Have you ever wondered how to make your woodturning projects smoother and easier? Using a DIY carbide insert wood lathe tool might just be the answer. Imagine crafting beautiful bowls or elegant pieces, all while using a tool you built yourself. Sounds exciting, right?

Carbide inserts are known for their sharpness and durability. They make turning wood a breeze. What if you could create a tool that gives you all these benefits without spending a fortune? Making a DIY carbide insert wood lathe tool can unlock a new level of creativity for any woodworker.

Did you know that carbide tools last longer than regular steel tools? This means you’ll spend less time sharpening and more time creating stunning pieces. And the best part? You can customize your tool to fit your style and needs!

So, are you ready to discover the world of DIY carbide insert wood lathe tools? Let’s dive into the details and find out how you can easily make your own and enhance your woodworking experience!

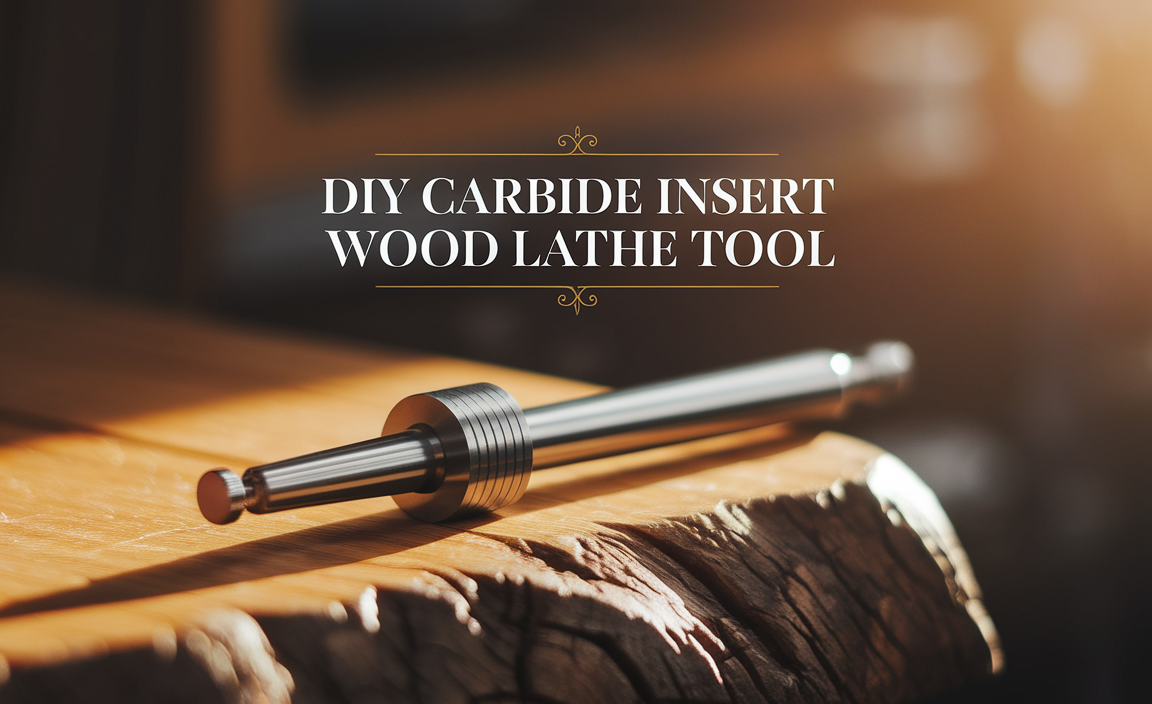

Diy Carbide Insert Wood Lathe Tool: A Step-By-Step Guide

Creating a DIY carbide insert wood lathe tool is easier than you think! This project helps you make a sharp, durable tool for woodturning. You’ll explore the materials needed, like carbide inserts and a robust handle. Imagine crafting beautiful wooden items like bowls or vases at home. A fun fact: carbide inserts last much longer than regular tools. Why not try making one? You’ll learn skills and boost your creativity while saving money!

Understanding Carbide Inserts

Definition and benefits of carbide inserts in woodturning.. Comparison with traditional tools: longevity, sharpness, and maintenance..

Carbide inserts are special tips used in tools for woodturning. They are made from a tough material that stays sharp longer than regular tools. Using these inserts means less time spent sharpening. Here are some benefits of carbide inserts:

- Longevity: They last much longer than traditional tools.

- Sharpness: They cut better and stay sharp for a longer time.

- Low Maintenance: Less need for frequent sharpening.

Switching to carbide inserts helps woodturners work faster and create smoother pieces. Imagine spending less time on tool maintenance and more time crafting!

What are the benefits of carbide inserts for woodturning?

Carbide inserts offer longer-lasting sharpness and require less upkeep, making them great for woodturners.

Step-by-Step Guide to Creating Your Own Carbide Insert Tool

Detailed instructions from planning to final assembly.. Safety tips throughout the DIY process.. Making your own carbide insert tool can be fun and rewarding. Start by gathering materials. You’ll need a piece of steel, carbide inserts, and some tools for shaping. Think about how you want your tool to look and work. Sketch your design first to make the process easier.

Here are some safety tips to remember:

- Always wear eye protection.

- Use gloves to avoid cuts.

- Keep your workspace tidy to prevent accidents.

Follow these steps to create your tool:

- Shape the steel to match your design.

- Attach the carbide inserts securely.

- Test the tool on scrap wood to make sure it works well.

With patience, your DIY carbide insert wood lathe tool will be ready for use. Enjoy creating beautiful projects!

How do I safely handle tools while making the carbide insert tool?

While making the tool, safety is key. Always wear protective gear like gloves and goggles. Keep your workspace organized and be aware of your surroundings. If you feel tired or distracted, take a break before continuing.

Choosing the Right Carbide Insert for Woodturning

Factors to consider: shape, size, and coating types.. Recommendations for various woodturning projects.. Choosing the perfect carbide insert can feel like a game of hide and seek. You want one that’s just right for your projects! First, think about the shape. Round inserts glide smoothly, while square ones carve deeper. Next is the size: smaller ones work great for fine details, and larger ones are better for big cuts. Lastly, the coating matters—some help resist wear and tear. Here’s a quick table to help you choose:

| Project Type | Insert Shape | Insert Size | Coating Type |

|---|---|---|---|

| Detail Work | Round | Small | Titanium |

| General Shaping | Square | Medium | Aluminum |

| Big Projects | Rectangular | Large | Chrome |

Pick wisely, and you’ll turn wood like a pro! Happy woodworking!

Maintenance and Care for Carbide Insert Tools

Cleaning techniques and best practices to extend tool life.. Tips on sharpening and replacing inserts..

Keeping your carbide insert tools happy is key to a smooth woodworking journey. First, clean your tools after each use. A little brush and some soapy water work wonders. Avoid soap operas, though—your tools won’t care! Next, check inserts regularly. If they get dull, it’s time to sharpen or replace them. Inserts are like your favorite snacks; once they’re gone, you need fresh ones!

| Task | Best Practice |

|---|---|

| Cleaning | Use a soft brush and mild soap. |

| Sharpening | Follow the manufacturer’s guidelines. |

| Replacing Inserts | Change when performance drops. |

These simple steps will keep your tools cutting smoothly. Remember, happy tools make for happy woodwork!

Common Mistakes to Avoid in DIY Tool Making

Pitfalls in material selection and tool assembly.. Troubleshooting common issues during use..

Making your own tools can be exciting, but common mistakes can happen. First, be careful when choosing materials. The wrong kind can break easily. Next, assemble your tool correctly. A loose part can cause problems later. Here are some key points to remember:

- Select strong, durable materials.

- Check each part during assembly.

- Tighten screws and bolts properly.

If you run into issues while using the tool, don’t worry. Many problems are easy to fix. Always check the blade and make sure it’s sharp. A dull blade makes work harder and less safe.

What are some common mistakes in DIY tool making?

Common mistakes include poor material choice and incorrect assembly. Always ensure you use sturdy materials and follow assembly guidelines closely.

Enhancing Your Wood Lathe Experience

Accessories and upgrades to improve lathe performance.. Community resources: forums, workshops, and online tutorials..

Upgrading your wood lathe can be a real game-changer! Adding the right accessories can make your projects smoother and more fun. Think about a good chuck or some high-quality carbide inserts. They help keep your tools sharp, just like a well-timed joke at a dull party! Joining community resources like forums and workshops can also boost your skills. You’ll meet fellow woodworkers and find great online tutorials that make learning enjoyable.

| Accessory | Benefit |

|---|---|

| Quality Chuck | Better grip on materials |

| Carbide Inserts | Longer cutting life |

| Tool Rest | Improved stability |

Conclusion

In conclusion, a DIY carbide insert wood lathe tool can enhance your woodworking experience. You can create precise cuts and smooth finishes easily. With simple materials and tools, you can build one yourself. Explore online tutorials for step-by-step guidance. Start your project today and enjoy the satisfaction of making your own woodworking tool! Keep learning and experimenting as you go.

FAQs

Certainly! Here Are Five Related Questions On The Topic Of Diy Carbide Insert Wood Lathe Tools:

Sure! Carbide insert wood lathe tools are special tools that help shape wood. You can make your own tools at home. First, you need some carbide inserts and handles. You can attach the inserts to the handles to create your tools. These tools are great for making smooth cuts on wood. Have fun making your own!

Sure! Just ask your question, and I’ll give you a short and simple answer.

What Materials And Tools Do I Need To Create My Own Carbide Insert Wood Lathe Tool?

To make your own carbide insert wood lathe tool, you’ll need some important items. First, get a piece of steel for the handle. You’ll also need a carbide insert, which is a small, hard piece that cuts the wood. Make sure you have screws to hold everything together. Finally, grab some tools like a drill and a wrench to help with assembly.

How Do I Choose The Right Carbide Insert For Different Woodturning Projects?

To choose the right carbide insert for woodturning, first think about the type of wood you will use. Softer woods need sharper inserts for a clean cut. For harder woods, use inserts that are strong and durable. You should also consider the shape of the insert to match your project. Always test a few to see which one works best for you!

What Are The Advantages Of Using Carbide Inserts Over Traditional High-Speed Steel (Hss) Tools For Wood Lathe Work?

Carbide inserts are better than high-speed steel (HSS) tools for wood lathe work. They stay sharp longer, so you don’t have to change them as often. This saves you time and effort. Carbide also cuts smoother, making your work look nicer. Plus, they are more durable, meaning they can last through tough projects without breaking easily.

Can I Modify Existing Wood Lathe Tools To Accommodate Carbide Inserts, And If So, How?

Yes, you can modify wood lathe tools to use carbide inserts. First, check if your tools are strong enough. Then, you can cut a slot or attach a holder for the carbide insert. Make sure the insert fits tightly and is secure. Always wear safety gear when you work!

What Are Some Common Troubleshooting Tips For Using Diy Carbide Insert Lathe Tools In Woodworking Projects?

If your DIY carbide insert lathe tool isn’t working well, try checking the sharpness. A dull tool can make rough cuts. Also, make sure the tool is set up correctly in the lathe. If you’re having trouble, adjust the speed of your lathe. Lastly, keep your work area clean to avoid getting stuck.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Certainly! Here Are Five Related Questions On The Topic Of Diy Carbide Insert Wood Lathe Tools:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Carbide insert wood lathe tools are special tools that help shape wood. You can make your own tools at home. First, you need some carbide inserts and handles. You can attach the inserts to the handles to create your tools. These tools are great for making smooth cuts on wood. Have fun making your own!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Just ask your question, and I’ll give you a short and simple answer.”}},{“@type”: “Question”,”name”: “What Materials And Tools Do I Need To Create My Own Carbide Insert Wood Lathe Tool?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To make your own carbide insert wood lathe tool, you’ll need some important items. First, get a piece of steel for the handle. You’ll also need a carbide insert, which is a small, hard piece that cuts the wood. Make sure you have screws to hold everything together. Finally, grab some tools like a drill and a wrench to help with assembly.”}},{“@type”: “Question”,”name”: “How Do I Choose The Right Carbide Insert For Different Woodturning Projects?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To choose the right carbide insert for woodturning, first think about the type of wood you will use. Softer woods need sharper inserts for a clean cut. For harder woods, use inserts that are strong and durable. You should also consider the shape of the insert to match your project. Always test a few to see which one works best for you!”}},{“@type”: “Question”,”name”: “What Are The Advantages Of Using Carbide Inserts Over Traditional High-Speed Steel (Hss) Tools For Wood Lathe Work?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Carbide inserts are better than high-speed steel (HSS) tools for wood lathe work. They stay sharp longer, so you don’t have to change them as often. This saves you time and effort. Carbide also cuts smoother, making your work look nicer. Plus, they are more durable, meaning they can last through tough projects without breaking easily.”}},{“@type”: “Question”,”name”: “Can I Modify Existing Wood Lathe Tools To Accommodate Carbide Inserts, And If So, How?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Yes, you can modify wood lathe tools to use carbide inserts. First, check if your tools are strong enough. Then, you can cut a slot or attach a holder for the carbide insert. Make sure the insert fits tightly and is secure. Always wear safety gear when you work!”}},{“@type”: “Question”,”name”: “What Are Some Common Troubleshooting Tips For Using Diy Carbide Insert Lathe Tools In Woodworking Projects?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If your DIY carbide insert lathe tool isn’t working well, try checking the sharpness. A dull tool can make rough cuts. Also, make sure the tool is set up correctly in the lathe. If you’re having trouble, adjust the speed of your lathe. Lastly, keep your work area clean to avoid getting stuck.”}}]}