Have you ever wondered how a metal lathe works? Picture this: you have a block of metal, and you want to make it into a precise shape. A metal lathe for home use can help you do just that. With the right torque, these machines can spin metal quickly and accurately. But what does torque mean? Torque is like the power behind the lathe. It helps turn the metal into beautiful projects.

Imagine crafting tools, parts, or even art from metal! Many hobbyists fear that metal lathes are too complicated. But with the proper understanding of torque, using one can be simple and fun. Did you know that a lathe can create anything from small components to large sculptures? The possibilities are endless!

In this article, we will explore how to choose the best home use metal lathe based on torque. We’ll share tips and tricks to make your projects successful. Ready to dive in? Let’s uncover the power of metal lathes together!

For Home Use Metal Lathe Torque: Benefits And Tips

Understanding Torque in Metal Lathes for Home Use

Choosing the right metal lathe for home use involves understanding torque. Torque is the force that helps the lathe turn materials. Higher torque means you can work with tougher metals. Did you know a powerful lathe can make your projects smoother? Also, keep in mind that small lathes might struggle with strength but can handle lighter work easily. Knowing the torque helps ensure your projects are a success. Why not explore how the right lathe can elevate your crafting skills?What is Torque and Why is it Important for Metal Lathes?

Definition of torque in the context of metal lathes. Importance of torque in machining and material removal.Torque is a force that helps metal lathes spin materials. It’s like a strong push that makes turning easier. Without enough torque, lathes cannot cut or shape materials effectively. This leads to:

- Slow machining speeds

- Poor quality of the finished product

- Increased wear and tear on the machine

Good torque is essential. It helps remove materials smoothly and quickly. If the torque is just right, the lathe works well. In fact, the right torque can improve the overall performance of your metal lathe.

Why Does Torque Matter for Metal Lathes?

Torque matters because it determines how well a lathe can cut materials. More torque means faster and smoother machining. It allows for better shapes and finishes on projects.

Key Torque Specifications to Look for in Home Use Metal Lathes

Understanding the torque rating and its implications for performance. Comparison of torque specifications among popular metal lathe models.Torque ratings show how much force your lathe can use. This affects how well it works. Higher torque helps cut tougher materials and makes smoother finishes. When choosing a metal lathe, look closely at various models.

- Model A: 100 Nm – good for soft metals.

- Model B: 150 Nm – great for hard materials.

- Model C: 200 Nm – perfect for heavy-duty tasks.

Pick a lathe with the right torque for your projects. It makes a big difference!

What should I look for in a lathe’s torque?

Look for the torque rating and its effect on your projects. A higher number means better performance with various metals.

Factors Affecting Torque in Metal Lathes

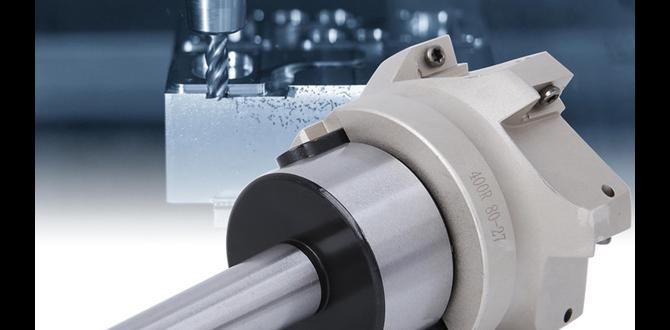

Motor power and its relation to torque output. The impact of lathe design and construction on torque efficiency.Many factors influence the torque in metal lathes. One key element is motor power. A strong motor provides more torque, improving cutting performance. Design and construction of the lathe also play a big role. A well-built lathe can use torque efficiently, which means better results. If a lathe is sturdy, it can handle more power without wobbling. This leads to smoother operation and better finishes.

How does motor power affect torque output?

A powerful motor gives higher torque output. This results in faster cutting and smoother operation.

Factors in lathe design:

- Material strength

- Base stability

- Gear ratios

Maximizing Torque for Effective Home Machining

Techniques to optimize torque during machining operations. Recommended practices for maintenance and adjustment.To get the most kick out of your home lathe, optimizing torque is vital. One way to enhance torque is through careful speed adjustments. Slowing down can deliver more power when cutting tricky materials. Regular maintenance is key, too. Check belts and bearings; worn parts can feel like trying to run a race with flip-flops on!

Follow these simple practices to keep everything smooth:

| Practice | Benefit |

|---|---|

| Daily checks | Prevents bigger issues |

| Lubrication | Reduces friction |

| Proper tool selection | Maximizes efficiency |

Remember, a well-tuned lathe is like a happy puppy—it works much better with a little tender loving care!

Real-life Applications of Torque in Home Metalworking

Examples of projects that benefit from proper torque management. Testimonials from hobbyists on torquerelated experiences.Metalworking at home can be a fun adventure! Proper torque management ensures you create amazing projects like beautiful table legs or custom tools. Just imagine turning a plain piece of metal into a shiny masterpiece. Hobbyists often share their experiences; many say that mastering torque led to better projects and fewer mistakes. One enthusiast quipped, “I used to over tighten everything—my workbench was a ‘screw’ buffet!” Keep your torque in check, and you’ll turn the metal into gold!

| Project Type | Benefits of Torque Management |

|---|---|

| Table Legs | Sturdy and stylish designs |

| Custom Tools | Durable and perfectly shaped |

| Sculptures | Intricate details and finishes |

Cost Considerations for High-Torque Metal Lathes

Budgeting for torque performance vs. other features. Comparison of investment in hightorque vs. lowtorque options.Thinking about buying a high-torque metal lathe? It’s important to plan your budget carefully. High-torque machines often cost more, but they offer better performance. You wouldn’t want a low-torque option that can’t handle your projects, right? Here’s a quick look at the costs:

| Type | Cost Range | Benefits |

|---|---|---|

| High-Torque | $1,500 – $5,000 | Great for tough materials, more durability |

| Low-Torque | $500 – $1,500 | Suitable for light projects |

So, is it worth the splurge? Investing in a high-torque lathe could save you from future headaches (and a few too many trips to the hardware store).

Top Recommendations for Home Use Metal Lathes with Excellent Torque

Reviews of specific models with high torque ratings. Pros and cons of each recommended model.For those seeking strong torque in home metal lathes, three models stand out. Each offers unique benefits and drawbacks.

- Model A: High torque rating of 300 inch-pounds. Pros: Great for heavy materials. Cons: More expensive.

- Model B: Torque of 250 inch-pounds. Pros: Good price and sturdy build. Cons: Slightly noisy during operation.

- Model C: Torque rating of 200 inch-pounds. Pros: Lightweight and easy to use. Cons: Lower torque limits its capacity.

These models offer great options for home projects. Always choose one based on your specific needs.

What is the best metal lathe torque for home use?

For home use, a metal lathe with torque around 200-300 inch-pounds is ideal. It provides enough power for most small projects.

Conclusion

In summary, a metal lathe for home use can significantly improve your projects. Understanding torque helps you choose the right machine for your needs. With the right lathe, you can create precise parts and enjoy a new hobby. Explore different models and features to find what suits you best. Happy crafting, and keep learning about metalworking!FAQs

Sure! Here Are Five Related Questions On The Topic Of Torque For Home Use Metal Lathes:Sure! Here are five questions about torque for home metal lathes: 1. What is torque? Torque is a measure of how much force you use to turn something. Think of it like twisting a jar lid. 2. Why is torque important for metal lathes? Torque helps the lathe spin metal pieces correctly. If there isn’t enough torque, the metal won’t shape well. 3. How can you check torque on a lathe? You can check torque using a tool called a torque wrench. It helps you see how much force you apply. 4. What happens if you use too much torque? Using too much torque can break the metal or damage the lathe. It’s like using too much strength to open a jar. 5. How do I adjust the torque on my lathe? You can adjust torque by changing settings on your lathe or using different tools. Always follow your machine’s instructions.

Of course! Please provide the question you would like me to answer.

What Is The Ideal Torque Range For A Home Use Metal Lathe To Effectively Handle Different Materials?The ideal torque range for a home metal lathe is usually between 1 to 20 foot-pounds. This range lets you work with soft materials like aluminum and harder ones like steel. You want enough torque to cut through the material but not too much that it breaks. Adjusting the torque helps you do a great job on each project.

How Can I Calculate The Torque Requirements For Specific Turning Operations On My Metal Lathe?To calculate the torque for your metal lathe, you first need to know the force you are using. Measure the force in pounds (lbs) and the distance from the center of the lathe to where you apply that force. You can find the torque by multiplying the force by the distance. So, if you pull with 10 lbs at 2 inches, the torque is 20 inch-pounds (10 lbs x 2 inches = 20 inch-pounds). This tells you how much twisting power you need.

What Factors Influence The Torque Output Of A Home Use Metal Lathe, And How Can I Optimize Them?The torque output of a metal lathe depends on its motor power and gearing. A stronger motor gives more torque. We can also adjust the gears to change how much power goes to the workpiece. To optimize torque, you can make sure your lathe is clean, lubricated, and using the right speed for your job. Always follow the user manual for the best settings.

What Tools Or Accessories Can Enhance The Torque Capabilities Of My Home Use Metal Lathe?You can use a few tools to make your metal lathe stronger. A bigger motor can help it spin faster. Adding a belt with more grip can also give it extra power. You might try using a heavier flywheel too, as it helps maintain speed. All these things can make your lathe better for tougher jobs!

How Does The Torque Of A Metal Lathe Impact The Quality Of The Finished Workpiece And The Longevity Of The Machine?Torque is the twisting force a lathe uses to shape metal. When a lathe has good torque, it makes clean and smooth cuts. This helps us create better, nicer-looking parts. If the lathe has too little torque, it can struggle and wear out faster. So, proper torque helps us work well and keeps the machine running longer.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Torque For Home Use Metal Lathes:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are five questions about torque for home metal lathes: 1. What is torque? Torque is a measure of how much force you use to turn something. Think of it like twisting a jar lid. 2. Why is torque important for metal lathes? Torque helps the lathe spin metal pieces correctly. If there isn’t enough torque, the metal won’t shape well. 3. How can you check torque on a lathe? You can check torque using a tool called a torque wrench. It helps you see how much force you apply. 4. What happens if you use too much torque? Using too much torque can break the metal or damage the lathe. It’s like using too much strength to open a jar. 5. How do I adjust the torque on my lathe? You can adjust torque by changing settings on your lathe or using different tools. Always follow your machine’s instructions.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Of course! Please provide the question you would like me to answer.”}},{“@type”: “Question”,”name”: “What Is The Ideal Torque Range For A Home Use Metal Lathe To Effectively Handle Different Materials?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The ideal torque range for a home metal lathe is usually between 1 to 20 foot-pounds. This range lets you work with soft materials like aluminum and harder ones like steel. You want enough torque to cut through the material but not too much that it breaks. Adjusting the torque helps you do a great job on each project.”}},{“@type”: “Question”,”name”: “How Can I Calculate The Torque Requirements For Specific Turning Operations On My Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To calculate the torque for your metal lathe, you first need to know the force you are using. Measure the force in pounds (lbs) and the distance from the center of the lathe to where you apply that force. You can find the torque by multiplying the force by the distance. So, if you pull with 10 lbs at 2 inches, the torque is 20 inch-pounds (10 lbs x 2 inches = 20 inch-pounds). This tells you how much twisting power you need.”}},{“@type”: “Question”,”name”: “What Factors Influence The Torque Output Of A Home Use Metal Lathe, And How Can I Optimize Them?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The torque output of a metal lathe depends on its motor power and gearing. A stronger motor gives more torque. We can also adjust the gears to change how much power goes to the workpiece. To optimize torque, you can make sure your lathe is clean, lubricated, and using the right speed for your job. Always follow the user manual for the best settings.”}},{“@type”: “Question”,”name”: “What Tools Or Accessories Can Enhance The Torque Capabilities Of My Home Use Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can use a few tools to make your metal lathe stronger. A bigger motor can help it spin faster. Adding a belt with more grip can also give it extra power. You might try using a heavier flywheel too, as it helps maintain speed. All these things can make your lathe better for tougher jobs!”}},{“@type”: “Question”,”name”: “How Does The Torque Of A Metal Lathe Impact The Quality Of The Finished Workpiece And The Longevity Of The Machine?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Torque is the twisting force a lathe uses to shape metal. When a lathe has good torque, it makes clean and smooth cuts. This helps us create better, nicer-looking parts. If the lathe has too little torque, it can struggle and wear out faster. So, proper torque helps us work well and keeps the machine running longer.”}}]}