Have you ever wondered how small pieces of metal turn into cool projects? Compact metal lathe cutting tools are the magic behind it all! These handy tools make it easy to shape and cut metal into whatever you want.

Imagine building a toy car or a piece of jewelry. With a metal lathe, you can create amazing shapes that are both fun and useful. It’s like being a wizard with metal!

Many people think that metal work is just for experts. But with compact metal lathe cutting tools, anyone can learn. You might even be surprised to find that these tools fit right on a workbench.

Did you know that a small lathe can help you make more than just parts? You can develop your skills and turn your ideas into real products. So why wait? Let’s dive into the world of compact metal lathe cutting tools!

Compact Metal Lathe Cutting Tools: Precision For Every Project

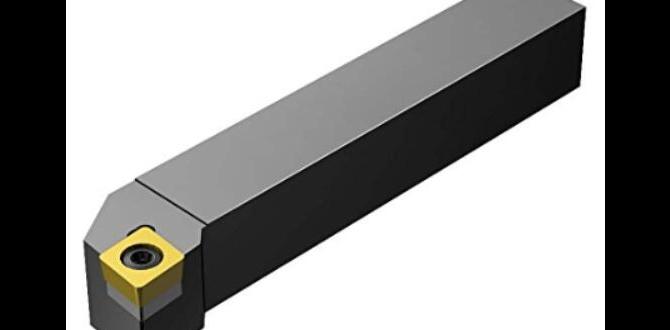

Compact Metal Lathe Cutting Tools

Are you curious about compact metal lathe cutting tools? These handy tools are perfect for small workshops. They help you shape and cut metal pieces with precision. Imagine easily creating parts for your projects! Different cutting tools, like carbide inserts and high-speed steel bits, offer versatility. Did you know that using the right tool can save time and make your work smoother? Learning to choose the best cutting tool can make a huge difference in your results!Types of Cutting Tools for Compact Metal Lathes

Description of various cutting tools including highspeed steel, carbide, and ceramic. Comparison of cutting tool materials for performance and durability.Different materials make cutting tools for compact metal lathes. Here are some of the main types:

- High-Speed Steel (HSS): Great for cutting at high speeds. It is easy to sharpen and good for many jobs.

- Carbide: Very hard and lasts longer than HSS. It cuts through tough materials well but can be more expensive.

- Ceramic: Excellent for high-speed machining. It holds its edge well but can be brittle and may break easily.

Each material has its own strengths. HSS is good for general use. Carbide is best for heavy-duty tasks. Ceramic is great for quick jobs but needs careful handling.

What are the main advantages of each cutting tool material?

HSS is affordable and easy to sharpen, making it a good choice for beginners.

Carbide is tough and lasts a long time, ideal for pro-level projects.

Ceramic offers speed and precision, but it requires careful use due to its fragility.

Essential Features of Cutting Tools

Key features to consider in cutting tools, such as geometry and coatings. How to choose the right cutting tool for specific tasks on a compact lathe.Choosing the right cutting tools is like picking the best ice cream flavor. You need to know the key features that matter! Look at the geometry of the tool—different shapes cut materials in various ways. For example, sharp edges help with fine work, while chunky edges are perfect for heavy jobs. Coatings are just as important; they can make tools last longer. Think of coatings like sunscreen for your tools!

| Feature | Benefit |

|---|---|

| Geometry | Helps in achieving precision. |

| Coatings | Increases durability and reduces friction. |

When using a compact lathe, selecting the right tool for your task is key. For turning and facing, choose pointed tools. For boring, grab a flat tool. Matching the tool with the job can turn your project from “meh” to “wow!”

Maintenance and Care for Longevity

Best practices for maintaining and sharpening metal lathe cutting tools. Importance of tool storage and handling to prevent damage.Keeping metal lathe cutting tools in good shape helps them last longer. Here are some simple tips:

- Always clean your tools after use to remove chips and grime.

- Sharpen them regularly for smooth cuts. A sharp tool works better!

- Store tools in a dry place, away from moisture, to prevent rust.

- Handle them carefully to avoid drops or dings.

These steps can make a big difference in their lifespan. A well-cared-for tool not only saves money but helps you work more safely.

How often should you sharpen metal lathe cutting tools?

You should sharpen your tools every few uses, or when they start to feel dull. Dull tools can lead to mistakes and unsafe conditions.

Common Issues and Troubleshooting

Typical problems encountered with cutting tools and their solutions. Tips for improving efficiency and performance during lathe operations.Working with cutting tools can come with some typical problems. Here are some common issues and easy solutions:

- **Dull blades:** Change or sharpen your tools regularly. This makes cuts smooth.

- **Vibration:** Ensure that tools are tightly secured. A stable tool helps reduce noise and improves results.

- **Chip buildup:** Clear chips often while working. This prevents jams and aids performance.

- **Incorrect speed:** Adjust the lathe speed based on the material. Each material needs its own right speed to cut well.

Improving your skills can enhance efficiency. Always check your setup. Practice regular maintenance. These actions keep your cutting tools in top shape.

What should I do if my cutting tool is dull?

**Sharpen the tool or replace it.** Dull tools make working harder and less safe.

How can I stop vibrations during operation?

**Ensure tools are tight and stable.** This will help minimize unwanted movements and improve your work quality.

Industry Applications of Compact Metal Lathe Cutting Tools

Various sectors using compact metal lathes and their specific cutting tool needs. Case studies demonstrating successful applications of cutting tools in realworld scenarios.Different industries rely on compact metal lathes for their unique cutting tool needs. For example, the automotive sector uses these tools to shape parts with precision—like machining tiny gears. The aerospace industry also benefits, crafting lightweight parts that withstand high stress. A case study shows a small shop that increased its output by 30% after switching to more efficient cutting tools. It’s a win-win!

| Industry | Cutting Tool Application |

|---|---|

| Automotive | Precision part shaping |

| Aerospace | Lightweight component creation |

| Manufacturing | Mass production of small parts |

Conclusion

In summary, compact metal lathe cutting tools are essential for precise machining tasks. They are durable, efficient, and perfect for small projects. You can improve your metalworking skills by practicing with these tools. Explore different types and techniques to find what works best for you. Keep learning and have fun creating with your compact lathe!FAQs

Sure! Here Are Five Related Questions On The Topic Of Compact Metal Lathe Cutting Tools:Sure! Here are five questions about compact metal lathe cutting tools: 1. **What is a metal lathe?** A metal lathe is a tool that shapes metal. It spins metal pieces while cutting them into the right shape. 2. **What are cutting tools?** Cutting tools are parts that slice or carve the metal. They help create shapes like cylinders or gears. 3. **How do I use a lathe?** To use a lathe, you place a metal piece on it. Then, you turn it on and use cutting tools to shape it. 4. **What materials can I cut?** You can cut various metals, like aluminum and steel. Some lathes can even cut plastic. 5. **How do I keep my tools sharp?** You can keep your tools sharp by using a file or sharpening stone. A sharp tool cuts better and lasts longer.

Sure! Please provide the question you would like me to answer.

What Are The Different Types Of Cutting Tools Commonly Used With Compact Metal Lathes?Compact metal lathes use several types of cutting tools. First, there are turning tools, which help shape the metal. Next, we have parting tools, which cut through the metal for separating pieces. You might also see facing tools, which make the ends flat and smooth. Finally, some lathes use boring tools to make holes.

How Do You Determine The Appropriate Cutting Tool Material For Specific Machining Tasks On A Compact Lathe?To choose the right cutting tool material for your compact lathe, you need to think about what you are machining. First, look at the material you will cut, like metal or plastic. Then, consider how hard that material is. Harder materials need stronger tools made of tough materials, like tungsten carbide. Finally, think about how quickly you will be working. Faster work may need a special coating to help the tool last longer.

What Factors Should Be Considered When Selecting Cutting Tool Geometry For Compact Metal Lathes?When choosing a cutting tool for a compact metal lathe, you should think about three main things. First, consider the type of material you’ll be working with. Different materials need different tool shapes. Second, think about the size of the pieces you’ll cut. Finally, look at the cutting angle. A good angle helps the tool cut smoothly and last longer.

How Can Maintenance And Sharpening Of Cutting Tools Influence The Performance Of A Compact Metal Lathe?Taking care of and sharpening cutting tools can make your compact metal lathe work better. When tools are sharp, they cut metal smoothly and easily. This helps you make cleaner shapes and sizes. If tools are dull, they struggle and can even break, making your work harder. So, keeping the tools sharp means more fun and better results!

What Safety Precautions Should Be Taken When Using Cutting Tools On A Compact Metal Lathe?When using cutting tools on a compact metal lathe, you should always wear safety glasses to protect your eyes. Keep your hair and loose clothes away from the machine to avoid getting caught. Make sure your hands are dry and not touching the tool while it’s moving. Always check the tool is secure before you start. Finally, don’t rush; take your time to stay safe.