Have you ever wondered what makes a metal lathe so powerful? It’s all about the right tools. One key tool that often gets overlooked is the metal lathe controller board. This small but mighty device can change how you work with metal. Imagine being able to control your lathe with precision and ease. Sounds cool, right?

Many hobbyists and professionals rely on metal lathe controller boards. These boards help them carve, shape, and finish metal pieces more effectively. But what exactly do these boards do? They interpret commands from your computer and translate them into actions for the lathe. This means you can create amazing projects with accuracy.

Did you know that using a good controller board can boost your productivity? You’ll spend less time fixing mistakes and more time making your dreams a reality. If you’re ready to dive into the world of metalworking, understanding these essential tools is crucial. Let’s explore how the right metal lathe controller board can elevate your skills and projects!

Essential Tools: Metal Lathe Controller Board For Precision

Essential Tools for Metal Lathe Controller Board

Metal lathe controller boards are vital for any woodworking or metalworking shop. These boards manage the machine’s movements, ensuring precision. Have you ever wondered how a craftsman achieves such accuracy? A good controller board allows users to program various tasks. Some boards even come with user-friendly interfaces, making setup easier. Fun fact: using the right tools can dramatically improve project quality. With the right metal lathe controller board, anyone can unleash their creative potential!Understanding Metal Lathe Controller Boards

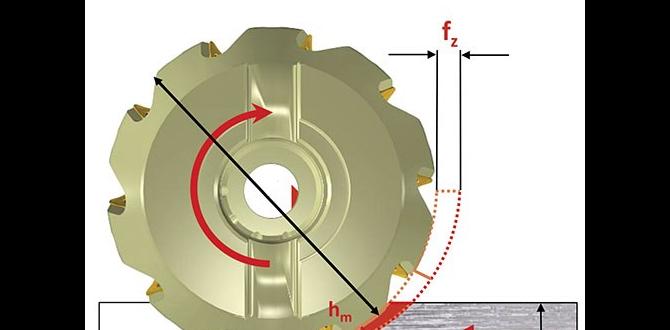

Definition and purpose of metal lathe controller boards. How they enhance lathe functionality and precision.Metal lathe controller boards are like the brains of a lathe machine. They help control the speed and direction of the cutting tools. This makes shaping metal pieces more precise. With the right controller board, you can create intricate designs that fit perfectly. Think of it as a remote control for your lathe—except it won’t fly away or run out of batteries! These boards are essential for both beginners and pros to ensure great results without the guesswork.

| Function | Benefit |

|---|---|

| Speed Control | Improves cutting efficiency |

| Precision Settings | Ensures accurate shapes |

| User Interface | Makes operation user-friendly |

Key Features of a High-Quality Metal Lathe Controller Board

Essential specifications to look for (e.g., power output, signal control). Importance of user interface and programming capabilities.Choosing a metal lathe controller board can feel like a treasure hunt. First, look for power output. A strong board can handle heavy tasks, making your projects smoother. Then, check its signal control. Think of it like having a conductor for an orchestra; precise control means better results! The user interface is key too. It should be easy to navigate, even for beginners. Lastly, consider programming capabilities—because who wants a dim-witted board? Remember, the right board can make you feel like a metal-shaping superhero!

| Feature | Importance |

|---|---|

| Power Output | Handles tougher tasks |

| Signal Control | Ensures precision |

| User Interface | Easy navigation for everyone |

| Programming Capabilities | Increases functionality |

Essential Tools for Installation and Maintenance

List of necessary tools for installing a controller board. Recommended maintenance tools to ensure longevity.When setting up a controller board, having the right tools makes a big difference. Here’s a list of must-have tools:

- **Screwdriver set**: Different sizes fit various screws.

- **Wrench**: Helps tighten parts securely.

- **Wire cutters**: Useful for cutting wires cleanly.

- **Soldering iron**: For connecting wires to the board.

- **Multimeter**: Measures voltage and checks connections.

For keeping your tools and metal lathe in shape, use:

- **Lubricants**: Keep moving parts working smoothly.

- **Cleaning brushes**: Remove dust and debris.

These tools help install and maintain your equipment. Enjoy smooth operations!

What are essential tools for maintenance?

Essential maintenance tools include lubricants, cleaning brushes, and replacement parts. These items help keep the metal lathe and controller running well.

Setting Up Your Metal Lathe Controller Board

Stepbystep guide for proper setup. Common pitfalls to avoid during installation.Setting up your metal lathe controller board can be fun. Start by reading the manual. It shows where each wire goes. Next, connect the power supply carefully. Be sure not to mix up the wires. Then, test the connections. A quick check can save time later. Finally, secure the board in place. This prevents movement while working. Avoid these common problems:

- Forgetting to power off before setup.

- Over-tightening screws.

- Ignoring safety measures.

Taking your time during setup will help you work better later on.

What are the steps to set up a metal lathe controller board?

Follow the manual, connect the wires correctly, and test everything before securing the setup.

Upgrading Your Metal Lathe Controller Board

Signs that indicate an upgrade is necessary. How to choose the best upgrade based on your lathe usage.Upgrading your metal lathe controller board can improve your machine’s performance. Watch for signs like slow operation or frequent errors. These mean it’s time to upgrade. Choosing the right upgrade depends on how you use your lathe. Consider the speed and precision you need. These points can help:

- Performance issues

- Compatibility with your lathe

- Features you desire

What are the signs that an upgrade is needed?

Signs include unexpected stops, error messages, or slower speeds.

How to choose the right upgrade?

Think about your work style. Pick features that match your tasks.

Safety Precautions When Using Metal Lathe Controller Boards

Important safety measures to consider. Tips for avoiding accidents and ensuring proper operation.Working safely with a metal lathe controller board is very important. To keep yourself and others safe, follow these key tips:

- Always wear safety goggles.

- Keep hands away from moving parts.

- Make sure to check tools before using them.

- Be aware of your surroundings.

- Read the manual carefully before starting.

These simple measures can help prevent accidents. Stay focused and never rush. Remember, safety first!

What are the key safety tips for metal lathe controller boards?

Important safety tips include wearing safety gear, keeping a clean workspace, and knowing your tools.

Frequently Asked Questions about Metal Lathe Controller Boards

Addressing common concerns and queries from users. Expert advice on troubleshooting and optimizing performance.Many users have questions about metal lathe controller boards. Understanding these tools can help you avoid problems and use them better. Here are some common concerns:

What are the main issues with metal lathe controller boards?

Common issues include connection problems, programming errors, and hardware failures. Make sure cables are connected properly. Check for bugs in your programming.

How can I improve performance?

To optimize your board, follow these tips:

- Keep software updated.

- Regularly clean connections.

- Use quality components.

Conclusion

In conclusion, a metal lathe controller board is essential for precise machining. It helps you control speed, direction, and more. Knowing the right tools improves your skills and results. If you’re interested in metalworking, consider researching different controller boards. You can also explore tutorials to enhance your understanding. Dive into this exciting field and start creating amazing projects!FAQs

Here Are Five Related Questions On The Topic Of Essential Tools For A Metal Lathe Controller Board:To control a metal lathe, you need a few important tools. First, you need a good power supply to make it work. Next, a microcontroller helps you tell the lathe what to do. You also need wires to connect everything together. Finally, some software helps you plan your projects and control the lathe easily.

Sure! Just let me know what question you want me to answer, and I’ll be happy to help.

What Are The Primary Functions Of A Controller Board In A Metal Lathe Setup?A controller board is like the brain of a metal lathe. It tells the lathe what to do and controls its parts. It helps you set the speed and direction of the cutting tool. You can also program different tasks to make your work easier and faster. Finally, it makes sure everything runs safely while you work.

Which Types Of Controller Boards Are Most Commonly Used With Cnc Metal Lathes?The most common types of controller boards used with CNC (Computer Numerical Control) metal lathes are the Arduino and Raspberry Pi. These boards help control the movements of the lathe. They take your commands and turn them into actions. Many people like these boards because they are easy to use and very popular. You can also find boards made by companies like Mach3 and LinuxCNC, which give good results.

What Features Should You Look For When Selecting A Controller Board For A Metal Lathe?When picking a controller board for a metal lathe, you should look for a few important features. First, check if it can easily connect to your computer. Next, see if it works well with the tools you want to use. You also want it to be easy to understand and set up. Finally, make sure it fits your budget.

How Does The Choice Of Controller Board Affect The Precision And Capabilities Of A Metal Lathe?The controller board is like the brain of the metal lathe. If you choose a good board, it helps the machine work accurately. This means it can make precise cuts and shapes in metal. A better board can also add more features, making it easier for you to use. So, picking the right board is important for a metal lathe’s performance.

What Are Some Common Troubleshooting Steps If A Metal Lathe Controller Board Fails To Operate Correctly?If your metal lathe controller board isn’t working, first, check if it is plugged in. Make sure all the wires are connected tightly. Next, look for any signs of damage, like cracks or burnt parts. You can also reset the board by turning it off and then back on. If it still doesn’t work, ask a helper or a professional for advice.