Did you know that a metal lathe can do more than just cut metals? It’s true! The heart of this machine is its control panel. This panel helps the lathe operate smoothly and efficiently. But what makes one control panel better than another? That’s the big question!

Imagine you are working on a cool project. You want to create something special but find it tricky to control the lathe. Having a great control panel can make all the difference. It can help you adjust speed and settings with just a few buttons.

In this article, we will take a closer look at different types of metal lathe control panels. We’ll compare their features and see which ones offer the best user experience. By the end, you’ll understand what to look for when choosing a control panel for your lathe. Get ready to discover more about these amazing tools!

Comparison Of Metal Lathe Control Panel Features And Benefits

Comparison of Metal Lathe Control Panels

Understanding metal lathe control panels can make a big difference in your projects. These panels vary in design and functionality. Some have simple knobs, while others feature advanced digital displays. Do you need precision? A panel with more controls might be best. Fun fact: a well-set panel can help you create smoother finishes. By comparing different types, you can pick one that suits your needs, making your metalworking experience easier and more enjoyable.Types of Metal Lathe Control Panels

Manual vs. Digital Control Panels. CNC Control Systems: Benefits and Drawbacks.There are two main types of metal lathe control panels: manual and digital. Manual panels require hands-on tuning. They are simple and easy to use. However, they depend on the operator’s skill. Digital panels offer features like accuracy and speed. They allow you to save settings for later use.

CNC control systems also exist. They automate the process, which saves time. Yet, they can be costly and need training. Here are some benefits and drawbacks:

- Benefits: Increases productivity

- Drawbacks: High upfront costs

Choosing the right panel is key for good results.

What is the difference between manual and digital control panels?

Manual panels need hands-on work, while digital panels offer automated features for precision. They cater to different needs and skills.

Key Features to Consider

User Interface Design and Accessibility. Programmability and Customization Options.Choosing the right metal lathe control panel is important. The user interface should be simple. This makes it easier for everyone, even beginners, to use. Look for large buttons and clear displays. Functionality matters too. Can you program it easily?

- Programmability: Check how easy it is to set custom programs.

- Customization: See if you can adjust settings to fit your needs.

A well-designed control panel enhances your experience. You’ll feel more confident using it. Plus, it can save you time while working. Think about these features before making your choice!

What is a user-friendly feature in control panels?

A user-friendly feature is a clear layout with big buttons and easy-to-read displays. It helps users understand various functions quickly and reduces mistakes.

Key Programmability Features:

- Easy programming steps

- Customizable settings

Performance Metrics

Accuracy and Precision in Operations. Processing Speed and Efficiency.Performance metrics are important for any machine. Metal lathes must be accurate and precise. Accuracy means the lathe makes the right cuts. Precision means it cuts exactly the same way every time. Speed matters too. A fast lathe gets the job done quicker. Efficiency means doing work with less waste. Together, these factors make a lathe great.

- Accuracy: Ensures correct measurements.

- Precision: Repeats cuts without mistakes.

- Speed: Completes tasks faster.

- Efficiency: Uses resources wisely.

What are the key performance metrics for a metal lathe?

Key metrics include accuracy, precision, processing speed, and efficiency. These help measure how well the lathe performs its tasks.

Compatibility with Metal Lathes

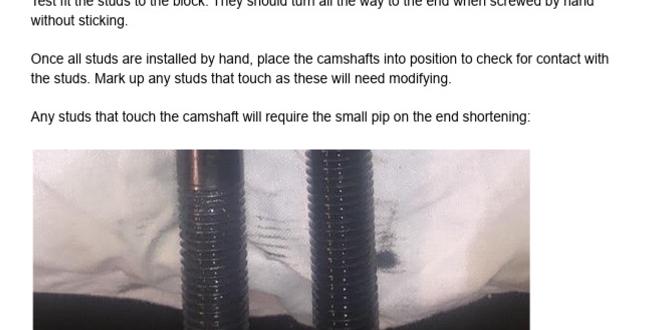

Integration with Various Lathe Models. Adapting Older Lathes for Modern Control Panels.Many lathe models are available, and not all control panels fit every machine. Modern panels work well with new lathes. However, older lathes need special adjustments for compatibility. Here’s what to keep in mind:

- Check Model Compatibility: Not every panel fits every lathe.

- Upgrade Easiness: Look for panels designed to fit older machines.

- Wiring Needs: Older lathes may require rewiring for new panels.

Can I use a modern control panel on an old lathe?

Yes, but you need to ensure it’s compatible and safe. Some old lathes require extra work to connect new panels correctly.

Durability and Maintenance

Material Quality and Construction. Maintenance Requirements and Lifespan.The materials used in the control panel are like the superhero cape of a metal lathe. Good quality materials ensure it can handle your wildest DIY dreams without falling apart. A well-built panel can last for years if treated right. Regular maintenance is key; think of it as giving your lathe a spa day. It’s not just about looking good but also about keeping everything running smoothly.

| Maintenance Task | Frequency |

|---|---|

| Inspect wiring | Monthly |

| Clean the panel | Weekly |

| Check for wear | Yearly |

Taking care of your metal lathe not only makes it last longer but also helps it work like a charm. Remember, every time you ignore maintenance, a tool fairy cries!

User Reviews and Feedback

Insights from Professional Machinists. Common Issues and Praise Across Different Models.Many professional machinists share their experiences with different metal lathe control panels. These insights can help buyers make better choices. Users often praise features that make setup easy and improve precision. However, some point out issues with complicated controls. Here are key takeaways:

- Praise for ease of use

- Complaints about unclear instructions

- Favorite features include digital displays

- Problems with occasional software glitches

What do users say about metal lathe control panels?

Users mention that clear displays and responsive controls are very helpful. Often, they appreciate features like programmable settings. However, some struggle when the manuals are hard to follow. Overall, reviews help others understand what to look for in quality tools.

Future Trends in Metal Lathe Control Technology

Innovations Affecting Control Panel Design. The Role of Automation and AI in Metal Lathing.Exciting changes are coming to metal lathe control panels! New designs focus on making them easier to use. Innovations like touchscreen displays let users see everything clearly. Automation and AI play a big role, too. They help machines work smarter and faster. This means less time fixing mistakes!

- Smart Sensors: Track performance in real-time.

- AI Assistance: Suggest optimal settings.

- Remote Control: Operate machines from anywhere.

How does automation improve metal lathes?

Automation makes metal lathes more accurate and efficient. With smart programming, machines can perform tasks with less human effort. This leads to higher quality products and fewer errors, making work easier for everyone.

Conclusion

In conclusion, comparing metal lathe control panels helps you choose the right one for your needs. Look for features like ease of use and control options. Understanding these differences can boost your skills in metalworking. We encourage you to explore various models online and read reviews. This way, you can make an informed choice and enhance your projects!FAQs

What Are The Key Differences Between Manual And Cnc Control Panels For Metal Lathes?Manual control panels let you move the metal lathe by hand. You twist knobs and push levers to shape the metal. CNC stands for Computer Numerical Control. With CNC, you use a computer to tell the lathe what to do. This makes it easier to make very precise shapes, and you can run it automatically.

How Do User Interfaces On Modern Metal Lathe Control Panels Enhance Operational Efficiency?Modern metal lathes have control panels with user-friendly screens. You can easily see all the settings at once. This lets you adjust machines quickly and correctly. With simple buttons, you save time when making changes. It helps us work smoothly and get more done!

What Safety Features Are Commonly Found On Metal Lathe Control Panels, And How Do They Compare Across Different Models?Metal lathe control panels usually have safety features like emergency stop buttons, protective covers, and clear warning lights. These help keep you safe while working. Different models may have more or fewer features, but most include these basics. Some may even have safety locks to stop the machine when you open a guard. Always check the safety features before you use the lathe!

How Does The Ease Of Programming On Various Metal Lathe Control Panels Influence User Preference?The ease of programming on metal lathe control panels makes it easier for you to use the machine. If the buttons and screens are simple, you can learn quickly. This means you can make what you want faster and with less help. So, people prefer machines that are easy to understand and use. It feels good to press a few buttons and get great results!

What Advancements In Technology Have Impacted The Design And Functionality Of Metal Lathe Control Panels In Recent Years?In recent years, control panels for metal lathes have become easier to use. They now have touch screens instead of buttons, which makes them more fun to operate. We also use smart technology that lets you connect to Wi-Fi. This means you can get updates and troubleshoot problems right from your phone. Overall, these changes help us work faster and more accurately.