Have you ever wanted to create something cool at home? Imagine building your own tools and gadgets using a metal lathe. It’s a fun way to get creative and learn new skills. But where do you start? That’s where CAD design comes in!

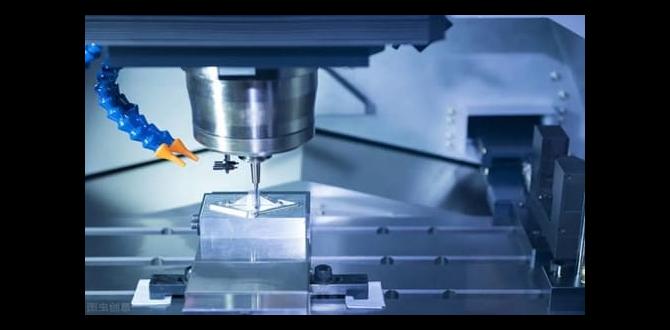

More and more people are using metal lathes for home projects. They love the idea of designing things on a computer and then making them real. With the right software, you can create precise designs for metal pieces. This makes working safer and more efficient.

Did you know that many professional machinists use CAD design before they start their projects? It helps them visualize their work and avoid mistakes. With a home-use metal lathe and CAD skills, you can join the fun!

In this article, we will explore how to get started with a metal lathe. You will learn about easy CAD design tips and tricks that will make your projects exciting. Are you ready to dive in and bring your ideas to life? Let’s get started!

For Home Use Metal Lathe Cad Design: Enhance Your Projects

For Home Use Metal Lathe CAD Design

A metal lathe is a fantastic tool for home projects. With CAD design, you can plan and visualize your projects easily. Imagine turning raw metal into beautiful shapes with precision! By using CAD software, you can design parts before making them, saving time and reducing errors. Did you know that beginners can create simple designs in just a day? This exciting journey into metalworking can inspire creativity while providing hands-on experience!Understanding Metal Lathes

Definition and types of metal lathes. Key features and functions relevant for home use.Metal lathes are machines that shape metal by rotating it against cutting tools. They come in different types, like benchtop lathes and mini lathes, perfect for home use! Key features include adjustable speeds and a tailstock for precision work. Fun fact: lathes can turn metal into beautiful shapes—like magic! Just think of it as a spinning artist, creating artwork from solid blocks. Why settle for boring when you can create masterpieces?

| Type of Lathe | Best For |

|---|---|

| Benchtop Lathe | Small projects |

| Mini Lathe | Hobbyists |

With a metal lathe, you’ll be crafting toys, tools, or even intricate designs. Time to unleash your inner metal wizard!

Benefits of Using CAD Design for Metal Lathes

Enhanced precision and efficiency. Design flexibility and ease of modifications.Using CAD design for metal lathes brings amazing perks! First, it boosts precision. You can create parts that fit together like puzzle pieces. Less guesswork means fewer mistakes, and that saves time! Next, you get design flexibility. Want to change your design? Easy-peasy! Just modify the plan and click save! No need for a whole new setup. With CAD, it’s like having a magic wand for your ideas! So, grab your lathe and let your creativity flow!

| Benefit | Description |

|---|---|

| Enhanced Precision | Parts are made to fit perfectly! |

| Design Flexibility | Change designs with a few clicks! |

Choosing the Right CAD Software for Metal Lathe Design

Popular CAD software options for hobbyists and professionals. Factors to consider when selecting CAD software.Finding the best CAD software for metal lathe design can feel like choosing ice cream flavors—so many options! Some popular choices include Fusion 360, SketchUp, and AutoCAD. Each has unique features suitable for hobbyists and pros alike. Consider factors like ease of use, cost, and available tutorials. You don’t want to get stuck learning a complex system when a simpler one can do the trick! Think of it like deciding whether to ride a tricycle or a rocket ship!

| Software | Level | Key Features |

|---|---|---|

| Fusion 360 | Intermediate | Cloud-based, excellent for collaboration! |

| SketchUp | Beginner-Friendly | Simple interface, great for quick designs. |

| AutoCAD | Professional | Advanced features for detailed work. |

Basic CAD Design Principles for Metal Lathes

Essential design techniques and best practices. Common mistakes to avoid in CAD design.Designing a metal lathe with CAD can be fun and tricky. Start with the basics: sketch your ideas clearly. Use simple shapes to create complex parts. Really, don’t overwhelm your design with too many details. Remember, less can be more—unless you’re talking about pizza toppings! Common mistakes include forgetting to double-check measurements. Always measure twice, not once, unless you want a surprise at the end. Here are the essential principles:

| Design Technique | Best Practices | Common Mistakes |

|---|---|---|

| Start Simple | Break down complicated designs into smaller parts. | Overcomplicating designs. |

| Check Dimensions | Always verify measurements before finalizing. | Ignoring small errors. |

| Use Layers | Organize different design elements on separate layers. | Mixing everything on one layer. |

Follow these tips, and you’ll be spinning metal faster than a cat chasing a laser pointer!

Step-by-Step Guide to Designing a Metal Lathe in CAD

Initial setup and workspace configuration. Creating basic components and assemblies.Starting your metal lathe design in CAD can be a fun adventure! First, set up your workspace so it feels comfy, like your favorite reading nook. Gather your tools and software, ensuring everything is in reach. Next, create basic components like the bed and headstock, ensuring they fit together like puzzle pieces. It might feel tricky, but think of it as building a robot friend. They don’t judge when you mess up!

| Steps | Tasks |

|---|---|

| 1 | Set up your workspace |

| 2 | Gather tools and software |

| 3 | Create basic components |

Keep it simple, and don’t forget to have fun. Remember, practice makes perfect. Soon, you’ll have a lathe that’s not only functional but also brings a smile to your face. Who knew designing could feel like a game?

Integrating Materials and Tools in Your Design

Selecting the right materials for your metal lathe. Tools and attachments to include in your design.Choosing the right materials for your metal lathe is key. Strong materials like steel or aluminum work well. They resist wear and can handle heavy tasks. Tools, like cutting bits and attachments, also matter. They help you shape metal accurately. Think about adding:

- Cutting tools for precision.

- Chucks to hold the metal firmly.

- Tool holders to change tools easily.

With these selections, your design will work great!

Why is material selection important for a metal lathe design?

Choosing the right materials ensures durability and performance. Strong materials help your lathe last longer and produce better results.

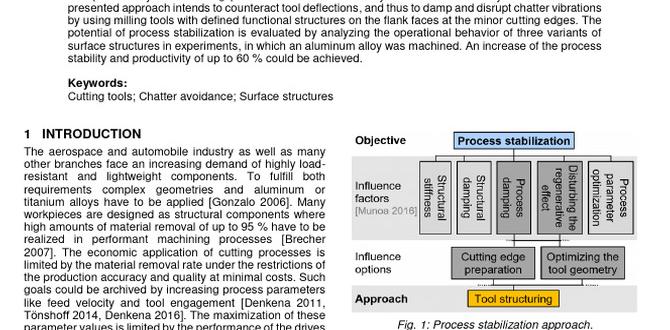

Testing and Validating Your CAD Design

Simulation tools for testing functionality. How to adjust designs based on test results.Before using your metal lathe, you should test your CAD design. Simulation tools are like superheroes for design! They help you check if everything will work as planned. Think of them as your personal design coach. If the results aren’t what you hoped for, don’t fret! Adjusting your design is easy-peasy. Just tweak the parts that need fixing and run the tests again. It’s like a game of trial and error, but with metal!

| Testing Tool | Purpose |

|---|---|

| Stress Analysis | Check if materials can handle pressure. |

| Motion Simulation | See how parts move together. |

| Thermal Testing | Ensure heat doesn’t ruin your design. |

Tips for Effective Metal Lathe CAD Design

Timesaving shortcuts and features in CAD software. Resources for continued learning and improvement.CAD software can be tricky, but it has many shortcuts to save your time. Use features like templates for faster starts. Keyboard shortcuts let you work quickly. Explore design reviews to catch mistakes early. After you’re comfortable, keep learning for improvement. Here are some ways to grow:

- Join online forums for tips.

- Watch video tutorials for hands-on help.

- Read blogs about CAD updates.

Staying curious helps you become a pro!

What are helpful resources for CAD learning?

Online tutorials, forums, and design challenges are great resources. They help you learn new tricks and improve your skills.

Real-World Applications of Home Use Metal Lathes

Examples of projects suited for home metal lathes. Success stories from hobbyists and professionals.Metal lathes are like magic wands for builders and creators! People use them for all sorts of fun projects. You can make beautiful wooden chairs or even spin fancy metal knobs. One hobbyist made a cool robot arm, while a pro crafted custom bicycle parts. Success stories abound, showing how home metal lathes transform ideas into reality.

| Project Type | Description |

|---|---|

| Furniture | Custom legs or intricate designs for tables. |

| Artwork | Sculptures and decorative pieces from metal. |

| Machinery Parts | Replacement or specialized parts for equipment. |

Who knew a lathe could create so much? Dive in, and who knows what creations await!

Conclusion

In conclusion, a home use metal lathe can transform your projects. With CAD design, you can plan your creations easily. This technology helps you visualize parts before making them. By exploring CAD resources, you can enhance your skills. So, dive into CAD tools today! Start designing your own metal projects and enjoy the process of creating!FAQs

Sure! Here Are Five Related Questions On The Topic Of Cad Design For Home Use Metal Lathes:Sure! When you use a computer program called CAD, it helps you create designs for metal working machines like lathes. A metal lathe turns metal pieces to make them into cool shapes. You can create your own designs and save them on the computer. This means you can build your own tools or toys at home! CAD makes it easier for you to plan what you want to make before you start working with metal.

Sure! Please share the question you want me to answer.

What Are The Key Specifications To Consider When Designing A Cad Model For A Home Use Metal Lathe?When designing a CAD model for a metal lathe, we need to think about the size first. It should fit in our workspace. Next, we should consider the power. A good motor helps it run smoothly. We also need to plan for speed settings. Different tasks need different speeds. Lastly, it’s important to make it easy to use and safe.

How Can Cad Software Be Utilized To Optimize The Workflow And Efficiency Of A Home Metal Lathe?You can use CAD (Computer-Aided Design) software to plan your projects on a metal lathe. It helps you design pieces on the computer first. This way, you see what the final item will look like before you start working. You can also check measurements easily, so everything fits perfectly. This makes your work faster and better.

What Design Features Can Be Integrated Into A Cad Model To Enhance The Safety And Usability Of A Home Metal Lathe?To make a home metal lathe safer and easier to use, we can add some helpful features in a CAD model. First, we can include emergency stop buttons that are easy to reach. Next, we can design protective covers to keep your hands safe from moving parts. We can also add clear labels and instructions so everyone knows how to use it correctly. Lastly, adjustable stands can help keep the machine at a comfy height for you.

How Do Different Materials Impact The Cad Design Process For A Home Use Metal Lathe?Different materials change how we design a metal lathe in Computer-Aided Design (CAD). If we use plastic, our design will be lighter but less strong. On the other hand, metal makes the lathe stronger but heavier. We need to think about how the lathe will be used and choose materials that fit. This helps us make a better machine.

What Are Some Common Challenges Faced In Creating A Cad Design For A Metal Lathe, And How Can They Be Overcome?Creating a CAD design for a metal lathe can be tricky. One challenge is getting the measurements right. If they’re off, the parts won’t fit. You can overcome this by double-checking your measurements and using tools to help. Another challenge is making sure the design works well with metal. Testing the design with a small model can help us see how it will work in real life.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Cad Design For Home Use Metal Lathes:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! When you use a computer program called CAD, it helps you create designs for metal working machines like lathes. A metal lathe turns metal pieces to make them into cool shapes. You can create your own designs and save them on the computer. This means you can build your own tools or toys at home! CAD makes it easier for you to plan what you want to make before you start working with metal.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please share the question you want me to answer.”}},{“@type”: “Question”,”name”: “What Are The Key Specifications To Consider When Designing A Cad Model For A Home Use Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When designing a CAD model for a metal lathe, we need to think about the size first. It should fit in our workspace. Next, we should consider the power. A good motor helps it run smoothly. We also need to plan for speed settings. Different tasks need different speeds. Lastly, it’s important to make it easy to use and safe.”}},{“@type”: “Question”,”name”: “How Can Cad Software Be Utilized To Optimize The Workflow And Efficiency Of A Home Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can use CAD (Computer-Aided Design) software to plan your projects on a metal lathe. It helps you design pieces on the computer first. This way, you see what the final item will look like before you start working. You can also check measurements easily, so everything fits perfectly. This makes your work faster and better.”}},{“@type”: “Question”,”name”: “What Design Features Can Be Integrated Into A Cad Model To Enhance The Safety And Usability Of A Home Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To make a home metal lathe safer and easier to use, we can add some helpful features in a CAD model. First, we can include emergency stop buttons that are easy to reach. Next, we can design protective covers to keep your hands safe from moving parts. We can also add clear labels and instructions so everyone knows how to use it correctly. Lastly, adjustable stands can help keep the machine at a comfy height for you.”}},{“@type”: “Question”,”name”: “How Do Different Materials Impact The Cad Design Process For A Home Use Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Different materials change how we design a metal lathe in Computer-Aided Design (CAD). If we use plastic, our design will be lighter but less strong. On the other hand, metal makes the lathe stronger but heavier. We need to think about how the lathe will be used and choose materials that fit. This helps us make a better machine.”}},{“@type”: “Question”,”name”: “What Are Some Common Challenges Faced In Creating A Cad Design For A Metal Lathe, And How Can They Be Overcome?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Creating a CAD design for a metal lathe can be tricky. One challenge is getting the measurements right. If they’re off, the parts won’t fit. You can overcome this by double-checking your measurements and using tools to help. Another challenge is making sure the design works well with metal. Testing the design with a small model can help us see how it will work in real life.”}}]}