The drill chuck for your lathe tailstock is a simple yet crucial tool that expands your lathe’s capabilities dramatically, allowing for precise drilling and more without complex setups. It’s an absolute must-have for any beginner looking to get the most out of their machine.

Ever found yourself wishing your trusty lathe could do more than just turn? Maybe you’ve pictured drilling perfectly centered holes right on the workpiece or holding a special tool securely in place. If so, you’ve likely come across the idea of a drill chuck for your lathe’s tailstock. It sounds simple, but for beginners, knowing how to use it and why it’s so important can make a world of difference. It unlocks a whole new level of accuracy and versatility, turning your lathe from a turning machine into a much more capable workshop companion. Don’t worry if it seems a bit technical at first; I’m here to break down exactly what it is, why you absolutely need one, and how to get the most out of it, step by step.

What is a Lathe Tailstock Drill Chuck?

At its core, a drill chuck for a lathe tailstock is a versatile attachment designed to hold and rotate drill bits, reamers, taps, or even small boring bars precisely. Think of it as a specialized clamp that grips the shank of your cutting tool, allowing you to use your lathe’s tailstock to feed that tool into a spinning workpiece. Unlike a standard drill press chuck, this one is specifically designed to be mounted to the tailstock quill, enabling you to position the cutting tool with the accuracy and control your lathe provides.

The tailstock itself is the part of the lathe that typically moves along the bed and can be locked in place to support the workpiece or hold this drill chuck. When you advance the tailstock quill using its handwheel, you’re directly feeding the drill bit or other tool into your spinning project. This setup is fantastic for creating precise center holes, drilling cross-holes, or reaming holes to exact sizes.

Key components of a drill chuck include:

- Jaws: These are the movable parts that grasp the tool shank. Most common drill chucks have three or four jaws.

- Sleeve/Barrel: This is the part you turn to open or close the jaws.

- Keyhole: The slot where you insert the chuck key.

- Shank: The part of the chuck that fits into the tailstock quill. This is often a Morse taper, like the inside of the tailstock quill, allowing for a secure, self-ejecting fit.

Why is a Drill Chuck Essential for Your Lathe Tailstock?

For anyone serious about precision work or simply looking to expand their lathe’s capabilities, a drill chuck for the tailstock isn’t just a nice-to-have; it’s a fundamental necessity. Here’s why:

- Unmatched Precision for Drilling: The primary advantage is the ability to drill perfectly centered holes. By mounting the workpiece securely in the lathe’s headstock chuck and the drill bit in the tailstock drill chuck, you ensure that the drill bit enters the workpiece exactly at its center. This is crucial for many projects, from creating dowel joints to drilling pilot holes for screws or tap holes.

- Versatile Tool Holding: Beyond just drill bits, these chucks can hold a variety of other tools. This includes:

- Reamers: For finishing holes to a very precise size and smooth surface.

- Taps: For cutting internal threads. This is a game-changer for creating tapped holes directly on your lathe without needing a separate tapping jig.

- Small Boring Bars: For precise internal diameter adjustments on larger holes.

- Countersinks and Center Drills: For creating precisely located pilot holes and chamfered starting points.

- Improved Accuracy and Repeatability: The solid connection between the tailstock quill and the drill chuck, combined with the lathe’s stable bed, allows for highly repeatable results. Once you set up a specific drilling depth or location, you can achieve that same result again and again.

- Enhanced Safety: Securely holding tools in a drill chuck reduces the risk of them spinning loose or vibrating erratically, which can be dangerous. A well-gripped tool is a safer tool.

- Streamlined Workflow: Instead of removing a workpiece to drill or tap on another machine, you can often perform these operations directly on the lathe. This saves significant time and reduces the chances of misalignment when re-chucking the part.

- Cost-Effective Tool Integration: Purchasing a drill chuck is a relatively inexpensive way to integrate a wide range of metalworking and woodworking operations onto your lathe, without needing to buy specialized machines for each task.

Types of Drill Chucks for Lathe Tailstocks

While the concept is simple, drill chucks come in a few varieties, and understanding them helps you choose the right one. The most common types you’ll encounter for lathe tailstocks are:

1. Keyed Drill Chucks

These are the most traditional and widely used type. They rely on a chuck key to tighten and loosen the jaws.

- How they work: A chuck key is inserted into one of several holes around the chuck’s body. Turning the key engages a gear mechanism that moves the jaws inward to grip the tool or outward to release it.

- Pros:

- Robust and durable.

- Excellent gripping power.

- Generally more affordable.

- Provide positive locking, reducing the chance of slippage under load.

- Cons:

- Requires a separate chuck key, which can be misplaced.

- Can be slower to operate than keyless chucks.

- Ensuring even pressure across all jaws requires deliberate tightening with the key.

- Shank Types: Most keyed chucks for lathe tailstocks will feature a Morse taper shank (MT1, MT2, MT3, etc.) to directly interface with the tailstock quill.

2. Keyless Drill Chucks

These chucks have become increasingly popular due to their ease of use and speed.

- How they work: You simply grip the outer sleeve or collar of the chuck and twist to tighten or loosen the jaws. The body of the chuck remains stationary, while the sleeve rotates.

- Pros:

- Extremely fast and convenient to operate.

- No need for a separate key.

- Often provide very even jaw pressure due to their design.

- Good for quick tool changes.

- Cons:

- Can be more expensive than keyed chucks.

- May not offer the same extreme gripping force as a well-tightened keyed chuck for very heavy-duty applications, though high-quality ones are very capable.

- Some users find them slightly less “positive” in their lock.

- Shank Types: Similar to keyed chucks, keyless variants will also typically have a Morse taper shank.

3. Jacobs Chucks (Brand Specific)

While not a separate type of mechanism, “Jacobs” is a highly reputable brand known for producing excellent quality drill chucks in both keyed and keyless designs. Many machinists swear by their durability and precision. When you see a “Jacobs” chuck, you’re often looking at a premium, reliable option.

Choosing the Right Drill Chuck for Your Lathe

When selecting a drill chuck for your lathe’s tailstock, several factors come into play. Getting this right ensures you have a tool that fits your lathe, your common tasks, and your budget.

| Factor | Considerations for Your Lathe |

|---|---|

| Morse Taper Size | This is paramount! Your tailstock quill has a specific Morse taper (MT). Common sizes are MT1, MT2, and MT3. You need a drill chuck with a shank that matches your quill’s taper size. For example, if your tailstock quill is MT2, you need an MT2 drill chuck. Check your lathe’s manual or measure the taper in the quill. A mismatched taper won’t fit securely and can be dangerous. Understanding Morse Taper Sizes can be very helpful. |

| Capacity (Drill Size Range) | Drill chucks are rated by the smallest and largest diameter shank they can securely grip. Common ranges are 1/16″ to 1/2″ (1.5mm to 13mm) or 1/8″ to 5/8″ (3mm to 16mm). Consider the typical size of drill bits you’ll be using for your projects. Most common lathe projects will fit within the 1/16″ to 1/2″ range. |

| Keyed vs. Keyless | As discussed, keyed chucks are often robust and affordable, while keyless chucks offer speed and convenience. For general hobbyist use, either is fine. If you do a lot of quick tool changes or value speed, keyless is a great choice. For maximum grip and lower cost, keyed is excellent. |

| Brand and Quality | Reputable brands like Jacobs, Bison, Albrecht, or even good quality import brands (check reviews!) offer better durability, accuracy, and a more consistent grip. While you can find very cheap chucks, they often compromise on precision and longevity, which can lead to frustration, poor results, and safety issues. Investing a bit more in a quality chuck pays off. |

| Intended Use | Are you primarily drilling small holes, or will you be reaming or tapping larger ones? For general drilling, a standard chuck is perfect. If you plan on frequent tapping, ensure the chuck has a good grip suitable for the torque involved. |

How to Install a Drill Chuck on Your Lathe Tailstock

Installing a drill chuck onto your lathe’s tailstock is a straightforward process, and it’s usually a one-time setup unless you have multiple chucks. The critical part is ensuring the taper size matches. For this guide, we’ll assume you have a drill chuck with a Morse taper shank and a tailstock quill with a corresponding Morse taper socket.

Tools You’ll Need:

- Your Drill Chuck with matching Morse Taper Shank

- A soft mallet or a block of wood (optional, for gentle persuasion)

- A clean rag

- A chuck key (if using a keyed chuck)

Step-by-Step Installation:

-

Clean the Taper Surfaces: Thoroughly clean both the Morse taper shank of the drill chuck and the inside of the tailstock quill with a clean rag. Any dirt, grime, or old lubricant can prevent a snug fit and lead to runout (wobble).

-

Identify the Taper Size: Double-check that the taper on your drill chuck matches the taper in your tailstock quill. They should correspond (e.g., MT2 on the chuck shank, MT2 in the quill). If they don’t match, DO NOT force it. You have the wrong chuck for your tailstock.

-

Insert the Chuck: Gently guide the Morse taper shank of the drill chuck into the tailstock quill. It should slide in smoothly with minimal resistance. A proper Morse taper is slightly undersized to allow for a snug, friction fit. It should seat itself in the quill.

-

Seat the Chuck (If Necessary): If the chuck doesn’t seem fully seated, you can gently tap the chuck’s taper shank with a soft mallet or a wooden block. Strike it squarely to ensure it seats evenly. The goal is to get a solid, metal-to-metal contact without damaging the tapers. Some tailstocks have a knockout bar or mechanism; consult your lathe’s manual on the proper way to eject the taper if needed.

-

Secure the Chuck: Once seated, the drill chuck is held in place by the friction fit of the Morse taper. There are no screws or clamps needed at this stage. The taper itself provides the secure mounting. If you needed to eject it later, you’d typically use a drift or the lathe’s knockout mechanism.

-

Test for Runout (Optional but Recommended): With the chuck installed, you can grab a dial indicator and, if desired, check for runout. Mount the indicator on your lathe’s toolpost and touch the indicator tip to the chuck’s jaws near their center. Advance the tailstock quill so the chuck is snug against the indicator rod and zero the indicator. Rotate the chuck by hand; any significant deflection indicates the taper seating might not be perfect or the chuck itself has runout.

Your drill chuck is now installed and ready to accept tools! Remember to always ensure a clean taper fit for the best results.

How to Use a Drill Chuck for Drilling and More

Now that your drill chuck is installed, let’s put it to work! Using it effectively involves a few key principles for accuracy and safety.

1. Preparing Your Workpiece and Lathe

- Secure the Workpiece: Ensure your workpiece is held very securely in the headstock chuck. For drilling operations, particularly off-center, a robust grip is essential.

- Align the Tailstock: Position the tailstock along the lathe bed. For drilling holes perfectly perpendicular to the lathe’s axis, ensure the tailstock is perfectly aligned with the headstock. You can test this by running a live center (or a pointed tool in the drill chuck) out to the face of the workpiece. If it marks perfectly concentric, you’re aligned. Many lathes have alignment screws for this on the tailstock base.

- Set the Tailstock Position: Move the tailstock up to the desired position along the bed, close enough to the workpiece for the drill bit to reach comfortably. Lock the tailstock securely in place.

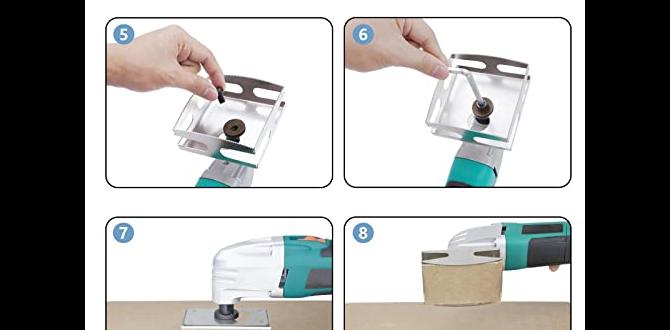

2. Installing a Tool (Drill Bit Example)

This is where operating the chuck itself comes in.

For Keyed Chucks:

- Insert the Drill Bit: Open the jaws of the drill chuck by turning the sleeve counter-clockwise with your fingers as far as it will go. Insert the shank of your drill bit into the center of the opened jaws.

- Grip the Tool: Turn the chuck sleeve clockwise with your fingers to close the jaws around the drill bit shank.

- Final Tightening: Insert the chuck key into one of the keyholes. Apply firm, even pressure to tighten the jaws. Turn in small increments, moving from one keyhole to another, around the chuck. Alternate between keyholes to ensure all three (or four) jaws tighten evenly, applying consistent gripping pressure. Overtightening can damage the chuck or the drill bit; the goal is a secure grip that won’t slip.

For Keyless Chucks:

- Open the Jaws: Grip the outer sleeve of the keyless chuck. Most will need to be twisted counter-clockwise to open the jaws fully.

- Insert the Drill Bit: Place the shank of the drill bit into the center of the opened jaws.

- Grip the Tool: Grip the outer sleeve firmly and twist clockwise. You’ll feel the jaws close around the drill bit. Many keyless chucks have an integrated mechanism that provides good grip without needing excessive force. Some higher-end ones might have a tightening assist feature.

3. Drilling the Hole

- Advance the Tailstock: Slowly advance the tailstock quill using its handwheel.