Have you ever wondered how metal parts are made? If so, you’re in the right place. A gearhead metal lathe bench is an impressive tool that can turn simple metal into something special. Whether you’re a hobbyist or a future engineer, these lathes can spark your creativity.

Imagine shaping a solid piece of metal into the perfect gear. It’s like magic! With the right skills, anyone can learn to use a gearhead metal lathe. It opens doors to countless projects.

Did you know that metal lathes have been around for centuries? They helped build everything from cars to airplanes. Today, they remain essential in workshops everywhere. So, let’s explore the world of gearhead metal lathes together!

Gearhead Metal Lathe Bench: Your Essential Tool Setup

Discovering the Gearhead Metal Lathe Bench

The gearhead metal lathe bench is a powerful tool for metalworking enthusiasts. It allows you to shape and cut metal pieces with precision. Imagine creating parts for your next project! From hobbyists to professionals, this lathe helps everyone. With its sturdy design, it offers stability while you work. Did you know that mastering this tool can open doors to new metalworking skills? Dive into the world of gearhead metal lathes to unlock your creativity!Understanding Gearhead Metal Lathes

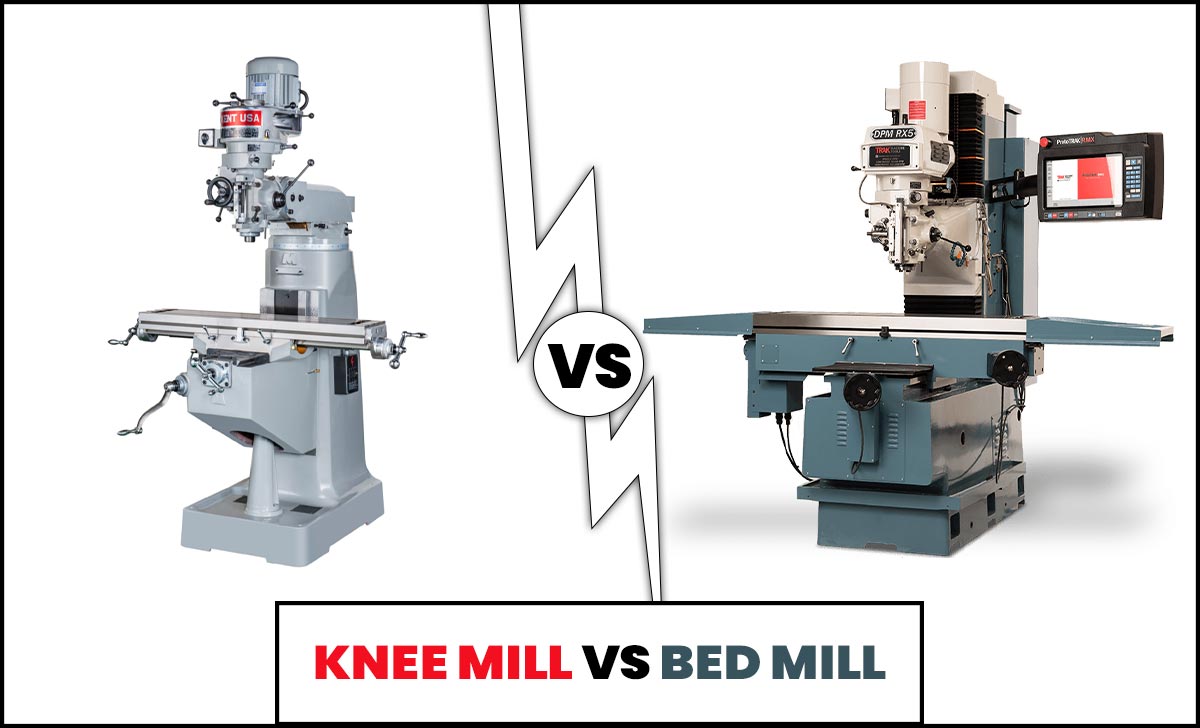

Definition and functionality of gearhead metal lathes. Key differences between gearhead and beltdriven lathes.A gearhead metal lathe is a powerful machine used for shaping metal. It spins the metal while tools cut, carve, or drill it. This type of lathe uses gears to change speeds easily, unlike beltdriven lathes, which rely on belts. Gearhead lathes offer more speed options and last longer. Here are some key differences:

- Speed Control: Gearhead lathes have faster and easier speed changes.

- Durability: Gearhead lathes tend to wear less than beltdriven ones.

- Power: Gearhead lathes can handle tougher materials better.

What is a gearhead metal lathe?

A gearhead metal lathe is a machine used to shape and cut metal pieces. It has a system of gears that makes it strong and efficient.

What is the difference between a gearhead and a beltdriven lathe?

The main difference is in how they operate. A gearhead lathe uses gears for speed changes, while a beltdriven lathe uses belts. This gives gearhead lathes quicker speed adjustments and longer life.

Benefits of Using a Gearhead Metal Lathe Bench

Enhanced precision and performance in machining. Versatility in handling various materials and projects.Using a gearhead metal lathe bench means you get top-notch precision and performance in your machining tasks. It helps you create smoother cuts and cleaner edges, almost like magic! You can work with different materials, from sturdy metals to softer plastics, making it super versatile. Imagine switching from making a metal bracket to crafting a toy car in no time! It’s like having a Swiss Army knife for your workshop without the confusion!

| Benefits | Description |

|---|---|

| Precision | Delivers accurate cutting for perfect results. |

| Versatility | Easily adapts to various materials and projects. |

Key Features to Look for in a Gearhead Metal Lathe

Motor power and torque specifications. Swing over bed and distance between centers.Choosing the right features in a gearhead metal lathe can make tasks easier. Start with motor power. More power means better performance. Next, look at torque specifications. High torque helps with tough materials.

Also, consider the swing over bed. This determines the size of the workpiece you can use. Finally, check the distance between centers. A longer distance can handle larger projects.

- Motor Power: Higher is better for tough jobs.

- Torque: More torque means better cutting power.

- Swing Over Bed: A larger width allows for bigger objects.

- Distance Between Centers: Longer distance is useful for bigger tasks.

What should I look for in a gearhead metal lathe?

You should check the motor power, torque, swing over bed, and distance between centers. These features help the lathe perform better and tackle larger jobs with ease.

Essential Accessories for Your Gearhead Metal Lathe

Recommended tools and attachments to enhance functionality. Safety equipment and maintenance tools necessary for operation.Using a gearhead metal lathe is not just about knowing how to operate it. Having the right accessories makes a big difference. Here are some recommended tools and attachments:

- Cutting tools for smooth finishes.

- Tool holders for easy changing.

- Chucks to hold workpieces securely.

Safety should always come first. Don’t forget:

- Safety goggles to protect your eyes.

- Ear protection from loud noise.

- Gloves to keep hands safe.

For keeping your lathe in top shape, maintenance tools are important too. Regular cleaning and oiling keep everything running smoothly.

What accessories do I need for my gearhead metal lathe?

A must-have for your lathe includes cutters, chucks, and safety gear. These improve performance and protect you while working.

Setup and Calibration of Your Gearhead Metal Lathe Bench

Stepbystep installation guide. Tips for proper calibration and alignment.Setting up your gearhead metal lathe bench can feel like a puzzle, but don’t worry; it’s easier than tying your shoelaces! Start by unpacking everything and laying it out. Follow the quick installation guide, just like a recipe but without the calories. For calibration, make sure everything is level. Use a bubble level – it’s like a magic wand! Check your alignment with a straight edge, and adjust as needed. Remember, a well-aligned lathe is a happy lathe!

| Step | Action |

|---|---|

| 1 | Unpack and arrange parts |

| 2 | Install according to the manual |

| 3 | Check for level with a bubble level |

| 4 | Align with a straight edge |

If you follow these steps, you’ll be spinning metal like a pro in no time. Remember, patience is key—slow down and enjoy the process. Who knows, you might just discover your inner metal wizard! Happy turning!

Common Problems and Troubleshooting Tips

Identifying frequent issues with gearhead lathes. Solutions and maintenance practices to prolong life.Gearhead lathes are handy tools, but they can face some hiccups. Common issues include noisy operation and trouble with speed changes. These problems usually come from dirt or worn gears. To tackle this, keep it clean and check for worn parts. Regular oiling can be a game-changer! Want to keep your lathe happy? Think of it like a pet; it needs care!

| Problem | Solution |

|---|---|

| Noisy operation | Clean and lubricate |

| Speed changes are difficult | Check gears and connections |

Expert Tips for Optimizing Performance

Techniques for achieving superior finishes. Best practices for tool selection and material handling.Want your gearhead metal lathe bench to shine? First, choose the right tools. High-quality cutting tools make a big difference. Dull tools are like trying to cut a steak with a butter knife—futile! Next, handle your materials carefully. Keep them clean and secure. This prevents nasty scratches and nicks. Lastly, use the right speed when cutting. Too fast? You’ll leave an uneven surface. The goal is a glassy finish that even your mirror would admire!

| Technique | Best Practice |

|---|---|

| Tool Selection | Use high-quality cutting tools. |

| Material Handling | Keep materials clean and secure. |

| Cutting Speed | Find the optimal speed for a smooth finish. |

Real-World Applications of Gearhead Metal Lathes

Use cases in various industries such as automotive and aerospace. Project ideas for hobbyists and professionals.Many industries benefit from gearhead metal lathes. In the automotive sector, they create engine parts and gears. The aerospace industry uses them to make precise components for planes. Hobbyists can also use these machines for fun projects.

- Build custom car parts.

- Make tools or gadgets.

- Repair household items.

A fun fact: Metal lathes are great for both professionals and beginners. They help bring ideas to life!

What projects can be done with gearhead metal lathes?

Easy projects include making small parts, crafting toys, and creating art pieces. These machines allow for creativity in both work and play.

Conclusion

In conclusion, a gearhead metal lathe bench is perfect for precise metalwork. It offers strong torque, making it easier to shape materials. You can customize your projects and boost your skills. If you’re interested, consider trying one out or reading more about its features. Remember, practice makes perfect, so get hands-on and enjoy creating!FAQs

Sure! Here Are Five Related Questions About A Gearhead Metal Lathe Bench:Sure! A gearhead metal lathe bench is a special tool we use to shape metal. It has a motor that helps it turn metal pieces. You can make things like rods or tubes with it. It’s important to always wear safety glasses when using the lathe. Make sure to follow safety rules, so you stay safe while working!

Sure! Please provide the question you’d like me to answer.

What Are The Key Features To Look For When Selecting A Gearhead Metal Lathe For A Workshop?When choosing a gearhead metal lathe for your workshop, look for a few important features. First, check the size. A bigger lathe lets you work on larger projects. Next, consider the motor power. A strong motor helps you cut metal easily. Also, look for easy controls so you can use it without trouble. Finally, make sure it has a sturdy base for safety while you work.

How Does A Gearhead Lathe Differ From A Belt-Driven Lathe In Terms Of Performance And Usability?A gearhead lathe uses gears to change speeds, while a belt-driven lathe uses belts. This makes the gearhead lathe faster and easier to control. You can switch speeds quickly on a gearhead lathe without stopping it. Belt-driven lathes need more time to change speeds. So, gearhead lathes are usually better for heavy work.

What Maintenance Practices Are Essential For Prolonging The Lifespan Of A Gearhead Metal Lathe?To keep your gearhead metal lathe running well, you should clean it often. Remove dust and metal shavings after each use. Check the oil level and add more if needed to keep everything running smoothly. Tighten any loose parts so they don’t break. Lastly, cover your lathe when you’re not using it to protect it from dust and damage.

What Types Of Projects Or Materials Are Best Suited For Machining On A Gearhead Metal Lathe?You can use a gearhead metal lathe for many fun projects! It works well for making parts like handles, rods, and small wheels. You can also shape wood and some soft metals like aluminum. These materials are easier to cut and shape with the lathe. Just remember that the lathe is best for round or cylindrical things!

How Can One Optimize The Setup Of A Gearhead Metal Lathe Bench For Increased Efficiency And Safety During Operations?To make your gearhead metal lathe setup better, keep your tools organized and within reach. Make sure the lathe is level and stable on a sturdy bench. Always put safety equipment, like goggles and gloves, nearby. Keep the work area clean and free of clutter, so you can move safely. Finally, read the manual to understand how to use the lathe properly.