Have you ever wanted to create your own tools? Imagine making a metal lathe right in your garage! With DIY metal lathe CAD design, you can turn that idea into reality. Many people dream of building machines, and a metal lathe is a great place to start. It helps you shape and cut metal with ease.

Using CAD software makes the design process easier. You can see your metal lathe on the screen before you make it. This way, you can plan each piece perfectly. Have you ever wished to design something that could actually work? With CAD, your vision can come to life!

Did you know that thousands of DIY enthusiasts are exploring metalworking today? They love creating custom tools and parts. You could be one of them! Dive into the world of DIY metal lathe CAD design and discover how fun and rewarding it can be.

Diy Metal Lathe Cad Design: Create Your Own Precision Tool

Creating a DIY metal lathe through CAD design opens up exciting possibilities. Imagine crafting precise parts for your projects! Readers learn how to use CAD software for designing lathe components. Understanding dimensions and material selection is crucial. It’s like building a puzzle where each piece fits perfectly. With the right skills, anyone can create their own tools. Did you know that many professionals start with DIY projects? Embrace creativity and start designing today!

Understanding Metal Lathes

Definition and purpose of metal lathes. Common applications in various industries.

Metal lathes are cool tools that shape metal into useful parts. They spin the metal while a cutting tool shapes it. Think of it like a giant pencil sharpener for metal! These machines are used in factories, car shops, and even art studios. They help create everything from bike frames to complex engine parts. Without them, your toy cars would struggle to go anywhere! Below is a table showing some common uses of metal lathes.

| Industry | Common Applications |

|---|---|

| Automotive | Engine parts, wheels |

| Manufacturing | Shafts, gears |

| Art | Sculptures, jewelry |

Whether making machines safer or crafting art, metal lathes do it all with style and precision!

Benefits of DIY Metal Lathes

Costeffectiveness and customization potential. Skill development and handson experience.

Building your own metal lathe brings many benefits. First, it saves money. Buying a new lathe can cost a fortune! But making one yourself? That’s like finding a treasure in your garage! Plus, you can customize it just the way you like. Want a cool color? Go for it!

Next, you get to develop skills. Working with tools teaches you a lot. It’s like playing a fun game where you level up every time. Each twist and turn makes you better. Many people say that hands-on experience is the best teacher!

| Benefit | Description |

|---|---|

| Cost-Effective | Cheaper than buying new. |

| Customization | Make it your own design! |

| Skill Development | Learn new skills while having fun! |

So, get ready to have some fun with metal lathes! Who knew savings and skills could be such a great duo?

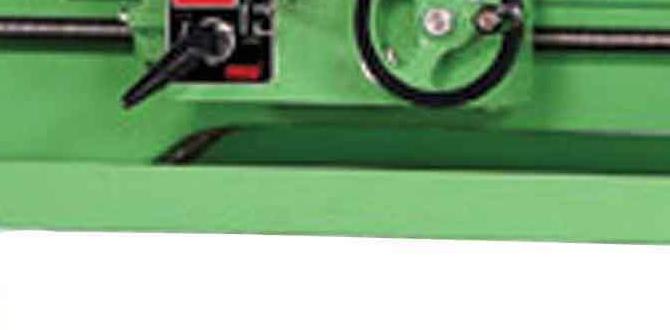

Essential Components of a Metal Lathe

Key parts: bed, headstock, tailstock, carriage. Materials needed for construction.

Building a metal lathe? Make sure you know the essentials! The main parts include the bed, which is like the lathe’s backbone, keeping everything steady. The headstock holds the motor and controls the spinning. The tailstock helps with support and feeds in tools. Lastly, there’s the carriage, which moves back and forth like a train on tracks. You’ll also need materials like steel and aluminum to bring your creation to life. Ready to get your DIY groove on?

| Component | Function |

|---|---|

| Bed | Supports and stabilizes |

| Headstock | Holds motor and controls |

| Tailstock | Provides support and tool feeding |

| Carriage | Moves tools back and forth |

Step-by-Step Guide to CAD Designing Your Metal Lathe

Initial planning and sketching out designs. Creating the design in CAD software.

Start by planning your metal lathe design. Think about what you want it to look like. Use pencil and paper for your first sketches. This helps you organize your ideas. Next, use a CAD program to create your design. This software makes it easy to turn your sketches into a 3D model. Here’s how to do it:

- Draw your designs on paper.

- Choose a CAD program you like.

- Begin with basic shapes in CAD.

- Add details like measurements and features.

With these steps, you’ll have a clear plan for your diy metal lathe cad design!

What is the first step in CAD design?

The first step is to sketch your ideas on paper before using the CAD software.

How do I create a design in CAD software?

Launch the CAD program, start with simple shapes, and gradually add details to build your design.

Tips for Efficient CAD Design

Best practices for modeling components. Common mistakes to avoid in CAD design.

Creating parts in CAD can be fun! Here are some tips to help you design better. First, keep your design simple. Complex shapes can confuse you later. Always take your time measuring parts carefully. Common mistakes include forgetting to check dimensions or misplacing parts. Make sure to save your work often, so you don’t lose anything. Use layers to organize your design. This makes it easier to adjust things later!

What are best practices in CAD design?

The best practices include:

- Plan your design first.

- Group similar parts together.

- Use standard dimensions.

- Double-check everything before finalizing.

What mistakes should I avoid in CAD design?

Watch out for these mistakes:

- Not labeling your parts.

- Overcomplicating designs.

- Ignoring software tools.

Prototyping and Testing Your Design

Methods for creating prototypes (3D printing, CNC machining). Testing for functionality and durability.

Creating a good prototype is key for your design. You can use methods like 3D printing and CNC machining. Both can help turn your digital model into a real thing.

- 3D printing is quick and easy. It adds layers to build your item.

- CNC machining is precise. It shapes materials exactly as you want.

Once you have a prototype, test it! Check if it works properly and can last long. This step is important to make sure your design is strong and useful.

What should you test in your prototype?

Focus on functionality and durability. Functionality means it works as expected. Durability means it can take a hit and still work well.

Resources for DIY Enthusiasts

Online communities and forums for support. Useful tutorial websites and videos for guidance.

For those diving into the world of DIY metal lathes, online communities are your best friends. Platforms like Reddit and specialized forums allow you to ask questions, share ideas, and find support. You can get advice quicker than you can say “lathe”! There are also many fantastic tutorial websites and videos to help you every step of the way. Here’s a quick table for some great resources:

| Resource | Description |

|---|---|

| Community discussions and help. | |

| YouTube | Step-by-step video tutorials. |

| Instructables | Project guides and ideas. |

With resources like these, building your metal lathe will be easier than trying to keep your cat out of a cardboard box! So, gather your tools, and let the fun begin!

Safety Considerations When Building and Using a Metal Lathe

Importance of safety gear and precautions. Potential hazards and how to mitigate them.

Building and using a metal lathe can be a fun adventure, but safety must come first! Always wear the right safety gear. This includes goggles, gloves, and ear protection to keep you safe from flying debris and noisy machines.

Potential hazards are everywhere. From sharp tools to spinning parts, staying alert is key. To mitigate risks, keep your workspace clean and well-lit. Proper training is a must! You wouldn’t try to bake without a recipe, would you?

| Safety Gear | Hazards | Precautions |

|---|---|---|

| Goggles | Flying metal chips | Keep area tidy |

| Gloves | Sharp tools | Use tools properly |

| Ear muffs | Heavy noise | Work in quiet zones |

Remember, safety isn’t a joke—so laugh all the way to a safe workshop!

Inspirational Projects and Examples

Showcase of successful DIY metal lathe projects. Lessons learned from experienced metal lathe builders.

Many DIY metal lathe projects inspire hobbyists around the world. Whether you’re making tools or parts, each project teaches something valuable. Here are a few successes:

- Custom tool holders: Perfect for organizing equipment.

- Miniature engines: Great for showcasing precision skills.

- Unique jewelry: Mixes creativity with metalworking.

Experienced builders share lessons. They suggest starting with simple designs. Mistakes can happen, but they often lead to new ideas. Learning from others helps improve your skills!

What can you learn from DIY metal lathe projects?

You can learn about proper techniques, tool maintenance, and design strategies. These insights make your projects smoother and more enjoyable!

Conclusion

In conclusion, DIY metal lathe CAD design opens up exciting possibilities for makers and hobbyists. You can create custom parts and improve your skills. Start by learning basic CAD software and exploring tutorials online. By designing your own lathe, you gain valuable experience and creativity. Dive into projects that excite you, and enjoy the journey of building and learning!

FAQs

What Software Options Are Best Suited For Designing A Diy Metal Lathe In Cad?

To design a DIY metal lathe, you can use several software options. Free programs like Tinkercad and SketchUp are great for beginners. They are easy to learn and fun to use. For more advanced designs, you might try Fusion 360. It has lots of tools to make detailed plans. Choose the one that feels best for you!

What Are The Key Design Considerations When Creating A Cad Model For A Metal Lathe?

When you create a Computer-Aided Design (CAD) model for a metal lathe, think about size first. Make sure everything fits together well. You also need to choose the right materials. This helps the lathe work better and last longer. Finally, remember how parts move and fit as you design. This way, the metal lathe can do its job smoothly.

How Can I Ensure That My Cad Design Accounts For Necessary Tolerances And Clearances In A Metal Lathe?

To make sure your CAD design fits a metal lathe, you should check the size of each part. First, look up the measurements for your lathe. Then, add extra space for moving parts. This extra space is called clearance. Finally, always double-check your design before you start making anything!

Are There Existing Cad Templates Or Libraries That Can Help Streamline The Design Process For A Diy Metal Lathe?

Yes, there are CAD templates and libraries you can use for designing a DIY metal lathe. CAD stands for Computer-Aided Design. These templates can help you save time and follow good designs. You can find them online for free or purchase them. Using these tools makes it easier to create your lathe.

What Kind Of Materials Should Be Specified In The Cad Design For A Robust And Durable Diy Metal Lathe?

For a strong and lasting DIY metal lathe, you should pick good materials. Use solid steel for the main parts. Steel is tough and can handle lots of work. Choose sturdy aluminum for lighter pieces. It’s easy to shape and helps reduce weight. You can also use tough plastic for some smaller parts.