Have you ever wondered how tiny metal parts are made with such precision? A compact metal lathe gear can make that happen. This little machine helps shape metal into useful products. From toys to tools, many objects start their journey on a lathe.

Imagine a craftsman in a small workshop, surrounded by sparks flying. With the help of a compact metal lathe gear, he transforms raw metal into amazing creations. Isn’t it fascinating how this simple device can turn plain metal into something extraordinary?

Did you know that compact metal lathe gears come in different sizes and types? Some are designed for hobbyists, while others are meant for professional use. This variety makes it easy for anyone to find the right lathe for their project.

Join us as we explore the world of compact metal lathe gears. You might be surprised at how much you can create with one!

Discover The Benefits Of Compact Metal Lathe Gears

Compact Metal Lathe Gear: What You Need to Know

A **compact metal lathe gear** is vital for precision in small-scale fabrications. These gears help shape and cut metal accurately. Imagine crafting tiny pieces for a model or a toy; the right gear makes all the difference! Did you know compact lathes are often used in home workshops? With their ease of use and small size, anyone can tackle projects. This tool is perfect for hobbyists and small manufacturers alike, making it an exciting addition to any workshop!What is a Compact Metal Lathe Gear?

Definition and function of a compact metal lathe gear. Importance in machining and manufacturing processes.A compact metal lathe gear is a small but important part of a machine. It helps shape and cut metal into different forms. Without this gear, machines would struggle to work. It connects various parts, allowing smooth movements.

- Defines the shape of metal pieces

- Improves accuracy in production

- Speeds up manufacturing processes

What are the main benefits of compact metal lathe gears?

Compact metal lathe gears provide precision, speed, and efficiency in machining. They help create exact shapes with less waste.

Key Features to Consider

Material options (e.g., steel, aluminum). Gear ratios and their impact on performance.Choosing the right materials for your compact metal lathe gear is crucial. Steel is strong and durable, while aluminum is lighter and easier to manage. Think of it like choosing between a sturdy backpack for a long hike and a stylish handbag for a dinner date—each has its purpose!

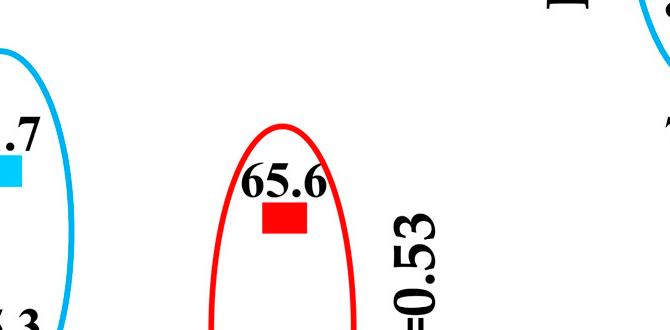

Next, consider the gear ratios. They can change how your lathe performs. A high gear ratio means more speed but less torque, which is like running really fast but not being able to lift your lunchbox! On the other hand, a lower gear ratio offers more power but less speed—ideal for tricky jobs.

| Material | Durability | Weight |

|---|---|---|

| Steel | High | Heavy |

| Aluminum | Medium | Light |

Remember, selecting the right features will give you the best results! So, choose wisely and happy crafting!

Benefits of Using Compact Metal Lathe Gears

Enhanced precision in machining. Spacesaving advantages for small workshops.Using compact metal lathe gears improves machining skills. These gears help make precise cuts and shapes, which means better quality work. For small workshops, they save space. They fit into tight spots where big tools won’t go. This is great for people who don’t have a lot of room. Here are some benefits:

- Enhanced precision: Creates accurate and clean designs.

- Space-saving: Perfect for small shops with limited space.

These advantages make compact metal lathe gears a smart choice for anyone working with metal. They help you work better and fit in tight spaces!

What is the main advantage of compact metal lathe gears?

The main advantage is improved precision in your projects. You can achieve exact measurements, which means better results every time!

Why are they important for small workshops?

They are important because they save space and fit into small areas. This allows more people to enjoy the benefits of machining!

Applications of Compact Metal Lathe Gears

Industries that utilize compact metal lathe gears (e.g., automotive, aerospace). Specific projects or tasks that benefit from their use.Many industries use compact metal lathe gears. They are vital in the automotive and aerospace sectors. These gears help make parts for cars, airplanes, and more. Tasks like cutting metal and shaping parts benefit from them. Here are some specific uses:

- Producing engine components

- Creating airplane fittings

- Making precision tools

Compact metal lathe gears ensure parts are strong and accurate. Projects become easier and faster with their help. This makes them important for engineers and builders.

What industries use compact metal lathe gears?

Automotive and aerospace industries commonly utilize compact metal lathe gears. They are crucial for making precise parts.

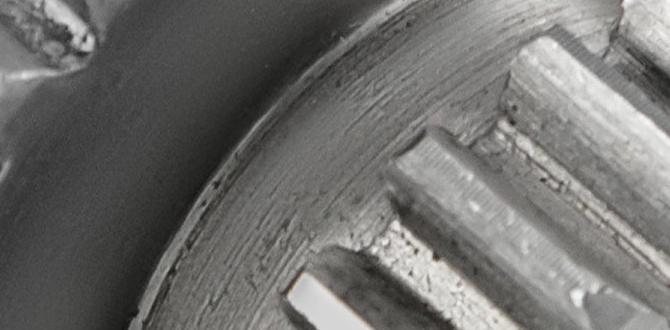

How to Maintain Compact Metal Lathe Gears

Best practices for regular maintenance. Common issues and troubleshooting tips.To keep your compact metal lathe gears in top shape, regular maintenance is key. Check the gears for wear and tear every month. Clean them often to avoid pesky buildup that can cause issues. Lubricate gears using light oil; it’s like giving them a spa day!

If you notice strange noises or sticky movements, don’t panic! These could be signs of low lubrication or dirt buildup. Check the screws and belts; they might need tightening or replacing. Remember, a little care goes a long way in prolonging their life!

| Common Issues | Troubleshooting Tips |

|---|---|

| Noisy operation | Check lubrication levels |

| Slipping belts | Tighten or replace belts |

| Dirt buildup | Clean gears regularly |

Choosing the Right Compact Metal Lathe Gear

Factors to consider when selecting a gear for specific needs. Recommended brands or manufacturers.Picking the right gear for your compact metal lathe is like finding the perfect shoe. You want comfort and style! Start by checking the size and type of gear that fits your projects. A strong gear can make all the difference, so look for trusted brands like Grizzly or Jet. They’re the superheroes in the lathe world. You’d be surprised how a good gear can turn a clunky project into a masterpiece!

| Brand | Features |

|---|---|

| Grizzly | Durable and reliable, perfect for beginners. |

| Jet | High precision, great for detailed work. |

| Haas | Industry favorite, known for top performance. |

DIY vs. Commercially Available Compact Metal Lathe Gears

Advantages and drawbacks of DIY options. Comparison of quality and cost with commercial products.Making your own compact metal lathe gear can be fun and rewarding. However, it has its ups and downs. Here are some advantages and drawbacks:

- **Advantages:**

- Custom designs to fit your needs.

- Often cheaper than buying.

- Learning new skills while creating.

- **Drawbacks:**

- May take longer to make.

- Quality might not match commercial products.

- Testing and adjustments needed for best results.

Commercial compact metal lathe gears are usually reliable. They save time and provide consistent quality. However, they can be pricier. Comparing costs helps you decide what works best for you.

What are the key benefits of DIY lathe gears?

Creating your own lathe gears allows you to save money and gain skills. It can be fulfilling and give you a unique piece that fits your needs. The journey of crafting your gear is often rewarding, and you might learn more than expected!

Future Trends in Compact Metal Lathe Gear Technology

Innovations in gear design and materials. The impact of automation and digital technologies on lathe gear development.New ideas in gear design and materials are popping up every day. Think lighter, stronger materials that make lathes run smoother. Automation is a game changer too! Robots and computers can create perfect gears faster than a cheetah on roller skates. Together, these trends promise to make compact metal lathe gear technology smarter and more efficient. One day, your lathe might even make coffee while it works! Now that’s what I call multitasking!

| Trend | Description |

|---|---|

| Innovative Materials | Lightweight yet strong materials for better performance |

| Automation | Robots for faster and accurate gear production |

Conclusion

In summary, compact metal lathe gears are essential for efficient machining. They help you create precise items in a small space. Remember to choose a reliable brand and maintain your lathe well. If you’re interested in machining, consider reading more about lathe projects and gear options. You can make amazing things with the right tools!FAQs

Sure! Here Are Five Related Questions On The Topic Of Compact Metal Lathe Gears:Sure! Compact metal lathe gears help machines turn metal pieces. You can change the gears to make the lathe work faster or slower. This lets you create different shapes easily. You should keep them clean to work well. It’s fun to learn how they fit together!

Sure! Please give me the question you want me to answer.

What Are The Key Features To Consider When Selecting A Compact Metal Lathe Gear For Precision Machining?When you pick a compact metal lathe gear, think about a few important features. First, check the size to make sure it fits your project. Next, look at the material. Strong metals work best for precise work. Then, see how many speeds it has. More speeds give you better control. Finally, think about the price to make sure it fits your budget. Choose wisely!

How Do Different Gear Ratios In A Compact Metal Lathe Affect Cutting Speed And Torque?Different gear ratios on a metal lathe change how fast and strong the machine can cut. A higher gear ratio makes the lathe spin faster, which gives you a quicker cut. But, this can reduce strength or torque, making it harder to cut through tough materials. A lower gear ratio means slower cutting but gives you more strength to handle hard metals. So, choosing the right gear ratio helps you cut better based on what you’re working on.

What Materials Are Commonly Used In The Construction Of Gears For Compact Metal Lathes, And How Do They Impact Durability?Gears for compact metal lathes are often made from steel, aluminum, or plastic. Steel gears are strong and last a long time. Aluminum gears are lighter and also pretty strong. Plastic gears are easy to make and cheaper, but they don’t last as long. The choice of material affects how long the gears will work without breaking.

What Maintenance Practices Should Be Followed To Ensure The Longevity And Optimal Performance Of Gears In Compact Metal Lathes?To keep the gears in compact metal lathes working well, we should do a few things. First, let’s keep them clean by dusting off any dirt. We can also check and add oil to help them move smoothly. It’s important to look for any damage or wear and get it fixed quickly. Finally, always follow the manufacturer’s instructions to keep everything in good shape.

How Do Compact Metal Lathe Gears Differ From Those Used In Full-Sized Lathes In Terms Of Design And Functionality?Compact metal lathe gears are smaller and lighter than those in full-sized lathes. This helps them work in tight spaces. They often have simpler designs, making them easier to use. Full-sized lathes can handle bigger projects and more power. So, compact lathes are great for small tasks, while full-sized ones are better for heavy-duty work.