Have you ever wanted to create perfect wooden shapes at home? Imagine a tool that helps you easily duplicate designs on a wood lathe. A DIY duplicator for wood lathe can make that dream a reality. This simple device can transform your woodworking experience.

Many woodworkers face challenges when trying to replicate their favorite projects. However, did you know that a wood lathe duplicator can save time and effort? You can make multiple copies of your designs quickly and accurately with one handy tool.

Picture this: You have a beautiful chair leg design, and you want to make four of them. Instead of measuring and carving each one, you can use a DIY duplicator. It perfectly mimics the shape you created. Isn’t that cool?

In this article, we’ll explore the exciting world of DIY duplicators for wood lathes. You’ll learn how to build your own, and we’ll share tips to make it work like a charm. Ready to boost your woodworking skills? Let’s dive in!

Essential Guide To Diy Duplicator For Wood Lathe Projects

DIY Duplicator for Wood Lathe

Discover the world of DIY duplicators for wood lathes. These handy tools allow woodworkers to easily replicate shapes and designs. Imagine crafting beautiful bowls or unique furniture parts without starting from scratch each time. You can build one using simple materials, usually found at home or a local store. Not only does this save time, but it also boosts your creativity. Who wouldn’t love making their own custom pieces? Unleash your woodworking potential today!Understanding Wood Lathe Duplicators

Definition and purpose of wood lathe duplicators. Benefits of using a duplicator in woodworking projects.A wood lathe duplicator is a tool that helps create copies of wood pieces. It works by tracing the shape of one piece and making new ones that look the same. This is useful for making chairs, table legs, and toys. Using a duplicator can save time and effort. Here are some benefits:

- Consistency: All pieces match perfectly.

- Speed: Complete projects faster.

- Less waste: Make the most of your wood.

What is the purpose of a wood lathe duplicator?

The purpose of a wood lathe duplicator is to simplify woodworking. It allows you to replicate intricate designs without much hassle. Using this tool can improve your craft and create beautiful pieces.

How can a duplicator benefit your woodworking?

A duplicator can greatly benefit your woodworking. It helps you create uniform pieces quickly and efficiently. This means you’ll have more time to enjoy your projects.

Essential Tools and Materials

List of required tools for constructing a duplicator. Recommended materials for durability and performance.To build a DIY duplicator for your wood lathe, you will need specific tools and materials. Here’s what you’ll need:

- Router – Helps shape the wood.

- Guides – Keeps everything aligned.

- Wood screws and bolts – For firm connections.

- Measuring tape – Ensures accurate dimensions.

- Wood pieces – Select durable types like maple or oak.

Choosing good materials will improve the duplicator’s performance. Make sure to pick strong woods, as they last longer. Using the right tools makes the process easier and fun!

What tools are needed for a wood lathe duplicator?

Essential tools include a router, measuring tape, wood screws, bolts, and guides.

Designing Your DIY Duplicator

Key design considerations for effective duplication. Sketching and planning dimensions for your duplicator.Creating your own duplicator is fun and useful! First, think about how big you want your projects to be. Measure twice because, in woodwork, mistakes can get costly. A good sketch can save your day—draw what you want and check if it fits. Make sure your design allows easy adjustments; nobody likes a stubborn duplicator. Don’t forget strong materials so your duplicator holds up during its wood adventures!

| Key Design Factors | Details |

|---|---|

| Size | Measure your pieces carefully! |

| Sketching | Draw it out to avoid mistakes. |

| Adjustability | Make it easy to change settings. |

| Materials | Strong stuff keeps it sturdy. |

Step-by-Step Assembly Process

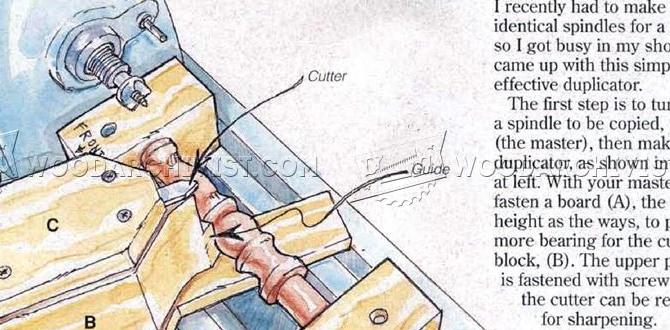

Detailed instructions on building the duplicator frame. How to install and adjust the cutting head.Building the duplicator frame is simple and fun! Start by gathering materials such as wood, screws, and brackets. Follow these steps:

- Cut the wood to size for the frame.

- Assemble the pieces using screws for strong connections.

- Secure the frame to your lathe.

Next, for the cutting head, attach it to the frame. Adjust it carefully by:

- Loosening the adjustment knob.

- Sliding the head to the desired height.

- Tightening the knob to hold it in place.

Now, you’re ready to create amazing wooden pieces!

How do I adjust the cutting head on my DIY duplicator?

To adjust the cutting head, loosen the adjustment knob, slide the head to the correct height, and then tighten the knob again. This keeps everything steady for accurate cuts.

Calibrating Your Duplicator for Precision

Techniques for ensuring accurate replication of designs. Importance of testing and adjustments before final use.To get your DIY duplicator working perfectly, you need to calibrate it well. Start by adjusting the tool rest and tailstock. Test the unit with simple shapes first. This helps find any problems quickly. Remember these points for accuracy:

- Check alignment of parts.

- Measure distances carefully.

- Make small adjustments as needed.

- Always do a test run.

Testing is vital! It ensures your designs come out just right. Make adjustments based on what you see. This way, you can avoid mistakes before your final project.

Why is Testing Important?

Testing ensures that each piece matches your design! It saves time and materials. Simple checks lead to better results.

Common Challenges and Solutions

Issues that may arise during construction and use. Troubleshooting tips for smoother operation.Building a DIY duplicator can have its quirks. Sometimes, it squeaks like a mouse when you least expect it! Common issues include incorrect alignment or a wobbly setup. These can mess up your project and ruin your day. No one wants an egg-shaped wood bowl, right? For smoother operation, double-check your measurements! Also, keep some wax handy for those pesky friction points.

| Issue | Solution |

|---|---|

| Wobbling | Check and tighten all screws. |

| Poor cuts | Adjust your blade angle. |

| Squeaking noise | Add sliding wax. |

With a few tweaks, you can turn that wood into a masterpiece rather than a funny-looking potato! If problems arise, don’t panic. Think of it as your machine finding its groove!

Finishing Touches and Enhancements

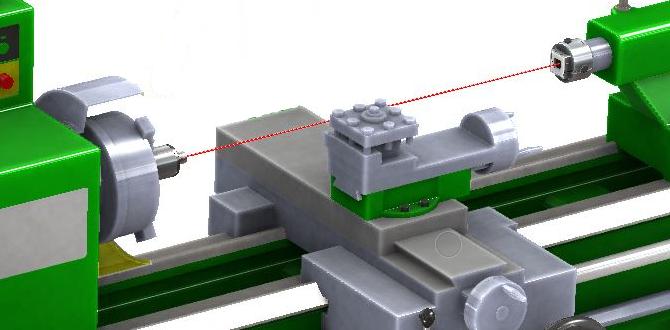

Suggested upgrades for increased functionality. How to maintain and care for your duplicator.Upgrading your DIY duplicator can help it work better. Consider adding a better cutting tool for cleaner cuts. Another upgrade might be a speed control feature. It lets you choose how fast to work. Regular care is important too. Keep it clean to avoid rust. Check all parts for damage.

- Clean it after use.

- Oil moving parts regularly.

- Store it in a dry place.

How can I make my duplicator work better?

Try to add a laser guide. It helps with accuracy. Also, think about a better support frame for stability. Both upgrades make projects smoother.

Real-Life Applications and Projects

Examples of projects suitable for using a wood lathe duplicator. Inspirational ideas for enhancing your woodworking skills.Wood lathe duplicators open up fun project possibilities. You can create repeated shapes quickly and easily. Here are some great ideas to get you started:

- Table legs: Make matching legs for tables.

- Bowl turning: Craft beautiful bowls from wood.

- Child’s toys: Design unique toy cars or animals.

- Candle holders: Create decorative candle holders.

- Furniture parts: Build parts for chairs or shelves.

These projects can boost your woodworking skills. They mix fun with learning. You will be amazed at what you can make!

What projects can beginners try with a wood lathe duplicator?

Beginners can start with simple projects like candle holders and small bowls. These projects build skills while being fun and rewarding.

Conclusion

In conclusion, a DIY duplicator for your wood lathe can enhance your woodworking skills. It lets you create copies of your designs easily. You can save time and materials with this tool. If you’re ready to build one, check online guides for tips. Experimenting with a duplicator can lead to exciting projects. Let’s get started and have fun crafting!FAQs

What Materials Do I Need To Build A Diy Duplicator For My Wood Lathe?To build a DIY duplicator for your wood lathe, you will need a few key materials. First, get some wood for the frame. You also need a metal or plastic arm to guide the cutting tool. Grab a cutting tool like a chisel that fits your lathe. Finally, don’t forget screws and brackets to hold everything together.

How Does A Wood Lathe Duplicator Work, And What Are Its Key Components?A wood lathe duplicator helps us make copies of wood shapes. First, you set a pattern shape to copy. As the wood spins, a cutting tool follows the shape of the pattern. The key parts are the lathe, the pattern arm, and the cutting tool. This way, you get matching wood pieces every time!

What Are Some Common Designs Or Plans Available For Constructing A Wood Lathe Duplicator?You can find different designs for making a wood lathe duplicator. One common plan uses a template that shapes the wood. Another design has a follower arm that moves along the template. Some plans include a simple frame with a pivot point. You can build one using wood, screws, and basic tools!

How Can I Ensure Accuracy And Precision When Using A Diy Duplicator On My Wood Lathe?To ensure accuracy and precision with your DIY duplicator on a wood lathe, first, check that everything is set up tightly. Use a sharp cutting tool to make clean cuts. Measure your workpiece carefully and mark where to cut. Take your time and don’t rush. Regularly check your progress to make sure everything is going well.

What Safety Precautions Should I Take When Operating A Wood Lathe With A Duplicator Attachment?When using a wood lathe with a duplicator, always wear safety goggles to protect your eyes. Keep your hair tied back and wear snug clothes. Make sure your tools are sharp and in good shape. Never touch the moving parts while they are spinning. Lastly, keep your hands away from the cutter and stay focused on your work.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Materials Do I Need To Build A Diy Duplicator For My Wood Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To build a DIY duplicator for your wood lathe, you will need a few key materials. First, get some wood for the frame. You also need a metal or plastic arm to guide the cutting tool. Grab a cutting tool like a chisel that fits your lathe. Finally, don’t forget screws and brackets to hold everything together.”}},{“@type”: “Question”,”name”: “How Does A Wood Lathe Duplicator Work, And What Are Its Key Components? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A wood lathe duplicator helps us make copies of wood shapes. First, you set a pattern shape to copy. As the wood spins, a cutting tool follows the shape of the pattern. The key parts are the lathe, the pattern arm, and the cutting tool. This way, you get matching wood pieces every time!”}},{“@type”: “Question”,”name”: “What Are Some Common Designs Or Plans Available For Constructing A Wood Lathe Duplicator? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can find different designs for making a wood lathe duplicator. One common plan uses a template that shapes the wood. Another design has a follower arm that moves along the template. Some plans include a simple frame with a pivot point. You can build one using wood, screws, and basic tools!”}},{“@type”: “Question”,”name”: “How Can I Ensure Accuracy And Precision When Using A Diy Duplicator On My Wood Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To ensure accuracy and precision with your DIY duplicator on a wood lathe, first, check that everything is set up tightly. Use a sharp cutting tool to make clean cuts. Measure your workpiece carefully and mark where to cut. Take your time and don’t rush. Regularly check your progress to make sure everything is going well.”}},{“@type”: “Question”,”name”: “What Safety Precautions Should I Take When Operating A Wood Lathe With A Duplicator Attachment? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When using a wood lathe with a duplicator, always wear safety goggles to protect your eyes. Keep your hair tied back and wear snug clothes. Make sure your tools are sharp and in good shape. Never touch the moving parts while they are spinning. Lastly, keep your hands away from the cutter and stay focused on your work.”}}]}