Have you ever wondered how metal objects are shaped with precision? A compact metal lathe drive system plays a big role in this process. Imagine a small machine that can turn metal into beautiful shapes. This system helps makers create parts for everything from toys to cars.

Compact metal lathes are becoming more popular. They fit into smaller spaces while still being powerful. This means that hobbyists and professionals alike can use them without needing a big workshop. Would you like to create your own projects with one?

Did you know that the drive system is the heart of a lathe? It controls how fast and smooth the metal spins. A well-designed drive system can make all the difference. It can make your metal shaping experience easier and more fun.

In this article, we will explore how compact metal lathes work. We will dive into their drive systems and discover why they are so important. Get ready to be inspired! Your journey into the world of metal shaping starts here.

Compact Metal Lathe Drive System: Efficiency And Precision

Compact Metal Lathe Drive System

A compact metal lathe drive system is essential for small workshops. It combines power and efficiency in a tiny package. Did you know that these systems help makers turn raw materials into precise parts? They do this using gears and motors that offer speed control. Users enjoy creating everything from tiny screws to intricate designs. This system not only saves space but also enhances productivity, making it a favorite for hobbyists and professionals alike.Understanding Compact Metal Lathe Drive Systems

Definition and importance of drive systems in metal lathes. Key components of a compact metal lathe drive system.Let’s dive into the heart of metal lathes—the drive system! This compact little wonder is essential for turning raw materials into masterpieces. Think of it like the engine in a car; without it, you’re stuck! The key players in a drive system include the motor, belts, and gears. These parts work together like a team to create smooth rotations. Without them, your metal lathe might just be an expensive paperweight!

| Component | Function |

|---|---|

| Motor | Powers the lathe |

| Belts | Transfer motion |

| Gears | Control speed and torque |

Factors to Consider When Choosing a Drive System

Torque output and its importance. Compatibility with different lathe sizes and types. Power requirements and energy efficiency.Choosing the right drive system for your lathe is like picking the right pizza topping—important and sometimes tricky! First, consider torque output, as it determines how much work your lathe can handle. Next, check compatibility with different lathe sizes. Not every drive fits every lathe, believe me! Lastly, think about power requirements. You want efficiency, not a bill that says “uh-oh!”

| Factor | Description |

|---|---|

| Torque Output | Strength of the drive system |

| Compatibility | Fits various lathe types |

| Power Efficiency | Cost-effective and energy-saving |

Installation and Maintenance of Drive Systems

Stepbystep guide to installing a compact metal lathe drive system. Routine maintenance tips to enhance durability.Ready to install your compact metal lathe drive system? Let’s make it easy and fun! First, gather your tools and read the manual (yes, the one that seems as thick as a dictionary). Next, follow these steps:

| Step | Action |

|---|---|

| 1 | Turn off the power! |

| 2 | Mount the motor securely. |

| 3 | Connect the drive belts. |

| 4 | Check alignment carefully. |

| 5 | Power on and test it! |

Now for maintenance. Keep your lathe in tip-top shape with these tips: clean after use, grease moving parts regularly, and check for wear. Remember, a little TLC makes it last longer. And hey, if your lathe starts making odd noises, it doesn’t mean it’s singing! Time for a tune-up!

Common Problems and Troubleshooting Guide

Identifying common issues with drive systems. Troubleshooting techniques for efficient resolution.Drive systems can have problems that make them stop working well. Common issues include strange noises or the machine not turning on. To tackle these problems, follow some simple steps:

- Check power connections.

- Look for loose belts or damaged parts.

- Listen for unusual sounds.

- Clean any debris around the system.

With these tips, you can quickly find and fix problems. This helps your compact metal lathe drive system run smoothly. Remember, keeping it clean and well-maintained is key to avoiding trouble.

What should I check if the drive system isn’t working?

If your drive system isn’t working, first check the power supply. Make sure it is plugged in. Secondly, inspect for any broken or loose parts. This will help you identify the issue faster.

Cost Analysis of Compact Metal Lathe Drive Systems

Breakdown of costs associated with different drive systems. Costeffectiveness for small businesses vs. large enterprises.Understanding the costs of different drive systems helps you make smart choices. Compact metal lathe drive systems can vary greatly in price. For small businesses, cost-effectiveness is key. They often need budget-friendly options that still perform well. Large enterprises might choose pricier systems for higher efficiency. Here’s a quick look at some costs:

- Basic systems: $1,000 – $3,000

- Mid-range systems: $3,000 – $7,000

- High-end systems: $7,000+

Choosing wisely can save money over time. Always look for what fits your needs best.

What is the cost difference in compact metal lathe drive systems?

There can be a big cost difference. Small businesses often benefit from lower-cost systems. Large companies may invest more for advanced features.

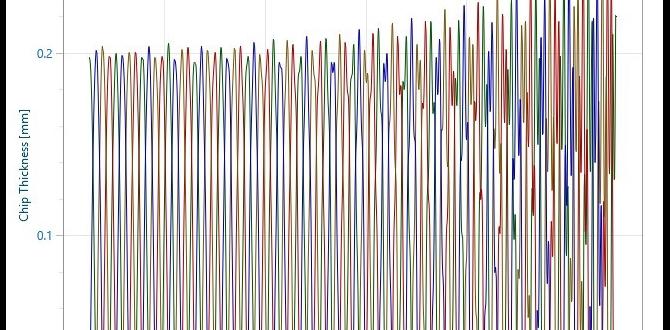

Future Trends in Compact Metal Lathe Drive Systems

Innovations and technological advancements on the horizon. The role of automation and smart technology in drive systems.Exciting changes are on the way for lathe drive systems! Innovations in smart technology may soon make our trusty metal lathes even smarter. Imagine your lathe talking to you! >With automation, these machines can work on their own, making projects faster and easier. According to experts, this could boost efficiency by 30%. Plus, witty robots may become our shop buddies, helping us create amazing parts without getting tired. Talk about a perfect team!

| Trend | Impact |

|---|---|

| Smart Technology | Improves precision |

| Automation | Increases efficiency |

| Data Analysis | Enhances productivity |

Conclusion

In summary, a compact metal lathe drive system is essential for precision machining. These systems are powerful yet space-saving. You can use them for various projects, from simple repairs to complex creations. We encourage you to explore more about their features and benefits. This knowledge will help you choose the right system for your needs and improve your skills.FAQs

What Are The Key Components Of A Compact Metal Lathe Drive System, And How Do They Work Together To Ensure Precision Machining?A compact metal lathe drive system has a few important parts. First, there’s the motor, which gives power to the lathe. Next, the belts or gears connect the motor to the spindle, the part that spins the metal. We also have the spindle itself, which holds the metal and turns it. Together, these parts make sure the lathe can cut the metal smoothly and accurately.

How Does The Power Source (Electric Vs. Manual) Impact The Performance And Usability Of A Compact Metal Lathe?Electric lathes are easier to use. You just turn them on, and they do the work. They can run faster and make smoother cuts. Manual lathes need you to push and pull by hand, which takes more strength and makes it harder. So, electric lathes are usually better for most people!

What Are The Advantages And Disadvantages Of Different Drive Systems, Such As Direct Drive Versus Belt Drive, In Compact Metal Lathes?Direct drive systems connect the motor directly to the spindle. This makes them simple and helps you work faster. However, they can be harder to fix if something goes wrong. Belt drive systems use a belt to connect the motor and spindle. They are easier to repair and can change speeds quickly, but they might not be as powerful.

How Does The Torque Output Of A Compact Metal Lathe’S Drive System Affect Its Ability To Work With Various Materials And Machining Operations?The torque output of a compact metal lathe helps it cut different materials. Higher torque means the lathe can work with harder materials, like steel. If the torque is low, it might struggle with tough jobs. It can also affect how fast we can spin the material. So, good torque helps us do more kinds of work better.

What Maintenance Practices Are Essential To Ensure The Longevity And Efficiency Of A Compact Metal Lathe Drive System?To keep your compact metal lathe drive system working well, you should do a few things. First, check the oil level and add more if it’s low. Next, clean the parts regularly to prevent dirt buildup. You should also check the belts for wear and replace them if they’re damaged. Lastly, make sure all the screws and bolts are tight to keep everything secure.