Have you ever watched a metal lathe in action? It’s fascinating to see how these machines work. But not all metal lathes are created equal. The carriage is a key part of the lathe that helps shape metal. How does it make a difference?

Imagine you are crafting a beautiful piece from a block of metal. The way the carriage moves can change everything. It affects the accuracy and smoothness of your project. A smooth carriage makes for a happy project!

In this article, we will dive into the comparison of metal lathe carriages. We’ll look at different types and what makes them unique. By the end, you’ll know which one might be best for your own crafting adventures. Ready to explore the world of metal lathes? Let’s get started!

A Comprehensive Comparison Of Metal Lathe Carriage Models

Comparison Metal Lathe Carriage

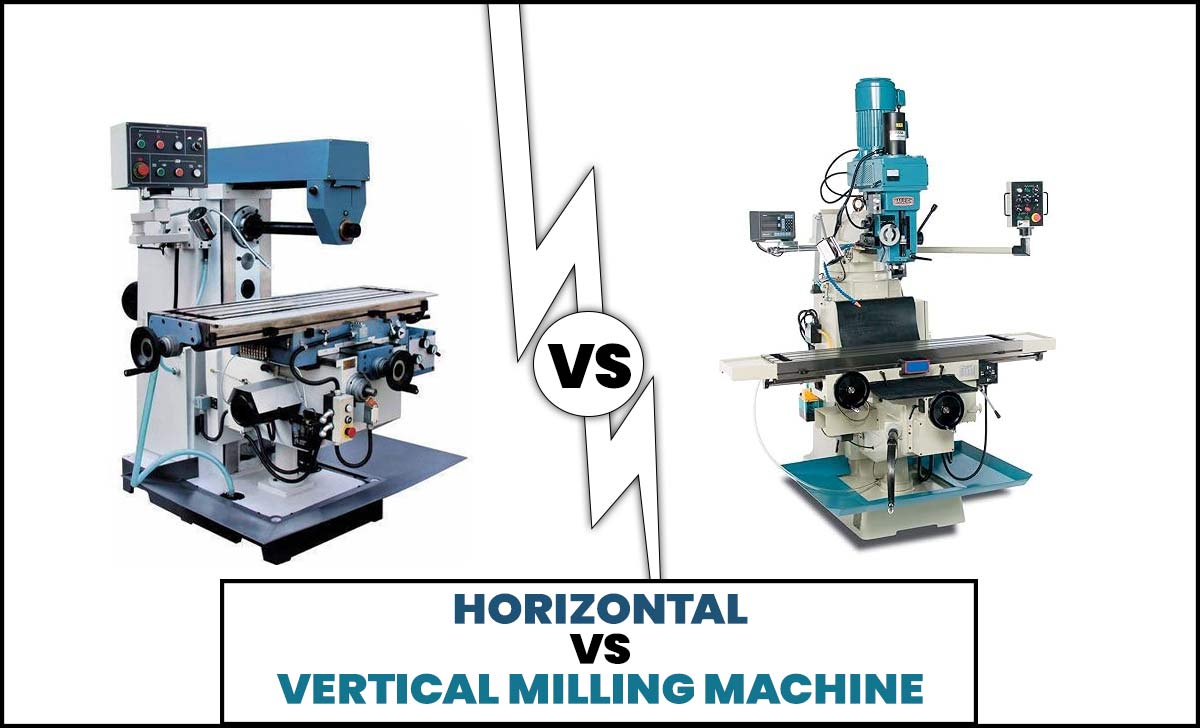

Many people wonder how metal lathe carriages differ. A comparison reveals key features that guide your choice. Carriages allow control over tool movement. Some are more adjustable, while others offer better stability. Did you know a sturdy carriage can affect precision? When choosing, consider size, weight, and materials. Each type suits different projects, from small hobbies to bigger tasks. Understanding these differences can lead you to the perfect lathe for your needs.Understanding Metal Lathe Carriages

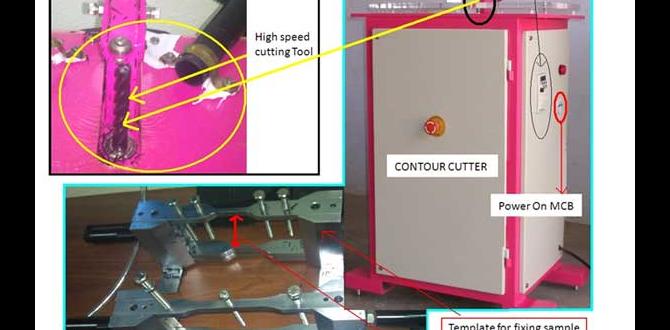

Definition and function of a metal lathe carriage. Types of carriages in metal lathes.A metal lathe carriage is a moving part of the lathe machine. It helps position the cutting tool correctly on the workpiece. This makes it easier to shape metal accurately. There are different types of carriages, which include:

- Flat Carriage: Simple and easy to use.

- Compound Carriage: Offers more flexibility for cutting angles.

- Tailstock Carriage: Supports the metal and adds stability.

Understanding these carriages helps in choosing the right lathe for your needs. Each option has its own special features, so pick one that matches your project!

What is the purpose of a metal lathe carriage?

The purpose of a metal lathe carriage is to hold and move the cutting tool along the metal workpiece. This helps shape the metal as needed. It is essential for precise machining.

Factors to Consider When Comparing Carriage Types

Material construction and durability. Size and compatibility with various lathe models. Weight and ease of movement.Choosing the right carriage type can feel like picking a favorite ice cream flavor—so many options! First, think about material construction & durability. Strong, high-quality materials last longer and resist wear. Next up is size and compatibility. Not all carriages fit every lathe model; make sure yours can give that perfect fit, like Cinderella’s glass slipper!

Weight is another factor. A heavy carriage can be stable but not easy to move. If you want to juggle, consider lighter options. Remember, if it’s too bulky, you might feel like a bodybuilder trying to lift an elephant!

| Factor | Considerations |

|---|---|

| Material | Strong, durable materials last longer |

| Size | Ensure compatibility with your lathe |

| Weight | Choose a balance of stability and ease |

Types of Metal Lathe Carriages

Quickchange carriages and their benefits. Conventional carriages and their applications. CNC lathe carriages and technology integration.Metal lathe carriages come in different styles, each with unique perks. First, there are quickchange carriages, which let you swap tools faster than a magician pulls a rabbit from a hat. They save time and boost efficiency on the job. Then, we have conventional carriages. These old-school heroes work well for many applications, from furniture making to creating shiny, pointy things. Lastly, CNC lathe carriages bring tech into the mix, automating tasks like pro robots. This means accuracy and less sweat for you!

| Type of Carriage | Benefits |

|---|---|

| Quickchange Carriage | Fast tool swapping, increased efficiency |

| Conventional Carriage | Versatile, great for many projects |

| CNC Lathe Carriage | Automated tasks, high precision |

Performance Metrics for Carriage Evaluation

Precision and accuracy in machining tasks. Speed and efficiency during operations. Maintenance and ease of use.Evaluating a lathe carriage involves looking at important performance metrics. First, precision and accuracy are vital for making exact parts. Then, speed and efficiency ensure tasks get done quickly. Lastly, maintenance and ease of use affect daily operations. A smooth experience helps users stay focused on their work.

What factors impact lathe carriage performance?

Key factors include precision, speed, and ease of operation. Precision avoids mistakes. Speed helps finish jobs faster. Ease makes machines user-friendly.

- Precision: Accurate cuts save time and materials.

- Speed: Fast operations boost productivity.

- Maintenance: Simple upkeep keeps the machine running longer.

Cost Analysis of Different Carriage Options

Price ranges for various types of carriages. Costbenefit analysis for hobbyists vs. professionals.Thinking about which carriage to choose can be quite a ride! Prices can sway like a pendulum, often ranging from $200 to $2,000. For hobbyists, a budget option can work perfectly. But professionals might need that shiny, expensive one! A simple cost-benefit analysis shows that spending more can lead to better features and durability. Remember, you want a carriage that won’t leave you high and dry, especially in the middle of a project!

| Carriage Type | Price Range | Best For |

|---|---|---|

| Basic Carriage | $200 – $600 | Hobbyists |

| Mid-Range Carriage | $600 – $1,200 | Serious Hobbyists |

| Professional Carriage | $1,200 – $2,000+ | Professionals |

User Experiences and Reviews

Summary of user feedback on different carriages. Case studies or testimonials from metalworking professionals.User feedback about different metal lathe carriages is quite telling. Many users enjoy how smoothly their machines operate with the right carriage. Professionals share stories of their challenges and successes. Here are some key points:

- Ease of Use: Many users found certain carriages simple to handle.

- Durability: Pros reported longer life with strong materials.

- Precision: Accurate cuts were a common praise point.

These insights show how important choosing the right carriage is for success in metalworking.

What do professionals say about metal lathe carriages?

Professionals often highlight the importance of precision and durability when selecting carriages. They value features that enhance performance and reduce downtime.

Future Trends in Metal Lathe Carriage Technology

Innovations in design and functionality. The role of automation and smart technology in carriage development.Exciting changes are coming for metal lathe carriages! Designers are embracing new shapes and materials, making machines more user-friendly and efficient. Automated features are popping up, like fancy sensors that help track the cutting process. Imagine your lathe giving you that “I’ve got this!” vibe. Smart technology is not just a buzzword; it’s becoming part of everyday tools, improving precision and speed. The future looks bright and a little bit quirky!

| Innovation | Description |

|---|---|

| Design | New shapes and materials for better usability |

| Automation | Smart sensors for precise tracking |

| Functionality | Enhanced features for improved speed |

Keep an eye out for these trends! They promise to make lathe work more fun and efficient than ever.

Conclusion

In summary, comparing metal lathe carriages helps you choose the right one for your project. Look for features like size, durability, and ease of use. Knowing these factors will improve your work and save time. Explore different models online or at local shops to see what fits your needs best. Keep learning and happy crafting!FAQs

Sure! Here Are Five Questions Related To The Comparison Of Metal Lathe Carriages:Sure! Here are some questions about metal lathe carriages. Why do carriages help move metal pieces? What is the main job of a carriage? How do different carriages change the way we use a lathe? What are some tools attached to the carriage? How can we keep a carriage clean and working well? Let me know if you need answers!

Sure! Please provide me with the question you’d like me to answer.

What Are The Key Differences Between A Flat Bed Lathe Carriage And A V-Bed Lathe Carriage In Terms Of Stability And Precision?A flat bed lathe has a flat surface, while a V-bed lathe has a V-shaped groove. The V-shape helps keep things steady. This makes the V-bed lathe more precise when carving shapes. The flat bed is good too, but it isn’t as stable. So, if you want extra accuracy, the V-bed is a better choice!

How Does The Design Of The Carriage Influence The Ease Of Operation And Control While Machining On A Metal Lathe?The carriage is a part of the metal lathe that holds the tools. A good design makes it easier for you to move the tools around. If it’s steady and smooth, you can control it better. This helps you create better shapes and cuts in the metal. So, a well-designed carriage makes machining simpler and faster!

What Materials Are Commonly Used In The Construction Of Metal Lathe Carriages, And How Do They Affect Durability And Weight?Metal lathe carriages are often made from steel or cast iron. Steel is strong and light, which helps with moving the lathe. Cast iron is heavier and very sturdy, making it durable. These materials help the lathe last a long time while balancing weight for easy use.

In What Ways Do Cnc Lathes Differ In Carriage Design Compared To Traditional Manual Lathes, Particularly Regarding Automation And Functionality?CNC lathes, or Computer Numerical Control lathes, have special carriages that move automatically. You don’t have to push or pull them like on manual lathes. This makes CNC lathes faster and more precise. The computer tells the machine where to go, so it helps create parts better. In manual lathes, we have to control the carriage ourselves, which takes more time.

How Do Different Carriage Designs Impact The Overall Performance And Capabilities Of A Metal Lathe, Especially For Various Machining Tasks?Different carriage designs on a metal lathe help you do different jobs better. A strong carriage keeps the cutting tool steady, which makes smoother cuts. Some designs let you move the tool up and down easily, helping with different shapes. When you change tasks, the right carriage can make your work faster and more precise. Overall, the design helps you create better parts.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Questions Related To The Comparison Of Metal Lathe Carriages:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are some questions about metal lathe carriages. Why do carriages help move metal pieces? What is the main job of a carriage? How do different carriages change the way we use a lathe? What are some tools attached to the carriage? How can we keep a carriage clean and working well? Let me know if you need answers!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide me with the question you’d like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Key Differences Between A Flat Bed Lathe Carriage And A V-Bed Lathe Carriage In Terms Of Stability And Precision?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A flat bed lathe has a flat surface, while a V-bed lathe has a V-shaped groove. The V-shape helps keep things steady. This makes the V-bed lathe more precise when carving shapes. The flat bed is good too, but it isn’t as stable. So, if you want extra accuracy, the V-bed is a better choice!”}},{“@type”: “Question”,”name”: “How Does The Design Of The Carriage Influence The Ease Of Operation And Control While Machining On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The carriage is a part of the metal lathe that holds the tools. A good design makes it easier for you to move the tools around. If it’s steady and smooth, you can control it better. This helps you create better shapes and cuts in the metal. So, a well-designed carriage makes machining simpler and faster!”}},{“@type”: “Question”,”name”: “What Materials Are Commonly Used In The Construction Of Metal Lathe Carriages, And How Do They Affect Durability And Weight?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Metal lathe carriages are often made from steel or cast iron. Steel is strong and light, which helps with moving the lathe. Cast iron is heavier and very sturdy, making it durable. These materials help the lathe last a long time while balancing weight for easy use.”}},{“@type”: “Question”,”name”: “In What Ways Do Cnc Lathes Differ In Carriage Design Compared To Traditional Manual Lathes, Particularly Regarding Automation And Functionality?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “CNC lathes, or Computer Numerical Control lathes, have special carriages that move automatically. You don’t have to push or pull them like on manual lathes. This makes CNC lathes faster and more precise. The computer tells the machine where to go, so it helps create parts better. In manual lathes, we have to control the carriage ourselves, which takes more time.”}},{“@type”: “Question”,”name”: “How Do Different Carriage Designs Impact The Overall Performance And Capabilities Of A Metal Lathe, Especially For Various Machining Tasks?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Different carriage designs on a metal lathe help you do different jobs better. A strong carriage keeps the cutting tool steady, which makes smoother cuts. Some designs let you move the tool up and down easily, helping with different shapes. When you change tasks, the right carriage can make your work faster and more precise. Overall, the design helps you create better parts.”}}]}