Have you ever watched a metalworker effortlessly shape a piece of metal? It’s fascinating, right? One key tool they use is a compact metal lathe. This device helps them create precise shapes by spinning metal while cutting it away. But what makes it even more interesting is the threading dial.

The threading dial helps the metalworker make perfect threads on the metal. Imagine trying to screw two pieces of metal together. If the threads don’t match, they won’t hold. That’s why mastering the threading dial is so important.

Did you know that many beginner metalworkers struggle with this part? Yet, once they learn its secrets, their work improves greatly. It’s like learning to ride a bike. Once you get it, you’ll never forget!

In this article, we will explore the compact metal lathe threading dial. You’ll discover how it works and why it’s a must-have for any metalworking enthusiast.

Compact Metal Lathe Threading Dial: Essential Tool Insights

Compact Metal Lathe Threading Dial

The compact metal lathe threading dial is an essential tool for precise machining. This dial helps users set accurate thread pitches, ensuring better fitting parts. Imagine creating screws or bolts that fit perfectly! It aids in threading operations, making it easier for hobbyists and professionals alike. Many compact lathes come with built-in dials, maximizing efficiency. Did you know that a well-calibrated threading dial can save hours of work? Discover the power of this simple, yet vital, device in your projects!Understanding Compact Metal Lathes

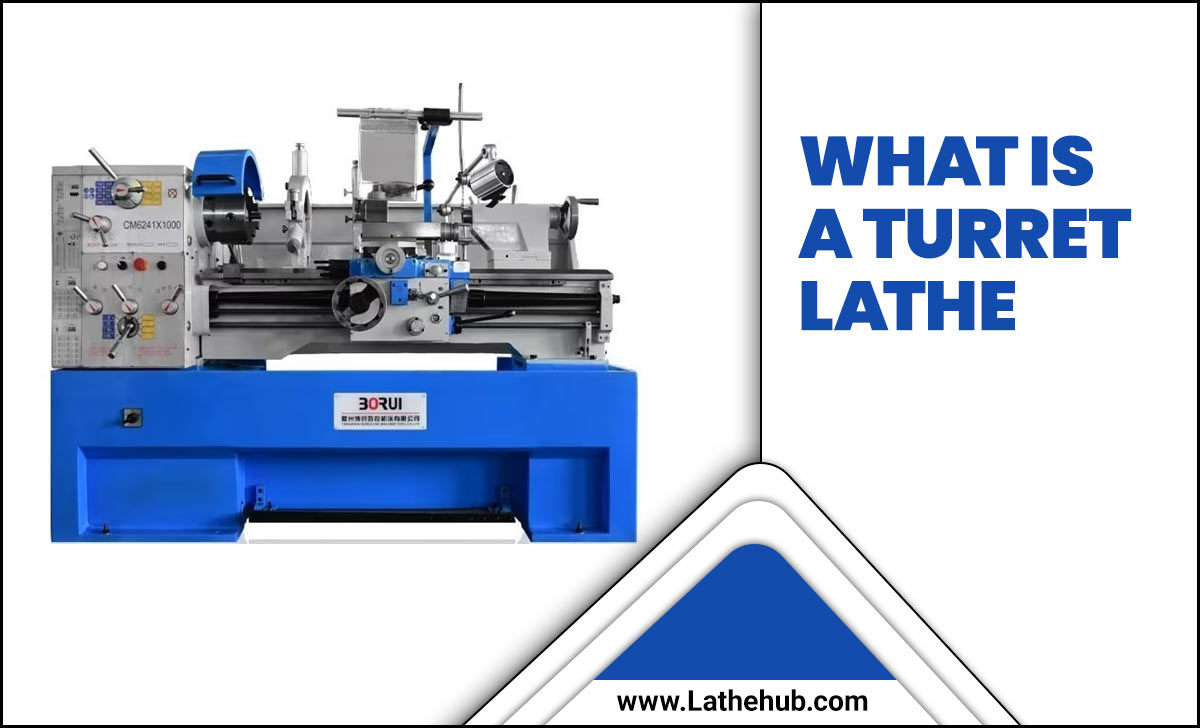

Definition and purpose of compact metal lathes. Key features and benefits for hobbyists and professionals.Compact metal lathes are nifty machines that shape metal into cool objects. They spin a workpiece while cutting tools shave off material, making them great for creating parts and projects. Hobbyists love them because they’re perfect for home workshops. Professionals use them for precision work. Imagine a cookie cutter but for metal! The small size lets them fit in tight spaces while still packing a punch. Plus, they often come with features like threading dials, making them easier to use.

| Key Features | Benefits |

|---|---|

| Compact Size | Accessible for small shops |

| User-Friendly Controls | Simplifies complex tasks |

| Durable Construction | Long-lasting performance |

The Importance of Threading Dials in Metal Lathes

Explanation of threading dials and their functionality. How threading dials improve accuracy and consistency.A threading dial is a clever little tool found on metal lathes. It helps to line everything up perfectly when you’re making threads on metal. Imagine trying to draw a straight line while blindfolded! That’s how tricky threading can be without help. The threading dial improves your accuracy and consistency, turning chaotic metalwork into smooth masterpieces. It’s like having a trusty sidekick that never lets you down.

| Benefits of Threading Dials |

|---|

| Increased Accuracy: Helps ensure your threads are perfectly aligned. |

| Consistency: Provides steady results, every time you use it. |

| Efficiency: Saves time by reducing mistakes and rework. |

In fact, many expert machinists say threading dials can turn a good project into a great one! So, if you’re into metal lathes, make sure to give that threading dial some love.

Choosing the Right Compact Metal Lathe with Threading Dial

Factors to consider when selecting a lathe. Popular models and their specifications.When picking a compact metal lathe with a threading dial, several factors come into play. First, think about the size you need—too big, and you might have a workout! Next, check the specifications that match your projects. Some popular models include the Mini Lathe, which is perfect for small jobs, and the Precision Lathe, built like a rock. Let’s peek at their specs:

| Model | Size | Power |

|---|---|---|

| Mini Lathe | 7×14 | 550W |

| Precision Lathe | 9×20 | 750W |

Lastly, consider the budget; you don’t want to break the bank unless you want your wallet to run away! Finding the right lathe can make your metalworking dreams come true (and maybe even impress your cat).

Setting Up Your Compact Metal Lathe Threading Dial

Stepbystep guide for installation. Common mistakes to avoid during setup.To set up your compact metal lathe threading dial, follow these easy steps:

- Start by placing the dial in the right position on the lathe.

- Tighten the screws carefully to secure the dial.

- Check the alignment to ensure it is straight.

- Test the dial by turning it to see if it moves smoothly.

Avoid these common mistakes:

- Don’t overtighten screws, as this can damage parts.

- Make sure the dial is level before securing it.

- Check for any loose parts before starting.

What are the best practices for maintaining the threading dial?

Regular cleaning and lubrication help keep your threading dial in good condition. Ensuring the parts are free from dust and debris will improve accuracy and longevity.

Setting up your threading dial correctly is key for smooth operation. Remember, taking your time now can prevent headaches later!

Techniques for Effective Threading with a Dial

Detailed threading techniques using a dial. Tips for achieving highquality threads.Threading with a dial can be simple and rewarding. First, set the dial to the desired pitch. For best results, keep the tool steady and maintain a consistent feed rate. It helps to use cutting oil for smoother operation. Always double-check measurements before cutting to avoid mistakes. Regularly clean the lathe to ensure a clear view of the workpiece. Remember, practice makes perfect!

What are the best tips for threading with a dial?

Use a sharp tool, maintain even pressure, and always measure your work.

Quick Tips for Higher Quality Threads

- Choose the right speed for your material.

- Ensure your lathe setup is level.

- Perform test cuts on scrap material.

Maintenance Tips for Compact Metal Lathes and Threading Dials

Regular maintenance procedures. Troubleshooting common issues with threading dials.Keeping your compact metal lathe and threading dial in tip-top shape is essential for smooth operation. Regular maintenance is like taking your machine to a spa day. Make sure to clean and lubricate parts often to avoid rust and wear, which are like uninvited guests at a great party! If your threading dial has issues, don’t panic. Check for misalignment or dirt, as these can cause hiccups in the threading. A little care can save you from big headaches later!

| Maintenance Tip | Common Issue |

|---|---|

| Clean regularly | Misalignment |

| Lubricate moving parts | Debris buildup |

| Inspect for wear | Unresponsive dial |

Innovative Uses of Compact Metal Lathes in Various Industries

Applications in automotive, aerospace, and machining. Examples of projects that benefit from compact lathes.Compact metal lathes are essential in many industries. They make parts for cars, airplanes, and machinery. This helps create strong and safe vehicles. Here are some examples of their use:

- In the automotive industry, they help shape engine parts.

- Aerospace businesses use them for light and strong components.

- Machining shops rely on them for precise tools and parts.

These machines save time and resources. They also allow for creativity in design. This leads to faster production and better products for everyone.

What are the benefits of using compact metal lathes?

Compact metal lathes provide efficiency, precision, and versatility for various projects. They help in producing high-quality parts quickly. Manufacturers can customize their designs with ease.

Future Trends in Compact Metal Lathe Technology

Innovations in threading dial design and functionality. Predictions for the evolution of metal lathe technology.The future of compact metal lathe technology looks bright. New designs promise better performance. One exciting change is the threading dial. Future dials will be more accurate and easier to use. Manufacturers aim to make them Smart, connecting to apps for real-time improvements.

Predictions show that these machines will become more automated. With advanced sensors, lathes will help users avoid mistakes. The goal is to enhance safety and efficiency. Here are some future trends:

- Innovative threading dials for better accuracy.

- Smart technology integration for real-time monitoring.

- Increased automation for easier operation.

What will change in metal lathe technology?

The technology will evolve with advanced sensors and connectivity. This makes machines safer and more efficient. Stronger focus will be on user-friendly designs that help both beginners and experts!

Conclusion

In summary, the compact metal lathe threading dial is essential for precise threading. It helps you measure accurately and create perfect screw threads. When using this tool, remember to adjust it carefully for the best results. We encourage you to practice threading and explore more about lathe techniques. Start your projects with confidence and enjoy crafting with your lathe!FAQs

Here Are Five Related Questions On The Topic Of Compact Metal Lathe Threading Dials:Sure! A compact metal lathe is a machine that helps shape metal. The threading dial on it is important for making threads, which are like spirals on a screw. When you turn the dial, it helps you move the cutting tool smoothly. This way, you can make the threads evenly and correctly. Using the threading dial makes your work more precise and easier!

Sure! Please provide the question you want me to answer.

What Is The Primary Function Of A Threading Dial On A Compact Metal Lathe?The threading dial helps you cut threads on a metal lathe. It shows you when to move the tool to make accurate threads. You can read the numbers on the dial to know when to start each pass. This way, your work turns out neat and tidy!

How Do You Properly Set Up And Use A Threading Dial For Precise Thread Cutting?To set up a threading dial, first, make sure your machine is off. Then, align the dial with the tool bit. Next, turn the dial to the right number based on your material. When you start cutting, watch the dial closely. Turn the handle when the needle on the dial is at the mark. This helps you make perfect threads every time!

What Are The Advantages Of Using A Threading Dial Compared To Other Methods Of Threading On A Lathe?A threading dial helps you make threads on a lathe more easily. It shows where to start cutting, so you get better results. You won’t have to guess or measure each time, making it faster. It also helps keep the threads even and neat. This way, your work looks great and works well when you put it together!

Can Threading Dials Be Used On Both Standard And Metric Threaded Projects, And If So, How?Yes, we can use threading dials for both standard and metric projects. Standard threads use inches, while metric threads use millimeters. You just need to set the dial to match the type you are using. This way, the threads will match correctly and fit well.

What Maintenance Tips Should Be Followed To Ensure The Longevity And Accuracy Of The Threading Dial On A Compact Metal Lathe?To keep the threading dial on your compact metal lathe working well, clean it often. Use a soft cloth to remove dust and grease. Check the dial for any damage, like scratches or bends, and fix them if you find any. Make sure the dial moves smoothly and doesn’t get stuck. Finally, oil the parts that need it to help them work better.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Here Are Five Related Questions On The Topic Of Compact Metal Lathe Threading Dials:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! A compact metal lathe is a machine that helps shape metal. The threading dial on it is important for making threads, which are like spirals on a screw. When you turn the dial, it helps you move the cutting tool smoothly. This way, you can make the threads evenly and correctly. Using the threading dial makes your work more precise and easier!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you want me to answer.”}},{“@type”: “Question”,”name”: “What Is The Primary Function Of A Threading Dial On A Compact Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The threading dial helps you cut threads on a metal lathe. It shows you when to move the tool to make accurate threads. You can read the numbers on the dial to know when to start each pass. This way, your work turns out neat and tidy!”}},{“@type”: “Question”,”name”: “How Do You Properly Set Up And Use A Threading Dial For Precise Thread Cutting?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To set up a threading dial, first, make sure your machine is off. Then, align the dial with the tool bit. Next, turn the dial to the right number based on your material. When you start cutting, watch the dial closely. Turn the handle when the needle on the dial is at the mark. This helps you make perfect threads every time!”}},{“@type”: “Question”,”name”: “What Are The Advantages Of Using A Threading Dial Compared To Other Methods Of Threading On A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A threading dial helps you make threads on a lathe more easily. It shows where to start cutting, so you get better results. You won’t have to guess or measure each time, making it faster. It also helps keep the threads even and neat. This way, your work looks great and works well when you put it together!”}},{“@type”: “Question”,”name”: “Can Threading Dials Be Used On Both Standard And Metric Threaded Projects, And If So, How?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Yes, we can use threading dials for both standard and metric projects. Standard threads use inches, while metric threads use millimeters. You just need to set the dial to match the type you are using. This way, the threads will match correctly and fit well.”}},{“@type”: “Question”,”name”: “What Maintenance Tips Should Be Followed To Ensure The Longevity And Accuracy Of The Threading Dial On A Compact Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep the threading dial on your compact metal lathe working well, clean it often. Use a soft cloth to remove dust and grease. Check the dial for any damage, like scratches or bends, and fix them if you find any. Make sure the dial moves smoothly and doesn’t get stuck. Finally, oil the parts that need it to help them work better.”}}]}