Have you ever watched a metal lathe in action? These machines spin metal to create amazing shapes. But what if I told you that gearhead metal lathe automation makes this process even better? Picture a workshop where machines do the hard work for you.

Imagine you want to make cool metal parts without spending all day in the shop. That’s where automation comes in. With gearhead metal lathe automation, you can sit back and let the machine handle the tough jobs. Exciting, right?

Did you know that some factories have machines that work all night? They make parts while people are asleep! This not only saves time but also makes work safer. The idea of machines helping us is not new, but automation takes it to the next level.

In this article, we will explore how gearhead metal lathe automation changes the game. You’ll discover how easy it is to use and why it’s becoming so popular. Let’s dive in and see what this amazing technology can do!

Gearhead Metal Lathe Automation: Boost Your Machining Efficiency

Gearhead Metal Lathe Automation Overview

Want to know how gearhead metal lathe automation changes the game? This technology boosts efficiency in metalworking shops. By automating tasks, it reduces human error and speeds up production. How cool is that? Imagine machines that can work tirelessly while you focus on design and creativity. In fact, many shops see a jump in productivity just by upgrading their lathes. Automation isn’t just a trend; it’s shaping the future of manufacturing!Understanding Gearhead Metal Lathes

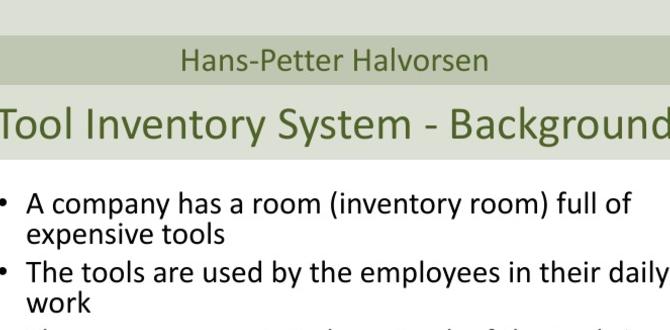

Definition and function of gearhead metal lathes. Key components of gearhead lathes and their roles.Gearhead metal lathes are powerful tools used for shaping metal. They spin metal pieces while cutting tools remove material. This process creates various shapes and sizes, making it crucial for many projects.

Key parts of a gearhead lathe include:

- Headstock: Controls the speed and movement of the workpiece.

- Tailstock: Supports long pieces and can hold tools.

- Bed: The base that keeps everything in place.

- Carriage: Moves tools along the metal piece.

Each part has an important role, ensuring the lathe works efficiently. Understanding these components helps users operate the lathe better.

What are the benefits of using a gearhead lathe?

Using a gearhead lathe allows for precise metal shaping, faster production, and better quality finishes.

The Importance of Automation in Metalworking

Advantages of automation in manufacturing processes. Impact of automation on productivity and precision.Automation plays a big role in metalworking. It helps companies make things faster and with fewer mistakes. This leads to better products. Here are some advantages:

- Increased speed: Machines work faster than people.

- Higher accuracy: Robots can cut metal more precisely.

- Less waste: Automation reduces materials that go unused.

Overall, automation makes factories run smoother and keeps customers happy.

Why is automation crucial for productivity?

It boosts productivity by speeding up processes and reducing errors. Automated machines work non-stop, leading to more items made in less time.

Components of Gearhead Metal Lathe Automation

Essential automation components (motors, sensors, software). Integration of automation systems with existing lathes.Let’s break down the key parts of gearhead metal lathe automation. First, you’ve got motors that power the lathe and make it spin like a top! Then, sensors keep an eye on things, ensuring everything is running smoothly. Don’t forget the software—it’s like the brain of the operation, telling the lathe what to do. All these components need to play nice with any existing lathes to maximize efficiency. It’s like getting your cranky cat and dog to share the same sunny spot on the floor!

| Components | Functions |

|---|---|

| Motors | Power the lathe, helping it turn and shape the metal. |

| Sensors | Monitor the process to ensure everything is working well. |

| Software | Controls the lathe and makes decisions based on sensor inputs. |

Benefits of Automating Your Gearhead Metal Lathe

Increased efficiency and reduced production time. Enhanced accuracy and consistency in machining.Imagine your gearhead metal lathe working like a superhero, zooming through tasks! Automating your lathe makes everything faster. This means you’ll see increased efficiency and less time spent peeking at the clock. Plus, you’ll enjoy enhanced accuracy, leaving no room for mistakes. Consistency becomes your best friend, making every piece feel like a copy of the last. Look at the magic:

| Benefit | Result |

|---|---|

| Increased Efficiency | More products in less time! |

| Enhanced Accuracy | No more oops moments! |

So, why not let your lathe become a machine marvel? You can go grab a snack while it does the heavy lifting!

Challenges in Gearhead Metal Lathe Automation

Common obstacles during implementation. Solutions for overcoming automation challenges.Automation in gearhead metal lathes faces some tricky bumps. Firstly, workers might resist change, thinking machines are trying to take their jobs. Yikes! Training is also a biggie. If nobody knows how to use the new tech, it might gather dust faster than grandma’s old sewing machine. Upgrading old machines can feel like trying to fit a square peg in a round hole.

To smooth things out, regular training sessions can help workers embrace the new tools. It’s all about teamwork! Plus, breaking down big tasks into smaller, manageable steps makes everything less scary, like piecing together a giant puzzle.

| Challenge | Solution |

|---|---|

| Resistance to Change | Regular Training |

| Insufficient Skills | Hands-on Workshops |

| Compatibility Issues | Gradual Upgrades |

By tackling these challenges head-on, we can make gearhead metal lathe automation shine brighter than a new penny!

Case Studies: Successful Gearhead Lathe Automation

Examples of businesses that benefited from automation. Lessons learned from automation implementations.Many businesses have experienced great success after automating their gearhead lathes. For example, a local machine shop increased production by 50%. They also saved time on setups, allowing workers to focus on more important tasks—like coffee breaks and planning world domination!

Lessons learned from these implementations include training staff properly and keeping machines well-maintained. Automation is not a magic wand; you need to care for your gearhead like a pet goldfish. Give it attention, and it will reward you with shiny, precise parts.

| Business Name | Benefit | Lesson Learned |

|---|---|---|

| ABC Machining | 50% boost in production | Staff training is key |

| XYZ Manufacturing | Reduced setup time | Maintenance matters |

In short, these automation success stories show how smart investments can lead to big gains. Now, who’s ready to get their hands dirty with some lathe magic?

Future Trends in Metal Lathe Automation

Emerging technologies shaping the future of lathes. Predictions for the evolution of gearhead lathe automation.New technologies are buzzing like a hive of bees in the world of metal lathe automation. Robots, AI, and smart sensors are making lathes sharper than a cat’s claws! These tools will help machines learn as they work. Predictions say gearhead lathes will soon be so automated that they might even start fixing dinner—well, maybe not that far!

| Technology | Impact |

|---|---|

| AI Integration | Improves precision and reduces waste. |

| Smart Sensors | Monitors performance in real-time. |

| Robotic Arms | Increases production speed. |

It’s all about making work easier and faster. Imagine a world where lathes run themselves while you relax with a soda! The future looks bright for gearhead metal lathe automation.

Getting Started with Gearhead Lathe Automation

Steps to evaluate your existing setup for automation. Resources and tools needed for successful integration.To kick off your gearhead lathe automation journey, first, take a good look at your current setup. Ask yourself, is it as smooth as butter or as clunky as a robot trying to dance? Check for existing tools and parts that can be automated.

Next, gather your secret weapons: resources and tools! Consider purchasing sensors, stepper motors, and control software. It’s like building a super cool robot sidekick, except this one won’t take your lunch!

| Resource | Purpose |

|---|---|

| Stepper Motors | Drive your lathe with precision |

| Sensors | Monitor speed and position |

| Control Software | Control functions and automation tools |

With the right setup and gear, automation becomes less of a mystery and more of an exciting adventure. So gear up, and let the automation begin!

Conclusion

In conclusion, gearhead metal lathe automation makes machining easier and more efficient. You can create precise parts quickly. This saves time and effort. Exploring automation will boost your skills and open new opportunities. We encourage you to learn more about this technology. Check out videos or tutorials to start your journey into metalworking and automation today!FAQs

What Are The Key Benefits Of Automating A Metal Lathe For Gearhead Machining Applications?Automating a metal lathe means machines can work on their own. This saves us time because we don’t have to do everything by hand. It also helps us make the same gears over and over without mistakes. Plus, we can use our time for other important tasks while the machine runs. Overall, it makes our work faster and easier!

Which Types Of Automation Technologies, Such As Cnc Or Robotics, Are Most Effective For Enhancing The Productivity Of Metal Lathes?To make metal lathes work better, we can use a few types of machines. CNC stands for Computer Numerical Control. CNC machines help us create exact shapes many times without mistakes. Robotics can also help by moving parts and tools quickly. Using these technologies means we can make more pieces in less time!

How Can Sensor Integration Improve The Precision And Efficiency Of Automated Metal Lathe Operations?Sensor integration helps us make metal lathes work better and more accurately. Sensors can check how the machine is running in real-time. This means we can fix problems before they happen. By knowing exactly what’s going on, we can also save time and materials. Overall, sensors help us create better parts faster!

What Are The Common Challenges Faced When Automating Gearhead Metal Lathes, And How Can They Be Overcome?When automating gearhead metal lathes, we often face a few challenges. One big problem is fixing the machines to work with computers. You can solve this by using special kits that help connect them. Another issue is making sure the lathe cuts correctly every time. We can overcome this by testing and adjusting the settings carefully. Finally, training people to use the new machines is important, so everyone knows how to work safely and efficiently.

What Advancements In Software And Controls Are Revolutionizing The Automation Of Metal Lathes In The Manufacturing Industry?New software and controls are making metal lathes smarter. These machines can now work on their own with less help from people. They use special programs to plan and fix problems quickly. This means they can create metal parts faster and better. With these changes, we can make more things in less time!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Key Benefits Of Automating A Metal Lathe For Gearhead Machining Applications? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Automating a metal lathe means machines can work on their own. This saves us time because we don’t have to do everything by hand. It also helps us make the same gears over and over without mistakes. Plus, we can use our time for other important tasks while the machine runs. Overall, it makes our work faster and easier!”}},{“@type”: “Question”,”name”: “Which Types Of Automation Technologies, Such As Cnc Or Robotics, Are Most Effective For Enhancing The Productivity Of Metal Lathes? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To make metal lathes work better, we can use a few types of machines. CNC stands for Computer Numerical Control. CNC machines help us create exact shapes many times without mistakes. Robotics can also help by moving parts and tools quickly. Using these technologies means we can make more pieces in less time!”}},{“@type”: “Question”,”name”: “How Can Sensor Integration Improve The Precision And Efficiency Of Automated Metal Lathe Operations? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sensor integration helps us make metal lathes work better and more accurately. Sensors can check how the machine is running in real-time. This means we can fix problems before they happen. By knowing exactly what’s going on, we can also save time and materials. Overall, sensors help us create better parts faster!”}},{“@type”: “Question”,”name”: “What Are The Common Challenges Faced When Automating Gearhead Metal Lathes, And How Can They Be Overcome? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When automating gearhead metal lathes, we often face a few challenges. One big problem is fixing the machines to work with computers. You can solve this by using special kits that help connect them. Another issue is making sure the lathe cuts correctly every time. We can overcome this by testing and adjusting the settings carefully. Finally, training people to use the new machines is important, so everyone knows how to work safely and efficiently.”}},{“@type”: “Question”,”name”: “What Advancements In Software And Controls Are Revolutionizing The Automation Of Metal Lathes In The Manufacturing Industry? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “New software and controls are making metal lathes smarter. These machines can now work on their own with less help from people. They use special programs to plan and fix problems quickly. This means they can create metal parts faster and better. With these changes, we can make more things in less time!”}}]}