Have you ever wanted to make your own tools? Imagine turning metal into beautiful parts for your projects. A DIY metal lathe power feed can help you do just that!

With a power feed, you can create smooth and precise cuts. This tech makes it easier and faster. Why struggle with manual feeds when you can let a machine do the hard work? Think about the time you could save!

Did you know that many hobbyists and makers are building their own metal lathes? It’s true! A DIY approach can teach you amazing skills while saving money. You’ll feel like a real engineer!

In this article, we’ll explore how to create your own DIY metal lathe power feed. You’ll learn the steps, the materials you need, and some tips to make it fun. Let’s dive into this exciting project together!

Diy Metal Lathe Power Feed: Enhance Your Machining Skills

Creating a DIY metal lathe power feed can transform your projects. Imagine the precision it offers with less manual effort! First, you’ll learn how different motors can enhance your lathe’s functionality. Choosing the right components is crucial. Many builders use simple tools you might already have at home. Did you know that adding a power feed can double your productivity? Embrace the challenge and enjoy crafting your unique setup!

Understanding Metal Lathe Power Feed

Definition and importance of power feed in metal lathes. Benefits of using a power feed vs. manual operation.

Power feed is a system that moves the workpiece on a metal lathe automatically. This is important because it saves time and effort. Unlike manual operation, power feed allows for smoother and more consistent cuts. You can work longer without tiring as it reduces fatigue. Here are some benefits of using a power feed:

- Increased accuracy

- Less manual effort

- Consistent speed

- Better surface finish

In short, using a power feed can make your projects easier and more efficient!

What is the importance of a power feed in metal lathes?

The importance of a power feed lies in its ability to enhance precision and reduce manual workload. This tool improves efficiency in metalworking tasks, making it indispensable for hobbyists and professionals alike.

Key Benefits of Power Feed:

- Saves Time: You complete tasks faster.

- Reduces Errors: Fewer mistakes in cuts.

- Increases Productivity: More projects done.

Step-by-Step Guide to Building a DIY Metal Lathe Power Feed

Tools and materials needed for construction. Detailed assembly instructions with diagrams.

To build your own metal lathe power feed, you will need some basic tools and materials. Here’s a simple list:

- Metal lathe

- Power drill

- Wrenches

- Power feed motor

- Drive pulleys

- Belts

- Support brackets

- Wiring

Follow these assembly steps:

- Attach the power feed motor to your lathe.

- Connect the drive pulleys using the belts.

- Secure the support brackets in place.

- Wire the motor according to the diagrams provided.

- Test it to ensure everything works smoothly.

With patience, you’ll have a working power feed!

What tools do I need for building a DIY metal lathe power feed?

You will need a metal lathe, power drill, wrenches, and a power feed motor among others. Each tool helps in making your project easier and more efficient.

Installation Process of Your DIY Power Feed

Preparations required before installation. Stepbystep installation guide on various lathe models.

Before you install your power feed, make sure you’re ready. Gather the right tools and materials. You’ll need a wrench, screws, and your power feed kit. Clear the area around your lathe. This helps you work better and safely.

Now, let’s look at how to install it step by step:

- Remove the old hand crank.

- Attach the power feed unit.

- Connect the wiring carefully.

- Test the connection before using.

Each lathe model may have slight differences. Always check the manual for specific steps.

What tools do I need for installation?

You need basic tools like a wrench, screwdriver, and the parts from the power feed kit.

Following these tips will help you set up your diy metal lathe power feed smoothly. Happy machining!

Tuning and Calibration for Optimal Performance

Importance of tuning for accuracy and efficiency. Tips for properly calibrating the power feed.

Tuning your metal lathe power feed is crucial. It helps make your work precise and fast. When you calibrate correctly, you save time and material. Here are some tips for tuning:

- Check the alignment of gears and belts.

- Adjust the feed rate to match your project needs.

- Test the machine with scrap materials first.

- Regularly clean and lubricate moving parts.

These steps ensure you get the best performance. Remember, a well-tuned lathe is a happy lathe!

Why Is Tuning Important?

Tuning ensures your metal lathe operates correctly and safely. It improves accuracy and can help you finish tasks quicker. A small adjustment can make a big difference in your projects.

Common Issues and Troubleshooting

Typical problems faced with DIY power feeds. Solutions and tips for effective troubleshooting.

DIY power feeds can be a real treat, but they also come with hiccups. Common issues include slipping, noise, or inconsistent speed. Don’t panic! You can fix these with some simple checks. Always ensure connections are tight and clean. If it’s noisy, maybe it needs a bit of lubrication or some gentle tapping. Sometimes it’s like your lathe’s just cranky and needs a snack—argh, machines!

| Problem | Solution |

|---|---|

| Slipping | Check and tighten connections |

| Noisy operation | Lubricate moving parts |

| Inconsistent speed | Inspect the motor and wiring |

Remember, even the toughest machines need some TLC. Troubleshooting can be fun, like a puzzle! So grab your tools, and let’s make those issues disappear. Who knew fixing things could lead to less hair-pulling and more “Aha!” moments?

Enhancing Your DIY Metal Lathe with Additional Upgrades

Optional features to consider for improved performance. Recommendations for safety enhancements.

Upgrading your DIY metal lathe can make it work even better! Consider adding features like digital readouts. They help you measure accurately and save time. For safety, always use guards around sharp areas. Don’t forget about emergency stop buttons—they’re like the superhero of your setup! Remember, safety first means you can keep turning metal without turning into a metal pancake.

| Optional Features | Safety Enhancements |

|---|---|

| Digital Readouts | Guards on Sharp Edges |

| Power Feed System | Emergency Stop Buttons |

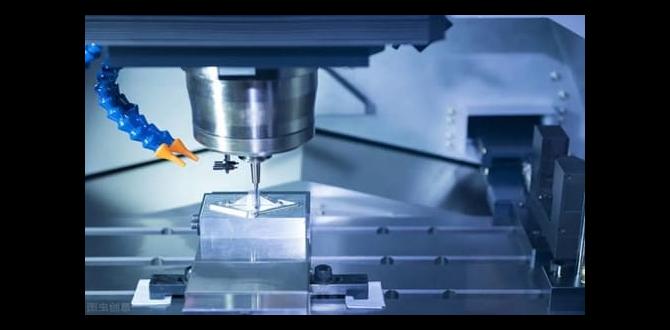

Real-Life Applications of DIY Power Feed in Metalworking

Examples of projects benefiting from power feed utilization. User testimonials and case studies.

In metalworking, a DIY power feed can make many projects easier and faster. For example, it helps smooth out long cuts and makes precise shapes. Users have shared that it improved their workflow and reduced tiredness. Here are some popular projects:

- Creating custom gears.

- Making parts for machines.

- Turning wood for crafts.

Testimonials reveal they achieved better results with power feeds. Many say it’s a game changer in their workshops.

What are some benefits of using a DIY power feed?

DIY power feeds improve precision and reduce labor, making projects easier and quicker.

Resources for Further Learning and Support

Recommended books, online courses, and forums. Community resources for DIY metalworkers.

Many resources can help you dive deeper into DIY metalworking. First, there are great books filled with tips, tricks, and fun project ideas. Think of them as your personal metalworking cheerleaders! Online courses can also guide you step-by-step without any messy paperwork. Plus, you can join forums where fellow metalworkers share secrets, support, and sometimes even bad puns! Here’s a handy table to get you started:

| Resource Type | Examples |

|---|---|

| Books | “The Metal Lathe” by Dave Gingery |

| Online Courses | Udemy Metalworking Courses |

| Forums | Home Machinist Forum |

These tools will help you become a metalwork wizard faster than you can say “sawdust!”

Conclusion

In summary, a DIY metal lathe power feed can make your projects easier and more accurate. You can save time and improve your work quality. Start experimenting with simple designs or modifications. Remember, practice is key to mastering this tool. We encourage you to explore more resources online to expand your knowledge and skills in metalworking!

FAQs

What Materials And Components Are Essential For Building A Diy Power Feed System For A Metal Lathe?

To build a DIY power feed system for a metal lathe, you need a few important parts. First, get a small electric motor to power the movement. You’ll also need a belt or chain to connect the motor to the lathe. Adding some gears can help control the speed. Finally, use a switch to turn the system on and off easily.

How Can You Design A Power Feed Mechanism To Ensure Precise And Consistent Feed Rates For Various Metal Lathe Operations?

To design a power feed for a metal lathe, you can use a motor to control the speed. First, we can add gears. Gears help change the speed of the motor to make it go faster or slower. Next, a control system lets you adjust the speed easily. Finally, we must test the feed rates to make sure they are steady for different metal jobs. This way, we can make nice and accurate parts!

What Motor Options Are Available For Powering A Diy Metal Lathe Power Feed, And How Do You Determine The Appropriate Specifications?

For a DIY metal lathe power feed, you can use a small electric motor or a stepper motor. Electric motors spin continuously, while stepper motors move in steps. To pick the right motor, think about how fast you want it to go and how much power you need. You should also check how heavy the parts are that the motor will move. Always make sure the motor fits your lathe properly.

What Are The Common Challenges Faced When Implementing A Power Feed On A Diy Metal Lathe, And How Can They Be Overcome?

When adding a power feed to a DIY metal lathe, you might face a few challenges. First, getting the right parts can be hard. You can solve this by checking online or local stores for supplies. Second, wiring might be confusing. To fix this, follow clear guides or ask someone for help. Lastly, you may need to adjust settings to get everything working right. Experimenting and being patient can help you through this.

How Can You Integrate A Control System For Variable Speed Adjustments In A Diy Metal Lathe Power Feed Setup?

To add a control system for changing speeds on your DIY metal lathe, you can use a speed controller. First, get a basic speed controller that fits your motor. Then, connect the controller to the power source and the motor. Next, test it to see if you can change the speed. Now you can adjust how fast your lathe moves!