Imagine you’re building a birdhouse. You want to make perfect cuts. But wait—should you use an end mill or a router bit? These tools sound similar, but they have unique uses. Let’s explore how they differ. Picture a chef with the right knife for every dish. The same goes for woodworkers and their tools. Choosing between an end mill and a router bit can change the whole game. Have you ever wondered why some cuts are smoother? Or why one tool might last longer? It might surprise you to know that a small difference in shape makes a big impact. Did you know some end mills can dance through metal, while router bits love wood? As we dive in, you’ll learn which tool fits your needs best.

End Mill Vs Router Bit: Key Differences Explained

End Mill vs Router Bit: What’s the Difference?

Ever wonder how craftsmen turn raw materials into beautiful creations? It often starts with tools like end mills and router bits. Though they look similar, they have different uses. An end mill carves through hard metals with precision, perfect for detailed projects. On the other hand, a router bit shapes wood and plastic, suitable for decorative work. Knowing the difference enhances craftsmanship skills. Which tool will you choose for your next masterpiece?What is a Router Bit?

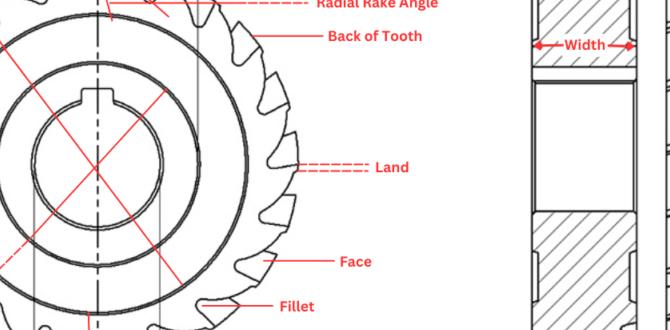

Description of router bits and their functional design. Types of router bits and their specific uses. Materials and construction of router bits.What is a Router Bit?

Router bits are like special tools for shaping wood. They come in different shapes and sizes for different jobs. These tools cut curves, edges, and other shapes in wood. There are many types, such as:

- Straight bits: used for making straight cuts.

- Flush trimming bits: help trim edges.

- Rabbeting bits: create steps or grooves.

Router bits are made from strong materials like carbide or steel. This makes them tough and long-lasting. They are really handy for carpenters and woodworkers to make furniture look nice!

End Mill vs Router Bit: Key Differences

Cutting techniques and capabilities. Speed and efficiency considerations. Tool design and structural differences.End mills and router bits may seem like tools from a sci-fi movie, but they are actually used for cutting. Now, let’s enter their world! End mills can cut sideways, up, down, and all around. They are like the ninjas of the tool world. Router bits, on the other hand, are experts in smooth, curved edges and are often found in woodworking. They go round and round like a merry-go-round.

When it comes to speed, end mills are fast but need to be treated like sports cars, while router bits are like bicycles—steady and on the go. As for design, end mills look like serious drill bits in suits, with many flutes. Router bits are more casual, with various shapes, kind of like a Swiss Army knife for wood.

| Feature | End Mill | Router Bit |

|---|---|---|

| Cutting Style | All directions | Primarily lateral |

| Common Use | Metal, Plastic | Wood, Laminates |

| Speed | Fast | Moderate |

| Design | Fluted, angled | Diverse profiles |

If you’re wondering, “Can I switch one for the other?” The answer is, not always. Each shines in its own game. Just remember, while both end mills and router bits have their talents, choosing the right one can be as crucial as picking socks for your shoes. As experts often say, “The right tool makes all the difference.”

Choosing the Right Tool for Your Project

Factors to consider when selecting between an end mill and a router bit. Material types and their compatibility with each tool. Project scale and precision requirements.Picking between an end mill or a router bit can feel like choosing your favorite ice cream flavor. It depends on several things. What are they, you ask? First, look at your project’s material. Are you working with wood, metal, or plastic? Each tool has its friendlier materials. End mills are metal experts, while router bits love wood and plastic. Second, think about how detailed your work needs to be. If it’s as precise as a cat landing on its feet, an end mill might suit you better. For larger, simpler projects, go with a router bit. Size matters, too! Big tasks need robust tools, while tiny details may require a gentler touch. Remember, even the best chef chooses the right knife for the job!

| Factor | End Mill | Router Bit |

|---|---|---|

| Material Compatibility | Metal-friendly | Loves wood and plastic |

| Project Precision | Great for detailed work | Ideal for larger projects |

| Project Scale | Suitable for small, intricate tasks | Handles big jobs well |

Common Mistakes in Tool Selection and Use

Misapplications and their consequences. Tips to avoid damaging workpieces and tools. Best practices for maintenance and longevity.Choosing the wrong tool can lead to mistakes. Using the wrong end mill or router bit can harm your work. It can also damage the tools. This happens due to the incorrect speed or depth settings.

- Misapplications and Consequences: Choosing the wrong bit can ruin your project. It can also dull the tool fast.

- Tips to Avoid Damage: Check the tool size. Use the right speed. Match the tool to the job.

- Maintenance and Longevity: Clean tools after use. Store them properly. Have them sharpened regularly.

What happens if you use the wrong tool?

Using the wrong tool often leads to poor results. It can scratch or break the workpiece. It can also wear out the tool quickly.Common Scenarios:

- Wrong tool: Jagged edges or uneven cuts.

- Mismatched speed: Burn marks on the workpiece.

Choosing the right tool keeps your project smooth. It ensures longer tool life. As a quote puts it, “The right tool for the right job.” Always remember! Proper care makes your work easier and more fun.

Case Studies and Usage Scenarios

Realworld applications of end mills in manufacturing. Examples of router bits in wood and acrylic projects. Comparative analysis of tool performance in different scenarios.In manufacturing, end mills are like the cool kids on the block. They are used in machining to cut metals with precision. Tools like these can create complex shapes effortlessly. Router bits shine when you want to carve wood or acrylic into pretty designs. They’re like magic wands for personal projects. Comparing these tools is like comparing superheroes. End mills are speedy with metal, while router bits handle wood with elegance. Choosing the right hero depends on your mission!

| Tool | Best Use |

|---|---|

| End Mill | Metalworking |

| Router Bit | Woodworking |

FAQs About End Mills and Router Bits

Answers to common questions from DIY enthusiasts and professionals. Clarifications on misconceptions and myths about each tool.What are common misconceptions about end mills and router bits?

Many think that end mills and router bits are the same. But they have key differences. An end mill is mostly for precision cutting on metal and harder materials. A router bit is typically for woodwork, creating shapes and designs. They are designed differently too. End mills have a flat tip, while router bits are often rounded or pointed.

Can I use a router bit in a milling machine?

No, it’s not safe. Router bits aren’t made for the force in milling machines. They can break, which may lead to damage or injuries. Always use the right tool for the job.

Difference in Materials:

End mills are for metal; router bits are for softer materials.

Purpose:

End mills are for precision and detail. Router bits are for shaping and cutting wood.

Choosing the right tool makes your work better and safer. Use the right tool for your job according to what you need to cut and how you need to cut it.

Conclusion

End mills and router bits are tools for cutting, each with specific uses. End mills excel in metalwork, while router bits are perfect for woods and plastics. Knowing their differences helps in picking the right tool. For deeper learning, explore more resources or try using both in projects. This will boost your skills and confidence.FAQs

What Are The Key Differences In Design And Function Between An End Mill And A Router Bit?An end mill and a router bit are tools for cutting, but they work differently. An end mill cuts metal, and a router bit cuts wood. An end mill is short and wide, but a router bit is longer and skinnier. An end mill can cut from the side and the tip, while a router bit mainly cuts from the side. They are each used for different projects based on the material they cut.

In What Scenarios Would It Be More Advantageous To Use An End Mill Over A Router Bit, And Vice Versa?Use an end mill when cutting hard materials like metal. It’s strong and can make precise cuts. Pick a router bit for softer materials like wood. It works fast and is great for shaping wood. Use the right tool to make your work easier and better!

How Do The Materials And Coatings Of End Mills And Router Bits Affect Their Performance And Longevity?The materials and coatings of end mills and router bits help them last longer and work better. Strong materials, like carbide, make the tools stay sharp and cut easily. Special coatings, like titanium nitride (TiN), reduce heat and prevent wear. This means you can use them for longer without needing new ones, saving money and time.

Can End Mills Be Effectively Used In Woodworking Applications Typically Suited For Router Bits, And What Considerations Are Needed?Yes, you can use end mills for woodworking, like you would with router bits. But, you need to be careful. Make sure the end mill is sharp and move it slowly. This helps to avoid burning the wood. Always wear safety gear to protect yourself.

What Are The Best Practices For Maintaining And Sharpening End Mills And Router Bits To Ensure Optimal Performance?To help your tools work their best, keep them clean. Wipe away dust and tiny bits after each use. Sharpen the edges with a special tool so they stay sharp. Store them in a safe place where they can’t get bumped or damaged. When you do these things, your tools will last longer and work better!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Key Differences In Design And Function Between An End Mill And A Router Bit?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “An end mill and a router bit are tools for cutting, but they work differently. An end mill cuts metal, and a router bit cuts wood. An end mill is short and wide, but a router bit is longer and skinnier. An end mill can cut from the side and the tip, while a router bit mainly cuts from the side. They are each used for different projects based on the material they cut.”}},{“@type”: “Question”,”name”: “In What Scenarios Would It Be More Advantageous To Use An End Mill Over A Router Bit, And Vice Versa?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Use an end mill when cutting hard materials like metal. It’s strong and can make precise cuts. Pick a router bit for softer materials like wood. It works fast and is great for shaping wood. Use the right tool to make your work easier and better!”}},{“@type”: “Question”,”name”: “How Do The Materials And Coatings Of End Mills And Router Bits Affect Their Performance And Longevity?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The materials and coatings of end mills and router bits help them last longer and work better. Strong materials, like carbide, make the tools stay sharp and cut easily. Special coatings, like titanium nitride (TiN), reduce heat and prevent wear. This means you can use them for longer without needing new ones, saving money and time.”}},{“@type”: “Question”,”name”: “Can End Mills Be Effectively Used In Woodworking Applications Typically Suited For Router Bits, And What Considerations Are Needed?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Yes, you can use end mills for woodworking, like you would with router bits. But, you need to be careful. Make sure the end mill is sharp and move it slowly. This helps to avoid burning the wood. Always wear safety gear to protect yourself.”}},{“@type”: “Question”,”name”: “What Are The Best Practices For Maintaining And Sharpening End Mills And Router Bits To Ensure Optimal Performance?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To help your tools work their best, keep them clean. Wipe away dust and tiny bits after each use. Sharpen the edges with a special tool so they stay sharp. Store them in a safe place where they can’t get bumped or damaged. When you do these things, your tools will last longer and work better!”}}]}