Have you ever thought about how a simple metal lathe can change your projects? Many hobbyists and professionals start with basic tools, but as they get better, they often look for ways to improve their equipment. That’s where a comparison metal lathe upgrade comes in.

Imagine this: You’re working on a cool project. Your lathe isn’t cutting the way you want. Maybe it’s too slow or doesn’t have enough power. You feel stuck. This is when you start wondering if an upgrade might help. Would it make your work easier? Could it save you time?

Here’s a fun fact: A better lathe can make a huge difference in your creations. It could allow you to try new techniques or work with tougher materials. Upgrading isn’t just about having the newest tool—it’s about unlocking new possibilities.

Let’s dive into how upgrading your metal lathe can boost your projects. We’ll explore the benefits and what to consider when making a decision. Whether you’re just starting out or have been crafting for years, this journey can inspire you to reach new heights.

Comparison Metal Lathe Upgrade: Choosing The Right Equipment

Comparison Metal Lathe Upgrade

When considering a metal lathe upgrade, it’s essential to understand the differences among models. Each lathe offers unique features that can enhance your projects. For instance, larger lathes can handle bigger materials but may require more space. If you often work on intricate designs, a lathe with advanced tooling features could save you time and effort. Upgrading can improve precision, resulting in better finished products. Have you thought about how an upgrade might boost your skills?Understanding Metal Lathes

Definition and purpose of metal lathes. Types of metal lathes for different applications.A metal lathe is a machine tool used to shape metal. It spins the metal while cutting tools shape it into various forms. This tool is important in manufacturing and crafting. Different types of metal lathes serve unique purposes, such as:

- Bench Lathes: Small, perfect for home workshops.

- Engine Lathes: Heavy-duty, used for industrial work.

- CNC Lathes: Computer-controlled for precise designs.

- Turret Lathes: Best for mass production with quick changes.

Each lathe type fits specific projects, enhancing creativity in metalworking.

What is a metal lathe used for?

A metal lathe is used to create parts by shaping metal into desired designs. It helps in making everything from simple tools to complex machine parts.

Signs That You Need an Upgrade

Performance issues with your current lathe. Limitations in precision and capabilities.If your lathe isn’t working well, it may be time for an upgrade. Are you frustrated by poor performance? This can slow down your projects. Check these signs:

- Inconsistent results: Your parts aren’t coming out as planned.

- Unusual noises: Loud sounds can signal a major problem.

- Difficulty in precision: Tiny details are hard to achieve.

- Limited features: You can’t do what you need to do.

These issues can hold you back. Upgrading to a better lathe can enhance your productivity and creativity.

How do I know if my lathe is underperforming?

Look for increased error rates and reduced efficiency. If you’re spending more time fixing mistakes, it’s time to consider an upgrade.

Key Features to Consider in Upgrading

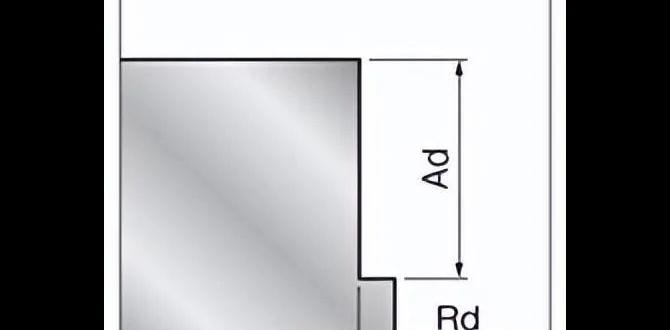

Motor power and speed variations. Bed length and swing over bed.Upgrading your lathe? Keep an eye on motor power and speed variations. A sturdy motor means quicker jobs and smoother cuts. Imagine your old lathe struggling like a tortoise; with a new one, it could be a cheetah! Next, consider the bed length and swing over bed. Longer beds offer more space for larger projects. Think of it as having more room for your favorite toys—everyone loves more space!

| Feature | Importance |

|---|---|

| Motor Power | Faster and smoother operations |

| Speed Variations | Versatility for different materials |

| Bed Length | More space for bigger projects |

| Swing Over Bed | Capability for larger workpieces |

Popular Upgrades for Metal Lathes

Digital readouts and CNC capabilities. Improved tooling and accessories.Upgrading a metal lathe can feel like adding rocket boosters to a bicycle! One popular upgrade is a digital readout system. This tool helps you see exactly where the cutting tool is. It makes measurements easier and can save you from accidentally cutting your workpiece into a weird shape.

Another upgrade is CNC (Computer Numerical Control) capabilities. This change allows you to program your lathe like a robot chef following a recipe. It means more precision and less room for human error—great for busy people!

Improved tooling and accessories can also enhance your lathe experience. Better tools mean smoother cuts and faster work. Plus, who doesn’t want their lathe to feel like it’s sporting a shiny new accessory?

| Upgrade Type | Benefits |

|---|---|

| Digital Readouts | Easy measurements, reduces mistakes. |

| CNC Capabilities | Precision work, more efficiency. |

| Improved Tooling | Smoother cuts, faster production. |

Budgeting for Your Upgrade

Cost factors to consider. Ways to maximize your investment.Upgrading your metal lathe can be exciting but requires careful thought about money. You should consider the following cost factors:

- Price of the new lathe

- Additional tools needed

- Installation costs

- Maintenance and repairs

To make the most of your investment:

- Research brands for quality

- Look for sales or discounts

- Consider used equipment

Smart budgeting can help you get the best lathe without breaking the bank.

What are the main cost factors to consider when upgrading a metal lathe?

Key cost factors include the price of the new lathe, any needed tools, installation fees, and maintenance costs.

User Reviews and Testimonials

Gathering insights from experienced users. Identifying strengths and weaknesses from realworld use.User reviews are a valuable way to learn about metal lathe upgrades. Experienced users share their honest thoughts. They highlight both strengths and weaknesses that can help others make decisions.

- Strengths: Many users praise the speed and precision of upgraded lathes.

- Weaknesses: Some mention a learning curve with new features.

Real-world experiences show how these upgrades can improve projects. Users note they can create better designs faster. These insights help others understand what to expect.

What do users say about metal lathe upgrades?

Users often mention ease of use and reliability. They appreciate how these upgrades boost their work quality.

Installation and Setup of Upgraded Lathes

Stepbystep installation process. Tips for maximizing performance postupgrade.Getting that shiny metal lathe set up is easier than making pancakes! First, unbox your lathe and check all parts. Next, follow the manual to connect each piece correctly. Remember, if something wiggles, it’s likely not snug enough! Once assembled, level the lathe using shims. A steady lathe makes for smoother cuts. After setup, try adjusting speeds for better performance—slow and steady wins the race! Lastly, consider a friendly cleaning routine to keep it happy and shiny. Just like your pet goldfish, it needs some TLC!

| Step | Action |

|---|---|

| 1 | Unbox and inspect parts |

| 2 | Follow the manual for assembly |

| 3 | Level the lathe with shims |

| 4 | Adjust speeds for better cutting |

| 5 | Establish a cleaning routine |

Maintaining Your Upgraded Metal Lathe

Best practices for maintenance. Troubleshooting common issues after upgrading.To keep your upgraded metal lathe purring like a happy kitten, you need some good maintenance habits. First, always clean it after use; even metal shavings can throw a wrench in things—literally! It’s like trying to eat your favorite meal with a fork full of spaghetti stuck in your teeth. You should also check the oil level regularly and lubricate it to keep everything moving smoothly.

If you run into pesky problems, don’t panic! Common issues often stem from misalignment or dull tools. Want to troubleshoot? Start by checking your settings. If the lathe starts acting like a grumpy cat, try tightening loose screws or replacing worn-out parts. Following these tips will ensure your upgrade runs like a charm and avoids turning into a big, metal headache!

| Task | Frequency |

|---|---|

| Clean machine | After each use |

| Check oil level | Weekly |

| Lubricate parts | Every month |

| Inspect tools | Before each job |

Conclusion

Upgrading your metal lathe can enhance your projects significantly. Look for improved precision, better speed, and advanced features. You’ll finish tasks faster and with greater quality. Consider your specific needs and budget when choosing upgrades. Research options and read reviews to make informed decisions. With the right upgrade, you’ll enjoy exciting new possibilities in your metalworking adventures!FAQs

Sure! Here Are Five Related Questions On The Topic Of Comparing Metal Lathe Upgrades:Sure! When you think about metal lathe upgrades, ask these questions: What makes one upgrade better than another? Does it help you work faster? Is it easy to use? How much does it cost? Will it last a long time? These questions will help you decide which upgrade is best for you!

Sure! Please provide the question you’d like me to answer.

What Are The Key Factors To Consider When Upgrading A Metal Lathe For Increased Precision And Efficiency?When you upgrade a metal lathe, think about a few important things. First, check the machine’s parts. Better parts help make more accurate shapes. Next, look for new tools or accessories. These can make your work easier and faster. Lastly, think about how much space you have. A bigger lathe needs more room!

How Does The Power And Torque Of Upgraded Metal Lathe Motors Impact Machining Performance?Upgraded motors in metal lathes give you more power and torque. This means you can cut metal faster and easier. It helps you make smoother shapes and better finishes. When you have more strength, you can work with harder materials too. Overall, it makes your machining tasks quicker and more fun!

What Are The Benefits Of Upgrading To A Cnc (Computer Numerical Control) Metal Lathe Compared To A Manual Lathe?Upgrading to a CNC metal lathe is like getting a super smart helper for your projects. It can do many tasks quickly and accurately. You can create more complex shapes without getting tired. This means you can save time and make better parts. Plus, you don’t have to focus as hard, which makes it easier to work!

How Can The Size And Weight Of An Upgraded Metal Lathe Affect Its Stability And Performance During Operation?The size and weight of a metal lathe help make it steady while it works. A heavier lathe doesn’t shake much, so it cuts better. If it’s bigger, you can make larger parts. This means you get smoother and more accurate results. A stable lathe helps us do our jobs well and quickly.

What Are The Most Common Accessories Or Features To Look For In A Metal Lathe Upgrade To Enhance Its Capabilities?When upgrading a metal lathe, you should look for some cool accessories. A better chuck holds your metal pieces more securely. A quick-change tool post helps you switch tools easily. A larger bed gives you more space to work on bigger projects. Finally, a digital readout shows measurements clearly, making it easier for you to be accurate.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Comparing Metal Lathe Upgrades:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! When you think about metal lathe upgrades, ask these questions: What makes one upgrade better than another? Does it help you work faster? Is it easy to use? How much does it cost? Will it last a long time? These questions will help you decide which upgrade is best for you!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you’d like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Key Factors To Consider When Upgrading A Metal Lathe For Increased Precision And Efficiency?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When you upgrade a metal lathe, think about a few important things. First, check the machine’s parts. Better parts help make more accurate shapes. Next, look for new tools or accessories. These can make your work easier and faster. Lastly, think about how much space you have. A bigger lathe needs more room!”}},{“@type”: “Question”,”name”: “How Does The Power And Torque Of Upgraded Metal Lathe Motors Impact Machining Performance?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Upgraded motors in metal lathes give you more power and torque. This means you can cut metal faster and easier. It helps you make smoother shapes and better finishes. When you have more strength, you can work with harder materials too. Overall, it makes your machining tasks quicker and more fun!”}},{“@type”: “Question”,”name”: “What Are The Benefits Of Upgrading To A Cnc (Computer Numerical Control) Metal Lathe Compared To A Manual Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Upgrading to a CNC metal lathe is like getting a super smart helper for your projects. It can do many tasks quickly and accurately. You can create more complex shapes without getting tired. This means you can save time and make better parts. Plus, you don’t have to focus as hard, which makes it easier to work!”}},{“@type”: “Question”,”name”: “How Can The Size And Weight Of An Upgraded Metal Lathe Affect Its Stability And Performance During Operation?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The size and weight of a metal lathe help make it steady while it works. A heavier lathe doesn’t shake much, so it cuts better. If it’s bigger, you can make larger parts. This means you get smoother and more accurate results. A stable lathe helps us do our jobs well and quickly.”}},{“@type”: “Question”,”name”: “What Are The Most Common Accessories Or Features To Look For In A Metal Lathe Upgrade To Enhance Its Capabilities?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When upgrading a metal lathe, you should look for some cool accessories. A better chuck holds your metal pieces more securely. A quick-change tool post helps you switch tools easily. A larger bed gives you more space to work on bigger projects. Finally, a digital readout shows measurements clearly, making it easier for you to be accurate.”}}]}