Have you ever wondered how to create amazing projects right at home? A metal lathe can help you do just that. With a simple wiring diagram for home use, you can turn your ideas into reality.

Imagine crafting parts or tools with precision. That’s what a metal lathe offers. But do you know how to connect it all? A wiring diagram is key to making your lathe work safely and effectively.

Here’s a fun fact: many people use metal lathes for hobbies and small businesses. With just the right wiring setup, you can join them and explore your creativity!

This article will guide you through the essential steps to follow for your home use metal lathe wiring diagram. Get ready to discover a world of possibilities!

For Home Use Metal Lathe Wiring Diagram Explained Simply

Understanding For Home Use Metal Lathe Wiring Diagram

A for home use metal lathe wiring diagram shows how to connect components correctly. This diagram is essential for safe and effective operations. It helps you understand where each wire goes and what each part does. Have you ever wondered how machines turn raw materials into beautiful shapes? Proper wiring ensures your lathe works smoothly. Knowing this can prevent accidents and extend your lathe’s life. Plus, wiring it right can boost your creativity in metalworking!Understanding the Basics of Metal Lathes

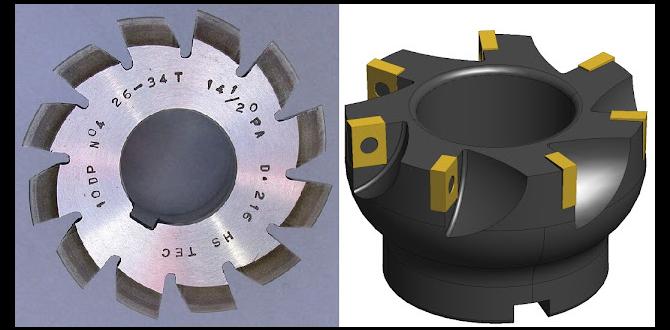

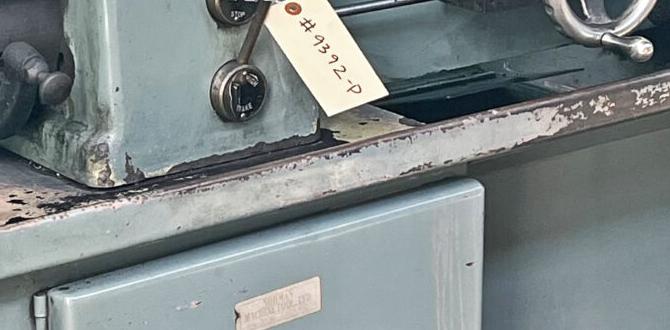

Components of a metal lathe and their functions. Importance of electrical wiring in lathe operations.Metal lathes are amazing machines! They have several parts, each playing a special role. The headstock holds the motor and drives the spindle. The tailstock supports the workpiece and can hold tools for drilling. Don’t forget the bed, which keeps everything steady and aligned. And let’s be honest, without proper electrical wiring, your lathe might just sit there like a potato! Good wiring allows smooth operation and helps avoid malfunctions.

| Component | Function |

|---|---|

| Headstock | Holds motor and rotates the spindle. |

| Tailstock | Supports workpieces and tools. |

| Bed | Stabilizes and aligns the lathe. |

Essential Tools and Materials Needed for Wiring

List of tools required for wiring a metal lathe. Types of wires and connectors suitable for lathes.To wire a metal lathe like a pro, you need some essential tools by your side. Grab a screwdriver, wire strippers, and a multimeter to make your task easier. A soldering iron can help you with tricky connections. For wires, use copper wires with a high gauge for safety and fun! Connectors like spade or ring terminals are great for secure links. Check out the table below for a quick overview:

| Tools | Purpose |

|---|---|

| Screwdriver | Tightening screws |

| Wire Strippers | Removing insulation |

| Multimeter | Testing circuits |

| Soldering Iron | Making secure connections |

Remember, wiring can be electrifying—literally! So, safety first. Always double-check your connections, and you’ll be turning that metal lathe into a masterpiece in no time!

Step-by-Step Wiring Process for Home Use Metal Lathe

Detailed wiring instructions from power source to motor. Safety precautions to take during the wiring process.Wiring your home use metal lathe is simple if you follow these steps. First, connect the power source to the lathe. Use strong, insulated wires. Ensure all connections are tight. Next, attach the wires to the motor. Double-check for any loose ends. Safety is key. Wear gloves and goggles. Always turn off the power when working. This keeps you safe while enjoying your project.

What precautions should I take while wiring?

Here are some safety tips:

- Always wear gloves and safety goggles.

- Turn off the power before starting.

- Use insulated tools to avoid shocks.

Troubleshooting Common Wiring Issues

Identifying signs of wiring problems. Tips for resolving electrical faults in metal lathes.Wiring problems can be tricky. Look for signs like strange noises, flickering lights, or machines that won’t start. These hints show something is wrong. To solve issues, follow these tips:

- Check connections for looseness.

- Inspect wires for damage.

- Test power outlets.

- Use a multimeter for readings.

Stay safe by turning off power before checking. Regular maintenance helps keep your metal lathe running smoothly.

What are common signs of wiring problems?

A flickering light or odd sounds from the machine can indicate wiring issues. These signs show something might be wrong with the electrical connections.

Tips to fix electrical faults

- Check if all connections are tight.

- Look for any signs of wear or damage.

- Test power sources for faults.

Upgrading Your Metal Lathe Wiring for Enhanced Performance

Benefits of upgrading wiring systems. Recommendations for advanced wiring configurations.Upgrading the wiring of your metal lathe can lead to better performance. This means your projects can be more precise and quicker. New wiring can also reduce wear and tear. Over time, this saves money on repairs. Here are some recommendations for advanced wiring configurations:

- Use thicker gauge wire for better electricity flow.

- Add a surge protector to prevent damage.

- Incorporate switches for easy control.

What are the benefits of upgrading wiring?

New wiring improves safety, efficiency, and the lifespan of your lathe.

Frequently Asked Questions about Metal Lathe Wiring

Common queries and expert answers. Tips for beginners in metal lathe electrical setup.Many people have questions about metal lathe wiring. Here are some common ones:

What are the basics of metal lathe wiring?

It’s important to understand the power source and connections needed for safety and function. Make sure to use the right gauge wire for your lathe size.

What tips help beginners get started?

- Read the manual: Always begin with the manufacturer’s instructions.

- Check connections: Make sure all wires are secure.

- Use protective gear: Safety comes first while setting up!

Wiring a metal lathe can be fun yet challenging. Remember to follow safety rules and ask questions if you’re unsure!

Conclusion

In summary, a metal lathe wiring diagram is essential for safe home use. It helps you connect the wiring correctly. By following the diagram, you can avoid mistakes. Make sure to read the manual for your specific lathe model, and always prioritize safety. We encourage you to explore more resources online for detailed instructions and tips!FAQs

What Are The Essential Electrical Components Required For Wiring A Home Use Metal Lathe?To wire a home metal lathe, you need a few important parts. First, you will need a power switch to turn it on and off. Next, use a circuit breaker to protect the lathe from too much electricity. You also need wires to connect everything together. Finally, it’s good to have a plug for the wall outlet.

How Do I Determine The Appropriate Power Supply Voltage And Amperage For My Metal Lathe?To find the right power supply for your metal lathe, first check its manual. This manual tells you the voltage and amperage needed. Voltage is how strong the electricity is, and amperage is how much electricity flows. Make sure your power supply matches these numbers. If you’re unsure, ask an adult for help!

What Safety Precautions Should I Take When Wiring A Metal Lathe For Home Use?When wiring a metal lathe, always turn off the power first. Use rubber gloves to keep safe from electricity. Make sure your workspace is dry and clean. Check wires for any damage before connecting them. Finally, ask an adult for help if you’re unsure.

Can I Use A Variable Speed Drive (Vsd) With My Metal Lathe, And If So, How Should It Be Wired?Yes, you can use a Variable Speed Drive (VSD) with your metal lathe. A VSD helps control the speed of the motor. To wire it, you connect the lathe’s motor wires to the VSD. Make sure to follow the instructions that come with the VSD carefully. Always ask for help if you’re unsure!

Where Can I Find A Specific Wiring Diagram For My Metal Lathe Model, And Are There General Wiring Diagrams Applicable To Various Models?You can find a specific wiring diagram for your metal lathe model in its user manual. If you don’t have the manual, check the manufacturer’s website. Many companies upload helpful documents online. There are also general wiring diagrams available, but make sure they match your lathe model closely. These can help you understand how to connect everything properly.