Have you ever wanted to create your own tools? Imagine making a metal lathe chuck with your own hands! What if you could craft something that fits perfectly with your projects? It’s easier than you think!

A DIY metal lathe chuck not only helps you hold your materials but also teaches you about machining. Did you know that the chuck is one of the most important parts of a lathe? It keeps your workpiece steady and safe. Without it, everything can spin out of control! Imagine the pride you would feel using something you built yourself.

This article will guide you through the exciting world of making metal lathe chucks. Get ready to discover tips, tricks, and the tools you’ll need. Let’s dive into the art of creating a chuck that will wow your friends and improve your projects!

Diy Metal Lathe Chuck: Create Your Own Precision Tool

Creating your own DIY metal lathe chuck can be a fun and rewarding project. A chuck helps hold your workpiece steady while you shape it. Fun fact: many metalworkers start with a basic design and customize it to their needs! First, gather materials like scrap metal and clamps. Carefully plan your design, then cut and assemble the pieces. With a little patience, you’ll have a custom tool that enhances your metalworking skills! Why not give it a try?

What is a Metal Lathe Chuck?

Definition and function of a metal lathe chuck. Importance in precision machining practices.

A metal lathe chuck is a device that holds materials, like metal or wood, while they spin on a lathe. Think of it as a friendly hug that keeps everything in place! This tool is essential in precision machining. It helps create exact shapes and smooth surfaces. Without a good chuck, your projects might end up looking like a lopsided pancake.

| Function | Importance |

|---|---|

| Holds materials securely | Improves accuracy in shaping |

| Enables smooth rotation | Prevents errors in measurements |

In short, a metal lathe chuck is a star player in the machining game. You need it for a successful project, or your results might just be a little too ‘wobbly’! And remember, a steady chuck means a happy craftsman!

Materials Needed for DIY Metal Lathe Chuck

List of essential materials and tools required. Recommendations on where to source materials.

To build your own metal lathe chuck, you’ll need some basic materials and tools. First, grab some metal blocks. Aluminum or steel works best. A drill, a set of chisels, and a hacksaw will also be your best buddies. Don’t forget to snag a few bolts and nuts! Find these at your local hardware store or online. Now, let’s take a look at the essentials:

| Material/Tool | Recommended Source |

|---|---|

| Metal Blocks | Local Hardware Store |

| Drill | Online Retailers |

| Chisels | Tool Shops |

| Hacksaw | Home Improvement Stores |

| Bolts and Nuts | Any Hardware Store |

With these supplies, you’ll be ready to work your magic. Remember, safety first! Always wear your goggles. You wouldn’t want flying metal to interrupt your DIY adventure!

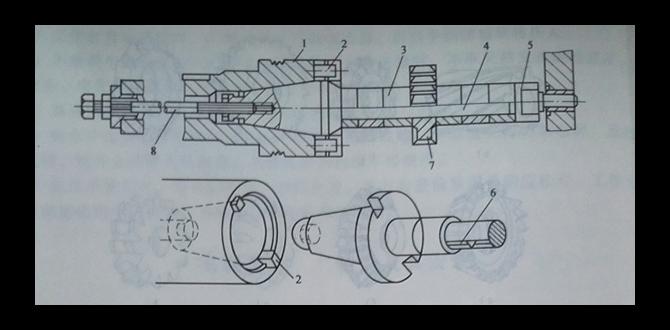

Step-by-Step Guide to Building a Metal Lathe Chuck

Detailed instructions for creating a threejaw chuck. Safety precautions and best practices during assembly.

Building a three-jaw chuck can be fun and rewarding! Start by gathering materials and tools. You’ll need metal pieces, screws, and a lathe. Make sure to wear safety goggles. No one wants a surprise visit to the eye doctor! Follow the steps carefully to assemble each jaw. Keep your fingers safe; they’re not tools! Below is a handy table for your reference:

| Step | Action |

|---|---|

| 1 | Gather materials. |

| 2 | Cut metal pieces to size. |

| 3 | Drill holes in each piece. |

| 4 | Attach jaws with screws. |

| 5 | Test your chuck! |

Remember to double-check your work. It’s better to be safe than sorry! With patience and care, you’ll create a metal lathe chuck that’s the star of your shop. Who knows? Maybe it will even show off its “metal” skills like a pro!

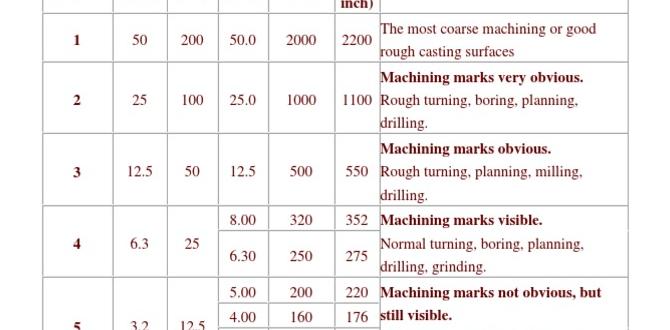

Tips for Enhancing Chuck Performance

Methods for achieving greater accuracy and gripping power. Maintenance tips for prolonging the life of the chuck.

To improve your chuck’s performance, focus on two key areas: accuracy and grip. Check the alignment of the chuck regularly. Ensure it is mounted tightly and straight. You can increase gripping power by cleaning the jaws and using a soft cloth for extra grip. For maintenance, keep it free from dust and oil. Here are some quick tips:

- Check and tighten screws often.

- Lubricate with light oil.

- Store in a dry place.

Following these steps will help your chuck work better and last longer!

How do I achieve better gripping power with my chuck?

Regularly clean jaws and apply light oil for a stronger grip.

Troubleshooting Common Issues

Identifying and fixing alignment problems. Solutions for restoring gripping force.

Have you ever felt like your metal lathe chuck is playing hard to get? Sometimes, alignment problems sneak in like a cheeky raccoon. To fix this, check the faceplate and center the chuck properly. If it still doesn’t hold tight, it might be time to give it a cleanser—rust can ruin the fun! It’s like a tight hug; no one likes a slippery squeeze!

| Issue | Solution |

|---|---|

| Alignment Problems | Check and adjust the faceplate. |

| Weak Gripping Force | Clean rust and debris for better contact. |

Remember, a happy lathe chuck means a happy machinist. Keep it aligned and clean for the best results!

Applications of DIY Metal Lathe Chucks

Common projects and tasks that benefit from using chucks. Case studies of successful DIY chuck implementations.

DIY metal lathe chucks are handy tools for many projects. They help in saving time and improving accuracy. Here are some common tasks that benefit from using chucks:

- Making custom parts for machines.

- Creating furniture or decorative items.

- Building prototypes for new designs.

People have successfully made chucks for their lathes, which improved their work. For instance, one hobbyist created a custom chuck for turning wood bowls. This made a huge difference in quality. Another builder crafted a chuck for metalworking, enhancing precision. These stories show how DIY chucks can transform projects.

What are some examples of DIY chuck projects?

Common examples include woodturning, metal shaping, and model building. Each project uses the chuck to hold material tight, ensuring a great finish.

Community Resources and Support

Online forums and groups for DIY enthusiasts. Recommended books and tutorials for further learning.

Connecting with others can make DIY projects fun and easier. Online forums and groups offer a great way to learn. You can share tips and ask questions from fellow DIY lovers. Here are some helpful resources:

- Facebook groups for DIY metal lathe projects.

- Reddit communities focused on metalworking.

- YouTube channels with tutorials and reviews.

Books can provide even more knowledge. Look for guides with step-by-step instructions. Check out your local library or online stores for popular titles.

What are some useful resources for DIY enthusiasts?

Online forums, groups, and books offer support and knowledge. These resources help you learn and create with others.

Conclusion

In summary, a DIY metal lathe chuck can save you money and enhance your projects. You can create custom parts and improve precision. Remember to choose the right materials and follow safety guidelines. Now that you know the basics, consider trying it out or reading more about metalworking. Get started on your next project today!

FAQs

What Materials Are Best Suited For Building A Diy Metal Lathe Chuck?

To build a DIY metal lathe chuck, you can use strong materials like steel or aluminum. Steel is tough and can handle heavy work. Aluminum is lighter and easier to shape, which makes it good for smaller projects. You will also need screws and other parts that hold everything together.

How Do You Accurately Align A Diy Lathe Chuck To Ensure Precision Machining?

To align a DIY lathe chuck, start by checking its mounting. You can use a dial indicator to see if it spins straight. Adjust the chuck gently using the screws until it is level. Make sure everything is tight before you start machining. Always double-check your alignment for the best results!

What Are The Different Types Of Diy Lathe Chucks, And How Do Their Designs Affect Machining Capabilities?

There are different types of DIY lathe chucks. The most common ones are three-jaw and four-jaw chucks. A three-jaw chuck is easy to use and holds round pieces well. A four-jaw chuck is more precise for square or odd-shaped items. The design of the chuck affects how well we can hold and shape our materials. Using the right chuck helps us make better projects!

What Tools And Techniques Are Required To Create A Functional And Durable Metal Lathe Chuck At Home?

To make a metal lathe chuck at home, you will need a few tools. Use a drill for making holes. A file helps smooth rough edges. You might need a hacksaw to cut metal pieces. Finally, use wrenches to tighten screws. Make sure to measure everything carefully to fit them together right!

What Safety Precautions Should Be Taken When Using A Diy Lathe Chuck In Metalworking Projects?

When using a DIY lathe chuck, always wear safety goggles to protect your eyes. Keep your hair tied back and wear tight clothing to avoid getting caught in the machine. Make sure your hands are clear of the spinning parts. Check that everything is secure before starting. If something feels wrong, turn off the machine immediately.