Imagine standing in a workshop, surrounded by buzzing machines and shiny metal pieces. You see a metal lathe humming softly, ready to turn tough metal into precise shapes. But wait! What if I told you there are essential tools that can make your work even better with a metal lathe?

Using a power feed on your metal lathe can change everything. It helps you move the cutting tool smoothly, saving time and effort. Have you ever felt tired from turning the handles too much? A power feed can take that strain away!

In this article, we’ll dive into the world of metal lathes and explore the essential tools you need to boost your projects. From understanding how a power feed works to picking out the best tools, you’ll be ready to tackle any metal project with confidence.

So, what are you waiting for? Let’s explore these tools together. Get ready to make your metalworking dreams come true!

Essential Tools For Metal Lathe Power Feed Setup

Essential Tools for Metal Lathe Power Feed

Metal lathes are vital for many machining projects. A power feed is one tool that makes operation smoother. It allows the lathe to move automatically, freeing your hands for other tasks. Imagine creating precise parts without manual effort! When using a power feed, speed and accuracy improve. This tool can handle various materials, making it versatile. So, whether you’re a beginner or an expert, understanding how power feeds work can enhance your metalworking skills.Understanding Power Feed Systems

Definition and purpose of power feed in metal lathes. Benefits of using power feed over manual operation.Power feed systems are like magic helpers for metal lathes. They automatically move the tool, so you don’t have to push it by hand. This makes your work smoother and faster! Imagine trying to juggle while eating a sandwich; it’s tough! Power feed makes it easy, like enjoying your sandwich without the fuss.

Using power feed has big perks. It boosts precision and saves your energy. You can focus on designing, not sweating over each turn. It’s less tiring, and let’s be honest, who doesn’t want that?

| Benefit | Description |

|---|---|

| Increased Accuracy | No more wobbly moves; tools cut better! |

| Less Fatigue | Work longer without feeling like a tired potato. |

| Time Efficiency | Finish jobs quicker than a cheetah on roller skates. |

In short, a power feed system adds a sprinkle of magic to your metal lathe work. It helps you create with flair while keeping your energy intact!

Essential Tools for Installing and Maintaining Power Feed

List of necessary tools for installation. Tools for regular maintenance and troubleshooting.Having the right tools makes installing and maintaining your power feed easier. Here’s a quick list of essential tools:

- Wrenches

- Screwdrivers

- Tape measure

- Calipers

- Lubricants

Regular maintenance tools are also important. With these, you can keep everything running smoothly:

- Oil for lubricating parts

- Cleaning brushes

- Parts replacement kits

These tools help you tackle problems and ensure your metal lathe functions well.

What tools do I need for power feed maintenance?

You need tools like cleaning brushes and oil for lubrication. These ensure your power feed runs smoothly and lasts longer.

Choosing the Right Metal Lathe for Power Feed

Key specifications to look for in a metal lathe. Recommendations for popular brands/models.Picking the right metal lathe for power feed can feel like a treasure hunt. First things first, check the motor power. It should be strong enough to handle your projects without a sweat. Next, look for a variable speed control. This lets you adjust how fast the lathe spins, like choosing between a turtle and a cheetah! Don’t forget about the bed length. A longer bed allows you to work on bigger pieces. Brands like Grizzly and Jet often come highly recommended.

| Brand | Model | Key Features |

|---|---|---|

| Grizzly | G0765 | Strong motor, compact design |

| Jet | JWL-1442 | Variable speed, sturdy build |

Choosing wisely means you’ll have a loyal buddy in your workshop! Making chips, not mistakes, is the name of the game!

DIY Modifications for Enhanced Power Feed Performance

Common modifications to improve power feed efficiency. Safety considerations for DIY enhancements.Making upgrades to your metal lathe can really kick its performance up a notch! A few common tweaks can boost power feed efficiency. For example, changing the drive belt can improve speed and reduce slipping. Adding a micro-switch helps with instant stops, making your workshop safer. Always wear safety goggles! DIY modifications can be fun, but remember, safety first. A well-ordered workspace stops accidents before they happen. So, grab those tools and let’s get crafting!

| Modification | Benefit |

|---|---|

| Upgrade drive belt | Improved speed and less slipping |

| Install micro-switch | Quicker stops, enhanced safety |

| Lubricate gears | Faster operation and reduced wear |

Power Feed Accessories and Attachments

Popular accessories that complement power feed systems. How attachments can enhance functionality and versatility.Adding accessories to your power feed system can be a game-changer! Think of them as the cool stickers on your bike—they make everything better. Accessories like power feed controls and gear racks can boost your metal lathe’s performance. They allow for smoother operations and help you try more complicated projects. Here’s a quick look at some popular add-ons:

| Accessory | Benefit |

|---|---|

| Power Feed Control | Improves precision while working |

| Digital Readout System | Makes measurements easy |

| Tool Holder | Quick tool changes |

These attachments can make your work feel like magic! With the right tools, your lathe can do almost anything. It’s like having a superhero sidekick ready to tackle those tricky projects by your side!

Tips for Operating Metal Lathes with Power Feed

Best practices for effective operation. Common mistakes to avoid when using power feed.Operating a metal lathe with power feed can be a blast! Remember to keep your work area tidy; a clean space is a happy place. Make sure all parts are securely attached, or you might have a mini “tool dance” on your hands. Avoid rushing; patience scores big points here. Many newcomers forget to adjust the speed, leading to uneven cuts. Don’t fret; everyone makes mistakes! Check out the table below for quick tips and common pitfalls:

| Best Practices | Common Mistakes |

|---|---|

| Keep tools sharp. | Ignoring safety gear. |

| Adjust speed properly. | Forgetting to check settings. |

| Regularly clean the lathe. | Rushing the operation. |

Following these tips will help you avoid mishaps and keep your projects smooth as butter!

Frequently Asked Questions about Metal Lathe Power Feed

Answers to common queries related to power feed systems. Additional resources for further learning and troubleshooting.Many people have questions about power feed systems for metal lathes. Here are some common queries:

What is a power feed system?

A power feed system helps a metal lathe move the cutting tool automatically. This makes machining easier and more precise.

How does it improve work?

Using a power feed increases speed and accuracy. It reduces human error and saves time.

Where can I find more information?

Check out these resources:

- Online videos: YouTube has tutorials.

- Books: Look for guides on metalworking.

- Forums: Join communities that discuss metal lathes.

These tools are great for learning and troubleshooting.

Conclusion

In conclusion, having essential tools for your metal lathe power feed makes your projects easier and more fun. These tools improve efficiency and precision, helping you achieve great results. You can explore different options to find what works best for you. So, dive into the world of metalworking and experiment with these tools to enhance your skills!FAQs

Certainly! Here Are Five Related Questions On The Topic Of Essential Tools For A Metal Lathe With A Focus On Power Feed:Sure! A metal lathe is a tool that spins metal so we can shape it. Power feed helps us move the cutting tool automatically instead of by hand. This makes our job easier and faster. Some important tools for a lathe are cutting tools, tool holders, and measuring tools. Having these tools helps us work safely and carefully.

Sure! Please give me the question you’d like me to answer.

What Are The Key Advantages Of Incorporating A Power Feed Mechanism In A Metal Lathe Compared To Manual Feeding?Using a power feed on a metal lathe makes work easier and faster. You don’t have to turn the handle by hand. This means you can keep your hands free and focus more on how the tool cuts. A power feed also helps make smoother and more even cuts. It’s a great way to save time and get better results!

How Do You Properly Set Up And Calibrate The Power Feed On A Metal Lathe For Optimal Performance?To set up the power feed on a metal lathe, start by checking the machine’s manual. Make sure the feed is clean and oiled. Next, adjust the speed settings to match the type of metal you’re using. You want the feed to move smoothly but not too fast. Finally, test the lathe with a small piece of metal to see how well it works. If it’s not right, make small changes until it feels perfect.

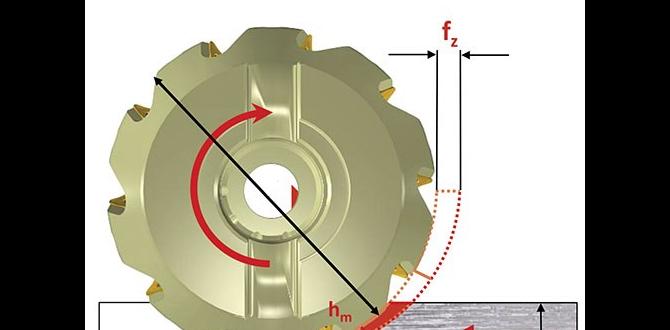

What Are The Essential Components Of A Power Feed System For A Metal Lathe, And How Do They Function Together?A power feed system for a metal lathe has a few key parts. First, there’s a motor that provides power. Then, there’s a gearbox to control the speed. The lead screw moves the cutting tool along the metal. All these parts work together to help you shape the metal smoothly and accurately.

Which Types Of Materials Are Best Suited For Machining With A Power Feed Lathe, And How Does The Power Feed Influence The Machining Process?You can use a power feed lathe to machine materials like aluminum and soft steel. These materials are easier to cut and shape. The power feed helps us move the cutting tool smoothly and at a steady speed. This makes it simpler to get good results and saves us time. Overall, it makes machining faster and more accurate.

What Safety Considerations Should Be Taken Into Account When Using A Power Feed On A Metal Lathe To Prevent Accidents?When using a power feed on a metal lathe, you should always wear safety goggles to protect your eyes. Keep your hands away from the spinning parts to avoid getting hurt. Make sure your clothes are tight and not loose, so they don’t get caught. Always check that the machine is turned off before you do any repairs. Lastly, keep the area clean to avoid tripping or slipping.