Have you ever wanted to make your own metal parts? Imagine creating something with your own hands! A mini metal lathe can help you do just that.

However, choosing the right one can be tricky. There are many options out there. That’s where our comparison of mini metal lathes comes in! We will help you understand their features and find the best fit for your needs.

Did you know that some mini lathes are so small they can fit on your desk? This makes them perfect for hobbyists or anyone working in a small space. You might be surprised to learn how easy they are to use, even for beginners.

So, what should you look for in a mini metal lathe? Is it size, power, or price? Let’s dive into the details and find out what makes these tools special!

Comparison Mini Metal Lathe: Which One Is Right For You?

Comparison Mini Metal Lathe

Mini metal lathes are essential tools for DIY enthusiasts and professionals. They allow you to shape and cut metal with precision. When comparing different mini lathes, consider key features like size, speed, and durability. Did you know some lathes can produce intricate designs from tiny parts? It’s like magic! Choosing the right one can enhance your projects and save time. Explore options to find the perfect fit for your needs. Happy crafting!What is a Mini Metal Lathe?

Definition and purpose of mini metal lathes. Typical applications and users of mini metal lathes.A mini metal lathe is a small, powerful tool used to shape and cut metal. It spins metal pieces while a cutting tool smooths them into the desired shape. Think of it like a spinning top that makes metal into art! These machines are great for hobbyists, engineers, and small workshops. They create parts for toys, models, and even furniture. If you’ve ever wanted to make something shiny and round, a mini metal lathe is the way to go!

| Applications | Typical Users |

|---|---|

| Creating small metal parts | Hobbyists |

| Repairing machinery | Engineers |

| Model making | Small workshop owners |

Mini metal lathes save time and make metal work fun! With these tools, turning your ideas into reality is easier than ever. So, if you’re eager to twist some metal into something cool, picking up a mini lathe might just be your next big adventure!

Key Features to Consider

Size and portability factors. Motor power and speed variability. Material construction and durability.Size matters when it comes to mini metal lathes, especially if you plan to move it around. A smaller lathe is easier to carry, but might limit large projects. Look for models that balance portability with the capacity to handle your work. Motor power is another key piece. A strong motor gives more speed and versatility for different tasks. Durability is crucial, too! Choose one made with tough materials to avoid wear and tear—because nobody likes a whiny lathe! Here’s a quick table of features:

| Feature | Importance |

|---|---|

| Size | Portability vs. capacity |

| Motor Power | Speed and variability |

| Material | Durability is key! |

Performance Analysis

Cutting precision and accuracy benchmarks. Feedback and reviews from experienced users.Cutting precision is key for any mini metal lathe. Users often measure accuracy with special gauges. Experienced buyers report high satisfaction with these machines. They find them easy to use and reliable. Performance benchmarks usually show consistent results. Many reviews highlight the following:

- High precision cuts

- Sturdy build quality

- Easy setup

Overall, these lathes impress users with their performance. Happy customers often share that these machines exceed their expectations.

How accurate is a mini metal lathe?

The cutting accuracy of a mini metal lathe can be within 0.001 inches. This level of precision is great for small projects.

Maintenance and Upkeep

Routine maintenance tips for mini metal lathes. Common issues and troubleshooting advice.Keeping your mini metal lathe in tip-top shape is crucial for its performance. Start with regular cleaning—dust and chips can spoil your smooth sailing. Check the belts and change them if they look worn out. Lubricate moving parts; they deserve a little pampering! Watch out for common issues like strange noises or shaking. If it sounds like a rock concert, trouble might be near. It’s like your lathe is asking for a vacation—maybe it just needs a tune-up! Here’s a quick table for reference:

| Routine Maintenance Tips | Common Issues | Troubleshooting Advice |

|---|---|---|

| Clean regularly | Unusual noises | Check for loose parts |

| Lubricate parts | Vibrations | Level the machine |

| Check belts often | Inaccurate cuts | Calibrate settings |

Remember, a little maintenance can save you from hefty repairs. Keep your lathe happy and it’ll work like a charm!

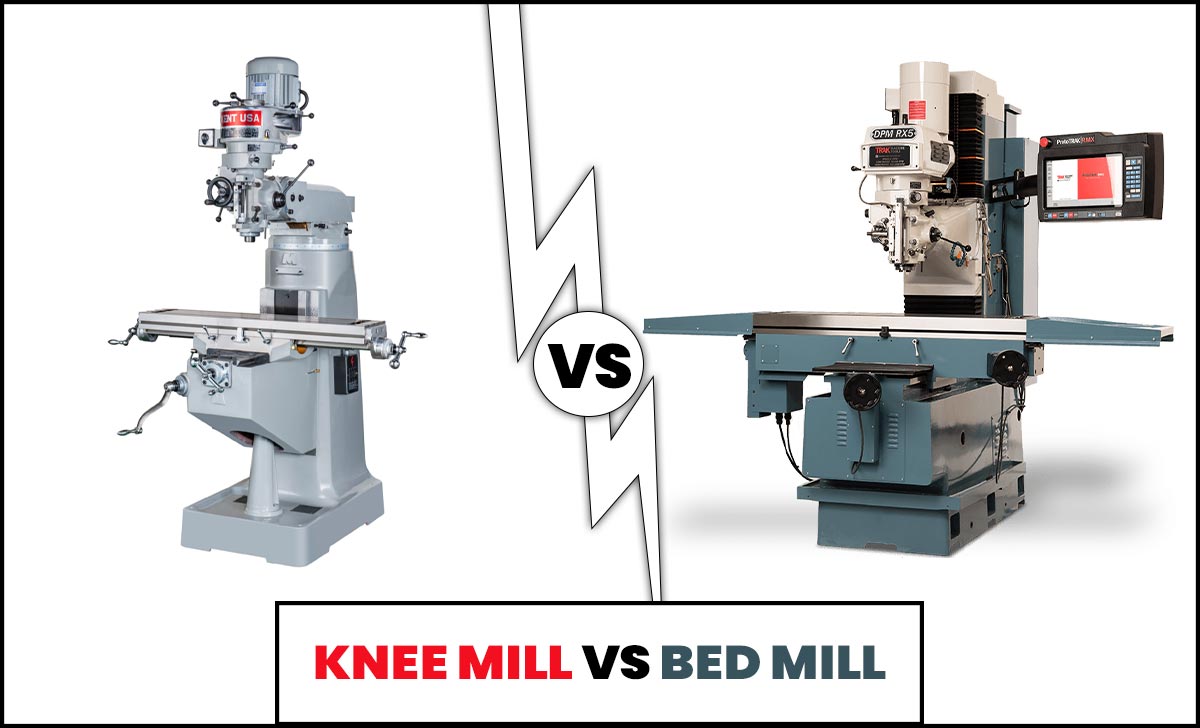

Comparison with Full-Size Lathes

Pros and cons of using mini lathes versus fullsize alternatives. Suitability for different projects and skill levels.Mini lathes and full-size lathes both have their perks. Mini lathes are lighter and perfect for small projects, ideal for beginners who might feel a bit wobbly. They take up less space, too, like a cat in a shoebox! However, full-size lathes can handle bigger jobs, making them great for professional work. On the flip side, mini lathes might struggle with heavy-duty tasks. Choose wisely based on what you plan to make and your skill level!

| Feature | Mini Lathe | Full-Size Lathe |

|---|---|---|

| Size | Compact | Large |

| Skill Level | Beginner-friendly | Advanced projects |

| Portability | Easy to move | Less portable |

| Project Type | Small items | Heavy-duty work |

Accessories and Enhancements

Essential accessories for optimizing mini lathe performance. Upgrades and aftermarket modifications available.To boost performance, consider key accessories for your mini lathe. These tools can make your tasks easier and improve results. For example:

- Tailstock Chucks: Help with precise drilling.

- Tool Holder Sets: Make changing tools faster.

- Digital Readouts: Improve accuracy in measurements.

- Upgraded Motors: Provide more power for tough jobs.

- Cutting Tools: Better tools mean smoother finishes.

Aftermarket upgrades can also enhance how your lathe works. New parts help it work better and last longer. Take the time to find what fits your needs!

What upgrades should I consider for my mini lathe?

Consider upgrades like better motors, enhanced tool holders, and digital readouts. These tools help make your lathe work smarter and faster!

User Guides and Best Practices

Safety measures while operating a mini metal lathe. Tips for beginners on maximizing efficiency and output.Safety is key when using a mini metal lathe. Always wear goggles to protect your eyes. Keep your hair tied back and avoid loose clothing. Make sure tools are sharp and in good shape. This helps prevent accidents. For beginners, here are some helpful tips:

- Understand the machine: Read the manual carefully.

- Start slow: Practice with low speeds before going faster.

- Keep your workspace clean: A tidy area helps prevent mistakes.

- Measure twice: Always double-check your measurements.

Using these practices will help you operate the lathe safely and efficiently. Remember, the more you practice, the better you’ll become!

What should beginners know about using a mini metal lathe?

Beginners should focus on safety and practice regularly. Understanding the machine and keeping a clean workspace are vital.

Conclusion

In conclusion, a comparison mini metal lathe helps you find the best option for your projects. We learned that size, power, and features matter. You should consider your needs and budget before buying. Explore reviews online and visit local shops to see different models. This way, you can make a smart choice that fits your workshop perfectly.FAQs

What Are The Key Specifications To Consider When Comparing Different Mini Metal Lathes?When comparing mini metal lathes, you should look at a few important things. First, check the size, or how big the lathe is. Next, consider the horsepower, which tells you how strong the machine is. Then, look at the speed range, or how fast it can spin. Finally, think about the materials you want to use, since some lathes work better with certain metals.

How Do The Power And Torque Ratings Of Various Mini Metal Lathes Impact Their Performance?The power and torque of a mini metal lathe tell us how strong it is. Power helps the lathe run fast, while torque helps cut hard materials. If you need to work with tough metal, a lathe with more torque is better. So, when choosing a lathe, think about what you want to make. More power and torque usually mean better performance.

What Are The Advantages And Disadvantages Of Digital Display Versus Analog Dials On Mini Metal Lathes?Digital displays are easy to read and show exact numbers. You can quickly see your measurements and adjust them precisely. However, they need batteries and might break if you drop the lathe. Analog dials have moving hands that some people find easier to understand, but they can be harder to read at times.

How Do The Dimensions And Weight Of A Mini Metal Lathe Affect Its Portability And Workspace Requirements?The size and weight of a mini metal lathe affect how easy it is to move. If it’s small and light, you can carry it around easily. A heavy lathe needs a big table and more space. So, bigger lathes can be harder to use in small areas. You want enough room to work comfortably!

In Terms Of Versatility, How Do Different Mini Metal Lathes Perform With Various Materials And Applications?Mini metal lathes are great for working with many different materials like aluminum, brass, and plastic. You can use them for making small parts, toys, or tools. Some lathes work better with soft materials, while others can handle harder metals. This means you can use them for many projects, making them very useful. Just pick the right lathe for your needs!