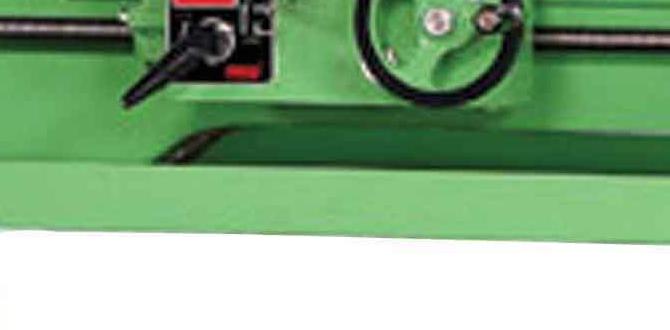

Have you ever wondered how metal workers create such precise shapes? A big part of that secret lies in the **metal lathe compound rest**. This tool might seem small, but it plays a crucial role in turning raw metal into beautiful finished pieces.

Imagine watching a craftsman expertly spin a piece of metal. The compound rest allows them to make exact cuts and adjustments. It gives them the power to shape metal with great accuracy. But not all compound rests are the same.

Some are designed for beginners, while others are built for pros. Have you ever thought about which one would suit your needs best? Comparing different types of metal lathe compound rests can help you find the right fit for your projects.

In this article, we will break down the differences between various compound rests. You’ll learn what to look for and why it matters. Let’s dive into the world of metal lathes and discover how a simple change can make a big difference!

A Comprehensive Comparison Of Metal Lathe Compound Rest Options

Comparison of Metal Lathe Compound Rest

When choosing a metal lathe compound rest, several factors come into play. These include stability, versatility, and ease of adjustment. A solid compound rest helps make smooth, precise cuts. Did you know that some designs offer extra features like quick-release? This can save time and improve safety. By comparing models, you can find the one that suits your needs best. Explore different options and enhance your metalworking skills!What is a Metal Lathe Compound Rest?

Definition and purpose of a compound rest in metal lathes. Importance of compound rests for precision and efficiency.A compound rest is a key part of a metal lathe that allows for precise movements and cuts. It supports the cutting tool at various angles, making it easier to create complex shapes. Think of it as the tool’s personal mini assistant. Without a compound rest, shaping metal would feel like trying to thread a needle in the dark. It boosts efficiency and accuracy, which every metalworker can appreciate. Just imagine crafting a perfect cylinder with less fuss!

| Feature | Benefit |

|---|---|

| Multi-Angle Adjustability | Allows for various cutting angles |

| Increased Precision | Enhances detail in projects |

| Time Saver | Reduces trial-and-error cutting |

This handy attachment can turn you from a regular worker into a metal wizard! So, if you want to impress your friends or just create amazing projects, a compound rest is the way to go.

Key Features to Consider

Size and adjustability for different lathe models. Accuracy and precision capabilities.Choosing a metal lathe compound rest? Look for these key details.

- Size and Adjustability: Ensure it fits different lathe models. A good fit means better work.

- Accuracy and Precision: Check if it provides exact measurements. High precision helps you create quality pieces.

Consider these points to find the best compound rest. The right choice improves your lathe skills and project results.

What makes a compound rest accurate?

Accuracy often comes from quality materials and strong construction. A well-made compound rest can track precise movements smoothly.

Why adjustability matters?

Adjustable features let you work with various projects easily. You can modify the settings to meet your needs, helping you produce better results.

Benefits of Upgrading Your Compound Rest

Enhanced stability and control during machining. Improved surface finish and dimensional accuracy.Upgrading your compound rest can feel like giving your lathe a superhero cape! This improvement means better stability and control while machining. You won’t feel like wrestling a wild octopus anymore! Plus, a new compound rest can make your work look super neat, leading to a smooth surface finish and true dimensional accuracy. Who wouldn’t want their projects to be cleaner than a cat’s paw? Consider this as your small step to turning ordinary pieces into masterpiece creations!

| Benefit | Description |

|---|---|

| Stability | More control during machining means fewer mistakes. |

| Surface Finish | Achieve a smooth, pro-like look on your work. |

| Dimensional Accuracy | Get the sizes right every time, like magic! |

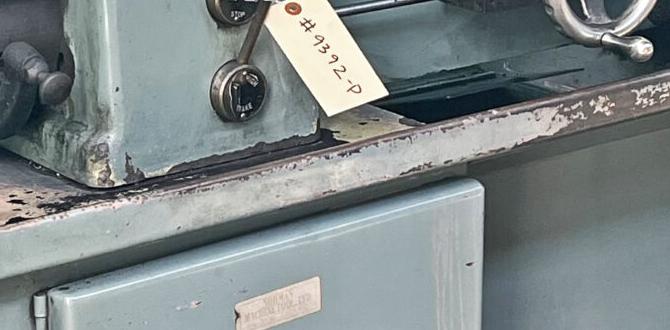

Comparison of Popular Brands

Review of leading manufacturers in the market. Performance analysis based on user feedback and expert reviews.Many brands offer metal lathes with great features. Users often talk about their experiences and share feedback. Some popular brands include:

- Grizzly: Known for quality and affordability.

- Jet: Praised for durable design and precision.

- Shop Fox: Offers versatile options for hobbyists and professionals.

Experts agree on performance based on hands-on reviews. Grizzly leads in value, while Jet offers robust build quality. Shop Fox stands out in versatility. User reviews trust these brands for reliable results.

What should I consider when choosing a metal lathe?

Look carefully at the size, price, and features. Be sure it fits your needs and workspace.

Installation and Maintenance Tips

Stepbystep guide for proper installation. Maintenance practices to prolong lifespan and efficiency.Installing and maintaining your metal lathe compound rest is easy with the right steps. First, ensure a clean workspace. Follow these steps for installation:

- Check parts for damage.

- Align the compound rest on the lathe.

- Secure screws tightly.

- Test movements before use.

For maintenance, keep the lathe clean. Lubricate moving parts regularly. Routine checks can prevent wear and tear. A well-maintained lathe can last years!

How can I extend the life of my metal lathe compound rest?

Regular cleaning and lubrication are key. Inspect parts frequently to catch issues early. Store in a dry place to avoid rust.

Common Issues and Troubleshooting

Identifying and resolving common problems with compound rests. Tips for preventing future issues.Common problems with the compound rest can slow down your work. The good news is that many of these issues are easy to fix. Check for looseness or wear in parts. Regular cleaning helps too. Also, keep everything lubricated. Here are some tips:

- Beware of rust on surfaces.

- Tighten screws regularly.

- Use proper tools to adjust settings.

By following these steps, you can keep your compound rest running smoothly.

What are some common problems with a compound rest?

Common problems include poor alignment, loose parts, and rust. Fixing these issues quickly helps maintain your metal lathe’s performance. Regular maintenance is key!

Cost Considerations and Value for Money

Price ranges for different types of compound rests. Evaluating the cost versus benefits of highend vs. budget options.When choosing a compound rest for your metal lathe, price matters, but so does value! Budget options can range from $100 to $300, while high-end ones might hit $500 or more. Just like picking a candy from a jar, you want to balance sweetness and cost. Here’s a quick look:

| Type | Price Range | Benefits |

|---|---|---|

| Budget | $100 – $300 | Good for beginners, gets the job done |

| High-end | $500+ | Durable, more features, smoother operation |

Think of it like a pizza: a cheaper slice may fill you up, but a gourmet pie offers toppings that dance on your taste buds! So, evaluate what you need to avoid “buyer’s regret.” Always consider how long you’ll stick with it—don’t pay gourmet prices if you’re just tasting!

Real User Experiences and Testimonials

Compilation of user reviews and experiences. Case studies highlighting the impact of compound rest upgrades on projects.User experiences offer valuable insights about metal lathes. Many users praise the compound rest upgrades for enhancing precision and ease of use. Here are some highlights:

- Increased Accuracy: Users reported better results in their projects.

- Time-Saving: With improved features, tasks took less time.

- User-Friendly: Many found the upgrade easy to install and operate.

Case studies show a clear impact. For example, one user transformed their woodworking project with a new compound rest. This helped them achieve flawless cuts and angles. Overall, the feedback shows that upgrading the compound rest leads to significant improvements in metal lathe projects.

How do upgrades impact metal lathe projects?

Upgrades significantly boost quality and speed. Users often finish projects faster and with greater precision.

Conclusion

In summary, comparing metal lathe compound rests helps you choose the best one for your projects. Look for features like accuracy and durability. Remember, a good compound rest makes cutting easier and more precise. If you want to dive deeper, explore reviews and guides to find the right tool for you. Happy turning!FAQs

What Are The Main Differences Between A Fixed Compound Rest And A Swivel Compound Rest On A Metal Lathe?A fixed compound rest allows you to move your tool in one direction. It stays in one position while you work. A swivel compound rest can rotate, letting you change the angle of your tool. This helps you make different shapes or cuts. So, the main difference is that one stays still, and the other can turn.

How Does The Design Of The Compound Rest Impact The Accuracy And Precision Of Machining Operations?The compound rest helps you move the tool in different directions easily. A good design lets you make tiny adjustments. This means you can cut more precisely. When you can control your cuts better, your finished work looks nicer and fits well. Overall, a well-designed compound rest makes your machining more accurate.

What Materials Are Commonly Used In The Construction Of Compound Rests, And How Do They Affect The Performance Of A Metal Lathe?Compound rests on metal lathes are usually made of cast iron, steel, or aluminum. Cast iron is strong and helps reduce vibrations. Steel is tough and keeps everything steady. Aluminum is light, making it easier to adjust. The material affects how well the lathe cuts and holds its position.

How Can The Adjustments And Settings Of The Compound Rest Influence The Quality Of Surface Finishes On Machined Parts?Adjusting the compound rest on a machine helps you control the tool better. When the angle is just right, the tool cuts smoothly. This makes the surface of the part feel nice and shiny. If the settings are off, the finish can be rough or uneven. So, careful adjustments lead to better-looking parts!

What Are The Advantages And Disadvantages Of Using An Aftermarket Compound Rest Compared To The Original Equipment Manufacturer’S (Oem) Component?Using an aftermarket compound rest can be great because it often has better features and is usually cheaper. You might find it easier to set up and adjust. However, it might not fit your equipment perfectly like the original part does. Sometimes, the quality can be lower, which may cause problems. So, you need to weigh these factors before deciding!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Main Differences Between A Fixed Compound Rest And A Swivel Compound Rest On A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A fixed compound rest allows you to move your tool in one direction. It stays in one position while you work. A swivel compound rest can rotate, letting you change the angle of your tool. This helps you make different shapes or cuts. So, the main difference is that one stays still, and the other can turn.”}},{“@type”: “Question”,”name”: “How Does The Design Of The Compound Rest Impact The Accuracy And Precision Of Machining Operations? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The compound rest helps you move the tool in different directions easily. A good design lets you make tiny adjustments. This means you can cut more precisely. When you can control your cuts better, your finished work looks nicer and fits well. Overall, a well-designed compound rest makes your machining more accurate.”}},{“@type”: “Question”,”name”: “What Materials Are Commonly Used In The Construction Of Compound Rests, And How Do They Affect The Performance Of A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Compound rests on metal lathes are usually made of cast iron, steel, or aluminum. Cast iron is strong and helps reduce vibrations. Steel is tough and keeps everything steady. Aluminum is light, making it easier to adjust. The material affects how well the lathe cuts and holds its position.”}},{“@type”: “Question”,”name”: “How Can The Adjustments And Settings Of The Compound Rest Influence The Quality Of Surface Finishes On Machined Parts? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Adjusting the compound rest on a machine helps you control the tool better. When the angle is just right, the tool cuts smoothly. This makes the surface of the part feel nice and shiny. If the settings are off, the finish can be rough or uneven. So, careful adjustments lead to better-looking parts!”}},{“@type”: “Question”,”name”: “What Are The Advantages And Disadvantages Of Using An Aftermarket Compound Rest Compared To The Original Equipment Manufacturer’S (Oem) Component? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Using an aftermarket compound rest can be great because it often has better features and is usually cheaper. You might find it easier to set up and adjust. However, it might not fit your equipment perfectly like the original part does. Sometimes, the quality can be lower, which may cause problems. So, you need to weigh these factors before deciding!”}}]}