calibrated During Use?You should check the alignment of a compact metal lathe often, like once a week. If you notice anything strange, check it right away. A good rule is to check it before starting a new big project. This helps keep your work accurate and safe!

What Are Common Signs Of Misalignment In A Compact Metal Lathe, And How Can They Be Diagnosed?Common signs of misalignment in a compact metal lathe include uneven cutting, strange noises, and parts that don’t fit together. You might notice your tool shakes or wobbles while working. To check for problems, you can use a level to see if everything is straight. You could also try to measure the distance between parts to see if they are the same. If something looks off, you might need to adjust the lathe to fix it.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Questions Related To Compact Metal Lathe Alignment:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are some simple answers about compact metal lathe alignment. 1. **What is a compact metal lathe?** A compact metal lathe is a machine that cuts metal into different shapes. It spins metal while tools shape it. 2. **Why is alignment important for a lathe?** Alignment makes sure everything is straight. This helps you make better and smoother cuts on the metal. 3. **How do you check if the lathe is aligned?** You can use a ruler or a special tool. Place it against the lathe and check for any gaps. 4. **What happens if the lathe is not aligned?** If it’s not aligned, the cuts can be crooked. This makes your project look bad and can waste materials. 5. **Can I fix the alignment myself?** Yes, you can! With some tools and patience, you can adjust the lathe to make it straight again.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure, I can help with that! Please let me know the question you want me to answer.”}},{“@type”: “Question”,”name”: “What Are The Key Steps Involved In Aligning A Compact Metal Lathe To Ensure Accurate Machining?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To align a compact metal lathe, start by checking the bed. Use a level to see if it’s straight. Next, adjust the tailstock so it lines up with the spindle. After that, check the cutting tool to make sure it’s at the right height. Finally, test the lathe with a small piece of metal to see if it cuts evenly.”}},{“@type”: “Question”,”name”: “How Can Misalignment In A Compact Metal Lathe Affect The Quality Of The Finished Workpiece?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When the parts of a compact metal lathe are not lined up correctly, it can cause problems. The cutting tool might not touch the metal evenly. This can make the shape not smooth or wonky. You might end up with a rough or uneven workpiece instead of a nice one. Good alignment is important to make sure everything looks and works well.”}},{“@type”: “Question”,”name”: “What Tools And Equipment Are Typically Required To Check And Adjust The Alignment Of A Compact Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To check and adjust the alignment of a compact metal lathe, you need a few simple tools. First, you use a level to see if it’s straight. A dial indicator helps measure tiny movements accurately. You might also use a straightedge, which is a flat ruler to check for straightness. Lastly, a wrench helps you tighten or loosen screws to make adjustments.”}},{“@type”: “Question”,”name”: “How Often Should The Alignment Of A Compact Metal Lathe Be Checked And Re-Calibrated During Use?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You should check the alignment of a compact metal lathe often, like once a week. If you notice anything strange, check it right away. A good rule is to check it before starting a new big project. This helps keep your work accurate and safe!”}},{“@type”: “Question”,”name”: “What Are Common Signs Of Misalignment In A Compact Metal Lathe, And How Can They Be Diagnosed?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Common signs of misalignment in a compact metal lathe include uneven cutting, strange noises, and parts that don’t fit together. You might notice your tool shakes or wobbles while working. To check for problems, you can use a level to see if everything is straight. You could also try to measure the distance between parts to see if they are the same. If something looks off, you might need to adjust the lathe to fix it.”}}]}